About Pressure Transmitters

More

About Pressure Switches

More

Oxygen Detectors

When your work area has too much or too little oxygen, these detectors alert you with an audible alarm, warning light, and vibrating alarm. You can adjust the high and low alarm trigger points to suit your environment.

A calibration check must be performed on the detector before each use to verify that it is working properly. The check can be performed with the press of a button.

The detector with a nonreplaceable battery should be thrown away at the end of its two-year lifespan.

| Measuring Range, % Vol. | Volume | Ht. | Wd. | Dp. | Temperature Range, °F | Batteries Included | Battery Chemistry | Environmental Rating | Each | |

Detectors with Nonreplaceable Battery | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0-25 | 95 dBA @ 30 cm. | 3 1/2" | 2" | 1" | -4° to 122° | Yes | Lithium | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Group G NEC Zone 0 Groups IIC, IIB, IIA IEC Zone 1 Groups IIC, IIB, IIA IP67 | 00000000 | 0000000 |

Detectors with Replaceable Battery | ||||||||||

| 0-25 | 95 dBA @ 30 cm. | 3 1/2" | 2" | 1" | -4° to 122° | Yes | Lithium | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Group G NEC Zone 0 Groups IIC, IIB, IIA IEC Zone 0 Groups IIC, IIB, IIA | 00000000 | 000000 |

| Batteries (Pkg. of 1) | 0000000 | Pkg. | 00000 |

Portable Multi-Gas Detectors with Probe

Use the probe to test the air in a hazardous area before entering. Great for confined spaces. This detector alerts you with an audible alarm, warning light, and vibrating alarm in the presence of combustible and toxic gases. You can adjust the alarm trigger points to suit your environment. There is also a motion sensor that sounds an alarm if the user becomes disabled.

A calibration check must be performed on the detector before each use to verify that it is working properly. The check requires a regulator and cylinder (sold separately).

Note: LEL is lower explosive limit.

| Detects (Measuring Range) | Volume | Temperature Range, °F | Batteries Included | Includes | Tube Lg., ft. | Environmental Rating | Each | |

| Acetone, Butane, Hydrogen, Methane, Pentane, Propane, Toluene (0-100% LEL), Oxygen (0-30% Vol.), Carbon Monoxide (0-1,999 ppm), Hydrogen Sulfide (0-200 ppm) | 95 dBA @ 30 cm. | -40° to 140° | Yes | Sampling Probe, Tubing Assembly, Rechargeable Lithium Ion Battery for Probe | 25 | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 0 Groups IIC, IIB, IIA IP68 | 00000000 | 000000000 |

Portable Multi-Gas Detectors

When this detector senses high levels of combustible and toxic gases, it alerts you with an audible alarm, warning light, and vibrating alarm. You can adjust the alarm trigger points to suit your environment. There is also a motion sensor that sounds an alarm if the user becomes disabled.

A calibration check must be performed on the detector before each use to verify that it is working properly. The check requires a regulator and cylinder (sold separately).

Note: LEL is lower explosive limit.

| Detects (Measuring Range) | Volume | Temperature Range, °F | Batteries Included | Environmental Rating | Each | |

| Acetone, Butane, Hydrogen, Methane, Pentane, Propane, Toluene (0-100% LEL), Oxygen (0-30% Vol.), Carbon Monoxide (0-1,999 ppm), Hydrogen Sulfide (0-200 ppm) | 95 dBA @ 30 cm. | -40° to 140° | Yes | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 0 Groups IIC, IIB, IIA IP68 | 00000000 | 000000000 |

Pressure Transmitters for Oxygen

- For Use With: Oxygen

- Accuracy: ±1.0%

- Pipe Connection: NPT Male

- Housing Material: Glass-Reinforced Nylon

- Connection Material: 304 Stainless Steel

- Temperature Range: -40° to 255° F

Adhere to safety standards and monitor pressure when working with high concentrations of oxygen. These transmitters are cleaned following ASME B40.100 IV guidelines and are sealed in an airtight bag to prevent contamination before use. Also known as transducers, they convert pressure to an electrical signal that can be interpreted by receiving devices, such as remote displays, programmable logic controllers, and motor speed controls. For your receiving device to interpret the signal from the transmitter, you will need to calibrate it for the transmitter's pressure range and output signal. As pressure increases, the output signal from the transmitter will increase. Transmitters will only provide accurate readings within the rated pressure range.

These transmitters are rated NEMA 4X and IP65 for protection from dust, weather, washdown, and corrosion. UL and C-UL recognized components and CE marked, they also meet American, Canadian, and European safety standards.

With a current output, they connect using two wires. The same wire is used to send a signal to the receiver and to power the transmitter. Current doesn’t lose signal over long distances and isn’t affected by electrical interference from other devices.

For technical drawings and 3-D models, click on a part number.

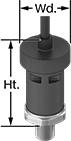

| Pressure Range, psi | Maximum Continuous Pressure, psi | Maximum Short-Term Pressure, psi | Input Voltage | Pipe Size | Ht. | Wd. | Environmental Rating | Each | |

4-20mA Current Output—Wire Leads | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0-30 | 60 | 60 | 9-36V DC | 1/4 | 2 3/8" | 1 5/16" | IP65, NEMA 4X | 0000000 | 0000000 |

| 0-60 | 120 | 120 | 9-36V DC | 1/4 | 2 3/8" | 1 5/16" | IP65, NEMA 4X | 0000000 | 000000 |

| 0-100 | 200 | 200 | 9-36V DC | 1/4 | 2 3/8" | 1 5/16" | IP65, NEMA 4X | 0000000 | 000000 |

| 0-300 | 600 | 600 | 9-36V DC | 1/4 | 2 3/8" | 1 5/16" | IP65, NEMA 4X | 0000000 | 000000 |

| 0-500 | 1,000 | 1,000 | 9-36V DC | 1/4 | 2 3/8" | 1 5/16" | IP65, NEMA 4X | 0000000 | 000000 |

| 0-1,000 | 2,000 | 2,000 | 9-36V DC | 1/4 | 2 3/8" | 1 5/16" | IP65, NEMA 4X | 0000000 | 000000 |

| 0-1,500 | 3,000 | 3,000 | 9-36V DC | 1/4 | 2 3/8" | 1 5/16" | IP65, NEMA 4X | 0000000 | 000000 |

Pressure Switches for Oxygen

Cleaned to ASTM G93 requirements and then bagged, these switches meet the strict cleaning standards required for oxygen service lines. Removing all contaminants extends the life of the switch and helps maintain a safe environment.

When a set pressure is reached, these switches can turn equipment on and off, activate automated controls, or signal alarms. They have an internal setpoint adjustment with a sliding cover to prevent accidental setting changes. They’re single pole, double throw (SPDT) and can either turn one device from off to on (normally open) or on to off (normally closed).

NEMA rated, they seal out dust and water from washdowns and the weather. These switches also meet UL 508, are CE marked, and are UL and C-UL recognized components, so they meet American, Canadian, and European safety standards.

For technical drawings and 3-D models, click on a part number.

| Setpoint, psi | Approximate Difference Between Setpoint and Reset Point, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Accuracy | Max. Switching Current | Process Temperature Range, °F | Connection Material | For Use With | Environmental Rating | Each | |

Wire Leads | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

1/8 NPT Male Pipe Connection | |||||||||||

| 4-50 | 3.5 | 1,000 | 3,000 | ±1.5% | 5 A @ 125 V AC 5 A @ 250 V AC 3 A @ 30 V DC 250 mA @ 125 V DC | 0° to 200° | Brass | Oxygen | NEMA 4 | 0000000 | 0000000 |

| 10-150 | 6 | 1,500 | 3,000 | ±1.5% | 5 A @ 125 V AC 5 A @ 250 V AC 3 A @ 30 V DC 250 mA @ 125 V DC | 0° to 200° | Brass | Oxygen | NEMA 4 | 0000000 | 000000 |

| 30-600 | 34 | 2,500 | 3,000 | ±1.5% | 5 A @ 125 V AC 5 A @ 250 V AC 3 A @ 30 V DC 250 mA @ 125 V DC | 0° to 200° | Brass | Oxygen | NEMA 4 | 0000000 | 000000 |

1/4 NPT Male Pipe Connection | |||||||||||

| 100-1,500 | 120 | 8,000 | 10,000 | ±1.5% | 5 A @ 125 V AC 5 A @ 250 V AC 3 A @ 30 V DC 250 mA @ 125 V DC | 0° to 200° | Brass | Oxygen | NEMA 4 | 0000000 | 000000 |

| 180-3,000 | 225 | 8,000 | 10,000 | ±1.5% | 5 A @ 125 V AC 5 A @ 250 V AC 3 A @ 30 V DC 250 mA @ 125 V DC | 0° to 200° | Brass | Oxygen | NEMA 4 | 0000000 | 000000 |

| 400-4,700 | 350 | 8,000 | 10,000 | ±1.5% | 5 A @ 125 V AC 5 A @ 250 V AC 3 A @ 30 V DC 250 mA @ 125 V DC | 0° to 200° | Brass | Oxygen | NEMA 4 | 0000000 | 000000 |

| 4,000-7,500 | 675 | 10,000 | 12,000 | ±1.5% | 5 A @ 125 V AC 5 A @ 250 V AC 3 A @ 30 V DC 250 mA @ 125 V DC | 0° to 200° | Brass | Oxygen | NEMA 4 | 0000000 | 000000 |

Sanitary Pressure and Vacuum Switches

When these 3-A certified switches reach a set pressure or vacuum, they trigger controls and alarms in food-processing, pharmaceutical, and biotech lines. They have a sleeve to shield internal parts from water and contaminants. Their surfaces are polished and their seams are continuously welded, so cleaning is easy and there’s little room for bacteria to grow. Made of 316 stainless steel, these switches stand up to harsh cleaners and sanitizers without rusting. Rated IP67 and NEMA 6, they’re dust tight and protected from washdowns and temporary submersion.

They connect using the same quick-clamp fittings (also known as tri-clamp fittings) that are common in sanitary lines, because they’re easy to take apart for cleaning. This end has a diaphragm that protects from corrosion and covers threads to keep them clean. The diaphragm is filled with 99.5% pure USP food-grade glycerin, reducing the risk of contamination if the diaphragm fails. The serial number is laser etched on the diaphragm to reduce crevices.

Twist the adjustable setpoint ring to make quick changes. These switches are single pole, double throw (SPDT) and can be installed to turn one circuit from off to on (normally open) or from on to off (normally closed).

All have a certificate with a traceable lot number and material test report.

Setpoint | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pressure, psi | Vacuum, in. of Hg | Approximate Difference Between Setpoint and Reset Point, psi | Maximum Continuous Pressure, psi | Maximum Short-Term Pressure, psi | Accuracy | Maximum Switching Current | Process Temp. Range, °F | Connection Material | For Use With | Specifications Met | Each | |

Wire Leads | ||||||||||||

1 1/2" Tube OD Quick-Clamp Connection | ||||||||||||

| 0-15 | 30-0 | 3 | 15 | 1,000 | ±2% | 5 A @ 125 V AC 5 A @ 250 V AC 3 A @ 28 V DC | -40° to 212° | 316 Stainless Steel | Argon, Beverage, Diesel Fuel, Food, Gasoline, Hydraulic Fluid, Inert Gas, Natural Gas, Nitrogen, Oil, Oxygen, Water | 3-A Certified 74-07, UL Listed | 00000000 | 0000000 |

2" Tube OD Quick-Clamp Connection | ||||||||||||

| 0-15 | 30-0 | 3 | 15 | 1,000 | ±2% | 5 A @ 125 V AC 5 A @ 250 V AC 3 A @ 28 V DC | -40° to 212° | 316 Stainless Steel | Argon, Beverage, Diesel Fuel, Food, Gasoline, Hydraulic Fluid, Inert Gas, Natural Gas, Nitrogen, Oil, Oxygen, Water | 3-A Certified 74-07, UL Listed | 00000000 | 000000 |

Economy Vacuum Switches

Choose these switches when you need reliable switching but not high accuracy. When they reach a set vacuum, they turn equipment on and off, signal automatic controls, or trigger alarms. They are single pole, double throw (SPDT) and can be installed to turn one circuit from off to on (normally open) or from on to off (normally closed). All meet American and European safety standards since they're UL recognized components and CE marked.

For technical drawings and 3-D models, click on a part number.

| Setpoint, in. of Hg | Approximate Difference Between Setpoint and Reset Point, in. of Hg | Maximum Continuous Pressure, psi | Maximum Short-Term Pressure, psi | Accuracy | Process Temperature Range, °F | Connection Material | For Use With | Each | |

Spade Terminals | |||||||||

|---|---|---|---|---|---|---|---|---|---|

1/8 NPT Male Pipe Connection | |||||||||

| 28.2-2.7 | 3 | 0 | 0 | ±5.5% | -30° to 185° | Chrome-Plated Zinc | Air, Argon, Cleaning Solutions, Diesel Fuel, Gasoline, Hydraulic Fluid, Inert Gas, Nitrogen, Oil, Oxygen, Water | 0000000 | 0000000 |

Combustion Efficiency Meters

Also known as a combustion analyzer, this meter measures boiler and furnace combustion efficiency. It automatically calibrates to normal atmospheric oxygen.

Measurement Range | Calculated Range | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Use On | Ambient Temp. | Flue Gas Temp. | Flue Gas Oxygen | Carbon Monoxide, ppm | Combustion Efficiency | Carbon Dioxide | Air Free Carbon Monoxide, ppm | Excess Air | Accuracy | Batteries Included | Each | |

| Kerosene, Natural Gas, Oil, Propane | 25° to 110° F | -4° to 1200° F | 0-20.9% | 0-2,000 | 0.1%-100% | 0-15% | 0-9,999 | 0-250% | ±0.3% of Oxygen Content | Yes | 0000000 | 0000000 |