About Padlocks

More

Lockout Labels for Padlocks

Wrap these labels around padlocks to comply with lockout/tagout procedures. All labels have space for an employee’s name and department.

Labels with a cover protect against moisture and smudging.

Danger—Locked Out labels conform to the padlock when heat is applied.

Danger—Do Not Operate, Danger—Do Not Remove This Lock, Danger—Verrouillee, and Peligro—Equipo Bloqueado labels have headers and safety colors that meet OSHA standards for indicating hazards. Use them in extreme conditions to indicate an imminently hazardous situation that, if not avoided, will result in death or serious injury.

| Ht. | Wd. | For Max. Padlock Body Size | Mount Type | Material | Includes | Specifications Met | Pkg. Qty. | Pkg. | |

| 5/8" | 4" | 3 5/8" Around | Adhesive Back, Wraparound | Vinyl Plastic | Laminating Cover | OSHA Compliant 29 CFR 1910.145 | 5 | 0000000 | 00000 |

| Ht. | Wd. | For Max. Padlock Body Size | Mount Type | Material | Includes | Specifications Met | Pkg. Qty. | Pkg. | |

| 3/4" | 5" | 4 5/8" Around | Adhesive Back, Wraparound | Vinyl Plastic | Laminating Cover | OSHA Compliant 29 CFR 1910.145 | 10 | 0000000 | 00000 |

| Ht. | Wd. | For Max. Padlock Body Size | Mount Type | Material | Includes | Specifications Met | Pkg. Qty. | Pkg. | |

| 3/4" | 4 1/2" | 4 1/8" Around | Adhesive Back, Wraparound | Vinyl Plastic | Laminating Cover | OSHA Compliant 29 CFR 1910.145 | 6 | 0000000 | 00000 |

| Ht. | Wd. | For Max. Padlock Body Size | Mount Type | Material | Includes | Pkg. Qty. | Pkg. | |

| 1" | 6 1/2" | 6 1/4" Around | Adhesive Back, Wraparound | Polyolefin Plastic | Clear Polyester Heat-Shrink Cover | 5 | 0000000 | 000000 |

| Ht. | Wd. | For Max. Padlock Body Size | Mount Type | Material | Includes | Specifications Met | Pkg. Qty. | Pkg. | |

| 3/4" | 4 1/2" | 4 1/8" Around | Adhesive Back, Wraparound | Vinyl Plastic | Laminating Cover | OSHA Compliant 29 CFR 1910.145 | 6 | 0000000 | 00000 |

Photo-Insert Lockout Labels for Padlocks

Add a photo in the designated square to identify the employee working a job. Wrap these labels around padlocks to comply with lockout/tagout procedures. These labels have a heat-shrink cover to protect the label from moisture and smudging. The cover conforms to the padlock when heat is applied.

| Ht. | Wd. | For Max. Padlock Body Size | Mount Type | Material | Pkg. Qty. | Pkg. | |

Lockout Tagout System—Locked Out By (English) | |||||||

|---|---|---|---|---|---|---|---|

| 1 1/4" | 6 1/2" | 6 1/4" Around | Adhesive Back, Wraparound | Polyolefin Plastic | 5 | 0000000 | 000000 |

Metal Engraving and Stamping Tags

Brass tags withstand abrasion and wear better than aluminum tags.

| Ht. | Wd. | Thick. | Max. Temp., °F | Hole Dia. | Pkg. Qty. | Pkg. | ||

Brass | ||||||||

|---|---|---|---|---|---|---|---|---|

| H | 1 3/4" | 1/2" | 0.05" | 200° | 3/16" | 12 | 00000000 | 000000 |

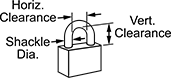

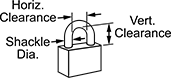

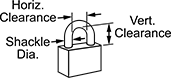

Extra-Clearance Choose-a-Color Lockout Padlocks with Labels

Locks have a vertical shackle clearance that's greater than 1” and include a Danger label as well as a write-on label marked Property of. Padlocks come in a variety of colors for lockout identification compliance. Choose these locks if you need locks that each open with a different key. All locks have random key numbers. They help you comply with OSHA 29 CFR 1910.147 procedures for the control of energy sources that could injure workers.

Pin-tumbler key locking mechanisms are the most difficult locking mechanisms to pick.

Stainless steel shackles resist corrosion better than hardened steel shackles.

For technical drawings and 3-D models, click on a part number.

Shackle | Body | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vertical Clearance | Horizontal Clearance | Dia. | Material | Ht. | Wd. | Thick. | Manufacturer and Model No. | Message | No. of Keys Included | No. of Tumbler Pins | Specifications Met | Choose a Body Color | Each | ||

Solid Plastic Body | |||||||||||||||

| 1 1/2" | 5/8" | 3/16" | Stainless Steel | 1 7/8" | 1 3/8" | 11/16" | Master Lock S31 | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | OSHA Compliant 29 CFR 1910.147 | 000000000 | 000000 | 00 | |

Each | |||||||||||||||

| 1-5 | 6-Up | ||||||||||||||

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | Master Lock 410 | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | 000000 | |

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 3" | 1 1/2" | 3/4" | Master Lock 411 | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | 00000 | |

| Each | |||||||||||||||

| 3" | 5/8" | 3/16" | Stainless Steel | 1 7/8" | 1 3/8" | 11/16" | Master Lock S31LT | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 00 | |

| 3" | 13/16" | 1/4" | Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | Master Lock 410LT | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 00 | |

| 3" | 13/16" | 1/4" | Hardened Steel | 3" | 1 1/2" | 3/4" | Master Lock 411LT | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 00 | |

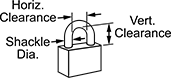

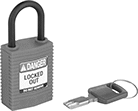

Nonconductive Choose-a-Color Lockout Padlocks with Labels

Safely lock out electrical equipment—these padlocks are made entirely out of plastic, so they don't conduct electricity. Unlike metal padlocks, they’re nonmagnetic and won’t spark. They come in a variety of colors that grab your attention and display a warning label that signals a machine is locked out. To meet lockout identification standards, assign colors to individuals or functions, such as red for electrical and blue for plumbing. Pair them with a hasp, chain, or another lockout device to meet OSHA 29 CFR 1910.147 procedures to prevent accidental startups.

These padlocks have a pin-tumbler key locking mechanism, which is the most difficult locking mechanism to pick. The more pins a lock has, the harder it is to pick. Choose them if you need locks that each open with a different key. All locks have random key numbers.

Padlocks with 1” vertical shackle clearance need less space to be secured, which helps them to fit in tight spaces such as an electrical cabinet.

Key-retaining padlocks don’t let you remove the key from the lock until you close the shackle. This makes sure you properly secure locks before walking away with the key.

Padlocks with a key cover make it easy to spot the included key—it matches the color of the padlock.

Shackle | Body | Each | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vertical Clearance | Horizontal Clearance | Dia. | Material | Ht. | Wd. | Thick. | Features | Manufacturer and Model No. | Message | No. of Keys Included | No. of Tumbler Pins | Choose a Body Color | 1-5 | 6-Up | |

Solid Plastic Body | |||||||||||||||

| 1" | 11/16" | 3/16" | Plastic | 1 11/16" | 1 1/4" | 3/4" | Key Cover | __ | Danger—Locked Out Do Not Remove | 1 | 6 | 00000000 | 000000 | 000000 | |

| 1 1/2" | 5/8" | 3/16" | Plastic | 1 7/8" | 1 3/8" | 11/16" | __ | Master Lock S32 | Danger—Locked Out Do Not Remove | 1 | 6 | 0000000 | 00000 | 00000 | |

| 1 1/2" | 3/4" | 1/4" | Plastic | 1 3/4" | 1 1/2" | 3/4" | Key-Retaining | Master Lock 406 | Danger—Locked Out Do Not Remove | 1 | 6 | 0000000 | 00000 | 00000 | |

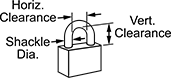

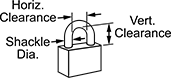

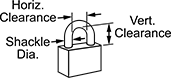

Weather-Resistant Choose-a-Color Lockout Padlocks with Labels

Lock out equipment outdoors to prevent accidental startups during maintenance. These padlocks come in a variety of colors that grab your attention and display a warning label that alerts you to locked-out machines. Assign colors to individuals or functions, such as blue for plumbing and red for electrical, to help meet lockout identification standards. Use them with a hasp, chain, or another lockout device to comply with OSHA 29 CFR 1910.147 standards for safe lockouts. To confirm equipment remains securely locked out during maintenance or repair, these padlocks retain the key in the cylinder until the shackle is relocked. Choose them if you need locks that each open with a different key. All have random key numbers.

These padlocks are made from materials that resist corrosion caused by rain and snow and have a plastic cover for an extra layer of protection. The cover also prevents them from scuffing nearby surfaces.

Brass-body locks resist corrosion better than aluminum-body locks. Aluminum-body locks are stronger than brass-body locks, which makes them more difficult to force open.

Steel shackles are plated with a combination of copper, nickel, and chrome for added corrosion resistance. They’re also stronger than stainless steel shackles. Hardened steel shackles are stronger than both steel and stainless steel shackles. Stainless steel shackles resist corrosion better than steel shackles and hardened steel shackles.

Shackles with a plastic coating resist corrosion. They’re less conductive than uncoated shackles, so they’re safer to use when locking out electrical equipment.

Padlocks with a 3″ body height have room for a second label (not included). They are useful when you need to add warning messages in multiple languages.

Padlocks with a plastic keyhole cover stop water and debris from entering the key cylinder to avoid jams and prevent internal components from freezing or rusting.

Shackle | Body | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vertical Clearance | Horizontal Clearance | Dia. | Material | Ht. | Wd. | Thick. | Manufacturer and Model Number | Message | No. of Keys Included | Specifications Met | Choose a Cover Color | Each | |

Solid Brass Body | |||||||||||||

| 1 1/2" | 3/4" | 1/4" | Plastic-Coated Copper-Nickel-Chrome-Plated Steel | 1 3/4" | 1 1/2" | 13/16" | Abus Lock 74M/40 | Danger—Locked Out Do Not Remove | 1 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | |

| 1 1/2" | 3/4" | 1/4" | Plastic-Coated Copper-Nickel-Chrome-Plated Steel | 3" | 1 1/2" | 13/16" | Abus Lock 74MLB/40 | Danger—Locked Out Do Not Remove | 1 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | |

Solid Aluminum Body | |||||||||||||

| 1 1/2" | 3/4" | 1/4" | Plastic-Coated Copper-Nickel-Chrome-Plated Steel | 1 3/4" | 1 1/2" | 13/16" | Abus Lock 74/40 | Danger—Locked Out Do Not Remove | 1 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | |

| 1 1/2" | 3/4" | 1/4" | Plastic-Coated Copper-Nickel-Chrome-Plated Steel | 3" | 1 1/2" | 13/16" | Abus Lock 74LB/40 | Danger—Locked Out Do Not Remove | 1 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | |

| 1 1/2" | 3/4" | 1/4" | Plastic-Coated Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | __ | Danger—Locked Out Do Not Remove | 1 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | |

Solid Aluminum Body with Plastic Keyhole Cover | |||||||||||||

| 1 1/2" | 7/8" | 3/16" | Stainless Steel | 1 3/4" | 1 1/2" | 3/4" | __ | Danger—Locked Out Do Not Remove | 1 | OSHA Compliant 29 CFR 1910.147 | Red | 0000000 | 00000 |

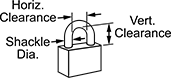

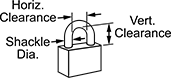

Weather-Resistant Extra-Clearance

Choose-a-Color Lockout Padlocks with Labels

Fit the extra-long shackle of these padlocks around oversized hasps and chains to lock out equipment outdoors. They come in a variety of colors that catch your eye and display a warning label that alerts you to locked-out machines. Assign colors to individuals or functions, such as blue for plumbing and red for electrical, to meet lockout identification standards. To prevent accidental startups during maintenance, pair them with a lockout device. This helps you comply with OSHA 29 CFR 1910.147 standards for safe lockouts. Made from materials that resist corrosion from rain and snow, these locks will operate smoothly even when exposed to the elements. They have a plastic cover that protects the lock body and prevents them from damaging nearby surfaces.

These padlocks don’t let you remove the key from the lock until you close the shackle. This makes sure you properly secure locks before walking away with the key. These locks are keyed differently, so they each open with a different key.

Brass-body locks resist corrosion better than aluminum-body locks. Aluminum-body locks are stronger and hold up better against break-in attempts than brass-body locks. They’re made of at least 70% recycled materials to help meet UL 2809-2 requirements for LEED-certified facilities.

Steel shackles are stronger than stainless steel shackles. Hardened steel shackles are stronger than unhardened steel and stainless steel shackles. Stainless steel shackles are more resistant to corrosion than steel or hardened steel shackles. Plastic-coated shackles help resist corrosion. The plastic also makes them less conductive, keeping you safe when locking out electrical panels or other equipment.

Shackle | Body | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vertical Clearance | Horizontal Clearance | Dia. | Material | Ht. | Wd. | Thick. | Manufacturer and Model No. | Message | No. of Keys Included | Choose a Cover Color | Specifications Met | Each | |

Solid Brass Body | |||||||||||||

| 2 15/16" | 3/4" | 1/4" | Plastic-Coated Copper-Nickel-Chrome-Plated Steel | 1 3/4" | 1 9/16" | 25/32" | Abus Lock 74M/40HB75 | Danger—Locked Out Do Not Remove | 1 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | |

Solid Aluminum Body | |||||||||||||

| 3" | 3/4" | 1/4" | Plastic-Coated Steel | 1 3/4" | 1 1/2" | 3/4" | __ | Danger—Locked Out Do Not Remove | 1 | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 0000000 | 00000 | |

| 3" | 3/4" | 1/4" | Plastic-Coated Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | __ | Danger—Locked Out Do Not Remove | 1 | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 0000000 | 00000 | |

Solid Aluminum Body with Plastic Keyhole Cover | |||||||||||||

| 3" | 7/8" | 3/16" | Stainless Steel | 1 3/4" | 1 1/2" | 3/4" | __ | Danger—Locked Out Do Not Remove | 1 | Red | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 00000 |

Weather-Resistant Extra-Clearance Choose-a-Color

Keyed Alike Lockout Padlocks with Labels

With an extra-long shackle, these padlocks fit around oversized hasps and thick chains on outdoor equipment to prevent accidental startup during maintenance. They come in a variety of colors that grab your attention and display a warning label to alert you to locked-out machines. To adhere to lockout identification practices, assign colors to individuals or departments, such as blue for plumbing and red for electrical. Use them with another lockout device to comply with OSHA 29 CFR 1910.147 standards for safe lockouts. They’re made from materials that resist corrosion caused by rain and snow. Their plastic cover protects the lock body and prevents them from damaging nearby surfaces.

These padlocks don’t let you remove the key from the lock until you close the shackle. This makes sure you properly secure locks before walking away with the key. Choose these locks if you need several locks that open with the same key.

Steel shackles are stronger than stainless steel shackles. Hardened steel shackles are stronger than both steel and stainless steel shackles. Stainless steel shackles are more corrosion resistant than both steel and hardened steel.

Padlocks with a plastic-coated shackle add a layer of protection against corrosion. They’re less conductive than uncoated shackles, so they’re safer to use when locking out electrical equipment.

Padlocks with a plastic keyhole cover shield water and debris from entering the key cylinder to avoid jams and prevent internal components from freezing or corrosion.

Shackle | Body | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vertical Clearance | Horizontal Clearance | Dia. | Material | Ht. | Wd. | Thick. | Manufacturer and Model No. | Message | No. of Keys Included | Choose a Cover Color | Key No. | Each | |

Solid Aluminum Body | |||||||||||||

| 2 15/16" | 3/4" | 9/32" | Plastic-Coated Copper-Nickel-Chrome-Plated Steel | 1 3/4" | 1 9/16" | 25/32" | Abus Lock 74/40HB75 | Danger—Locked Out Do Not Remove | 1 | 08109A | 0000000 | 000000 | |

| 2 15/16" | 3/4" | 9/32" | Plastic-Coated Copper-Nickel-Chrome-Plated Steel | 1 3/4" | 1 9/16" | 25/32" | Abus Lock 74/40HB75 | Danger—Locked Out Do Not Remove | 1 | MC123 | 0000000 | 00000 | |

| 3" | 3/4" | 1/4" | Plastic-Coated Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | __ | Danger—Locked Out Do Not Remove | 1 | TT04004 | 0000000 | 00000 | |

Solid Aluminum Body with Plastic Keyhole Cover | |||||||||||||

| 3" | 7/8" | 3/16" | Stainless Steel | 1 3/4" | 1 1/2" | 3/4" | __ | Danger—Locked Out Do Not Remove | 1 | Red | TT04004 | 0000000 | 00000 |

Extra-Clearance Choose-a-Color Master Keyed Lockout Padlocks with Labels

Locks have a vertical shackle clearance that's greater than 1" and include a Danger label as well as a write-on label marked Property of. Padlocks come in a variety of colors for lockout identification compliance. They help you comply with OSHA 29 CFR 1910.147 procedures for the control of energy sources that could injure workers. Choose these locks if you want individual locks or groups of locks that open with their own key, but also open with a master key. The included keys have random key numbers; master keys are sold separately. If the lock keyed to the master key number you want isn't listed, order the "Other Master Key Numbers" and specify your desired master key number and lock color.

Pin-tumbler key locking mechanisms are the most difficult locking mechanisms to pick.

For technical drawings and 3-D models, click on a part number.

Padlocks | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Shackle | Body | Master Keys | |||||||||||||

| Vertical Clearance | Horizontal Clearance | Dia. | Material | Ht. | Wd. | Thick. | Message | No. of Keys Included | No. of Tumbler Pins | Master Key No. | Specifications Met | Each | Each | ||

Solid Plastic Body | |||||||||||||||

Master Lock 410—Black Body | |||||||||||||||

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | BY8 | OSHA Compliant 29 CFR 1910.147 | 000000000 | 000000 | 000000000 | 000000 |

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | Other Master Key Numbers | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000 | 00 |

Master Lock 410—Blue Body | |||||||||||||||

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | BY5 | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000000 | 00000 |

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | Other Master Key Numbers | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000 | 00 |

Master Lock 410—Green Body | |||||||||||||||

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | BY4 | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000000 | 00000 |

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | Other Master Key Numbers | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000 | 00 |

Master Lock 410—Orange Body | |||||||||||||||

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | BY2 | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000000 | 00000 |

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | Other Master Key Numbers | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000 | 00 |

Master Lock 410—Purple Body | |||||||||||||||

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | BY7 | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000000 | 00000 |

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | Other Master Key Numbers | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000 | 00 |

Master Lock 410—Red Body | |||||||||||||||

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | BY1 | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000000 | 00000 |

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | Other Master Key Numbers | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000 | 00 |

Master Lock 410—Teal Body | |||||||||||||||

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | BY6 | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000000 | 00000 |

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | Other Master Key Numbers | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000 | 00 |

Master Lock 410—Yellow Body | |||||||||||||||

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | BY3 | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000000 | 00000 |

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | Other Master Key Numbers | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000 | 00 |

Master Lock 411—Black Body | |||||||||||||||

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 3" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | BY16 | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000000 | 00000 |

Master Lock 411—Blue Body | |||||||||||||||

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 3" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | BY13 | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000000 | 00000 |

Master Lock 411—Green Body | |||||||||||||||

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 3" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | BY12 | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000000 | 00000 |

Master Lock 411—Orange Body | |||||||||||||||

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 3" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | BY10 | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000000 | 00000 |

Master Lock 411—Purple Body | |||||||||||||||

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 3" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | BY15 | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000000 | 00000 |

Master Lock 411—Red Body | |||||||||||||||

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 3" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | BY9 | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000000 | 00000 |

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 3" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | Other Master Key Numbers | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000 | 00 |

Master Lock 411—Teal Body | |||||||||||||||

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 3" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | BY14 | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000000 | 00000 |

Master Lock 411—Yellow Body | |||||||||||||||

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 3" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | BY11 | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 000000000 | 00000 |

Weather-Resistant Choose-a-Color Keyed Alike Lockout Padlocks with Labels

Lock out equipment outdoors to prevent accidental startups during maintenance. These padlocks come in a variety of colors to grab your attention and display a warning label that alerts you to locked-out machines. Made of corrosion-resistant materials and enclosed in a plastic cover, they stand up to rain and snow. The plastic cover also keeps them from scuffing up surfaces. To help you follow lockout identification practices, you can assign colors to individuals or functions. For example, use blue for plumbing and red for electrical. These padlocks help you comply with OSHA 29 CFR 1910.147 standards for safe lockouts. To make sure equipment remains secure, they retain the key in the cylinder until the shackle is locked. Choose them if you need several locks that open with the same key.

Brass-body padlocks are more corrosion resistant than aluminum-body padlocks, but they aren’t as strong. Aluminum-body padlocks are stronger than brass-body padlocks, so they handle physical attacks better. However, they aren’t as corrosion resistant.

Padlocks with a steel shackle have a stronger shackle than those with a stainless steel shackle. The shackle is coated in plastic to resist corrosion. The coating is also nonconductive for safe lockouts of electrical panels and other electrical equipment. For the strongest shackle, choose those with a hardened steel shackle.

Padlocks with a stainless steel shackle have a more corrosion-resistant shackle than those with a steel shackle. They also have a plastic keyhole cover that keeps out water and debris so the keyhole doesn’t freeze, jam, or rust.

Shackle | Body | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vertical Clearance | Horizontal Clearance | Dia. | Material | Ht. | Wd. | Thick. | Manufacturer and Model No. | Message | No. of Keys Included | Key No. | Specifications Met | Choose a Cover Color | Each | |

Solid Brass Body | ||||||||||||||

| 1 1/2" | 3/4" | 1/4" | Plastic-Coated Copper-Nickel-Chrome-Plated Steel | 1 3/4" | 1 1/2" | 13/16" | Abus Lock 74M/40 | Danger—Locked Out Do Not Remove | 1 | 90018 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | |

| 1 1/2" | 3/4" | 1/4" | Plastic-Coated Copper-Nickel-Chrome-Plated Steel | 1 3/4" | 1 1/2" | 13/16" | Abus Lock 74M/40 | Danger—Locked Out Do Not Remove | 1 | MC122 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | |

Solid Aluminum Body | ||||||||||||||

| 1 1/2" | 3/4" | 1/4" | Plastic-Coated Copper-Nickel-Chrome-Plated Steel | 1 3/4" | 1 1/2" | 13/16" | Abus Lock 74/40 | Danger—Locked Out Do Not Remove | 1 | 08109A | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | |

| 1 1/2" | 3/4" | 1/4" | Plastic-Coated Copper-Nickel-Chrome-Plated Steel | 1 3/4" | 1 1/2" | 13/16" | Abus Lock 74/40 | Danger—Locked Out Do Not Remove | 1 | MC119 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | |

| 1 1/2" | 3/4" | 1/4" | Plastic-Coated Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | __ | Danger—Locked Out Do Not Remove | 1 | TT04004 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | |

Solid Aluminum Body with Plastic Keyhole Cover | ||||||||||||||

| 1 1/2" | 7/8" | 3/16" | Stainless Steel | 1 3/4" | 1 1/2" | 3/4" | __ | Danger—Locked Out Do Not Remove | 1 | TT04004 | OSHA Compliant 29 CFR 1910.147 | Red | 0000000 | 00000 |

Extra-Clearance Choose-a-Color Keyed Alike Lockout Padlocks with Labels

Locks have a vertical shackle clearance that's greater than 1" and include a Danger label as well as a write-on label marked Property of. Padlocks come in a variety of colors for lockout identification compliance. They help you comply with OSHA 29 CFR 1910.147 procedures for the control of energy sources that could injure workers. Choose these locks if you need several locks that open with the same key. If the lock or key with the key number you want isn’t listed, order the "Other Key Numbers" and specify your desired key number.

Pin-tumbler key locking mechanisms are the most difficult locking mechanisms to pick.

For technical drawings and 3-D models, click on a part number.

Shackle | Body | Each | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vertical Clearance | Horizontal Clearance | Dia. | Material | Ht. | Wd. | Thick. | Message | No. of Keys Included | No. of Tumbler Pins | Choose a Body Color | Choose a Key No. | Specifications Met | 1-5 | 6-Up | |

Solid Plastic Body | |||||||||||||||

Master Lock 410 | |||||||||||||||

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | 000000 | ||

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | Other Key Numbers | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 00000 | |

Master Lock 411 | |||||||||||||||

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 3" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | 00000 | ||

| 1 1/2" | 13/16" | 1/4" | Hardened Steel | 3" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove Property Of: | 1 | 6 | Other Key Numbers | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | 00000 | |

Nonconductive Choose-a-Color Keyed Alike Lockout Padlocks with Labels

Lock out electrical equipment safely—made entirely of plastic, these padlocks don’t conduct electricity. They’re also nonmagnetic and won’t spark, unlike metal padlocks. To alert others to locked-out equipment, they display a warning label and come in a variety of eye-catching colors. To help you follow lockout identification practices, you can assign colors to individuals or functions. For example, use blue for plumbing and red for electrical. Pair them with a hasp, chain, or other lockout device to meet OSHA 29 CFR 1910.147 procedures to prevent accidental startups.

They have a pin-tumbler key locking mechanism—the hardest type to pick. Choose these padlocks if you need several locks that open with the same key. If the lock or key with the key number you want isn’t listed, order the "Other Key Numbers" and specify your desired key number.

Padlocks with a key cover make it easy to spot the included key—it matches the color of the padlock. These padlocks are compact to fit in tight spaces such as electrical cabinets.

Key-retaining padlocks won’t let you remove the key from the lock until you close the shackle. This makes sure you properly secure them before walking away with the key.

Shackle | Body | Each | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vertical Clearance | Horizontal Clearance | Dia. | Material | Ht. | Wd. | Thick. | Features | Manufacturer and Model No. | Message | No. of Keys Included | Choose a Body Color | Choose a Key No. | 1-5 | 6-Up | |

Solid Plastic Body | |||||||||||||||

| 1" | 11/16" | 3/16" | Plastic | 1 5/8" | 1 1/4" | 3/4" | Key Cover | __ | Danger—Locked Out Do Not Remove | 1 | MC114 | 00000000 | 000000 | 000000 | |

| 1 1/2" | 3/4" | 1/4" | Plastic | 1 3/4" | 1 1/2" | 3/4" | Key-Retaining | Master Lock 406 | Danger—Locked Out Do Not Remove | 1 | 000000 | 00000 | 00000 | ||

| 1 1/2" | 3/4" | 1/4" | Plastic | 1 3/4" | 1 1/2" | 3/4" | Key-Retaining | Master Lock 406 | Danger—Locked Out Do Not Remove | 1 | Other Key Numbers | 00000000 | 00000 | 00000 | |

Weather-Resistant Choose-a-Color

Flexible-Shackle Lockout Padlocks with Labels

Weave the shackle on these padlocks through lockouts on outdoor valves, electrical panels, or other equipment during repairs without the hassle of extra cables or padlocks. To alert others to the maintenance, they have a warning label and come in a variety of striking colors. Assign colors to individuals or functions to follow lockout identification practices. For example, use blue for plumbing and red for electrical. These padlocks help you comply with OSHA 29 CFR 1910.147 standards for safe lockouts. To make sure equipment remains secure, these padlocks retain the key in the cylinder until the shackle is locked. Because the shackle is flexible, you can also tuck the body out of the way or fit it into tight spaces. However, the shackle is thinner than a standard padlock shackle, so it’s easier to cut. Each padlock opens with a different key and all have random key numbers.

The aluminum body and stainless steel shackle resist corrosion from rain and snow. A plastic cover over the body and a plastic coating on the braided shackle add another layer of protection from the elements and prevent scuffs on nearby surfaces.

Shackle | Body | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Dia. | Material | Ht. | Wd. | Thick. | Manufacturer and Model No. | Message | No. of Keys Included | No. of Tumbler Pins | Choose a Cover Color | Specifications Met | Each | |

Solid Aluminum Body | |||||||||||||

| 8" | 1/8" | Polyurethane-Coated Braided Stainless Steel | 1 1/2" | 1 9/16" | 27/32" | Abus Lock 76/40CAB | Danger—Locked Out Do Not Remove | 1 | 8 | NSF Registered H1, OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | |

| 16" | 1/8" | Polyurethane-Coated Braided Stainless Steel | 1 1/2" | 1 9/16" | 27/32" | Abus Lock 76/40CAB | Danger—Locked Out Do Not Remove | 1 | 8 | NSF Registered H1, OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | |

Weather-Resistant Choose-a-Color Flexible-Shackle

Keyed Alike Lockout Padlocks with Labels

Snake the shackle on these padlocks through lockouts on outdoor valves, electrical panels, or other equipment during repairs—no extra cables or padlocks needed. These padlocks come in a variety of eye-catching colors and include a warning label that alerts others to the maintenance. To adhere to lockout identification practices, assign colors to individuals or functions, such as blue for plumbing and red for electrical. They help you comply with OSHA 29 CFR 1910.147 standards for safe lockouts. As an added confirmation that equipment remains secure, these padlocks retain the key in the cylinder until the shackle is locked. Choose them if you need several locks that open with the same key.

The aluminum body and stainless steel shackle resist corrosion from rain and snow. A plastic cover over the body and polyurethane coating on the shackle add another layer of protection from the elements and prevent scuffs on nearby surfaces.

Shackle | Body | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Dia. | Material | Ht. | Wd. | Thick. | Message | No. of Keys Included | No. of Tumbler Pins | Choose a Cover Color | Key No. | Specifications Met | Each | |

Solid Aluminum Body | |||||||||||||

Abus Lock 76/40CAB | |||||||||||||

| 8" | 1/8" | Polyurethane-Coated Braided Stainless Steel | 1 1/2" | 1 9/16" | 27/32" | Danger—Locked Out Do Not Remove | 1 | 8 | 85069 | OSHA Compliant 29 CFR 1910.147, NSF Registered H1 | 0000000 | 000000 | |

| 16" | 1/8" | Polyurethane-Coated Braided Stainless Steel | 1 1/2" | 1 9/16" | 27/32" | Danger—Locked Out Do Not Remove | 1 | 8 | 85069 | OSHA Compliant 29 CFR 1910.147, NSF Registered H1 | 0000000 | 00000 | |

Extra-Clearance Flexible-Shackle Lockout Padlocks with Labels

A long, flexible shackle means you can weave these locks through tight areas and around valves and other bulky tools. Use them like a cable lockout. They’re bright red with a danger label to make it clear that equipment is locked out to prevent unauthorized use for safety. This helps you comply with OSHA 29 CFR 1910.147 procedures. Because the cable is flexible, it also makes your lock body easier to adjust once secured. You can tuck the body out of the way and fit it into tight spaces, such as a circuit breaker cabinet. However, the shackle is thinner than a standard padlock shackle, so it’s easier to cut.

The lock body and coating on the cable are plastic, so they won’t scratch nearby surfaces. The lock body also resists corrosion. Choose these locks if you need locks that each open with a different key. All locks have random key numbers.

Shackle | Body | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Dia. | Material | Ht. | Wd. | Thick. | Color | Message | No. of Keys Included | No. of Tumbler Pins | Specifications Met | Each | |

Solid Plastic Body | ||||||||||||

| 24" | 3/16" | Polyurethane-Coated Braided Steel | 2" | 1 1/4" | 1/2" | Red | Danger—Locked Out Do Not Remove | 1 | 6 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |

| 36" | 3/16" | Polyurethane-Coated Braided Steel | 2" | 1 1/4" | 1/2" | Red | Danger—Locked Out Do Not Remove | 1 | 6 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 |

| 48" | 3/16" | Polyurethane-Coated Braided Steel | 2" | 1 1/4" | 1/2" | Red | Danger—Locked Out Do Not Remove | 1 | 6 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 |

Choose-a-Color Flexible-Shackle Lockout Padlocks with Labels

Eye-catching colors and a danger label on these padlocks alert others to locked-out machines. Snake the flexible shackle through cramped spaces or multiple lockouts—no extra cables or padlocks needed. The shackle is flexible enough that you can tuck the lock body into tight areas, such as a circuit breaker cabinet. To follow lockout identification practices, assign different colors to individuals or functions. For example, use blue for plumbing and red for electrical. They help you comply with OSHA 29 CFR 1910.147 safety procedures.

They resist corrosion and prevent scuffs and scrapes on nearby surfaces because the body is plastic and the shackle is coated in nylon. The shackle coating also reduces its conductivity, so they're a good choice for locking out electrical equipment. However, since the shackle is thinner than a traditional padlock, it's easier to cut.

To make sure you’ve secured equipment properly, you can’t take the key out until the shackle is locked. Choose these padlocks if you need locks that each open with a different key.

Shackle | Body | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Dia. | Material | Ht. | Wd. | Thick. | Message | No. of Keys Included | No. of Tumbler Pins | Choose a Body Color | Specifications Met | Each | |

Solid Plastic Body | ||||||||||||

| 7 7/8" | 3/16" | Nylon-Coated Braided Steel | 1 3/8" | 1 1/4" | 5/8" | Danger—Locked Out Do Not Remove | 1 | 5 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | |

| 15 3/4" | 3/16" | Nylon-Coated Braided Steel | 1 3/8" | 1 1/4" | 5/8" | Danger—Locked Out Do Not Remove | 1 | 5 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | |

Choose-a-Color Flexible-Shackle Keyed Alike Lockout Padlocks with Labels

A danger label and distinct colors make these flexible-shackle locks useful for lockout identification practices. Assign a color to tasks or departments and use these locks to prevent equipment from being used during maintenance or repair. This helps you comply with OSHA 29 CFR 1910.147 procedures. The steel shackle is braided and flexible, so you can secure it around small tools and equipment to prevent theft and unauthorized use. They also easily secure multiple hasps or lockout devices without a separate cable or multiple padlocks. Because the shackle is flexible, it’s easier to tuck the lock body out of the way and fit it into tight spaces, such as a circuit breaker cabinet. However, the shackle is thinner than a standard padlock shackle, so it’s easier to cut.

The lock body is plastic, so it resists corrosion and won’t scratch nearby surfaces. A nylon coating on the shackle also prevents scuffs and scrapes. These locks are key retaining, so you can’t remove the key from the lock until the shackle is closed. This reduces risk in lockout applications because your lock must be properly secured before you walk away with the key. Choose these locks if you need several locks that open with the same key.

Shackle | Body | Each | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Dia. | Material | Ht. | Wd. | Thick. | Message | No. of Keys Included | No. of Tumbler Pins | Choose a Body Color | Key No. | Specifications Met | 1-5 | 6-Up | |

Solid Plastic Body | ||||||||||||||

| 7 7/8" | 3/16" | Nylon-Coated Braided Steel | 1 3/8" | 1 1/4" | 5/8" | Danger—Locked Out Do Not Remove | 1 | 5 | MC115 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | 000000 | |

| 15 3/4" | 3/16" | Nylon-Coated Braided Steel | 1 3/8" | 1 1/4" | 5/8" | Danger—Locked Out Do Not Remove | 1 | 5 | MC115 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | 00000 | |