Filter by

System of Measurement

Thread Size

Fastener Strength Grade/Class

Material

Finish

Thread Spacing

Specifications Met

Thread Direction

Drive Style

Export Control Classification Number (ECCN)

Locking Type

DFARS Specialty Metals

REACH

Thread Fit

Hex Nuts

The most commonly used hex nuts, these are suitable for fastening most machinery and equipment.

Medium-Strength Steel

|

These Grade 5 or Class 8 nuts are your go-to for fastening most machinery and equipment. To avoid stripped threads during installation, make sure your screw has a comparable strength rating.

Zinc-Plated Steel—A step up from plain steel, the zinc plating withstands occasional exposure to moisture.

Black-Oxide Steel—Typically chosen for their appearance, these nuts have a dark, matte coating to create a finished look. They offer minimal corrosion resistance, so they're best for dry environments.

Steel—Best for dry environments since moisture will cause these nuts to rust.

Thread Size | Wd., mm | Ht., mm | Fastener Strength Grade/Class | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 × 4.5 mm | 65 | 34 | ISO Class 8 | DIN 934 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 × 4.5 mm | 65 | 34 | ISO Class 8 | DIN 934 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 × 3 mm | 65 | 34 | ISO Class 8 | DIN 934 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 × 4.5 mm | 65 | 34 | ISO Class 8 | DIN 934 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength Steel

|

Rated Grade 8, Grade C, or Class 10, these nuts are about 25% stronger than medium-strength steel nuts. They are commonly used to fasten components in valves, pumps, motors, and other high-stress applications. To avoid stripped threads during installation, make sure your screw has a comparable strength rating.

Zinc-Plated Steel—A step up from plain steel, the zinc plating withstands occasional exposure to moisture.

Steel—Best for dry environments since moisture will cause these nuts to rust.

Extreme-Strength Steel

|

These nuts are about 20% stronger than high-strength steel nuts. To avoid stripped threads during installation, make sure your screw has a comparable strength rating.

Steel—Best for dry environments since moisture will cause these nuts to rust.

Thread Size | Wd., mm | Ht., mm | Fastener Strength Grade/Class | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 × 4.5 mm | 65 | 34 | ISO Class 12 | DIN 934 | 1 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant Stainless Steel

|

18-8 Stainless Steel—The choice for wet and outdoor environments, these nuts resist rust. However, they won't hold up to the harsh chemicals that 316 stainless steel can.

Black-Oxide 18-8 Stainless Steel—Typically chosen for their appearance, these nuts have a dark, matte coating to create a finished look. They resist rust in wet and outdoor environments, but won't hold up to the harsh chemicals that 316 stainless steel can.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these nuts won't degrade when exposed to harsh weather, salt water, and most chemicals.

Low-Strength Steel with Material Certificate

|

Rated Grade 2, Class 6, or lower, these nuts are about half as strong as medium-strength nuts. They are suitable for light duty fastening applications, such as securing access panels. Use them with screws that have a similar strength rating to avoid stripping threads during installation.

Black-Oxide Steel—Typically chosen for their appearance, these nuts have a dark, matte coating to create a finished look. They offer minimal corrosion resistance, so they're best for dry environments.

Steel—Best for dry environments since moisture will cause these nuts to rust.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Thin-Profile Hex Nuts

About half the height of standard-profile nuts, these fit in spaces with low clearance. You can also use them as jam nuts by threading them against another hex nut to hold it in place.

Medium-Strength Steel

|

These Grade 5 or Class 04 nuts are your go-to for fastening most machinery and equipment. To avoid stripped threads during installation, make sure your screw has a comparable strength rating.

Zinc-Plated Steel—A step up from plain steel, the zinc plating withstands occasional exposure to moisture.

Steel—Best for dry environments since moisture will cause these nuts to rust.

Thread Size | Wd., mm | Ht., mm | Fastener Strength Grade/Class | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 × 4.5 mm | 65 | 21 | ISO Class 04 | DIN 439B, ISO 4035 | 1 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 × 1.5 mm | 65 | 16 | — | DIN 936 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 × 3 mm | 65 | 16 | — | DIN 936 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 × 3 mm | 65 | 21 | ISO Class 04 | DIN 439B, ISO 4035 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 × 4.5 mm | 65 | 16 | — | DIN 936 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant Stainless Steel

|

18-8 Stainless Steel—The choice for wet and outdoor environments, these nuts resist rust. However, they won't hold up to the harsh chemicals that 316 stainless steel can.

Thread Size | Wd., mm | Ht., mm | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 × 4.5 mm | 65 | 16 | DIN 936 | 1 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heavy-Profile Hex Nuts

About 10% wider and taller than standard-profile hex nuts, these handle heavier loads by distributing them over a larger area.

Extreme-Strength Steel

|

These nuts are about 20% stronger than high-strength steel nuts. To avoid stripped threads during installation, make sure your screw has a comparable strength rating.

Steel—Best for dry environments since moisture will cause these nuts to rust.

Nylon-Insert Locknuts

Versatile yet economical, these are the most commonly used locknuts. The nylon insert grips the screw to prevent loosening from moderate vibration without damaging threads. However, the insert may become brittle if exposed to high temperatures. These locknuts are reusable a handful of times, but the holding power decreases with each use.

High-Strength Steel

|

Rated Grade 8, Grade C, or Class 10, these locknuts are about 25% stronger than medium-strength steel nuts. To avoid stripped threads during installation, make sure your screw has a comparable strength rating.

Zinc-Plated Steel—A step up from plain steel, the zinc plating withstands occasional exposure to moisture.

Thread Size | Wd., mm | Ht., mm | Fastener Strength Grade/Class | Insert Max. Temp., ° F | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 × 4.5 mm | 65 | 42 | ISO Class 10 | 220 | DIN 985 | 1 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Medium-Strength Steel

|

These Grade 5 or Class 8 nuts are your go-to for fastening most machinery and equipment. To avoid stripped threads during installation, make sure your screw has a comparable strength rating.

Zinc-Plated Steel—A step up from plain steel, the zinc plating withstands occasional exposure to moisture.

Thread Size | Wd., mm | Ht., mm | Fastener Strength Grade/Class | Insert Max. Temp., ° F | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 × 3 mm | 65 | 42 | ISO Class 8 | 220 | DIN 985, ISO 10511 | 1 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

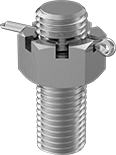

Locknuts for use with Cotter Pins

Use these locknuts to secure rotating parts subjected to mild vibration, such as the wheels on carts and hand trucks. They’re not recommended for use on parts exposed to high vibration because the pin can shear under prolonged stress. These nuts are reusable, but you'll need a new cotter pin (not included) with each use.

Medium-Strength Steel

|  |

These Grade 5 or Class 8 nuts are your go-to for fastening most machinery and equipment. To avoid stripped threads during installation, make sure your screw has a comparable strength rating.

Steel—Best for dry environments since moisture will cause these nuts to rust.

Thread Size | Wd., mm | Ht., mm | Fastener Strength Grade/Class | For Cotter Pin Dia., mm | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 × 4.5 mm | 65 | 46 | ISO Class 8 | 8 | DIN 935 | 1 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

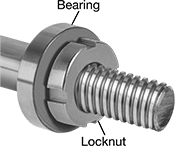

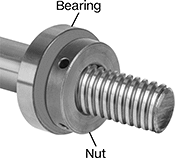

Bearing Locknuts

|

|

Zinc-Plated Carbon Steel |

With a nylon insert that grips your threaded shaft or spindle without damaging its threads, these locknuts—also called shaft nuts—hold bearings, bushings, gears, and pulleys prone to vibration tightly in place. They come as one piece, so you can easily clamp them onto your shaft or spindle. But, since they aren’t made entirely of metal, they don’t stand up to heat as well as all-metal locknuts. Slots in their sides mean you can tighten and loosen them with a spanner wrench or spanner socket. Their face is also chamfered to help keep the size and weight of your assembly at a minimum. All meet international standards for bearing locknut dimensions.

Zinc-Plated Carbon Steel—Zinc-plated carbon steel locknuts resist rusting from some moisture, but you shouldn’t use them with salt water or chemicals. They are strong and resist wear, though they don’t stand up to corrosion as well as 303 stainless steel locknuts.

Thread Spacing—When choosing your thread spacing, consider the precision of your application. The finer the threads, the more control you have when making adjustments.

Thread | Zinc-Plated Carbon Steel | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Spacing | OD, mm | Wd., mm | Insert Max. Temp., ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chamfered Face | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 × 1.5 mm | Extra Fine | 62 | 15 | 210 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

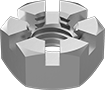

Bearing Nuts

|

Carbon Steel Stepped Face |

Often paired with spring lock washers to strengthen their hold, these bearing nuts—also known as shaft nuts—keep vibration from shifting bearings, bushings, pulleys, and gears on your threaded shaft or spindle. They have slotted sides, so you can tighten and loosen them with a spanner wrench or spanner socket.

Carbon Steel—Carbon steel bearing nuts are strong and resist wear.

Stepped Face—Use stepped-face bearing nuts with DIN 462 spring lock washers. You can also use them in pairs or with other bearing nuts. For the nut closer to the bearing, position the stepped face towards the bearing. All meet DIN standards for bearing lockout dimensions.

Thread Spacing—When choosing your thread spacing, consider the precision of your application. The finer the threads, the more control you have when making adjustments.

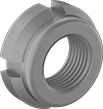

Thin-Profile Bearing Nuts

|

|

Used in pairs or with another bearing nut, these thin-profile nuts—often called shaft nuts—hold bearings, bushings, pulleys, and gears in place on your threaded shaft or spindle. Threading two nuts tightly against each other makes it harder for vibration to loosen your assembly than if you used only one nut. For the nut closer to the bearing, position the stepped face towards the bearing. These thin-profile nuts have holes on the side, so you can tighten and loosen them with a pin spanner wrench. All meet DIN 1816, an international standard for bearing locknut dimensions.

Carbon Steel—Carbon steel bearing nuts are strong and resist wear.

Thread Spacing—When choosing your thread spacing, consider the precision of your application. The finer the threads, the more control you have when making adjustments.

Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Spacing | OD, mm | Wd., mm | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stepped Face | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 × 1.5 mm | Extra Fine | 62 | 12 | DIN 1816 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

T-Slot Nuts

Designed to slide into T-slot tracks on machine tool tables, use these nuts to secure clamps and workpieces.

Metric

|  |

Fully Threaded—Fully threaded nuts allow a stud to extend beyond the bottom of the nut.

Base, mm | Fully Threaded | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | For Slot Wd., mm | Ht. | Wd. | Overall Ht., mm | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 × 4.5 mm | 48 | 30 | 75 | 60 | DIN 508 | 000000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded on Both Ends Setup Studs

Known as setup studs, these studs withstand sideways forces better than fully threaded studs because they have a strong unthreaded middle. The unthreaded middle also makes more contact with unthreaded holes, creating better alignment than a fully threaded stud.