How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About On/Off Valves

More

About Hose

More

About Metal Tubing

More

Liquid Nitrogen Hose with Threaded Fittings

- Temperature Range: -320° to 1,500° F

- Maximum Vacuum: 29" of Hg @ 72° F

- Material: 321 Stainless Steel with 304 Stainless Steel Braid

- Female Fittings Swivel Until Tightened

Transfer liquid nitrogen across a wide temperature range with this hose. Hose comes cleaned, capped, and bagged to meet CGA (Compressed Gas Association) G4.1. The braid provides good flexibility in high-vibration applications. Female fittings swivel until tightened for easy installation.

Hose with Cover—A cover surrounds the braid to protect it from damage.

| Pipe Size | Thread Size | ID | OD | Bend Radius | Max. Pressure | 1 1/2 ft. | 3 ft. | 4 ft. | 6 ft. | 8 ft. | 10 ft. | 12 ft. | |

304 Stainless Steel NPT Male × 316 Stainless Steel 45° Flared UNF Female | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3/8 | 3/4"-16 | 1/2" | 13/16" | 4 7/8" | 1,160 psi @ 72° F | 00000000 | |||||||

316 Stainless Steel 45° Flared UNF Female × 316 Stainless Steel 45° Flared UNF Female | |||||||||||||

| __ | 3/4"-16 × 3/4"-16 | 1/2" | 13/16" | 4 7/8" | 1,160 psi @ 72° F | 00000000 | |||||||

316 Stainless Steel NPT Male × 316 Stainless Steel 45° Flared UNF Female | |||||||||||||

| 1/2 | 3/4"-16 | 1/2" | 13/16" | 4 7/8" | 1,160 psi @ 72° F | 00000000 | |||||||

| Pipe Size | Thread Size | ID | OD | Bend Radius | Max. Pressure | Cover Material | 1 1/2 ft. | 3 ft. | 4 ft. | 6 ft. | 8 ft. | 10 ft. | 12 ft. | |

304 Stainless Steel NPT Male × 316 Stainless Steel 45° Flared UNF Female | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3/8 | 3/4"-16 | 1/2" | 15/16" | 4 7/8" | 1,160 psi @ 72° F | 304 Stainless Steel | 00000000 | |||||||

316 Stainless Steel 45° Flared UNF Female × 316 Stainless Steel 45° Flared UNF Female | ||||||||||||||

| __ | 3/4"-16 × 3/4"-16 | 1/2" | 15/16" | 4 7/8" | 1,160 psi @ 72° F | 304 Stainless Steel | 00000000 | |||||||

316 Stainless Steel NPT Male × 316 Stainless Steel 45° Flared UNF Female | ||||||||||||||

| 1/2 | 3/4"-16 | 1/2" | 15/16" | 4 7/8" | 1,160 psi @ 72° F | 304 Stainless Steel | 00000000 | |||||||

Liquid Nitrogen Hose with Tube and Threaded Fittings

- Temperature Range: -325° to 1,250° F

- Maximum Vacuum: 29" of Hg @ 72° F

- Material: 316 Stainless Steel with 304 Stainless Steel Braid

The Yor-Lok tube fitting is also known as an instrumentation fitting. It has two sleeves (double ferrules) that bite into metal tubing for a strong seal. Use this air-cleaned hose to transfer liquid nitrogen across a wide temperature range.

Liquid Nitrogen Hose with Tube Stem Fittings

- Temperature Range: -325° to 1,250° F

- Maximum Vacuum: 29" of Hg @ 72° F

- Material: 316 Stainless Steel with 304 Stainless Steel Braid

The fittings are a short length of tubing that inserts into the end of another tube fitting. Use this air-cleaned hose to transfer liquid nitrogen across a wide temperature range.

Liquid Nitrogen Hose with Yor-Lok Tube Fitting and Tube Stem Fitting

- Temperature Range: -325° to 1,250° F

- Maximum Vacuum: 29" of Hg @ 72° F

- Material: 316 Stainless Steel with 304 Stainless Steel Braid

Also known as instrumentation fittings, the Yor-Lok fitting has two sleeves (double ferrules) that bite into metal tubing for a strong seal. The tube stem fitting is a short length of tubing that inserts into the end of another tube fitting. Use this air-cleaned hose to transfer liquid nitrogen across a wide temperature range.

Liquid Nitrogen Hose with Yor-Lok Tube Fittings

- Temperature Range: -325° to 1,250° F

- Maximum Vacuum: 29" of Hg @ 72° F

- Material: 316 Stainless Steel with 304 Stainless Steel Braid

The fittings are also known as instrumentation fittings. They have two sleeves (double ferrules) that bite into metal tubing for a strong seal. Use this air-cleaned hose to transfer liquid nitrogen across a wide temperature range.

Argon, Nitrogen, and Oxygen Hose with Male and Female Threaded Fittings

- Temperature Range: -65° to 450° F

- Maximum Vacuum: 28" of Hg @ 72° F

- Material: PTFE with 304 Stainless Steel Cover

This hose is often called pigtail hose. It comes cleaned, capped, and bagged to meet CGA (Compressed Gas Association) G4.1. Hose should not be used underground.

For technical drawings and 3-D models, click on a part number.

Argon, Nitrogen, and Oxygen Hose with Female Threaded Fittings

- Temperature Range: -65° to 450° F

- Maximum Vacuum: 28" of Hg @ 72° F

- Material: PTFE with 304 Stainless Steel Cover

This hose is often called pigtail hose. It comes cleaned, capped, and bagged to meet CGA (Compressed Gas Association) G4.1. Hose should not be used underground.

For technical drawings and 3-D models, click on a part number.

High-Temperature Argon, Nitrogen, and Oxygen Hose

- Temperature Range: -320° to 1,500° F

- Maximum Vacuum: 29" of Hg @ 72° F

- Material: 316 Stainless Steel with 304 Stainless Steel Cover

Transfer industrial gases in temperatures up to 1500° F. The braided reinforcement provides good flexibility in high-vibration applications. A cover surrounds the braid to protect it from damage. Hose comes cleaned, capped, and bagged to meet CGA (Compressed Gas Association) G4.1. It should not be used underground.

For technical drawings and 3-D models, click on a part number.

Touch-Safe Insulated Cryogenic Hose with Threaded Fittings

- Temperature Range: -325° to 200° F

- Material: 321 Stainless Steel with 304 Stainless Steel Cover

- Both Fittings Swivel Until Tightened

To maintain the temperature of liquids as cold as -325° F, this hose has vacuum insulation and a reflective barrier. This prevents heat transfer in the same way a thermos does, so the exterior of the hose won’t freeze or form condensation. Even when used with liquid argon, liquid carbon dioxide, liquid methane, and liquid nitrogen, this hose is safe to handle. It meets strict ASME design and testing standards for process piping systems.

This hose comes ready to use—you don’t need to create the vacuum yourself. To install, thread the fittings on this hose onto a freezer or other equipment in your plant or laboratory. Both ends swivel until tightened, so you don’t need to rotate the entire hose during installation. With ribbed insulation inside and spiral reinforcement outside, this hose won’t crack or leak when you bend and flex it around obstacles. The cover is 304 stainless steel, which stands up to wear and tear and won’t corrode from mild chemicals and water.

For technical drawings and 3-D models, click on a part number.

Tube Connection | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CGA Number | For Tube OD | Thread Size | Pipe Size | ID | OD | Bend Radius | Max. Pressure | Specifications Met | 3 ft. | 4 ft. | 6 ft. | 8 ft. | 10 ft. | 12 ft. | |

316 Stainless Steel 37°, 45° Flared UN/UNF (JIC) Female × 316 Stainless Steel Threaded NPT Male | |||||||||||||||

| 295 | 1/4" | 7/16"-20 | 1/4 | 1/4" | 1 1/8" | 6 1/2" | 150 psi @ 72° F | ASME B31.3 | 0000000 | ||||||

| 295 | 3/8" | 9/16"-18 | 3/8 | 3/8" | 1 3/8" | 7 1/2" | 150 psi @ 72° F | ASME B31.3 | 0000000 | ||||||

| 295 | 1/2" | 3/4"-16 | 1/2 | 1/2" | 1 11/16" | 8 1/2" | 150 psi @ 72° F | ASME B31.3 | 0000000 | ||||||

Touch-Safe Insulated Cryogenic Hose with Tube Stem Fittings

- Temperature Range: -325° to 200° F

- Material: 321 Stainless Steel with 304 Stainless Steel Cover

Sealed vacuum insulation and a reflective barrier inside this hose maintains the temperature of liquids as cold as -325° F. Similar to a thermos, this prevents heat transfer, so the exterior of the hose won’t freeze or form condensation. This hose is safe to handle, even when used with liquid nitrogen, liquid argon, liquid carbon dioxide, and liquid methane. It meets strict ASME design and testing standards for process piping systems.

The tube stems on each end slide into tube fittings on a freezer or other equipment in your plant or laboratory. With ribbed insulation inside and spiral reinforcement outside, this hose won’t crack or leak when you bend and flex it around obstacles. The cover is 304 stainless steel, which stands up to wear and tear and won’t corrode from mild chemicals and water.

For technical drawings and 3-D models, click on a part number.

| Stem OD | ID | OD | Bend Radius | Max. Pressure | Specifications Met | 3 ft. | 4 ft. | 6 ft. | 8 ft. | 10 ft. | 12 ft. | |

316 Stainless Steel Tube Stem × 316 Stainless Steel Tube Stem | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/4" × 1/4" | 1/4" | 1 1/8" | 6 1/2" | 150 psi @ 72° F | ASME B31.3 | 0000000 | ||||||

| 3/8" × 3/8" | 3/8" | 1 3/8" | 7 1/2" | 150 psi @ 72° F | ASME B31.3 | 0000000 | ||||||

| 1/2" × 1/2" | 1/2" | 1 11/16" | 8 1/2" | 150 psi @ 72° F | ASME B31.3 | 0000000 | ||||||

Thick-Wall Galvanized Iron and Steel Threaded Pipe Nipples and Pipe

Made of galvanized iron or steel, this pipe has fair corrosion resistance. It has thick, Schedule 80 walls for good strength in medium-pressure applications.

Seamless pipe has a smooth interior for unrestricted flow and is stronger than welded pipe.

Straight reducers are also known as swage nipples.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Natural Gas, Nitrogen Gas, Oil, Steam, Water

- Specifications Met: ASTM B633, ASTM A234, MSS SP-95, ASME B1.20.1

- Fittings: Use Class 300 iron or steel

- Flanges: Use Class 300 steel

Pipe Size | |||||||

|---|---|---|---|---|---|---|---|

| (A) | (B) | Lg. | Thread Type | Construction | Material | Each | |

| 3/4 | 1/8 | 3" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

| 2 | 1/4 | 6 1/2" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

| 2 1/2 | 3/4 | 7" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

| 2 1/2 | 1 | 7" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

| 2 1/2 | 1 1/4 | 7" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

| 2 1/2 | 1 1/2 | 7" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

| 2 1/2 | 2 | 7" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

| 3 | 1/2 | 8" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

| 3 | 3/4 | 8" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

| 3 | 1 | 8" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

| 3 | 1 1/4 | 8" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

| 3 | 1 1/2 | 8" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

| 3 | 2 | 8" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

| 3 | 2 1/2 | 8" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

| 4 | 1/2 | 9" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

| 4 | 3/4 | 9" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

| 4 | 1 | 9" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

| 4 | 1 1/4 | 9" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

| 4 | 1 1/2 | 9" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

| 4 | 2 | 9" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

| 4 | 2 1/2 | 9" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

| 4 | 3 | 9" | NPT | Seamless | Galvanized Iron | 00000000 | 000000 |

Super-Thick-Wall Steel Threaded Pipe Nipples and Pipe

Also known as Schedule XXH, this heavy duty pipe has the thickest, strongest walls of all the threaded pipe we offer. Pipe is seamless, so it has a smooth interior for unrestricted flow. Use in noncorrosive environments.

Fully threaded pipe is also known as a close nipple; it is threaded on each end to the center.

For technical drawings and 3-D models, click on a part number.

- For Use With: See table

- Specifications Met: ASTM A733, ASME B1.20.1, ASTM A106

- Fittings: Use Class 6000 steel

- Flanges: Use Class 1500 steel

| Pipe Size | Dash Size | Lg. | Thread Type | Construction | Material | For Use With | Each | |

| 1 1/4 | 20 | 1 5/8" | NPT | Seamless | Steel | Air, Hydraulic Fluid, Nitrogen Gas, Oil, Steam, Water | 0000000 | 000000 |

- For Use With: See table

- Specifications Met: ASTM A733, ASME B1.20.1, ASTM A106

- Fittings: Use Class 6000 steel

- Flanges: Use Class 1500 steel

| Lg. | Thread Type | Construction | Material | For Use With | Each | |

1/2 Pipe Size—08 Dash Size | ||||||

|---|---|---|---|---|---|---|

| 5" | NPT | Seamless | Steel | Air, Hydraulic Fluid, Nitrogen Gas, Oil, Steam, Water | 0000000 | 000000 |

3/4 Pipe Size—12 Dash Size | ||||||

| 5" | NPT | Seamless | Steel | Air, Hydraulic Fluid, Nitrogen Gas, Oil, Steam, Water | 0000000 | 00000 |

1 Pipe Size—16 Dash Size | ||||||

| 5" | NPT | Seamless | Steel | Air, Hydraulic Fluid, Nitrogen Gas, Oil, Steam, Water | 0000000 | 00000 |

1 1/4 Pipe Size—20 Dash Size | ||||||

| 2" | NPT | Seamless | Steel | Air, Hydraulic Fluid, Nitrogen Gas, Oil, Steam, Water | 0000000 | 00000 |

| 3" | NPT | Seamless | Steel | Air, Hydraulic Fluid, Nitrogen Gas, Oil, Steam, Water | 0000000 | 00000 |

| 4" | NPT | Seamless | Steel | Air, Hydraulic Fluid, Nitrogen Gas, Oil, Steam, Water | 0000000 | 00000 |

| 5" | NPT | Seamless | Steel | Air, Hydraulic Fluid, Nitrogen Gas, Oil, Steam, Water | 0000000 | 00000 |

| 6" | NPT | Seamless | Steel | Air, Hydraulic Fluid, Nitrogen Gas, Oil, Steam, Water | 0000000 | 00000 |

1 1/2 Pipe Size—24 Dash Size | ||||||

| 5" | NPT | Seamless | Steel | Air, Hydraulic Fluid, Nitrogen Gas, Oil, Steam, Water | 0000000 | 00000 |

2 Pipe Size—32 Dash Size | ||||||

| 5" | NPT | Seamless | Steel | Air, Hydraulic Fluid, Nitrogen Gas, Oil, Steam, Water | 0000000 | 00000 |

- For Use With: See table

- Specifications Met: ASTM A733, ASME B1.20.1, ASTM A106

- Fittings: Use Class 6000 steel

- Flanges: Use Class 1500 steel

| Lg. | Thread Type | Construction | Material | For Use With | Each | |

1 Pipe Size—16 Dash Size | ||||||

|---|---|---|---|---|---|---|

| 5" | NPT | Seamless | Steel | Air, Hydraulic Fluid, Nitrogen Gas, Oil, Steam, Water | 0000000 | 000000 |

1 1/4 Pipe Size—20 Dash Size | ||||||

| 2" | NPT | Seamless | Steel | Air, Hydraulic Fluid, Nitrogen Gas, Oil, Steam, Water | 0000000 | 00000 |

| 3" | NPT | Seamless | Steel | Air, Hydraulic Fluid, Nitrogen Gas, Oil, Steam, Water | 0000000 | 00000 |

| 4" | NPT | Seamless | Steel | Air, Hydraulic Fluid, Nitrogen Gas, Oil, Steam, Water | 0000000 | 00000 |

| 5" | NPT | Seamless | Steel | Air, Hydraulic Fluid, Nitrogen Gas, Oil, Steam, Water | 0000000 | 00000 |

| 6" | NPT | Seamless | Steel | Air, Hydraulic Fluid, Nitrogen Gas, Oil, Steam, Water | 0000000 | 00000 |

Stainless Steel Tubing for Corrosive Gases

- Temperature Range: -340° to 800° F

- Bending Method: Tube Bender

- Compatible Tube Fittings: Compression

A thin layer of silicon on the interior provides a smooth surface and offers protection against corrosive gases.

Seamless tubing is smoother and stronger than welded tubing and can be flared without splitting. Welded tubing is more economical than seamless tubing; it has a smoothed weld bead on the inside to reduce particle buildup.

304 stainless steel has very good corrosion resistance.

316 stainless steel offers excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

| OD | Wall Thick. | ID | Max. Pressure | Temper Rating | 1 ft. | 3 ft. | 6 ft. | |

Welded 304 Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

For Use With Ammonia, Nitrogen Oxide, Sulphur Oxide | ||||||||

| 1/8" | 0.02" | 0.085" | 3,000 psi @ 72° F | Soft | 00000000 | |||

| 1/4" | 0.02" | 0.21" | 2,000 psi @ 72° F | Soft | 00000000 | |||

Seamless 316 Stainless Steel | ||||||||

For Use With Ammonia, Nitrogen Oxide, Sulphur Oxide | ||||||||

| 1/8" | 0.035" | 0.055" | 8,500 psi @ 72° F | Soft | 00000000 | |||

| 1/4" | 0.035" | 0.18" | 4,300 psi @ 72° F | Soft | 00000000 | |||

Miniature Stainless Steel Tubing for Corrosive Gases

- Temperature Range: -340° to 800° F

- Bending Method: Tube Bender

- Compatible Tube Fittings: Compression

A thin layer of silicon on the interior provides a smooth surface and offers protection against corrosive gases. Tubing has thin walls and is made to tight tolerances for use in precision applications. It is welded with a smoothed weld bead on the inside to reduce particle buildup. It also has very good corrosion resistance. To cut this tubing, you can use abrasive cutoff wheels and deburring tools (not included).

For technical drawings and 3-D models, click on a part number.

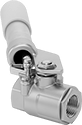

Threaded On/Off Valves for Refrigerant

- Valve Type: Ball

- For Use With: Refrigerant

- Seal Material: PTFE Plastic

- Specifications Met: NACE (National Association of Corrosion Engineers) MR0103, NACE (National Association of Corrosion Engineers) MR0175

Often used in HVAC or refrigeration systems, these valves are designed to control the flow of ammonia, nitrogen, and other harsh chemicals. To prevent accidental spills, a spring on the handle will automatically close the valve if you lose your grip. It’s also known as a deadman’s handle. The ball has a vent to relieve gas buildup when the valve is closed. Made from 316 stainless steel, these valves have excellent corrosion resistance.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | For Refrigerant Number | Features | Each | |

316 Stainless Steel Body | |||||||||

|---|---|---|---|---|---|---|---|---|---|

NPT Female × NPT Female | |||||||||

| 1/4 | 8.4 | 2,000 psi @ 100° F | -20° to 500° | 29 | 2 1/16" | R-134A, R-717, R-728, R-744 | Vented Ball | 0000000 | 0000000 |

| 3/8 | 7.2 | 2,000 psi @ 100° F | -20° to 500° | 29 | 2 1/16" | R-134A, R-717, R-728, R-744 | Vented Ball | 0000000 | 000000 |

| 1/2 | 15 | 2,000 psi @ 100° F | -20° to 500° | 29 | 2 1/4" | R-134A, R-717, R-728, R-744 | Vented Ball | 0000000 | 000000 |

| 3/4 | 30 | 2,000 psi @ 100° F | -20° to 500° | 29 | 3" | R-134A, R-717, R-728, R-744 | Vented Ball | 0000000 | 000000 |

| 1 | 43 | 2,000 psi @ 100° F | -20° to 500° | 29 | 3 3/8" | R-134A, R-717, R-728, R-744 | Vented Ball | 0000000 | 000000 |