How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

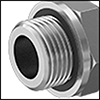

Extreme-Pressure Stainless Steel Threaded Pipe Fittings

With the strength to handle extreme pressures, these fittings can be used to connect equipment in hydraulic fluid lines. 316 stainless steel fittings have excellent corrosion resistance. BSPP and metric male threads have either a gasket or a gasket and washer to prevent leaks.

For technical drawings and 3-D models, click on a part number.

Male Threads with

Gasket and Washer

- For Use With: See table

- Specifications Met: See table

316 Stainless Steel | |||||||

|---|---|---|---|---|---|---|---|

| Pipe Size (A) | Dash Size (A) | Thread Size (B) | Max. Pressure | For Use With | Specifications Met | Each | |

BSPP Male × Metric Male | |||||||

| 3/8 | 06 | M20 × 1.5 mm | 5,000 psi @ 72° F | Hydraulic Fluid, Oil, Water | DIN 7631, ISO 1179, ISO 8434-6, ISO 9974 | 00000000 | 000000 |

| 1/2 | 08 | M20 × 1.5 mm | 4,500 psi @ 72° F | Hydraulic Fluid, Oil, Water | DIN 7631, ISO 1179, ISO 8434-6, ISO 9974 | 00000000 | 00000 |

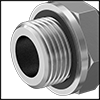

Compact Extreme-Pressure Steel Threaded Pipe Fittings

These fittings are strong enough to handle extreme pressures, yet small enough to fit into cramped spaces. They are galvanized and zinc-plated steel, which have better corrosion resistance than plain steel fittings. BSPP and metric male threads have either a gasket, or a gasket and washer, to prevent leaks.

For technical drawings and 3-D models, click on a part number.

(SAE Straight) Male

Threads with Gasket and Washer

- For Use With: See table

- Specifications Met: See table

| Pipe Size (A) | Dash Size (A) | Thread Size (B) | Max. Pressure | Material | For Use With | Specifications Met | Each | |

BSPP Male × Metric Male | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2 | 08 | M20 × 1.5 mm | 4,500 psi @ 72° F | Galvanized Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Oil, Water | DIN 7631, ISO 1179, ISO 6149, ISO 8434-6, ISO 9974 | 00000000 | 000000 |

Metal Barbed Hose Fittings for Air and Water

Slide the barbed end into rubber hose and secure with the appropriate clamp or crimp-on hose ferrule.

Brass fittings are softer than other metal fittings, so they’re easier to thread together. Plain brass fittings have good corrosion resistance.Aluminum fittings are lighter in weight than other metal fittings. They have good corrosion resistance.

Fittings with a threaded end are also known as hose nipples.

Metric, UN/UNF (SAE Straight), and BSPP male threads with gasket protect against leaks.

For technical drawings and 3-D models, click on a part number.

UN/UNF (SAE Straight)

Male Threads with Gasket

- Maximum Pressure: See table

- Maximum Vacuum: 27 in. of Hg @ 72° F

- Temperature Range: See table

- Attachment Type: See table

- Specifications Met: See table

| For Hose ID | Thread Size | Gasket Material | Max. Pressure | Temperature Range, °F | Attachment Type | Pkg. Qty. | Pkg. | |

Brass | ||||||||

|---|---|---|---|---|---|---|---|---|

| 3/4" | M20 × 1.5 mm | Buna-N Rubber | 300 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | 1 | 00000000 | 000000 |

| 19mm | M20 × 1.5 mm | Buna-N Rubber | 250 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | 1 | 00000000 | 00000 |

Aluminum | ||||||||

| 3/4" | M20 × 1.5 mm | Buna-N Rubber | 125 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | 1 | 00000000 | 00000 |

| 19mm | M20 × 1.5 mm | Buna-N Rubber | 125 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | 1 | 00000000 | 00000 |

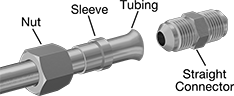

37° Flared Fittings for Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil

- Tubing: Use with seamless steel

- Specifications Met: SAE J514

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately. Fittings are zinc-plated steel for fair corrosion resistance.

To prevent leaks, UN/UNF (SAE Straight) male threads have a gasket. Metric and BSPP male threads have either a gasket or a gasket and washer.

For technical drawings and 3-D models, click on a part number.

- Temperature Range: See table

| For Tube OD | Thread Size | Thread Pitch, mm | Material | Gasket Material | Max. Pressure | Temp. Range, °F | Each | |

Metric Threads | ||||||||

|---|---|---|---|---|---|---|---|---|

| 5/8" | M20 | 1.5 | Zinc-Plated Steel | Buna-N Rubber | 2,300 psi @ 72° F | -30° to 200° | 00000000 | 000000 |

- Temperature Range: -60° to 400° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on steel tubing that is flared to 37°. Sleeves are zinc-plated steel for fair corrosion resistance. They are also known as ferrules.

Inch × metric sleeve adapters convert the fitting from inch to metric.

- Temperature Range: -60° to 400° F

| For Tube OD | Nut Material | Max. Pressure | Each | |

| 5/8" | Zinc-Plated Steel | 3,000 psi @ 72° F | 000000000 | 00000 |