How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

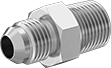

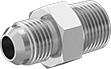

Extreme-Pressure Stainless Steel Threaded Pipe Fittings

With the strength to handle extreme pressures, these fittings can be used to connect equipment in hydraulic fluid lines. 316 stainless steel fittings have excellent corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads. UN/UNF (SAE Straight) threads are also known as O-ring boss threads; the male threads have a gasket to prevent leaks.

For technical drawings and 3-D models, click on a part number.

(SAE Straight) Male

Threads with Gasket

- For Use With: See table

- Specifications Met: See table

316 Stainless Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size (A) | Dash Size (A) | Thread Size (B) | Dash Size (B) | Max. Pressure | Max. Steam Pressure | For Use With | Specifications Met | Each | |

NPTF Male × UN/UNF (SAE Straight) Male | |||||||||

| 1/4 | 04 | 1/2"-20 | 05 | 6,000 psi @ 72° F | 6,000 psi @ 200° F | Hydraulic Fluid, Oil, Steam, Water | SAE J514 | 000000000 | 000000 |

Metal Barbed Hose Fittings for Air and Water

Slide the barbed end into rubber hose and secure with the appropriate clamp or crimp-on hose ferrule.

Brass fittings are softer than other metal fittings, so they’re easier to thread together. Plain brass fittings have good corrosion resistance. Fittings with a threaded end are also known as hose nipples.

Fittings with a 45° flared end are also known as refrigeration and SAE fittings.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: 250 psi @ 72° F

- Temperature Range: -40° to 160° F

- Attachment Type: Use Crimp-On Hose Ferrules, except For 1/2" Hose ID: Use Band-and-Buckle Clamps

- Specifications Met: SAE J476

| For Hose ID | For Tube OD | Thread Size | Pkg. Qty. | Pkg. | |

Brass | |||||

|---|---|---|---|---|---|

| 5/16" | 5/16" | 1/2"-20 | 5 | 0000000 | 000000 |

Metal Push-On Barbed Hose Fittings for Air and Water

Fittings have sharper barbs than standard barbed hose fittings to grip rubber push-on hose with no clamps or ferrules required. The more you pull on the fittings, the tighter the hose will grip.

Brass fittings are softer than other metal fittings, so they’re easier to thread together. They have good corrosion resistance.

Fittings with a flared end meet JIC or SAE standards for dimensions. Fittings with a 45° flared end are also known as refrigeration and SAE fittings. Fittings with a female 37° and 45° flared end have a dual-angle seat that accepts both 37° and 45° flared fittings.

The optional installation tool (sold separately) allows you to connect large quantities of barbed fittings to push-on hose. Use the built-in cutter to squarely cut the hose without fraying. Next, lubricate either the push-on hose, fitting or both. Then, clamp the hose into the tool’s vise and apply light pressure on the handle to drive into the fitting.

Note: To ensure proper connection, the barbed end has to be pushed in all the way, with the hose end concealed by the ring.

For technical drawings and 3-D models, click on a part number.

Mounting Hole | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Hose ID Range | Lg. | Ht. | Dp. | Dia. | No. of | Mounting Fasteners Included | Each | |

| 1/4" to 3/4" | 13 1/2" | 7" | 2 3/8" | 5/8" | 4 | No | 00000000 | 0000000 |

International Standard ISO B Quick-Disconnect Hose Couplings for Hydraulic Fluid

A complete coupling consists of a plug and a socket (both sold separately) that connect and disconnect quickly. Use them if you need frequent access to a hydraulic hose line. All of the International Standard ISO B quick-disconnect plugs are compatible with any of the International Standard ISO B quick-disconnect sockets of the same coupling size, regardless of the pipe size. Couplings meet ISO 7241-1 Series B dimensional and performance standards and are compatible with Parker 60 couplings. Also known as double shut-off couplings, the plugs and sockets both have a shut-off valve that stops the flow when the coupling is separated.

Push-to-connect sockets are easier to connect than sleeve-lock sockets. Connect by pushing the plug into the socket until you hear a click. To disconnect, slide the sleeve on the socket forward until the plug ejects.

Zinc-plated steel is stronger and more durable than other metals. It has fair corrosion resistance.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size. Pressure ratings are given for static (constant) pressure conditions.

Warning: Never attempt to connect or disconnect couplings when operating at maximum pressure. Stop the flow before you disconnect the line.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: 3,500 psi @ 72° F

- Temperature Range: -10° to 212° F

- Compatible With: ISO 7241-1 Series B, Parker 60

- Specifications Met: ISO 7241-1 Series B

45° Flared Fittings for Copper and Brass Tubing

- Temperature Range: -65° to 250° F

- Tubing: Use with seamless brass and copper that meets ASTM B280

No sleeve is required to assemble these fittings, which makes for a faster, more convenient installation compared to 37° flared fittings. They require a nut (sold separately) for each tube end. Fittings are also known as refrigeration and SAE fittings. They are brass for good corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water; except adapters for 1/8" and 1" tube OD are not for use with fuel oil

- Specifications Met: See table

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water; except nuts for 1" tube OD are not for use with fuel oil

- Specifications Met: SAE J512, SAE J513, UL Listed; except nuts for 1" tube OD meet SAE J512 and SAE J513 only

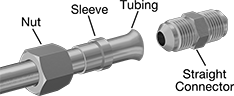

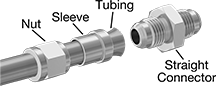

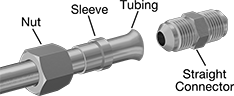

37° Flared Fittings for Copper Tubing

- For Use With: Air, Fuel Oil, Mineral Oil, Water

- Temperature Range: -40° to 400° F

- Tubing: Use with seamless copper

- Specifications Met: ISO 8434, MIL-F-18866, SAE J514

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They can handle higher pressures than 45° flared fittings. Fittings are brass for good corrosion resistance. They require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

For technical drawings and 3-D models, click on a part number.

37° Flared Fittings for Stainless Steel Tubing

- Tubing: Use with welded or seamless 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Specifications Met: ISO 8434, SAE J514, except fittings with BSPP and BSPT threads meet SAE J514 only

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They withstand high pressure, so they’re often used in hydraulic applications. Made from 316 stainless steel, they resist corrosion from water and chemicals. A complete fitting requires a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

For technical drawings and 3-D models, click on a part number.

- For Use With: See table

- Temperature Range: See table

| For Tube OD | Pipe Size | For Use With | Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 5/16" | 1/8 | Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 000000000 | 000000 |

| 5/16" | 1/4 | Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 000000000 | 00000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

| For Tube OD | Nut Material | Each | |

| 5/16" | 316 Stainless Steel | 000000000 | 000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on stainless steel tubing that is flared to 37°. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

Inch × metric sleeve adapters convert the fitting from inch to metric.

Precision AN 37° Flared Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -320° to 1200° F

- Tubing: Use with seamless 304 or 316 stainless steel

- Specifications Met: See Table

The threads on the tube end of these fittings are Class 3A or 3B and adhere to tighter tolerances than other 37° flared fittings. They are made to exact AS (formerly AN) specifications and provide a tight metal-to-metal seal on tubing that is flared to 37°. Fittings require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

304 stainless steel fittings have very good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | Pipe Size | Max. Pressure | Specifications Met | Each | |

304 Stainless Steel | |||||

|---|---|---|---|---|---|

ANPT Threads | |||||

| 5/16" | 1/4 | 3,000 psi @ 72° F | AN816-5-4J, ASTM A380, SAE AS4841 | 00000000 | 000000 |

| For Tube OD | Max. Pressure | Specifications Met | Each | |

304 Stainless Steel | ||||

|---|---|---|---|---|

| 5/16" | 3,000 psi @ 72° F | AN818-5J, ASTM A380, SAE AS4841 | 00000000 | 000000 |

| For Tube OD | Max. Pressure | Specifications Met | Each | |

304 Stainless Steel | ||||

|---|---|---|---|---|

| 5/16" | 3,000 psi @ 72° F | AN819-5J, ASTM A380, MS20819, SAE AS4841, SAE AS5176 | 00000000 | 00000 |

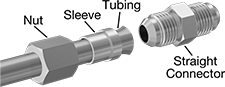

37° Flared Fittings for Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil

- Tubing: Use with seamless steel

- Specifications Met: SAE J514

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately. Fittings are zinc-plated steel for fair corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads.

For technical drawings and 3-D models, click on a part number.

- Temperature Range: See table

| For Tube OD | Pipe Size | Material | Max. Pressure | Temp. Range, °F | Each | |

NPTF Threads | ||||||

|---|---|---|---|---|---|---|

| 5/16" | 1/8 | Zinc-Plated Steel | 5,000 psi @ 72° F | -60° to 400° | 000000000 | 00000 |

- Temperature Range: -60° to 400° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on steel tubing that is flared to 37°. Sleeves are zinc-plated steel for fair corrosion resistance. They are also known as ferrules.

Inch × metric sleeve adapters convert the fitting from inch to metric.

- Temperature Range: -60° to 400° F

| For Tube OD | Nut Material | Max. Pressure | Each | |

| 5/16" | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 00000 |

Grease Fittings

Thread these fittings into motors, bearings, engine blocks, and other machinery to create a lubrication point. They’re also known as hydraulic grease fittings.

Zinc-plated steel fittings have mild corrosion resistance.

Fittings with a check valve prevent grease from leaking when pressure causes backward flow. The valve stays closed when not in use to keep out dirt and other contaminants.

UNF threads are similar to threads on a machine screw or bolt. They require a sealant, such as an O-ring, to minimize leakage.

For technical drawings and 3-D models, click on a part number.

Male

Threads

Pkg. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | Overall Ht. | Thread Lg. | Shank Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Pkg. Qty. | 1-9 | 10-Up | |

1/2"-20 UNF Threads | ||||||||||

| Zinc-Plated Steel | 11/16" | 1/4" | 1/4" | 9/16" | 1,450 | Ball | 10 | 00000000 | 000000 | 000000 |

Pkg. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | Overall Ht. | Thread Lg. | Shank Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Pkg. Qty. | 1-9 | 10-Up | |

1/2"-20 UNF Threads | ||||||||||

| Zinc-Plated Steel | 7/8" | 1/4" | 1/4" | 9/16" | 1,450 | Ball | 3 | 00000000 | 000000 | 000000 |

Pkg. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | Overall Ht. | Thread Lg. | Shank Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Pkg. Qty. | 1-9 | 10-Up | |

1/2"-20 UNF Threads | ||||||||||

| Zinc-Plated Steel | 57/64" | 1/4" | 1/4" | 9/16" | 1,450 | Ball | 5 | 00000000 | 000000 | 000000 |