How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

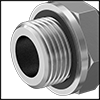

Miniature Medium-Pressure Stainless Steel Threaded Pipe Fittings

When space is at a premium choose these compact fittings. Though small in size, they have the strength to handle medium-pressure applications. Fittings are stainless steel for very good corrosion resistance.

Metric, BSPP, and UN/UNF (SAE Straight) male threads have a gasket to protect against leaks. Made from fluoroelastomer, these gaskets resist chemicals, including benzene, butyl alcohol, and ethylene glycol. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

For technical drawings and 3-D models, click on a part number.

UN/UNF (SAE Straight)

Male Threads with Gasket

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Specifications Met: ASTM A314, ASTM A320, ASTM A582

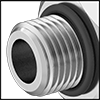

Compact Extreme-Pressure Steel Threaded Pipe Fittings

These fittings are strong enough to handle extreme pressures, yet small enough to fit into cramped spaces. They are galvanized and zinc-plated steel, which have better corrosion resistance than plain steel fittings. BSPP and metric male threads have either a gasket, or a gasket and washer, to prevent leaks.

For technical drawings and 3-D models, click on a part number.

(SAE Straight) Male Threads

with Gasket and Washer

- For Use With: See table

- Specifications Met: See table

| Pipe Size (A) | Dash Size (A) | Thread Size (B) | Max. Pressure | Material | For Use With | Specifications Met | Each | |

NPT Male × Metric Male | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4 | 04 | M10 × 1 mm | 6,000 psi @ 72° F | Galvanized Steel | Air, Hydraulic Fluid, Oil, Water | ASME B1.20.3, DIN 2353, ISO 8434-1 | 00000000 | 000000 |

BSPP Male × Metric Male | ||||||||

| 1/8 | 02 | M10 × 1 mm | 5,000 psi @ 72° F | Galvanized Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Oil, Water | DIN 7631, ISO 1179, ISO 6149, ISO 8434-6, ISO 9974 | 00000000 | 00000 |

| 1/4 | 04 | M10 × 1.5 mm | 6,000 psi @ 72° F | Galvanized Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Oil, Water | DIN 7631, ISO 1179, ISO 6149, ISO 8434-6, ISO 9974 | 00000000 | 00000 |

High-Pressure Brass Threaded Pipe Fittings

These fittings have the strength to handle high-pressure applications. They are brass for good corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water, Natural Gas, Oil

- Specifications Met: SAE J530, SAE J531

| Pipe Size | Thread Size | Max. Pressure | Male End Gasket Material | Each | |

NPTF Female × Metric Male | |||||

|---|---|---|---|---|---|

| 1/8 | M10 × 1 mm | 1,000 psi @ 72° F | Fluorocarbon Rubber | 000000000 | 000000 |

Miniature Medium-Pressure Aluminum Threaded Pipe Fittings

Their small size makes these miniature fittings a good choice for cramped, confined spaces. They are designed to handle medium-pressure applications. Fittings are aluminum, which is lightweight with good corrosion resistance.

Metric and UN/UNF (SAE Straight) male threads have a gasket to protect against leaks.

For technical drawings and 3-D models, click on a part number.

Metal Barbed Hose Fittings for Air and Water

Slide the barbed end into rubber hose and secure with the appropriate clamp or crimp-on hose ferrule.

Brass fittings are softer than other metal fittings, so they’re easier to thread together. Plain brass fittings have good corrosion resistance. Nickel-plated brass fittings resist corrosion better than plain brass fittings.

Aluminum fittings are lighter in weight than other metal fittings. They have good corrosion resistance.

Stainless steel fittings have very good corrosion resistance. 303 stainless steel fittings won’t rust when exposed to water, making them good for areas that require frequent cleanings. Fittings with a threaded end are also known as hose nipples.

Metric, UN/UNF (SAE Straight), and BSPP male threads with gasket protect against leaks.

For technical drawings and 3-D models, click on a part number.

UN/UNF (SAE Straight)

Male Threads with Gasket

- Maximum Pressure: See table

- Maximum Vacuum: 27 in. of Hg @ 72° F

- Temperature Range: See table

- Attachment Type: See table

- Specifications Met: See table

| For Hose ID | Thread Size | Gasket Material | Max. Pressure | Temperature Range, °F | Attachment Type | Specifications Met | Pkg. Qty. | Pkg. | |

Brass | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/4" | M10 × 1 mm | Buna-N Rubber | 300 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | __ | 1 | 00000000 | 000000 |

| 3/8" | M10 × 1 mm | Buna-N Rubber | 300 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | __ | 1 | 00000000 | 00000 |

| 1/2" | M10 × 1 mm | __ | 250 psi @ 72° F | -40° to 160° | Worm-Drive Clamp, Crimp-On Hose Ferrule | SAE J476 | 1 | 0000000 | 00000 |

| 6mm | M10 × 1 mm | Buna-N Rubber | 300 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | __ | 1 | 00000000 | 00000 |

| 8mm | M10 × 1 mm | Buna-N Rubber | 300 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | __ | 1 | 00000000 | 00000 |

| 9mm | M10 × 1 mm | Buna-N Rubber | 300 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | __ | 1 | 00000000 | 00000 |

| 13mm | M10 × 1 mm | __ | 250 psi @ 72° F | -40° to 160° | Worm-Drive Clamp, Crimp-On Hose Ferrule | SAE J476 | 1 | 0000000 | 00000 |

Nickel-Plated Brass | |||||||||

| 1/4" | M10 × 1 mm | Buna-N Rubber | 125 psi @ 72° F | -20° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | __ | 1 | 00000000 | 00000 |

Aluminum | |||||||||

| 1/4" | M10 × 1 mm | Buna-N Rubber | 125 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | __ | 1 | 00000000 | 00000 |

| 3/8" | M10 × 1 mm | Buna-N Rubber | 125 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | __ | 1 | 00000000 | 00000 |

| 1/2" | M10 × 1 mm | Buna-N Rubber | 125 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | __ | 1 | 00000000 | 00000 |

| 8mm | M10 × 1 mm | Buna-N Rubber | 125 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | __ | 1 | 00000000 | 00000 |

| 9mm | M10 × 1 mm | Buna-N Rubber | 125 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | __ | 1 | 00000000 | 00000 |

| 12mm | M10 × 1 mm | Buna-N Rubber | 125 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | __ | 1 | 00000000 | 00000 |

303 Stainless Steel | |||||||||

| 1/4" | M10 × 1 mm | Buna-N Rubber | 125 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | __ | 1 | 00000000 | 00000 |

| 3/8" | M10 × 1 mm | Buna-N Rubber | 125 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | __ | 1 | 00000000 | 00000 |

| 1/2" | M10 × 1 mm | Buna-N Rubber | 125 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | __ | 1 | 00000000 | 00000 |

| 6mm | M10 × 1 mm | Buna-N Rubber | 125 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | __ | 1 | 00000000 | 00000 |

| 8mm | M10 × 1 mm | Buna-N Rubber | 125 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | __ | 1 | 00000000 | 00000 |

| 9mm | M10 × 1 mm | Buna-N Rubber | 125 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | __ | 1 | 00000000 | 00000 |

| 13mm | M10 × 1 mm | Buna-N Rubber | 125 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | __ | 1 | 00000000 | 00000 |

Metal Barbed Hose Fittings for Chemicals and Petroleum

Made of stainless steel, these fittings stand up to a wide variety of chemicals, as well as fuels, gasoline, and oils. To connect, slide the barbed end into plastic or rubber hose and secure with a clamp.

Adapters are also known as hose nipples; they adapt a barbed end to a threaded end.

Metric and UN/UNF (SAE Straight) male threads have a gasket to protect against leaks.

For technical drawings and 3-D models, click on a part number.

- For Use With: See table

- Maximum Pressure: See table

- Temperature Range: -40° to 300° F

- Attachment Type: Use Band-and-Buckle Clamps

Thread | |||||||

|---|---|---|---|---|---|---|---|

| For Hose ID | Size | Pitch, mm | Gasket Material | Max. Pressure | For Use With | Each | |

316 Stainless Steel | |||||||

| 1/4" | M10 | 1 | Fluoroelastomer Rubber | 125 psi @ 72° F | Acetone, Diesel Fuel, Ethanol, Fuel Oil, Gasoline, Mineral Oil, Mineral Spirits, Vegetable Oil | 000000000 | 000000 |

| 3/8" | M10 | 1 | Fluoroelastomer Rubber | 125 psi @ 72° F | Acetone, Diesel Fuel, Ethanol, Fuel Oil, Gasoline, Mineral Oil, Mineral Spirits, Vegetable Oil | 000000000 | 00000 |

| 1/2" | M10 | 1 | Fluoroelastomer Rubber | 125 psi @ 72° F | Acetone, Diesel Fuel, Ethanol, Fuel Oil, Gasoline, Mineral Oil, Mineral Spirits, Vegetable Oil | 000000000 | 00000 |

| 6mm | M10 | 1 | Fluoroelastomer Rubber | 125 psi @ 72° F | Acetone, Diesel Fuel, Ethanol, Fuel Oil, Gasoline, Mineral Oil, Mineral Spirits, Vegetable Oil | 000000000 | 00000 |

| 8mm | M10 | 1 | Fluoroelastomer Rubber | 125 psi @ 72° F | Acetone, Diesel Fuel, Ethanol, Fuel Oil, Gasoline, Mineral Oil, Mineral Spirits, Vegetable Oil | 000000000 | 00000 |

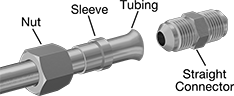

37° Flared Fittings for Steel Tubing

Male Threads with

Gasket and Washer

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil

- Tubing: Use with seamless steel

- Specifications Met: SAE J514

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately. Fittings are zinc-plated steel for fair corrosion resistance.

To prevent leaks, UN/UNF (SAE Straight) male threads have a gasket. Metric and BSPP male threads have either a gasket or a gasket and washer.

For technical drawings and 3-D models, click on a part number.

Male Threads with

Gasket and Washer

- Temperature Range: See table

- Temperature Range: -60° to 400° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on steel tubing that is flared to 37°. Sleeves are zinc-plated steel for fair corrosion resistance. They are also known as ferrules.

Inch × metric sleeve adapters convert the fitting from inch to metric.

- Temperature Range: -60° to 400° F

| For Tube OD | Nut Material | Max. Pressure | Each | |

| 1/4" | Zinc-Plated Steel | 4,500 psi @ 72° F | 000000000 | 00000 |

Plastic Barbed Tube Fittings for Air and Water

Fittings have barbs that grip onto tubing.

Nylon fittings have excellent impact and abrasion resistance.

For technical drawings and 3-D models, click on a part number.

- Temperature Range: See table

- Tubing: Semi-Clear: Use with firm or soft (Durometer 45A-80A) polyurethane rubber or PVC plastic

Opaque: Use with firm or soft (Durometer 40A-80A) polyurethane rubber or PVC plastic

| For Tube ID | Thread Size | Material | Color | Clarity | Max. Pressure | Temp. Range, °F | Pkg. Qty. | Pkg. | |

Metric Threads | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 4mm | M10 × 1 mm | Nylon Plastic | Gray | Opaque | 145 psi @ 72° F | -40° to 190° | 10 | 00000000 | 000000 |

| 6mm | M10 × 1 mm | Nylon Plastic | Gray | Opaque | 145 psi @ 72° F | -40° to 190° | 10 | 00000000 | 00000 |

| 8mm | M10 × 1 mm | Nylon Plastic | Gray | Opaque | 145 psi @ 72° F | -40° to 190° | 10 | 00000000 | 00000 |

- Temperature Range: See table

- Tubing: Semi-Clear: Use with firm or soft (Durometer 45A-80A) polyurethane rubber or PVC plastic

Opaque: Use with firm or soft (Durometer 40A-80A) polyurethane rubber or PVC plastic

| For Tube ID | Thread Size | Material | Color | Clarity | Max. Pressure | Temp. Range, °F | Pkg. Qty. | Pkg. | |

Metric Threads | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 8mm | M10 × 1 mm | Nylon Plastic | Gray | Opaque | 145 psi @ 72° F | -40° to 190° | 10 | 00000000 | 000000 |

Grease Fittings

Thread these fittings into motors, bearings, engine blocks, and other machinery to create a lubrication point. They’re also known as hydraulic grease fittings.

Zinc-plated steel fittings have mild corrosion resistance. Brass fittings resist corrosion better than zinc-plated steel fittings. 303 stainless steel fittings are more corrosion resistant than brass fittings and have good chemical resistance. 316 stainless steel fittings resist corrosion and chemicals better than 303 stainless steel fittings and can be used in saltwater environments.

Fittings with a check valve prevent grease from leaking when pressure causes backward flow. The valve stays closed when not in use to keep out dirt and other contaminants.

For technical drawings and 3-D models, click on a part number.

Male

Threads

Pkg. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Overall Ht. | Thread Lg. | Shank Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Specifications Met | Pkg. Qty. | 1-9 | 10-Up | |

M10 × 1 mm Metric Threads | |||||||||||

| Zinc-Plated Steel | 15mm | 5.9mm | 5.9mm | 11mm | 8,000 | Ball | DIN 71412 | 10 | 0000000 | 00000 | 00000 |

| Brass | 15mm | 5.5mm | 5.5mm | 11mm | 10,000 | Ball | DIN 71412 | 5 | 0000000 | 00000 | 0000 |

| 303 Stainless Steel | 15mm | 5.8mm | 5.8mm | 11mm | 8,000 | Ball | __ | 1 | 0000000 | 0000 | 0000 |

| 316 Stainless Steel | 15mm | 5.5mm | 5.5mm | 11mm | 1,450 | Ball | DIN 71412 | 1 | 0000000 | 00000 | 0000 |

M10 × 1.25 mm Metric Threads | |||||||||||

| Zinc-Plated Steel | 15mm | 5.5mm | 5.5mm | 11mm | 1,450 | Ball | DIN 71412 | 10 | 00000000 | 0000 | 0000 |

M10 × 1.5 mm Metric Threads | |||||||||||

| Zinc-Plated Steel | 15mm | 5.9mm | 5.9mm | 11mm | 8,000 | Ball | DIN 71412 | 10 | 0000000 | 00000 | 0000 |

| Brass | 15mm | 5.5mm | 5.5mm | 11mm | 1,450 | Ball | DIN 71412 | 5 | 00000000 | 00000 | 00000 |

| 303 Stainless Steel | 15mm | 5.5mm | 5.5mm | 11mm | 1,450 | Ball | DIN 71412 | 1 | 0000000 | 0000 | 0000 |

| 316 Stainless Steel | 15mm | 5.5mm | 5.5mm | 11mm | 10,000 | Ball | DIN 71412 | 1 | 0000000 | 00000 | 00000 |

Pkg. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Overall Ht. | Thread Lg. | Shank Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Specifications Met | Pkg. Qty. | 1-9 | 10-Up | |

M10 × 1 mm Metric Threads | |||||||||||

| Zinc-Plated Steel | 19mm | 5.6mm | 5.6mm | 11mm | 8,000 | Ball | DIN 71412 | 10 | 0000000 | 000000 | 000000 |

| Brass | 20mm | 5.5mm | 5.5mm | 11mm | 10,000 | Ball | DIN 71412 | 3 | 0000000 | 00000 | 00000 |

| 303 Stainless Steel | 19mm | 5.6mm | 5.6mm | 11mm | 8,000 | Ball | __ | 1 | 0000000 | 0000 | 0000 |

M10 × 1.25 mm Metric Threads | |||||||||||

| Zinc-Plated Steel | 20mm | 5.5mm | 5.5mm | 11mm | 1,450 | Ball | DIN 71412 | 10 | 00000000 | 00000 | 00000 |

M10 × 1.5 mm Metric Threads | |||||||||||

| Zinc-Plated Steel | 21mm | 6.9mm | 6.9mm | 11mm | 8,000 | Ball | __ | 10 | 0000000 | 00000 | 00000 |

| 303 Stainless Steel | 20mm | 5.5mm | 5.5mm | 11mm | 1,450 | Ball | DIN 71412 | 1 | 0000000 | 0000 | 0000 |

Pkg. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Overall Ht. | Thread Lg. | Shank Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Specifications Met | Pkg. Qty. | 1-9 | 10-Up | |

M10 × 1 mm Metric Threads | |||||||||||

| Zinc-Plated Steel | 25mm | 5.5mm | 5.5mm | 11mm | 1,450 | Ball | DIN 71412 | 10 | 00000000 | 000000 | 000000 |

Pkg. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Overall Ht. | Thread Lg. | Shank Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Specifications Met | Pkg. Qty. | 1-9 | 10-Up | |

M10 × 1 mm Metric Threads | |||||||||||

| Zinc-Plated Steel | 24mm | 5.6mm | 5.6mm | 11mm | 8,000 | Ball | DIN 71412 | 10 | 0000000 | 000000 | 000000 |

| Brass | 25mm | 5.5mm | 5.5mm | 11mm | 10,000 | Ball | DIN 71412 | 3 | 0000000 | 00000 | 00000 |

| 303 Stainless Steel | 23mm | 5.6mm | 5.6mm | 11mm | 8,000 | Ball | __ | 1 | 0000000 | 0000 | 0000 |

M10 × 1.25 mm Metric Threads | |||||||||||

| Zinc-Plated Steel | 25mm | 5.5mm | 5.5mm | 11mm | 1,450 | Ball | DIN 71412 | 10 | 00000000 | 0000 | 0000 |

M10 × 1.5 mm Metric Threads | |||||||||||

| Zinc-Plated Steel | 26mm | 6.9mm | 6.9mm | 11mm | 8,000 | Ball | __ | 10 | 0000000 | 00000 | 00000 |

| 303 Stainless Steel | 25mm | 5.5mm | 5.5mm | 11mm | 1,450 | Ball | DIN 71412 | 1 | 0000000 | 00000 | 00000 |

Pkg. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Overall Ht. | Thread Lg. | Shank Lg. | Square Size | Max. Pressure, psi | Check Valve Type | Specifications Met | Pkg. Qty. | 1-9 | 10-Up | |

M10 × 1 mm Metric Threads | |||||||||||

| Zinc-Plated Steel | 18mm | 5.5mm | 5.5mm | 11mm | 1,450 | Ball | DIN 71412 | 5 | 00000000 | 000000 | 000000 |

Button-Head Grease Fittings

Often used on earth movers, mining equipment, and other heavy machinery, these fittings have a T-shaped top that holds the dispensing tip in place so it won’t pop off when adding grease. They're best for machinery requiring high volumes of grease because they let more grease pass through than standard grease fittings, thanks to a larger opening. An integral check valve prevents grease from leaking when pressure causes backward flow. The valve stays closed when not in use to keep out dirt and other contaminants.

Zinc-plated steel fittings have mild corrosion resistance. 303 stainless steel fittings are more corrosion resistant than zinc-plated steel fittings and have good chemical resistance.

For technical drawings and 3-D models, click on a part number.

Each | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Overall Ht. | Thread Lg. | Shank Lg. | Hex Size | Head Dia. | Max. Pressure, psi | Check Valve Type | Specifications Met | 1-9 | 10-Up | |

M10 × 1 mm Metric Threads | |||||||||||

| Zinc-Plated Steel | 14mm | 6mm | 6mm | 11mm | 10mm | 1,450 | Ball | DIN 3404 | 0000000 | 00000 | 00000 |

| Zinc-Plated Steel | 17mm | 6mm | 6mm | 17mm | 16mm | 10,000 | Ball | DIN 3404 | 0000000 | 0000 | 0000 |

| 303 Stainless Steel | 17mm | 6mm | 6mm | 17mm | 16mm | 10,000 | Ball | DIN 3404 | 0000000 | 00000 | 00000 |

M10 × 1.5 mm Metric Threads | |||||||||||

| Zinc-Plated Steel | 17mm | 6mm | 6mm | 17mm | 16mm | 1,450 | Ball | DIN 3404 | 0000000 | 0000 | 0000 |

Flush-Style Grease Fittings

The nipple doesn't stick out, so these fittings fit in tight spaces and won't be damaged if something knocks into them. An integral check valve prevents grease from leaking when pressure causes backward flow. The valve stays closed when not in use to keep out dirt and other contaminants.

Zinc-plated steel fittings have mild corrosion resistance.

Install Styles A, B, and D with a slotted screwdriver. Install Style C with a hex wrench.

For technical drawings and 3-D models, click on a part number.

Pkg. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Material | Overall Ht. | Thread Lg. | Shank Lg. | Slot Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Specifications Met | Pkg. Qty. | 1-9 | 10-Up | |

Straight with Male Threads | |||||||||||||

M10 × 1 mm Metric Threads | |||||||||||||

| D | Zinc-Plated Steel | 10mm | 10mm | 10mm | 10mm | __ | 1,450 | Ball | DIN 3405 | 5 | 00000000 | 000000 | 000000 |

| C | Zinc-Plated Steel | 9.5mm | 6.5mm | 6.5mm | __ | 11mm | 10,000 | Ball | DIN 3405 | 5 | 0000000 | 0000 | 0000 |

M10 × 1.5 mm Metric Threads | |||||||||||||

| C | Zinc-Plated Steel | 9.5mm | 6.5mm | 6.5mm | __ | 11mm | 1,450 | Ball | DIN 3405 | 5 | 00000000 | 0000 | 0000 |

Self-Tapping Grease Fittings for Unthreaded Holes

To fit securely in unthreaded holes, these fittings cut threads as they’re installed. Use a hex wrench to install. Fittings can be driven in, but then are not pressure rated. They're zinc-plated steel for mild corrosion resistance. All have an integral check valve that prevents grease from leaking when pressure causes backward flow. The valve stays closed when not in use to keep out dirt and other contaminants. These fittings are also known as hydraulic grease fittings.

For technical drawings and 3-D models, click on a part number.

Pkg. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Hole Dia. | Material | Overall Ht. | Shank Lg. | Thread Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Pkg. Qty. | 1-9 | 10-Up | |

M10 × 1 mm Metric Threads | |||||||||||

| 9.6-9.7mm | Zinc-Plated Steel | 15mm | 5.5mm | 5.5mm | 11mm | 10,000 | Ball | 10 | 0000000 | 00000 | 00000 |

Pkg. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Hole Dia. | Material | Overall Ht. | Shank Lg. | Thread Lg. | Square Size | Max. Pressure, psi | Check Valve Type | Pkg. Qty. | 1-9 | 10-Up | |

M10 × 1 mm Metric Threads | |||||||||||

| 9.6-9.7mm | Zinc-Plated Steel | 18mm | 5.5mm | 5.5mm | 11mm | 10,000 | Ball | 5 | 0000000 | 000000 | 000000 |

Pkg. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Hole Dia. | Material | Overall Ht. | Shank Lg. | Thread Lg. | Square Size | Max. Pressure, psi | Check Valve Type | Pkg. Qty. | 1-9 | 10-Up | |

M10 × 1 mm Metric Threads | |||||||||||

| 9.6-9.7mm | Zinc-Plated Steel | 20mm | 5.5mm | 5.5mm | 11mm | 10,000 | Ball | 5 | 0000000 | 000000 | 000000 |

Self-Tapping Flush-Style Grease Fittings for Unthreaded Holes

Ensure a secure fit in unthreaded holes—these fittings cut threads as they’re installed. Use them in tight spaces where protruding fittings won't work. Install with a hex wrench. Fittings can be driven in, but then are not pressure rated. They’re zinc-plated steel for mild corrosion resistance. An integral check valve prevents grease from leaking when pressure causes backward flow. The valve stays closed when not in use to keep out dirt and other contaminants.

For technical drawings and 3-D models, click on a part number.

Pkg. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Hole Dia. | Material | Overall Ht. | Shank Lg. | Thread Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Specifications Met | Pkg. Qty. | 1-9 | 10-Up | |

Straight with Male Threads | ||||||||||||

M10 × 1 mm Metric Threads | ||||||||||||

| 9.6-9.7 mm | Zinc-Plated Steel | 8.5 mm | 5.5 mm | 5.5 mm | 11 mm | 10,000 | Ball | DIN 3405 | 1 | 0000000 | 00000 | 00000 |

Grease Fitting Adapters

When the size or thread type of a fitting doesn't match an existing opening, use these adapters to make the connection.

Zinc-plated steel adapters have mild corrosion resistance. Brass adapters resist corrosion better than zinc-plated steel adapters. UNF threads are similar to threads on a machine screw or bolt. They require a sealant, such as an O-ring, to minimize leakage.

For technical drawings and 3-D models, click on a part number.