How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About On/Off Valves

More

Threaded On/Off Valves

Use these valves in general purpose applications, such as those with water, oil, air, and inert gas.

Plated brass valves are more corrosion resistant than plain brass and bronze valves. Bronze valves are stronger and more durable than brass valves for a longer service life. 316 stainless steel valves have the best corrosion resistance.

Full-port valves do not restrict flow. Standard-port valves slightly restrict flow.

FM-approved valves are used in fire suppression systems. They help isolate parts of water supply systems in buildings and plants.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Ball

- For Use With: See table

- Seal Material: See table

- Specifications Met: See table

Lever handles give you the most leverage for quickly opening and closing valves with minimal effort.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | Ball Material | Seal Material | For Use With | Specifications Met | Each | |

BSPT Female × BSPT Female | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/4 | 1.2 | 600 psi @ 100° F | 150 psi @ 365° F | -40° to 350° | 29.9 | Full | 1 3/4" | Chrome-Plated Brass | Fluoroelastomer Rubber | Water, Oil, Air, Steam | FM Approved | 0000000 | 000000 |

| 3/8 | 10 | 600 psi @ 100° F | 150 psi @ 365° F | -40° to 350° | 29.9 | Full | 1 3/4" | Brass | Fluoroelastomer Rubber | Water, Oil, Air, Steam | FM Approved | 0000000 | 00000 |

| 1/2 | 46 | 600 psi @ 100° F | 150 psi @ 365° F | -40° to 350° | 29.9 | Full | 2 5/16" | Brass | Fluoroelastomer Rubber | Water, Oil, Air, Steam | FM Approved | 0000000 | 00000 |

| 3/4 | 66 | 600 psi @ 100° F | 150 psi @ 365° F | -40° to 350° | 29.9 | Full | 2 1/2" | Brass | Fluoroelastomer Rubber | Water, Oil, Air, Steam | FM Approved | 0000000 | 00000 |

| 1 | 93 | 600 psi @ 100° F | 150 psi @ 365° F | -40° to 350° | 29.9 | Full | 3 3/16" | Brass | Fluoroelastomer Rubber | Water, Oil, Air, Steam | FM Approved | 0000000 | 00000 |

| 1 1/2 | 144.4 | 600 psi @ 100° F | __ | -40° to 350° | 29.9 | Full | 4" | Chrome-Plated Brass | PTFE Plastic | Water, Oil, Air | FM Approved | 0000000 | 00000 |

| 2 | 206.8 | 600 psi @ 100° F | __ | -40° to 350° | 29.9 | Full | 4 3/4" | Chrome-Plated Brass | PTFE Plastic | Water, Oil, Air | FM Approved | 0000000 | 000000 |

- Valve Type: Ball

- For Use With: Air, Oil, Steam, Water

- Seal Material: Fluoroelastomer Rubber

- Specifications Met: FM Approved

Lever handles give you the most leverage for quickly opening and closing valves with minimal effort.

Lockable handles can be fixed in place using a padlock (not included).

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | Ball Material | For Max. Shackle Dia. | Each | |

BSPT Female × BSPT Female | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/4 | 4.5 | 600 psi @ 100° F | 150 psi @ 365° F | -40° to 350° | 29.9 | Full | 1 3/4" | Chrome-Plated Brass | 9/32" | 00000000 | 000000 |

| 3/8 | 9.5 | 600 psi @ 100° F | 150 psi @ 365° F | -40° to 350° | 29.9 | Full | 1 3/4" | Chrome-Plated Brass | 9/32" | 00000000 | 00000 |

| 1/2 | 32.3 | 600 psi @ 100° F | 150 psi @ 365° F | -40° to 350° | 29.9 | Full | 2 5/16" | Chrome-Plated Brass | 9/32" | 00000000 | 00000 |

| 3/4 | 48.5 | 600 psi @ 100° F | 150 psi @ 365° F | -40° to 350° | 29.9 | Full | 2 1/2" | Chrome-Plated Brass | 9/32" | 00000000 | 00000 |

| 1 | 80.9 | 600 psi @ 100° F | 150 psi @ 365° F | -40° to 350° | 29.9 | Full | 3 3/16" | Chrome-Plated Brass | 9/32" | 00000000 | 00000 |

| 1 1/4 | 92.4 | 600 psi @ 100° F | 150 psi @ 365° F | -40° to 350° | 29.9 | Full | 3 11/16" | Chrome-Plated Brass | 9/32" | 00000000 | 00000 |

| 1 1/2 | 144.4 | 600 psi @ 100° F | 150 psi @ 365° F | -40° to 350° | 29.9 | Full | 4" | Chrome-Plated Brass | 9/32" | 00000000 | 00000 |

| 2 | 206.8 | 600 psi @ 100° F | 150 psi @ 365° F | -40° to 350° | 29.9 | Full | 4 3/4" | Chrome-Plated Brass | 9/32" | 00000000 | 000000 |

- Valve Type: Ball

- For Use With:

NPT: Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon

BSPT: Air, Oil, Water, Steam - Seal Material: Fluoroelastomer Rubber

- Specifications Met:

NPT: FM Approved, UL Listed, CSA-US Certified, CSA Certified

BSPT: FM Approved

T-handles resist accidental movement when bumped or snagged.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | Ball Material | Each | |

BSPT Female × BSPT Female | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1/4 | 4.5 | 600 psi @ 100° F | 150 psi @ 365° F | -40° to 350° | 29.9 | Full | 1 3/4" | Chrome-Plated Brass | 0000000 | 000000 |

| 3/8 | 9.5 | 600 psi @ 100° F | 150 psi @ 365° F | -40° to 350° | 29.9 | Full | 1 3/4" | Chrome-Plated Brass | 0000000 | 00000 |

| 1/2 | 32.3 | 600 psi @ 100° F | 150 psi @ 365° F | -40° to 350° | 29.9 | Full | 2 5/16" | Chrome-Plated Brass | 0000000 | 00000 |

| 3/4 | 48.5 | 600 psi @ 100° F | 150 psi @ 365° F | -40° to 350° | 29.9 | Full | 2 1/2" | Chrome-Plated Brass | 0000000 | 00000 |

| 1 | 80.9 | 600 psi @ 100° F | 150 psi @ 365° F | -40° to 350° | 29.9 | Full | 3 3/16" | Chrome-Plated Brass | 0000000 | 00000 |

| 1 1/2 | 144.4 | 600 psi @ 100° F | 150 psi @ 365° F | -40° to 350° | 29.9 | Full | 4" | Chrome-Plated Brass | 0000000 | 00000 |

- Valve Type: Ball

- For Use With:

NPT: Argon, Helium, Krypton, Neon, Oil, Steam, Water, Xenon

BSPP and BSPT: Air, Argon, Helium, Krypton, Neon, Oil, Steam, Water, Xenon

UN/UNF: Air, Argon, Oil, Steam, Water - Seal Material: PTFE Plastic

Lever handles give you the most leverage for quickly opening and closing valves with minimal effort.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temperature Range, °F | Port Type | End-to-End Lg. | Ball Material | Each | |

BSPT Female × BSPT Female | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/4 | 8.4 | 600 psi @ 100° F | 150 psi @ 365° F | -20° to 450° | Full | 2 1/16" | Chrome-Plated Bronze | 0000000 | 000000 |

| 3/8 | 7.2 | 600 psi @ 100° F | 150 psi @ 365° F | -20° to 450° | Full | 2 1/16" | Chrome-Plated Bronze | 0000000 | 00000 |

| 3/8 | 7.2 | 600 psi @ 100° F | 150 psi @ 365° F | -20° to 450° | Full | 2 1/16" | 316 Stainless Steel | 0000000 | 00000 |

| 1/2 | 15 | 600 psi @ 100° F | 150 psi @ 365° F | -20° to 450° | Full | 2 1/4" | Chrome-Plated Bronze | 0000000 | 00000 |

| 3/4 | 30 | 600 psi @ 100° F | 150 psi @ 365° F | -20° to 450° | Standard | 3" | Chrome-Plated Bronze | 0000000 | 00000 |

| 1 | 43 | 600 psi @ 100° F | 150 psi @ 365° F | -20° to 450° | Standard | 3 3/8" | Chrome-Plated Bronze | 000000 | 00000 |

| 1 1/4 | 48 | 600 psi @ 100° F | 150 psi @ 365° F | -20° to 450° | Standard | 4" | Chrome-Plated Bronze | 0000000 | 00000 |

| 2 | 108 | 600 psi @ 100° F | 150 psi @ 365° F | -20° to 450° | Standard | 4 11/16" | Chrome-Plated Bronze | 0000000 | 000000 |

- Valve Type: Ball

- For Use With: See table

- Seal Material: PTFE Plastic

Lever handles give you the most leverage for quickly opening and closing valves with minimal effort.

Lockable handles can be fixed in place using a padlock (not included).

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | Ball Material | For Max. Shackle Dia. | For Use With | Each | |

BSPT Female × BSPT Female | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/4 | 1.3 | 2000 psi @ 100° F | 150 psi @ 360° F | -30° to 400° | 29 | Standard | 2" | 316 Stainless Steel | 11/32" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Steam | 0000000 | 000000 |

| 3/8 | 2.6 | 2000 psi @ 100° F | __ | -30° to 400° | Not Rated | Standard | 2 3/8" | 316 Stainless Steel | 5/16" | Water, Oil, Argon, Helium, Krypton, Neon, Xenon | 0000000 | 00000 |

| 1/2 | 9.2 | 2000 psi @ 100° F | 150 psi @ 360° F | -30° to 400° | 29 | Standard | 2 15/16" | 316 Stainless Steel | 11/32" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Steam | 0000000 | 00000 |

| 3/4 | 12.6 | 2000 psi @ 100° F | 150 psi @ 360° F | -30° to 400° | 29 | Standard | 2 5/16" | 316 Stainless Steel | 11/32" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Steam | 0000000 | 00000 |

| 1 | 17.3 | 2000 psi @ 100° F | 150 psi @ 360° F | -30° to 400° | 29 | Standard | 2 13/16" | 316 Stainless Steel | 11/32" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Steam | 0000000 | 000000 |

BSPT Female × BSPT Male | ||||||||||||

| 1/4 | 1.3 | 2000 psi @ 100° F | 150 psi @ 365° F | -40° to 400° | Not Rated | Standard | 2" | 316 Stainless Steel | 23/64" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | 0000000 | 00000 |

| 1/2 | 9.2 | 2000 psi @ 100° F | 150 psi @ 365° F | -40° to 400° | Not Rated | Standard | 3 1/4" | 316 Stainless Steel | 23/64" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | 0000000 | 000000 |

BSPT Male × BSPT Male | ||||||||||||

| 1/4 | 1.3 | 2000 psi @ 100° F | 150 psi @ 360° F | -30° to 400° | 29 | Standard | 2 15/16" | 316 Stainless Steel | 11/32" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Steam | 0000000 | 00000 |

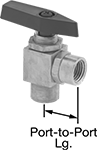

Panel-Mount Threaded On/Off Valves

Access the handle of these valves while protecting your line behind an instrument panel. They have threads and a hex nut below the handle for panel mounting.

316 stainless steel valves are more corrosion resistant than brass valves.

Standard-port valves slightly restrict flow.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Ball

- For Use With:

316 Stainless Steel: Water, Oil, Air, Nitrogen

Brass: Water, Oil, Air - Seal Material: See table

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | Seal Material | Port Type | End-to-End Lg. | Panel Cutout Dia. | Each | |

Brass Body | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

BSPT Female × BSPT Female | ||||||||||

| 1/4 × 1/4 | 0.9 | 3000 psi @ 70° F | -30° to 295° | 29 | PTFE Plastic | Standard | 2 1/2" | 3/4" | 00000000 | 0000000 |

316 Stainless Steel Body | ||||||||||

BSPT Female × BSPT Female | ||||||||||

| 1/8 × 1/8 | 0.5 | 3000 psi @ 70° F | -30° to 295° | 29 | PTFE Plastic | Standard | 1 5/8" | 19/32" | 00000000 | 000000 |

| 1/4 × 1/4 | 0.9 | 3000 psi @ 70° F | -30° to 295° | 29 | PTFE Plastic | Standard | 2 1/16" | 25/32" | 00000000 | 000000 |

| 1/2 × 1/2 | 6.3 | 3000 psi @ 70° F | -30° to 295° | 29 | PTFE Plastic | Standard | 3 7/16" | 13/16" | 00000000 | 000000 |

| 3/4 × 3/4 | 6.1 | 3000 psi @ 70° F | -30° to 295° | 29 | PTFE Plastic | Standard | 3 9/16" | 13/16" | 00000000 | 000000 |

BSPT Male × BSPT Male | ||||||||||

| 1/4 × 1/4 | 1.2 | 3000 psi @ 70° F | -30° to 295° | 29 | PTFE Plastic | Standard | 3" | 3/4" | 0000000 | 000000 |

- Valve Type: Ball

- For Use With:

316 Stainless Steel: Water, Oil, Air, Nitrogen

Brass: Water, Oil, Air - Seal Material:

316 Stainless Steel: PTFE Plastic

Brass: Fluoroelastomer Rubber

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | Port Type | Port-to-Port Lg. | Panel Cutout Dia. | Each | |

316 Stainless Steel Body | |||||||||

|---|---|---|---|---|---|---|---|---|---|

BSPT Female × BSPT Female | |||||||||

| 1/4 × 1/4 | 0.7 | 3000 psi @ 70° F | -30° to 295° | 29 | Standard | 1 1/4" | 3/4" | 0000000 | 0000000 |

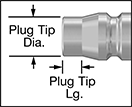

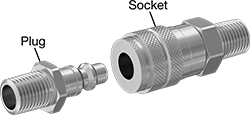

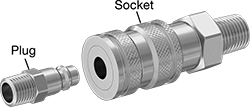

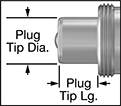

Industrial Quick-Disconnect Hose Couplings for Air

A complete coupling consists of a plug and a socket (both sold separately or in a set) that connect and disconnect quickly. Use them if you need frequent access to a line. They are also known as industrial interchange couplings. All Industrial plugs are compatible with any of the Industrial sockets of the same coupling size, regardless of the pipe size or barbed hose ID.

Steel is stronger and more durable than other metals. Zinc-plated steel has fair corrosion resistance and should be used primarily in dry environments. Brass is softer than other metals, so it’s easier to thread together. It has good corrosion resistance. Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

- Maximum Pressure: 230 psi @ 72° F

- Temperature Range: 0° to 212° F

- Specifications Met: Fed. Spec. A-A-593439, ISO 6150/B

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Push-to-connect sockets join by forcefully pushing the plug and socket together until you hear a click. Unlike sleeve-lock sockets, you should not slide back the sleeve to connect. To disconnect, slide the sleeve on the socket forward until the plug ejects.

- Maximum Pressure: 300 psi @ 72° F

- Temperature Range: -40° to 225° F

- Specifications Met: Fed. Spec. A-A-59439, ISO 6150/B, except 3/8 Coupling Size Sockets: ISO 6150/B

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Sleeve-lock sockets connect by sliding back the sleeve on the socket, inserting the plug, and releasing the sleeve. To disconnect, slide the sleeve back and pull out the plug.

Universal Quick-Disconnect Hose Sockets for Air

Sockets accommodate five common plug shapes: Industrial, ARO, Lincoln, Tru-Flate, and European. Use them with a plug of the same coupling size to frequently connect and disconnect your line. Sockets are push-to-connect style. To connect, push the plug into the socket until you hear a click. To disconnect, slide the sleeve on the socket forward until the plug ejects. Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Brass sockets have good corrosion resistance.

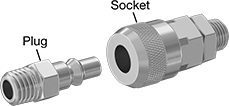

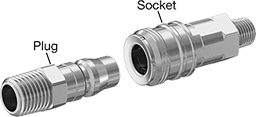

ARO Quick-Disconnect Hose Couplings for Air

A complete coupling consists of a plug and a socket (both sold separately or in a set) that connect and disconnect quickly. Use them if you need frequent access to a line. All ARO plugs are compatible with any of the ARO sockets of the same coupling size, regardless of the pipe size or barbed hose ID.

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Push-to-connect sockets are easier to connect than sleeve-lock sockets. Connect by pushing the plug into the socket until you hear a click. To disconnect, slide the sleeve on the socket forward until the plug ejects.

Steel is stronger and more durable than other metals. Zinc-plated steel has fair corrosion resistance and should be used primarily in dry environments.Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

- Maximum Pressure:

For NPT Threads: 300 psi @ 72° F

For BSPT Threads: 230 psi @ 72° F - Maximum Vacuum:

For NPT Threads: 26 in. of Hg @ 72° F

For BSPT Threads: Not Rated - Temperature Range:

For NPT Threads: -40° to 225° F

For BSPT Threads: 0° to 212° F

European Quick-Disconnect Hose Couplings for Air

With an unobstructed air path, these couplings have better airflow than other coupling shapes of the same size. A complete coupling consists of a plug and a socket (both sold separately) that connect and disconnect quickly. Use them if you need frequent access to a line. All European plugs are compatible with any of the European sockets, regardless of the pipe size or barbed hose ID. Made of zinc-plated steel, all are strong and durable, have fair corrosion resistance, and should be used primarily in noncorrosive environments.

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line. They are push-to-connect style. To connect, push the plug into the socket until you hear a click. To disconnect, slide the sleeve on the socket forward until the plug ejects. The sleeve is made of zinc-plated brass, which has better corrosion resistance than zinc-plated steel.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Japanese Quick-Disconnect Hose Couplings for Air

A complete coupling consists of a plug and a socket (both sold separately) that connect and disconnect quickly. Use them if you need frequent access to a line. All Japanese plugs are compatible with any of the Japanese sockets, regardless of the pipe size or barbed hose ID. Plugs and sockets are zinc-plated steel, which is strong and durable. They have fair corrosion resistance, so they should be used primarily in dry environments.

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line. They are push-to-connect style. To connect, push the plug into the socket until you hear a click. To disconnect, slide the sleeve on the socket forward until the plug ejects.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

High-Pressure Thread-Lock Quick-Disconnect

Hose Couplings for Hydraulic Fluid

A complete coupling consists of a plug and a socket (both sold separately) that thread together to form a stronger connection than other types of quick-disconnect couplings. To connect, insert the plug into the socket, then slide the sleeve forward and thread it onto the plug. To disconnect, unthread the plug from the sleeve, then slide the sleeve back and pull out the plug. All of the High-Pressure Thread-Lock quick-disconnect plugs are compatible with any of the High-Pressure Thread-Lock quick-disconnect sockets of the same coupling size, regardless of the pipe size. Couplings are compatible with Enerpac Series and Parker 3000 couplings. Also known as double shut-off couplings, the plugs and sockets both have a shut-off valve that stops the flow when the coupling is separated.

Zinc-plated steel plugs and sockets are stronger and more durable than 316 stainless steel plugs and sockets. They have fair corrosion resistance.Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size. Pressure ratings are given for static (constant) pressure conditions.

Warning: Stop the flow before you disconnect the line.

- Maximum Pressure: 10,000 psi @ 72° F

- Temperature Range:

NPTF and NPT Threads: -40° to 250° F

BSPT and BSPP Threads: -40° to 180°F - Compatible With: Enerpac Series, Parker 3000