How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Conduit

More

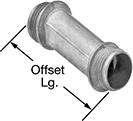

Connectors for Medium-Wall (IMC) and Thick-Wall (Rigid) Steel Conduit

Join pieces of medium-wall (IMC) and thick-wall (rigid) conduit.

Offset elbow connectors join knockouts on outlet boxes or enclosures that do not align.

For technical drawings and 3-D models, click on a part number.

Conduit or Electrical Box Connection | ||||||||

|---|---|---|---|---|---|---|---|---|

| Conduit Trade Size | Pipe Size | Thread Type | Gender | Offset Lg. | Material | Specifications Met | Each | |

| 1/2 | 1/2 | NPSM | Male | 3/4" | Zinc | UL Listed, CSA Certified | 0000000 | 00000 |

| 3/4 | 3/4 | NPSM | Male | 3/4" | Zinc | UL Listed, CSA Certified | 0000000 | 0000 |

| 1 | 1 | NPSM | Male | 3/4" | Zinc | UL Listed, CSA Certified | 0000000 | 0000 |

| 1 1/4 | 1 1/4 | NPSM | Male | 3/4" | Zinc | UL Listed, CSA Certified | 0000000 | 0000 |

| 1 1/2 | 1 1/2 | NPSM | Male | 3/4" | Zinc | UL Listed, CSA Certified | 0000000 | 0000 |

| 2 | 2 | NPSM | Male | 3/4" | Zinc | UL Listed, CSA Certified | 0000000 | 00000 |

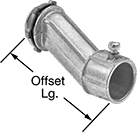

Adapters for Thin-Wall (EMT) Steel Conduit

Use these adapters to attach thin-wall (EMT) steel conduit to a knockout in an outlet box or enclosure. The screw-clamp end tightens around conduit with a screw.

For technical drawings and 3-D models, click on a part number.

Conduit Connection | Electrical Box Connection | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Conduit Trade Size | Gender | Pipe Size | Thread Type | Gender | Offset Lg. | Includes | Specifications Met | Each | |

Screw-Clamp Conduit Connection × Threaded Electrical Box Connection | |||||||||

| 1/2 | Female | 1/2 | NPSM | Male | 3/8" | Locknut | UL Listed, CSA Certified | 0000000 | 00000 |

| 3/4 | Female | 3/4 | NPSM | Male | 3/4" | Locknut | UL Listed, CSA Certified | 0000000 | 0000 |

| 1 | Female | 1 | NPSM | Male | 1" | Locknut | UL Listed | 0000000 | 00000 |

Butt-Weld Fittings for Stainless Steel Tubing

- For Use With: See table

- Temperature Range: See table

- Tubing:

304 Stainless Steel: Use with 304/304L stainless steel that meets ASTM A213, ASTM A269, or ASTM A270, except DIN EN 10357 fittings with only ASTM A269 or ASTM A270

316 Stainless Steel: Use with 316/316L stainless steel that meets ASTM A213, ASTM A269, or ASTM A270, except ASME BPE and DIN EN 10357 fittings with only ASTM A269 or ASTM A270 - Specifications Met: See table

Weld these fittings to tubing for a permanent, flush connection that permits smooth flow through a line.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Offset straight reducers are also known as eccentric reducers. They have offset centers so your line can drain.

| For Tube OD (A) | For Tube OD (B) | Max. Pressure | Max. Vacuum | Temp. Range, °F | Wall Thick. | For Use With | Specifications Met | Each | |

304/304L Stainless Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Polished | |||||||||

| 1 1/2" | 1" | 600 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Dairy, Food | 3-A Certified 63-04 | 00000000 | 000000 |

| 2" | 1 1/2" | 550 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Dairy, Food | 3-A Certified 63-04 | 00000000 | 00000 |

| 2 1/2" | 2" | 450 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Dairy, Food | 3-A Certified 63-04 | 00000000 | 00000 |

| 3" | 1 1/2" | 350 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Dairy, Food | 3-A Certified 63-04 | 00000000 | 000000 |

| 3" | 2" | 350 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Dairy, Food | 3-A Certified 63-04 | 00000000 | 00000 |

| 3" | 2 1/2" | 350 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Dairy, Food | 3-A Certified 63-04 | 00000000 | 00000 |

| 4" | 3" | 250 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.083" | Dairy, Food | 3-A Certified 63-04 | 00000000 | 00000 |

Dull | |||||||||

| 1 1/2" | 1" | 600 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Air, Food, Water | __ | 00000000 | 00000 |

| 2" | 1" | 550 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Air, Food, Water | __ | 00000000 | 00000 |

| 2" | 1 1/2" | 550 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Air, Food, Water | __ | 00000000 | 00000 |

| 2 1/2" | 2" | 450 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Air, Food, Water | __ | 00000000 | 00000 |

| 3" | 2" | 350 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Air, Food, Water | __ | 00000000 | 00000 |

| 3" | 2 1/2" | 350 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Air, Food, Water | __ | 00000000 | 00000 |

| 4" | 3" | 250 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Air, Food, Water | __ | 00000000 | 00000 |

| 6" | 4" | 120 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.083" | Air, Food, Water | __ | 00000000 | 000000 |

316/316L Stainless Steel | |||||||||

Polished | |||||||||

| 1" | 1/2" | 600 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Dairy, Food | 3-A Certified 63-04 | 00000000 | 00000 |

| 1" | 3/4" | 600 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Dairy, Food | 3-A Certified 63-04 | 00000000 | 00000 |

| 1 1/2" | 1" | 600 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Dairy, Food | 3-A Certified 63-04 | 0000000 | 00000 |

| 2" | 1 1/2" | 550 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Dairy, Food | 3-A Certified 63-04 | 0000000 | 00000 |

| 2 1/2" | 2" | 450 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Dairy, Food | 3-A Certified 63-04 | 0000000 | 00000 |

| 3" | 2" | 350 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Dairy, Food | 3-A Certified 63-04 | 0000000 | 00000 |

| 3" | 2 1/2" | 350 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Dairy, Food | 3-A Certified 63-04 | 0000000 | 00000 |

Dull | |||||||||

| 1" | 1/2" | 600 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Air, Food, Water | __ | 00000000 | 00000 |

| 2" | 1 1/2" | 550 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Air, Food, Water | __ | 00000000 | 00000 |

| 4" | 3" | 250 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.083" | Air, Food, Water | __ | 00000000 | 00000 |

Brass Push-to-Connect Fittings for Copper Tubing

- Tubing: Use with K, M, L copper, polyethylene plastic

Connect these fittings to copper tubing with a push—no heat, solder, or flux required. They have an internal gripping ring and O-ring that hold the fitting secure. They also come with a tube support if you want to use them with polyethylene plastic (PEX) tubing. They are also known as instant fittings. Fittings are brass for good corrosion resistance. They are compatible with SharkBite® fittings. To adhere to safety standards for drinking water systems, use fittings that meet NSF/ANSI 61.

- For Use With: Air, Drinking Water, Water

- Temperature Range: 32° to 200° F

- Specifications Met: NSF/ANSI 61

Fittings with offset configuration are smooth inside the longer end, giving extra clearance so they can slide freely over the end of a tube to repair a leak. They’re also known as slip couplings and repair couplings.

Use the chamfering and deburring depth gauge tool (sold separately) to deburr tubing before inserting it into the fitting.

| For Copper Tube Size | For Tube OD | Each | |

| 3/8, 1/2, 3/4, 1 | 1/2", 5/8", 7/8", 1 1/8" | 00000000 | 000000 |

Solder-Connect Fittings for Copper Tubing

- Temperature Range: 32° to 200° F

Solder these fittings to copper tubing or the tube end of another fitting for a permanent, leak-tight connection. They are also known as sweat fittings. Fittings have good corrosion resistance. To adhere to safety standards for drinking water systems, use fittings that meet NSF/ANSI 61 or EN 1057.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water

- Tubing: Use with K, M, L copper

- Specifications Met: ASME B16.22, MSS-SP104, NSF/ANSI 61

Offset straight reducers are also known as eccentric reducers. They have offset centers so the line can drain.

Tube Connection (A) | Tube Connection (B) | ||||||

|---|---|---|---|---|---|---|---|

| Copper Tube Size | For Tube OD | Copper Tube Size | For Tube OD | Material | Max. Pressure | Each | |

| 3/4 | 7/8" | 1/2 | 5/8" | Copper | 400 psi @ 72° F | 00000000 | 000000 |

| 1 | 1 1/8" | 3/4 | 7/8" | Copper | 400 psi @ 72° F | 00000000 | 00000 |

| 1 1/4 | 1 3/8" | 3/4 | 7/8" | Copper | 400 psi @ 72° F | 00000000 | 00000 |

| 1 1/4 | 1 3/8" | 1 | 1 1/8" | Copper | 400 psi @ 72° F | 00000000 | 00000 |

High-Polish Metal Quick-Clamp Sanitary Tube Fittings

- Temperature Range: See Gaskets

The smooth finish inside these fittings makes it easy to remove product residue. Also known as aseptic and tri-clamp fittings, they connect with a gasket, a clamp, and another quick-clamp fitting for a fast and easy way to access your line. The pressure rating of the fitting will vary depending on the clamp you choose, and the temperature rating will vary based on the gasket material you choose.

316 stainless steel fittings have excellent corrosion resistance.

3-A certified fittings comply with sanitary standards.

Note: To complete a connection, you’ll need two quick-clamp fittings, a clamp, and a gasket (all sold separately).

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Beverage, Dairy, Food, Water

- Tubing: Use with welded 304/304L or 316/316L stainless steel that meets ASTM A269 or ASTM 270

- Specifications Met: 3-A Certified 63-04

Offset straight reducers are also known as eccentric reducers; they connect one pipe to another smaller-diameter pipe and have the centers offset so the line can drain.

Tube Connection (A) | Tube Connection (B) | 316/316L Stainless Steel | |||

|---|---|---|---|---|---|

| For Tube OD | Flange OD | For Tube OD | Flange OD | Each | |

| 3/4" | 0.984" | 1/2" | 0.984" | 00000000 | 0000000 |

| 1" | 1.984" | 1/2" | 0.984" | 00000000 | 000000 |

| 1" | 1.984" | 3/4" | 0.984" | 00000000 | 000000 |

| 1 1/2" | 1.984" | 1/2" | 0.984" | 00000000 | 000000 |

| 1 1/2" | 1.984" | 3/4" | 0.984" | 00000000 | 000000 |

| 2" | 2.516" | 1 1/2" | 1.984" | 00000000 | 00000 |

| 2 1/2" | 3.047" | 2" | 2.516" | 00000000 | 00000 |

| 3" | 3.579" | 2" | 2.516" | 00000000 | 000000 |

Recessed Nut, Hole for

Lockout, and 2-Pin Hinge

Clamps with wing nut tighten by hand. Clamps with bolt tighten with a wrench. They handle higher pressures than wing-nut clamps for a stronger, more secure hold.

| For Tube OD | For Flange OD | Bolt Material | Max. Pressure | For Tube Specifications Met | Specifications Met | Each | |

304 Stainless Steel with Wing Nut | |||||||

|---|---|---|---|---|---|---|---|

| 1/2", 3/4" | 0.984" | __ | 1,200 psi @ 72 ° F | ASTM A269, ASTM A270 | __ | 00000000 | 00000 |

| 1", 1 1/4", 1 1/2" | 1.984" | __ | 500 psi @ 72 ° F | ASTM A269, ASTM A270 | __ | 00000000 | 00000 |

| 2" | 2.516" | __ | 450 psi @ 72 ° F | ASTM A269, ASTM A270 | __ | 00000000 | 00000 |

| 2 1/2" | 3.047" | __ | 400 psi @ 72 ° F | ASTM A269, ASTM A270 | __ | 00000000 | 00000 |

| 3" | 3.579" | __ | 350 psi @ 72 ° F | ASTM A269, ASTM A270 | __ | 00000000 | 00000 |

304 Stainless Steel with Wing Nut, Spring Loaded | |||||||

| 1/2", 3/4" | 0.984" | __ | 1,200 psi @ 72 ° F | ASTM A269, ASTM A270 | __ | 0000000 | 00000 |

| 1", 1 1/4", 1 1/2" | 1.984" | __ | 500 psi @ 72 ° F | ASTM A269, ASTM A270 | __ | 0000000 | 00000 |

| 2" | 2.516" | __ | 450 psi @ 72 ° F | ASTM A269, ASTM A270 | __ | 0000000 | 00000 |

| 2 1/2" | 3.047" | __ | 400 psi @ 72 ° F | ASTM A269, ASTM A270 | __ | 0000000 | 00000 |

| 3" | 3.579" | __ | 350 psi @ 72 ° F | ASTM A269, ASTM A270 | __ | 0000000 | 00000 |

304 Stainless Steel with Bolt | |||||||

| 1/2", 3/4" | 0.984" | 304 Stainless Steel | 1,500 psi @ 72 ° F | ASTM A269, ASTM A270 | __ | 00000000 | 00000 |

| 1", 1 1/4", 1 1/2" | 1.984" | 304 Stainless Steel | 1,500 psi @ 72 ° F | ASTM A269, ASTM A270 | __ | 00000000 | 00000 |

| 2" | 2.516" | 304 Stainless Steel | 1,000 psi @ 72 ° F | ASTM A269, ASTM A270 | __ | 00000000 | 00000 |

| 2 1/2" | 3.047" | 304 Stainless Steel | 1,000 psi @ 72 ° F | ASTM A269, ASTM A270 | __ | 00000000 | 00000 |

| 3" | 3.579" | 304 Stainless Steel | 1,000 psi @ 72 ° F | ASTM A269, ASTM A270 | __ | 00000000 | 00000 |

316 Stainless Steel with Wing Nut and 2-Pin Hinge | |||||||

| 1/2", 3/4" | 0.984" | __ | 700 psi @ 72 ° F | __ | __ | 0000000 | 00000 |

| 1", 1 1/4", 1 1/2" | 1.984" | __ | 700 psi @ 72 ° F | __ | __ | 0000000 | 00000 |

| 2" | 2.516" | __ | 700 psi @ 72 ° F | __ | __ | 0000000 | 00000 |

| 2 1/2" | 3.047" | __ | 700 psi @ 72 ° F | __ | __ | 0000000 | 00000 |

| 3" | 3.579" | __ | 580 psi @ 72 ° F | __ | __ | 0000000 | 00000 |

316 Stainless Steel with Safety Wing Nut and 2-Pin Hinge | |||||||

| 1/2", 3/4" | 0.984" | __ | 720 psi @ 72 ° F | __ | __ | 0000000 | 00000 |

| 1", 1 1/4", 1 1/2" | 1.984" | __ | 720 psi @ 72 ° F | __ | __ | 0000000 | 00000 |

| 2" | 2.516" | __ | 720 psi @ 72 ° F | __ | __ | 0000000 | 00000 |

| 3" | 3.579" | __ | 580 psi @ 72 ° F | __ | __ | 0000000 | 00000 |

316 Stainless Steel with Double Bolt | |||||||

| 1", 1 1/4", 1 1/2" | 1.984" | 316 Stainless Steel | 2,400 psi @ 72 ° F | __ | ASME BPVC.VIII | 0000000 | 000000 |

| 2" | 2.516" | 316 Stainless Steel | 1,300 psi @ 72 ° F | __ | ASME BPVC.VIII | 0000000 | 000000 |

| 3" | 3.579" | 316 Stainless Steel | 1,300 psi @ 72 ° F | __ | ASME BPVC.VIII | 0000000 | 000000 |

316 Stainless Steel with Recessed Nut, Hole for Lockout, and 2-Pin Hinge | |||||||

| 1/2", 3/4" | 0.984" | __ | 720 psi @ 72 ° F | __ | __ | 0000000 | 00000 |

| 1", 1 1/4", 1 1/2" | 1.984" | __ | 720 psi @ 72 ° F | __ | __ | 0000000 | 00000 |

| 2" | 2.516" | __ | 720 psi @ 72 ° F | __ | __ | 0000000 | 00000 |

| 3" | 3.579" | __ | 580 psi @ 72 ° F | __ | __ | 0000000 | 00000 |

White Nylon Plastic with Wing Nut | |||||||

| 1/2", 3/4" | 0.984" | __ | 150 psi @ 72 ° F | ASTM A269, ASTM A270 | __ | 00000000 | 00000 |

| 1", 1 1/4", 1 1/2" | 1.984" | __ | 150 psi @ 72 ° F | ASTM A269, ASTM A270 | __ | 00000000 | 00000 |

| 2" | 2.516" | __ | 150 psi @ 72 ° F | ASTM A269, ASTM A270 | __ | 00000000 | 00000 |

| 2 1/2" | 3.047" | __ | 150 psi @ 72 ° F | ASTM A269, ASTM A270 | __ | 00000000 | 00000 |

| 3" | 3.579" | __ | 150 psi @ 72 ° F | ASTM A269, ASTM A270 | __ | 00000000 | 00000 |

Buna-N gaskets are oil resistant. EPDM gaskets resist water and steam and work well in humid environments. Silicone gaskets withstand high temperatures. Fluoroelastomer gaskets stand up to fuel, oil, and acid condensates. PTFE gaskets withstand harsh chemicals, with the exception of molten alkali metal and elemental fluorine.

| For Tube OD | ID | OD | Thick. | Temp. Range, °F | Color | Specifications Met | Each | |

Buna-N Rubber | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2" | 0.380" | 0.860" | 0.178" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

| 3/4" | 0.620" | 0.860" | 0.178" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1" | 0.900" | 1.980" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 000 |

| 2" | 1.900" | 2.520" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 000 |

| 2 1/2" | 2.400" | 3.050" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3" | 2.900" | 3.580" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

EPDM Rubber | ||||||||

| 1/2" | 0.380" | 0.860" | 0.178" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3/4" | 0.620" | 0.860" | 0.178" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2 1/2" | 2.400" | 3.050" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3" | 2.900" | 3.580" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

Silicone Rubber | ||||||||

| 1/2" | 0.380" | 0.860" | 0.178" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3/4" | 0.620" | 0.860" | 0.178" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1" | 0.900" | 1.980" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2 1/2" | 2.400" | 3.050" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3" | 2.900" | 3.580" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

Fluoroelastomer Rubber | ||||||||

| 1/2" | 0.380" | 0.860" | 0.178" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3/4" | 0.620" | 0.860" | 0.178" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1" | 0.900" | 1.980" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3" | 2.900" | 3.580" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

PTFE Plastic | ||||||||

| 1/2" | 0.380" | 0.860" | 0.178" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 3/4" | 0.620" | 0.860" | 0.178" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 1" | 0.900" | 1.980" | 0.203" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.203" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 2 1/2" | 2.400" | 3.050" | 0.203" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 3" | 2.900" | 3.580" | 0.203" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

For Tube OD | |||||||

|---|---|---|---|---|---|---|---|

| Gasket Connection | Standard Connection | Wall Thick. | Material | For Tube Specifications Met | Includes | Each | |

| 1" | 1" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 304 Stainless Steel Nut | 0000000 | 0000000 |

| 1 1/2" | 1 1/2" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 304 Stainless Steel Nut | 0000000 | 000000 |

| 2" | 2" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 304 Stainless Steel Nut | 0000000 | 000000 |

| 2 1/2" | 2 1/2" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 304 Stainless Steel Nut | 0000000 | 000000 |

For Tube OD | ||||||

|---|---|---|---|---|---|---|

| Gasket Connection | Standard Connection | Wall Thick. | Material | For Tube Specifications Met | Each | |

| 1" | 1" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

| 1 1/2" | 1 1/2" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

| 2" | 2" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

| 2 1/2" | 2 1/2" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

Flange OD | |||||||

|---|---|---|---|---|---|---|---|

| For Tube OD | Extra-Support Connection | Standard Connection | Wall Thick. | Material | For Tube Specifications Met | Each | |

| 1" | 1.995" | 1.984" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

| 1 1/2" | 1.995" | 1.984" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 00000 |

| 2" | 2.64" | 2.516" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

| 3" | 3.87" | 3.579" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

Flange OD | |||||||

|---|---|---|---|---|---|---|---|

| For Tube OD | Extra-Support Connection | Standard Connection | Wall Thick. | Material | For Tube Specifications Met | Each | |

| 1" | 1.995" | 1.984" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

| 1 1/2" | 1.995" | 1.984" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 00000 |

| 2" | 2.64" | 2.516" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

| 3" | 3.87" | 3.579" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

Vacuum Fittings for Steel Tubing

- For Use With: Air, Glass, Plastic Pellets, Resins, Wood Chips

- Temperature Range: -10° to 180° F

- Tubing: Galvanized Steel: Use with steel, galvanized steel

Steel: Use with steel

Use these fittings to create an air vacuum system without the hassle of brazing and welding. Insert two fittings into a clamp (sold separately) and tighten to form a secure seal.

Galvanized steel fittings have fair corrosion resistance. Fittings without a finish should only be used in noncorrosive environments.

For technical drawings and 3-D models, click on a part number.

Galvanized Steel | Steel | |||||

|---|---|---|---|---|---|---|

| For Tube OD | Max. Pressure | Max. Vacuum | Each | Each | ||

| 2 1/8" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

| 2 1/2" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 3" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 3 1/2" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 4" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

| 5" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

| 6" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 000000 | 0000000 | 000000 |