About Pipe Size

More

About Pressure Gauges

More

About Pressure Transmitters

More

Oxygen Detectors

When your work area has too much or too little oxygen, these detectors alert you with an audible alarm, warning light, and vibrating alarm. You can adjust the high and low alarm trigger points to suit your environment.

A calibration check must be performed on the detector before each use to verify that it is working properly. The check can be performed with the press of a button.

The detector with a nonreplaceable battery should be thrown away at the end of its two-year lifespan.

| Measuring Range, % Vol. | Volume | Ht. | Wd. | Dp. | Temperature Range, °F | Batteries Included | Battery Chemistry | Environmental Rating | Each | |

Detectors with Nonreplaceable Battery | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0-25 | 95 dBA @ 30 cm. | 3 1/2" | 2" | 1" | -4° to 122° | Yes | Lithium | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Group G NEC Zone 0 Groups IIC, IIB, IIA IEC Zone 1 Groups IIC, IIB, IIA IP67 | 00000000 | 0000000 |

Detectors with Replaceable Battery | ||||||||||

| 0-25 | 95 dBA @ 30 cm. | 3 1/2" | 2" | 1" | -4° to 122° | Yes | Lithium | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Group G NEC Zone 0 Groups IIC, IIB, IIA IEC Zone 0 Groups IIC, IIB, IIA | 00000000 | 000000 |

| Batteries (Pkg. of 1) | 0000000 | Pkg. | 00000 |

Portable Multi-Gas Detectors

When this detector senses high levels of combustible and toxic gases, it alerts you with an audible alarm, warning light, and vibrating alarm. You can adjust the alarm trigger points to suit your environment. There is also a motion sensor that sounds an alarm if the user becomes disabled.

A calibration check must be performed on the detector before each use to verify that it is working properly. The check requires a regulator and cylinder (sold separately).

Note: LEL is lower explosive limit.

| Detects (Measuring Range) | Volume | Temperature Range, °F | Batteries Included | Environmental Rating | Each | |

| Acetone, Butane, Hydrogen, Methane, Pentane, Propane, Toluene (0-100% LEL), Oxygen (0-30% Vol.), Carbon Monoxide (0-1,999 ppm), Hydrogen Sulfide (0-200 ppm) | 95 dBA @ 30 cm. | -40° to 140° | Yes | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 0 Groups IIC, IIB, IIA IP68 | 00000000 | 000000000 |

Portable Multi-Gas Detectors with Probe

Use the probe to test the air in a hazardous area before entering. Great for confined spaces. This detector alerts you with an audible alarm, warning light, and vibrating alarm in the presence of combustible and toxic gases. You can adjust the alarm trigger points to suit your environment. There is also a motion sensor that sounds an alarm if the user becomes disabled.

A calibration check must be performed on the detector before each use to verify that it is working properly. The check requires a regulator and cylinder (sold separately).

Note: LEL is lower explosive limit.

| Detects (Measuring Range) | Volume | Temperature Range, °F | Batteries Included | Includes | Tube Lg., ft. | Environmental Rating | Each | |

| Acetone, Butane, Hydrogen, Methane, Pentane, Propane, Toluene (0-100% LEL), Oxygen (0-30% Vol.), Carbon Monoxide (0-1,999 ppm), Hydrogen Sulfide (0-200 ppm) | 95 dBA @ 30 cm. | -40° to 140° | Yes | Sampling Probe, Tubing Assembly, Rechargeable Lithium Ion Battery for Probe | 25 | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 0 Groups IIC, IIB, IIA IP68 | 00000000 | 000000000 |

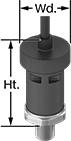

Pressure Transmitters for Oxygen

- For Use With: Oxygen

- Accuracy: ±1.0%

- Pipe Connection: NPT Male

- Housing Material: Glass-Reinforced Nylon

- Connection Material: 304 Stainless Steel

- Temperature Range: -40° to 255° F

Adhere to safety standards and monitor pressure when working with high concentrations of oxygen. These transmitters are cleaned following ASME B40.100 IV guidelines and are sealed in an airtight bag to prevent contamination before use. Also known as transducers, they convert pressure to an electrical signal that can be interpreted by receiving devices, such as remote displays, programmable logic controllers, and motor speed controls. For your receiving device to interpret the signal from the transmitter, you will need to calibrate it for the transmitter's pressure range and output signal. As pressure increases, the output signal from the transmitter will increase. Transmitters will only provide accurate readings within the rated pressure range.

These transmitters are rated NEMA 4X and IP65 for protection from dust, weather, washdown, and corrosion. UL and C-UL recognized components and CE marked, they also meet American, Canadian, and European safety standards.

With a current output, they connect using two wires. The same wire is used to send a signal to the receiver and to power the transmitter. Current doesn’t lose signal over long distances and isn’t affected by electrical interference from other devices.

For technical drawings and 3-D models, click on a part number.

| Pressure Range, psi | Maximum Continuous Pressure, psi | Maximum Short-Term Pressure, psi | Input Voltage | Pipe Size | Ht. | Wd. | Environmental Rating | Each | |

4-20mA Current Output—Wire Leads | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0-30 | 60 | 60 | 9-36V DC | 1/4 | 2 3/8" | 1 5/16" | IP65, NEMA 4X | 0000000 | 0000000 |

| 0-60 | 120 | 120 | 9-36V DC | 1/4 | 2 3/8" | 1 5/16" | IP65, NEMA 4X | 0000000 | 000000 |

| 0-100 | 200 | 200 | 9-36V DC | 1/4 | 2 3/8" | 1 5/16" | IP65, NEMA 4X | 0000000 | 000000 |

| 0-300 | 600 | 600 | 9-36V DC | 1/4 | 2 3/8" | 1 5/16" | IP65, NEMA 4X | 0000000 | 000000 |

| 0-500 | 1,000 | 1,000 | 9-36V DC | 1/4 | 2 3/8" | 1 5/16" | IP65, NEMA 4X | 0000000 | 000000 |

| 0-1,000 | 2,000 | 2,000 | 9-36V DC | 1/4 | 2 3/8" | 1 5/16" | IP65, NEMA 4X | 0000000 | 000000 |

| 0-1,500 | 3,000 | 3,000 | 9-36V DC | 1/4 | 2 3/8" | 1 5/16" | IP65, NEMA 4X | 0000000 | 000000 |

Gas Pressure Gauges

Use these gauges with pumps, filters, regulators, and in process lines to monitor the pressure of compressed gas. Mount them with the dial face upright. Gauges for use with acetylene can also be used in welding applications.

Gauges with brass case are cleaned to meet ASME B40.1, Level IV for oxygen service.

Gauges with 304 stainless steel case are cleaned and bagged to meet ASME B40.1, Level IV for oxygen service.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Acetylene, Carbon Dioxide, and Oxygen

- Accuracy: ±2% Mid Scale (Grade B)

Available Pressure Ranges | ||

|---|---|---|

| Pressure Range, psi | Graduation Marks, psi | Numeric Increments, psi |

| 0 to 30 | 1 | 5 |

| 0 to 60 | 1 | 10 |

| 0 to 100 | 2 | 20 |

| 0 to 200 | 5 | 40 |

| 0 to 400 | 10 | 50 |

| 0 to 600 | 10 | 100 |

| 0 to 1,000 | 20 | 200 |

| 0 to 2,000 | 50 | 400 |

| 0 to 3,000 | 50 | 500 |

| 0 to 4,000 | 100 | 500 |

- For Use With: Oxygen

- Accuracy: ±1% Mid Scale (Grade A); except

4" Dial Dia.: ±1% Full Scale (Grade 1A)

Available Pressure Ranges | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Bottom and Center Back Connections | Lower Back Connection | ||||||||

Pressure Range | Graduation Marks | Numeric Increments | Graduation Marks | Numeric Increments | |||||

| psi | kPa | psi | kPa | psi | kPa | psi | kPa | psi | kPa |

2 1/2" Dial Diameter | |||||||||

| 0 to 15 | 0 to 102 | 0.2 | 2 | 3 | 20 | __ | __ | __ | __ |

| 0 to 30 | 0 to 205 | 0.5 | 5 | 5 | 50 | __ | __ | __ | __ |

| 0 to 100 | 0 to 680 | 2 | 10 | 20 | 100 | __ | __ | __ | __ |

| 0 to 200 | 0 to 1,350 | 5 | 50 | 50 | 200 | __ | __ | __ | __ |

| 0 to 300 | 0 to 2,050 | 5 | 50 | 50 | 500 | __ | __ | __ | __ |

| 0 to 600 | 0 to 4,100 | 10 | 100 | 100 | 1,000 | __ | __ | __ | __ |

4" Dial Diameter | |||||||||

| 0 to 15 | 0 to 103 | 0.2 | 1 | 3 | 10 | 0.2 | 1 | 3 | 10 |

| 0 to 30 | 0 to 206 | 0.5 | 2 | 5 | 20 | 0.5 | 2 | 5 | 20 |

| 0 to 100 | 0 to 680 | 1 | 10 | 10 | 100 | 1 | 10 | 10 | 100 |

| 0 to 200 | 0 to 1,360 | 2 | 20 | 20 | 200 | 2 | 20 | 20 | 200 |

| 0 to 300 | 0 to 2,060 | 5 | 20 | 50 | 200 | 5 | 20 | 50 | 200 |

| 0 to 600 | 0 to 4,100 | 10 | 50 | 100 | 500 | 10 | 100 | 100 | 1,000 |

| Dial Diameter | Pipe Size | Environment Temp. Range, °F | Process Temp. Range, °F | Mounting Orientation | Each | |

Bottom Connection | ||||||

|---|---|---|---|---|---|---|

NPT Male | ||||||

| 2 1/2" | 1/4 | -40° to 140° | -40° to 140° | Upright | 0000000 | 000000 |

| 4" | 1/4 | -40° to 140° | -40° to 140° | Upright | 0000000 | 00000 |

Center Back Connection | ||||||

NPT Male | ||||||

| 2 1/2" | 1/4 | -40° to 140° | -40° to 140° | Upright | 0000000 | 00000 |

Lower Back Connection | ||||||

NPT Male | ||||||

| 4" | 1/4 | -40° to 140° | -40° to 140° | Upright | 0000000 | 00000 |

Combustion Efficiency Meters

Also known as a combustion analyzer, this meter measures boiler and furnace combustion efficiency. It automatically calibrates to normal atmospheric oxygen.

Measurement Range | Calculated Range | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Use On | Ambient Temp. | Flue Gas Temp. | Flue Gas Oxygen | Carbon Monoxide, ppm | Combustion Efficiency | Carbon Dioxide | Air Free Carbon Monoxide, ppm | Excess Air | Accuracy | Batteries Included | Each | |

| Kerosene, Natural Gas, Oil, Propane | 25° to 110° F | -4° to 1200° F | 0-20.9% | 0-2,000 | 0.1%-100% | 0-15% | 0-9,999 | 0-250% | ±0.3% of Oxygen Content | Yes | 0000000 | 0000000 |