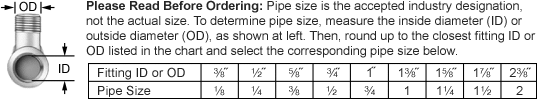

How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Pipe Size and Spray Nozzles

More

Steam Nozzles

Specifically designed for steam, these nozzles direct steam better than standard spray nozzles.

For technical drawings and 3-D models, click on a part number.

Steam Capacity, lbs./hr. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 10 psi | @ 25 psi | @ 50 psi | @ 75 psi | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Pattern | Spray Angle | Each | |

303 Stainless Steel | ||||||||||||

1/4 Male NPT | ||||||||||||

| 1.1 | 2.4 | 5.8 | 5 | 0.041" | 9/16" | 7/8" | 435 | 1020° | Solid Stream | 0° | 0000000 | 000000 |

| 2.4 | 5.6 | 8.3 | 8.4 | 0.051" | 9/16" | 7/8" | 435 | 1020° | Solid Stream | 0° | 0000000 | 00000 |

| 3.6 | 6.1 | 9 | 13 | 0.052" | 9/16" | 7/8" | 435 | 1020° | Solid Stream | 0° | 0000000 | 00000 |

| 5.3 | 8.2 | 13 | 19 | 0.065" | 9/16" | 7/8" | 435 | 1020° | Solid Stream | 0° | 0000000 | 00000 |

| 9.5 | 15 | 22 | 32 | 0.082" | 9/16" | 7/8" | 435 | 1020° | Solid Stream | 0° | 0000000 | 00000 |

| 15 | 20 | 32 | 45 | 0.104" | 9/16" | 7/8" | 435 | 1020° | Solid Stream | 0° | 0000000 | 00000 |

| 21 | 33 | 54 | 75 | 0.13" | 9/16" | 7/8" | 435 | 1020° | Solid Stream | 0° | 0000000 | 00000 |

Low-Pressure Stainless Steel Unthreaded Pipe Flanges

Bolt two flat-surface flanges or two raised-surface flanges of the same size together with a

Long-neck weld flanges have a square-cut end for welding directly to a pressure vessel or tank. With a longer neck than butt-weld flanges, they stick out farther from your tank wall for easier access to bolts. These flanges eliminate the need to weld a flange to a length of pipe.

Forged flanges have better strength than cast flanges. 304 stainless steel flanges offer very good corrosion resistance, and 316 stainless steel flanges have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Specifications Met: ASME B16.5, ASTM A182

- Certification: Material Certificate with Traceable Lot Number and Test Report

Bolt Hole | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Construction | Flange OD | Overall Lg. | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Each | |

304/304L Stainless Steel | |||||||||||

| 1 | Seamless | 4 1/4" | 9" | 1/2" | 0.62" | 4 | 3 1/8" | 230 psi @ 72° F | 175 psi @ 300° F | 000000000 | 0000000 |

| 1 1/2 | Seamless | 5" | 9" | 1/2" | 0.62" | 4 | 3 7/8" | 230 psi @ 72° F | 175 psi @ 300° F | 000000000 | 000000 |

| 2 | Seamless | 6" | 9" | 5/8" | 3/4" | 4 | 4 3/4" | 230 psi @ 72° F | 175 psi @ 300° F | 000000000 | 000000 |

| 3 | Seamless | 7 1/2" | 12" | 5/8" | 3/4" | 4 | 6" | 230 psi @ 72° F | 175 psi @ 300° F | 000000000 | 000000 |

| 4 | Seamless | 9" | 12" | 5/8" | 3/4" | 8 | 7 1/2" | 230 psi @ 72° F | 175 psi @ 300° F | 000000000 | 00000000 |

| 6 | Seamless | 11" | 12" | 3/4" | 0.88" | 8 | 9 1/2" | 230 psi @ 72° F | 175 psi @ 300° F | 000000000 | 00000000 |

316/316L Stainless Steel | |||||||||||

| 1 | Seamless | 4 1/4" | 9" | 1/2" | 0.62" | 4 | 3 1/8" | 230 psi @ 72° F | 175 psi @ 300° F | 000000000 | 000000 |

| 1 1/2 | Seamless | 5" | 9" | 1/2" | 0.62" | 4 | 3 7/8" | 230 psi @ 72° F | 175 psi @ 300° F | 000000000 | 000000 |

| 2 | Seamless | 6" | 9" | 5/8" | 3/4" | 4 | 4 3/4" | 230 psi @ 72° F | 175 psi @ 300° F | 000000000 | 000000 |

| 3 | Seamless | 7 1/2" | 12" | 5/8" | 3/4" | 4 | 6" | 230 psi @ 72° F | 175 psi @ 300° F | 000000000 | 000000 |

| 4 | Seamless | 9" | 12" | 5/8" | 3/4" | 8 | 7 1/2" | 230 psi @ 72° F | 175 psi @ 300° F | 000000000 | 00000000 |

| 6 | Seamless | 11" | 12" | 3/4" | 0.88" | 8 | 9 1/2" | 230 psi @ 72° F | 175 psi @ 300° F | 000000000 | 00000000 |

Low-Pressure Steel Unthreaded Pipe Flanges

Bolt two flat-surface flanges or two raised-surface flanges of the same size together with a gasket (sold separately) to create an access point in a pipe line. Flanges are for use with low-pressure applications in noncorrosive environments.

Long-neck weld flanges have a square-cut end for welding directly to a pressure vessel or tank. With a longer neck than butt-weld flanges, they stick out farther from your tank wall for easier access to bolts. These flanges eliminate the need to weld a flange to a length of pipe.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Specifications Met: ASME B16.5, ASTM A105

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use steel

- Fittings: Use iron or steel

Bolt Hole | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Wall Thick. | Flange OD | Overall Lg. | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Construction | Max. Pressure | Max. Steam Pressure | Each | |

| 1 | 0.47" | 4 1/4" | 9" | 1/2" | 5/8" | 4 | 3 1/8" | Seamless | 285 psi @ 72° F | 230 psi @ 300° F | 000000000 | 0000000 |

| 1 1/2 | 0.53" | 5" | 9" | 1/2" | 5/8" | 4 | 3 7/8" | Seamless | 285 psi @ 72° F | 230 psi @ 300° F | 000000000 | 000000 |

| 2 | 0.53" | 6" | 9" | 5/8" | 3/4" | 4 | 4 3/4" | Seamless | 285 psi @ 72° F | 230 psi @ 300° F | 000000000 | 000000 |

| 3 | 0.625" | 7 1/2" | 12" | 5/8" | 3/4" | 4 | 6" | Seamless | 285 psi @ 72° F | 230 psi @ 300° F | 000000000 | 000000 |

| 4 | 0.655" | 9" | 12" | 5/8" | 3/4" | 8 | 7 1/2" | Seamless | 285 psi @ 72° F | 230 psi @ 300° F | 000000000 | 000000 |

| 6 | 0.78" | 11" | 12" | 3/4" | 1" | 8 | 9 1/2" | Seamless | 285 psi @ 72° F | 230 psi @ 300° F | 000000000 | 000000 |

Inline Steam Cleaners

Connect these cleaners to existing steam lines to remove dirt, grease, and heavy oils from most surfaces.

Nozzle for 1,500-psi cleaners is sold separately.

Wand | Handle | Nozzle Connection | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Temp., °F | Lg. | Material | For Hose ID | Wand Connection Gender | Type | Material | No. of Spray Nozzles | Spray Angle | Pipe Size | Thread Type | Gender | Each | |

| 390° | 30" | Stainless Steel | 3/4" | Male | Rigid | Plastic | 1 | 65° | 3/4 | NPT | Female | 00000000 | 0000000 |

Wand | Wand Connection | Handle | Nozzle Connection | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Temp., °F | Lg. | Material | Pipe Size | Thread Type | Gender | Type | Material | Nozzle Holder Angle | Pipe Size | Thread Type | Gender | Each | |

| 450° | 36" | Steel | 1/2 | NPT | Female | Rigid | Zinc-Plated Steel | 45° | 3/8 | NPT | Male | 0000000 | 000000000 |

| 450° | 36" | Steel | 1/2 | NPT | Female | Swivel | Zinc-Plated Steel | 45° | 3/8 | NPT | Male | 0000000 | 00000000 |

| NPT Male Nozzles for 1,500-psi Cleaners | 0000000 | Each | 0000000 |

Inline Steam Cleaners with Control Panel

Combine the power of steam and detergent to remove dirt, grease, and heavy oils from most surfaces. Siphon detergent from a drum (not included) and use the control panel to regulate the steam/detergent mixture and change the temperature and flow rate. These cleaners connect to existing steam lines. No electrical connections required. Cleaners come with a steam gun and a wire-reinforced rubber hose.

Note: The steam gun must be within inches of your surface for effective cleaning.

Pressure, psi | Pressure Hose | Inlet Connection | Wand | Wand Connection | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Rate, gpm | Min. | Max. | Max. Temp., °F | ID | Lg., ft. | Material | Pipe Size | Thread Type | Gender | Lg. | Material | Pipe Size | Thread Type | Gender | Handle Type | No. of Spray Nozzles | Spray Angle | Each | |

| 2-3.2 | 60 | 125 | 350° | 1/2" | 25 | Rubber | 3/4 | NPT | Male | 45" | Steel | 1/2 | NPT | Female | Swivel | 2 | 30° | 000000 | 000000000 |

| 2-3.2 | 60 | 125 | 350° | 1/2" | 50 | Rubber | 3/4 | NPT | Male | 45" | Steel | 1/2 | NPT | Female | Swivel | 2 | 30° | 000000 | 00000000 |