About Hinges

More

About Rod Ends

More

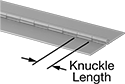

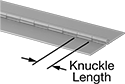

Mil. Spec. Piano Hinges without Holes

Choose these hinges for their adherence to strict military standards for material and construction. Longer than other hinges, piano hinges run the entire length of doors and lids for strength and durability. All of these hinges have a standard clearance—when they are closed, the distance between the leaves is about the same as the pin diameter.

302 stainless steel hinges are more corrosion resistant than aluminum. They also have good chemical resistance.

Aluminum hinges are about half the weight of steel. They have mild corrosion resistance.

Note: Prices are 15% to 20% lower when you buy 10 or more hinges of the same size.

For technical drawings and 3-D models, click on a part number.

Between

Hinge Leaves

Knuckle | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| O'all Wd. | Pin Dia. | Pin Material | Lg. | Dia. | Range of Motion | Specifications Met | 1 ft. | 3 ft. | 6 ft. | |

0.04" Leaf Thick. | ||||||||||

| 1 1/4" | 3/32" | 302 Stainless Steel | 1/2" | 0.174" | 270° | A-A-55590 | 0000000 | |||

| 1 1/2" | 3/32" | 302 Stainless Steel | 1/2" | 0.174" | 270° | A-A-55590 | 0000000 | |||

| 2" | 3/32" | 302 Stainless Steel | 1/2" | 0.174" | 270° | A-A-55590 | 0000000 | |||

0.06" Leaf Thick. | ||||||||||

| 2" | 1/8" | 302 Stainless Steel | 5/8" | 0.245" | 270° | A-A-55592 | 0000000 | |||

Between

Hinge Leaves

Knuckle | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| O'all Wd. | Pin Dia. | Material | Pin Material | Lg. | Dia. | Length | Range of Motion | Specifications Met | 1-9 | 10-Up | |

0.044"-0.056" Leaf Thick. | |||||||||||

| 1 1/16" | 3/32" | 2024 Aluminum | Cadmium-Plated 302 Stainless Steel | 1/2" | 0.206" | 6 ft. | 270° | MS20001-2 | 0000000 | 0000000 | 0000000 |

| 1 1/4" | 3/32" | 2024 Aluminum | Cadmium-Plated 302 Stainless Steel | 1/2" | 0.206" | 6 ft. | 270° | MS20001-3 | 0000000 | 000000 | 000000 |

| 1 1/2" | 3/32" | 2024 Aluminum | Cadmium-Plated 302 Stainless Steel | 1/2" | 0.206" | 6 ft. | 270° | MS20001-4 | 0000000 | 000000 | 000000 |

| 2" | 3/32" | 2024 Aluminum | Cadmium-Plated 302 Stainless Steel | 1/2" | 0.206" | 6 ft. | 270° | MS20001-6 | 0000000 | 000000 | 000000 |

| 2 1/2" | 3/32" | 2024 Aluminum | Cadmium-Plated 302 Stainless Steel | 1/2" | 0.206" | 6 ft. | 270° | MS20001-9 | 0000000 | 000000 | 000000 |

0.064"-0.076" Leaf Thick. | |||||||||||

| 2" | 3/16" | 2024 Aluminum | Cadmium-Plated 302 Stainless Steel | 1/2" | 0.340" | 6 ft. | 270° | MS20001-8 | 0000000 | 000000 | 000000 |

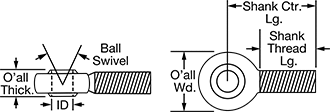

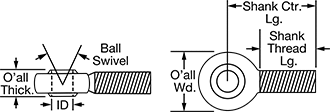

Mil. Spec. Ball Joint Rod Ends

Made of cadmium-plated steel, these rod ends generally handle higher loads than stainless steel, aluminum, and nylon rod ends. They provide moderate corrosion resistance. All have a PTFE liner that allows smooth ball rotation and eliminates the need for lubrication. Liner meets SAE AS81820.

Rod ends with an oversized shank have a shank that is one size larger than the ID to handle greater stress.

For technical drawings and 3-D models, click on a part number.

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Static Radial Load Cap., lbs. | Specifications Met | Material | Choose a Shank Thread Direction | Each | |

Ball Joints | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5/16"-24 | 5/16" | 14° | 7/8" | 7/16" | 1 7/8" | 1 3/16" | 7,150 | MIL-B-81935 SAE AS81820 SAE AS81935 | Cadmium-Plated Alloy Steel | Right Hand | 00000000 | 0000000 |

| 3/8"-24 | 3/8" | 8° | 1" | 1/2" | 1 15/16" | 1 3/16" | 8,550 | MIL-B-81935 SAE AS81820 SAE AS81935 | Cadmium-Plated Alloy Steel | 0000000 | 000000 | |

| 7/16"-20 | 7/16" | 10° | 1 1/8" | 9/16" | 2 1/8" | 1 1/4" | 12,000 | MIL-B-81935 SAE AS81820 SAE AS81935 | Cadmium-Plated Alloy Steel | Right Hand | 00000000 | 000000 |

| 1/2"-20 | 1/2" | 9° | 1 5/16" | 5/8" | 2 7/16" | 1 7/16" | 19,500 | MIL-B-81935 SAE AS81820 SAE AS81935 | Cadmium-Plated Alloy Steel | 0000000 | 000000 | |

| 5/8"-18 | 5/8" | 12° | 1 1/2" | 3/4" | 2 5/8" | 1 9/16" | 21,900 | MIL-B-81935 SAE AS81820 SAE AS81935 | Cadmium-Plated Alloy Steel | 0000000 | 000000 | |

| 3/4"-16 | 3/4" | 13° | 1 3/4" | 7/8" | 2 7/8" | 1 11/16" | 29,300 | MIL-B-81935 SAE AS81820 SAE AS81935 | Cadmium-Plated Alloy Steel | 0000000 | 000000 | |

| 7/8"-14 | 7/8" | 6° | 2" | 7/8" | 3 3/8" | 2" | 34,500 | MIL-B-81935 SAE AS81820 SAE AS81935 | Cadmium-Plated Alloy Steel | Right Hand | 00000000 | 000000 |

Ball Joints with Oversized Shank | ||||||||||||

| 5/16"-24 | 3/16" | 15° | 13/16" | 7/16" | 1 9/16" | 15/16" | 2,350 | MIL-B-81935 SAE AS81820 SAE AS81935 | Cadmium-Plated Alloy Steel | Right Hand | 00000000 | 000000 |

| 5/16"-24 | 1/4" | 15° | 13/16" | 7/16" | 1 9/16" | 15/16" | 4,850 | MIL-B-81935 SAE AS81820 SAE AS81935 | Cadmium-Plated Alloy Steel | 0000000 | 000000 | |

| 1 1/4"-12 | 1" | 12° | 2 3/4" | 1 3/8" | 4 1/8" | 2 5/16" | 80,300 | MIL-B-81935 SAE AS81820 SAE AS81935 | Cadmium-Plated Alloy Steel | Right Hand | 00000000 | 000000 |

Internally Threaded Mil. Spec. Ball Joint Rod Ends

Made of cadmium-plated steel, these rod ends generally handle higher loads than stainless steel, aluminum, and nylon rod ends. They provide moderate corrosion resistance. All have a PTFE liner that allows smooth ball rotation and eliminates the need for lubrication. Liner meets SAE AS81820.

Rod ends with an oversized shank have a shank that is one size larger than the ID to handle greater stress.

For technical drawings and 3-D models, click on a part number.

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Static Radial Load Cap., lbs. | Specifications Met | Material | Shank Thread Direction | Each | |

Ball Joints | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3/8"-24 | 3/8" | 8° | 1" | 1/2" | 1 13/16" | 1" | 8,550 | MIL-B-81935 SAE AS81820 SAE AS81935 | Cadmium-Plated Alloy Steel | Right Hand | 00000000 | 0000000 |

| 7/16"-20 | 7/16" | 10° | 1 1/8" | 9/16" | 2" | 1 1/8" | 12,000 | MIL-B-81935 SAE AS81820 SAE AS81935 | Cadmium-Plated Alloy Steel | Right Hand | 00000000 | 000000 |

| 1/2"-20 | 1/2" | 9° | 1 5/16" | 5/8" | 2 1/4" | 1 1/4" | 19,500 | MIL-B-81935 SAE AS81820 SAE AS81935 | Cadmium-Plated Alloy Steel | Right Hand | 00000000 | 000000 |

| 5/8"-18 | 5/8" | 12° | 1 1/2" | 3/4" | 2 1/2" | 1 3/8" | 21,900 | MIL-B-81935 SAE AS81820 SAE AS81935 | Cadmium-Plated Alloy Steel | Right Hand | 00000000 | 000000 |

| 3/4"-16 | 3/4" | 13° | 1 3/4" | 7/8" | 2 7/8" | 1 5/8" | 29,300 | MIL-B-81935 SAE AS81820 SAE AS81935 | Cadmium-Plated Alloy Steel | Right Hand | 00000000 | 000000 |

| 7/8"-14 | 7/8" | 6° | 2" | 7/8" | 3 3/8" | 1 7/8" | 34,500 | MIL-B-81935 SAE AS81820 SAE AS81935 | Cadmium-Plated Alloy Steel | Right Hand | 00000000 | 000000 |

Ball Joints with Oversized Shank | ||||||||||||

| 5/16"-24 | 1/4" | 15° | 13/16" | 7/16" | 1 7/16" | 3/4" | 4,850 | MIL-B-81935 SAE AS81820 SAE AS81935 | Cadmium-Plated Alloy Steel | Right Hand | 00000000 | 000000 |

| 1 1/4"-12 | 1" | 12° | 2 3/4" | 1 3/8" | 4 1/8" | 2 1/8" | 80,300 | MIL-B-81935 SAE AS81820 SAE AS81935 | Cadmium-Plated Alloy Steel | Right Hand | 00000000 | 000000 |

Internally Threaded High-Speed Ball Bearing Rod Ends

A double row of precision ball bearings allows high speeds and smooth operation. Seals keep lubricant in and dirt out.

Cadmium-plated alloy steel rod ends offer moderate corrosion resistance. They have an oversized shank, which is one size larger than the ID, to handle greater stress. Their lubricant meets MIL-PRF-81322. These rod ends won't require ongoing lubrication.

For technical drawings and 3-D models, click on a part number.

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Static Radial Load Cap., lbs. | Specifications Met | Shank Thread Direction | Each | |

Ball Joints with Oversized Shank | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Cadmium-Plated Alloy Steel | |||||||||||

| 1/4"-28 | 3/16" | 20° | 3/4" | 1/2" | 1 3/8" | 3/4" | 1,000 | MIL-PRF-81322, MS21153 | Right Hand | 0000000 | 0000000 |

| 5/16"-24 | 1/4" | 20° | 15/16" | 9/16" | 1 7/16" | 3/4" | 1,700 | MIL-PRF-81322, MS21153 | Right Hand | 0000000 | 000000 |

High-Speed Ball Bearing Rod Ends

A double row of precision ball bearings allows high speeds and smooth operation. Rod ends are made of cadmium- or zinc-plated steel, which both offer moderate corrosion resistance. Seals keep lubricant in and dirt out.

Cadmium-plated steel rod ends have lubricant that meets MIL-PRF-81322. They won’t require ongoing lubrication. Those with an oversized shank have a shank that is one size larger than the ID to handle greater stress.

For technical drawings and 3-D models, click on a part number.

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Static Radial Load Cap., lbs. | Specifications Met | Shank Thread Direction | Each | |

Ball Joints | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Cadmium-Plated Alloy Steel | |||||||||||

| 10-32 | 3/16" | 20° | 25/32" | 7/16" | 1 3/8" | 3/4" | 1,000 | MIL-PRF-81322, MS21151 | Right Hand | 0000000 | 0000000 |

Ball Joints with Oversized Shank | |||||||||||

Cadmium-Plated Alloy Steel | |||||||||||

| 1/4"-28 | 3/16" | 20° | 3/4" | 7/16" | 1 9/16" | 1" | 1,000 | MIL-PRF-81322, MS21151 | Right Hand | 0000000 | 000000 |

| 3/8"-24 | 1/4" | 20° | 15/16" | 9/16" | 1 7/8" | 1 1/8" | 1,700 | MIL-PRF-81322, MS21151 | Right Hand | 0000000 | 000000 |

| 3/8"-24 | 5/16" | 20° | 1 1/4" | 7/8" | 2 7/16" | 1 9/16" | 2,900 | MIL-PRF-81322, MS21151 | Right Hand | 0000000 | 000000 |

| 7/16"-20 | 5/16" | 20° | 1 1/4" | 7/8" | 2 7/16" | 1 9/16" | 2,900 | MIL-PRF-81322, MS21151 | Right Hand | 0000000 | 000000 |

Mil. Spec. Machinable-Bore Single U-Joints

Drill the bores to create custom U-joints that meet strict military standards for material and construction. These U-joints come apart and have a small, centered starter hole on each end to make drilling easy. Because they’re single U-joints, they connect and transfer torque between two shafts that are misaligned at an angle. They have a pin-and-block joint, so they handle higher torque at lower speeds than other joint types such as those with needle bearings, making them a good choice for most applications. Made of steel with hardened yoke ears for added strength and durability, they handle a good amount of torque.

Drill holes through the U-joint and your shafts and then connect using spring pins. They have a ball-spring oil fitting to keep lubricant in the joint.

Your shafts’ misalignment will affect the speed and torque the U-joint will be able to transmit. The more the shafts are misaligned, the less speed and torque the U-joint will be able to transmit.

For technical drawings and 3-D models, click on a part number.

Torque | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Max. Shaft Dia. | For Max. Shaft Dp. | Joint Dia. | Overall Lg. | Max. Operating Angle | Max. Speed, rpm | Max. Torque, in.-lbs. | 3° Operating Angle | 10° Operating Angle | Joint Type | Includes | Specifications Met | Each | |

Steel | |||||||||||||

| 1/2" | 1" | 7/8" | 3" | 35° | 1,500 | 1,800 | 345 in.-lbs. @ 300 rpm | 225 in.-lbs. @ 300 rpm | Pin and Block | Ball-Spring Oil Fitting | MIL-DTL-20625 Class A | 0000000 | 0000000 |

| 9/16" | 1 3/16" | 1" | 3 3/8" | 35° | 1,500 | 3,050 | 585 in.-lbs. @ 300 rpm | 380 in.-lbs. @ 300 rpm | Pin and Block | Ball-Spring Oil Fitting | MIL-DTL-20625 Class A | 0000000 | 000000 |

| 3/4" | 1 1/4" | 1 1/4" | 3 3/4" | 35° | 1,500 | 5,500 | 1,055 in.-lbs. @ 300 rpm | 685 in.-lbs. @ 300 rpm | Pin and Block | Ball-Spring Oil Fitting | MIL-DTL-20625 Class A | 0000000 | 000000 |

| 7/8" | 1 5/16" | 1 1/2" | 4 1/4" | 35° | 1,500 | 9,000 | 1,730 in.-lbs. @ 300 rpm | 1,125 in.-lbs. @ 300 rpm | Pin and Block | Ball-Spring Oil Fitting | MIL-DTL-20625 Class A | 0000000 | 000000 |

| 1" | 1 9/16" | 1 3/4" | 5" | 35° | 1,500 | 14,000 | 2,690 in.-lbs. @ 300 rpm | 1,750 in.-lbs. @ 300 rpm | Pin and Block | Ball-Spring Oil Fitting | MIL-DTL-20625 Class A | 0000000 | 000000 |

| 1 3/16" | 1 5/8" | 2" | 5 7/16" | 35° | 1,500 | 22,000 | 4,230 in.-lbs. @ 300 rpm | 2,750 in.-lbs. @ 300 rpm | Pin and Block | Ball-Spring Oil Fitting | MIL-DTL-20625 Class A | 0000000 | 000000 |

| 1 1/2" | 2 1/16" | 2 1/2" | 7" | 35° | 1,500 | 32,000 | 6,150 in.-lbs. @ 300 rpm | 4,000 in.-lbs. @ 300 rpm | Pin and Block | Ball-Spring Oil Fitting | MIL-DTL-20625 Class A | 0000000 | 000000 |

Corrosion-Resistant Mil. Spec. Machinable-Bore Single U-Joints

Made to meet strict military standards for material and construction, these stainless steel U-joints also balance strength with good corrosion resistance. Customize their bores until they fit your shafts. They come apart and have a small, centered starter hole on each end to make drilling easy. Because they’re single U-joints, they connect and transfer torque between two shafts that are misaligned at an angle. They have a pin-and-block joint, so they handle higher torque at lower speeds than other joint types such as those with needle bearings, making them a good choice for most applications.

Drill holes through the U-joint and your shafts and then connect using spring pins.

Your shafts’ misalignment will affect the speed and torque the U-joint will be able to transmit. The more the shafts are misaligned, the less speed and torque the U-joint will be able to transmit.

U-joints with a ball-spring oil fitting keep lubricant in the joint.

For technical drawings and 3-D models, click on a part number.

Torque | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Max. Shaft Dia. | For Max. Shaft Dp. | Joint Dia. | Overall Lg. | Max. Operating Angle | Max. Speed, rpm | Max. Torque, in.-lbs. | 3° Operating Angle | 10° Operating Angle | Joint Type | Includes | Specifications Met | Each | |

303 Stainless Steel | |||||||||||||

| 7/32" | 11/16" | 3/8" | 1 3/4" | 35° | 1,500 | 100 | Not Rated | Not Rated | Pin and Block | __ | MIL-U-20625A Class C | 0000000 | 0000000 |

| 9/32" | 3/4" | 1/2" | 2" | 35° | 1,500 | 375 | Not Rated | Not Rated | Pin and Block | __ | MIL-U-20625A Class C | 0000000 | 000000 |

| 3/8" | 13/16" | 5/8" | 2 1/4" | 35° | 1,500 | 610 | Not Rated | Not Rated | Pin and Block | __ | MIL-U-20625A Class C | 0000000 | 000000 |

| 7/16" | 31/32" | 3/4" | 2 11/16" | 35° | 1,500 | 1,000 | Not Rated | Not Rated | Pin and Block | __ | MIL-U-20625A Class C | 0000000 | 000000 |

| 1/2" | 1 1/32" | 7/8" | 3" | 35° | 1,500 | 1,350 | Not Rated | Not Rated | Pin and Block | __ | MIL-U-20625A Class C | 0000000 | 000000 |

| 9/16" | 1 3/16" | 1" | 3 3/8" | 35° | 1,500 | 1,900 | 365 in.-lbs. @ 300 rpm | 235 in.-lbs. @ 300 rpm | Pin and Block | Ball-Spring Oil Fitting | MIL-U-20625A Class C | 0000000 | 000000 |

| 5/8" | 1 7/32" | 1 1/8" | 3 1/2" | 35° | 1,500 | 2,200 | Not Rated | Not Rated | Pin and Block | Ball-Spring Oil Fitting | MIL-U-20625A Class C | 0000000 | 000000 |

| 3/4" | 1 1/4" | 1 1/4" | 3 3/4" | 35° | 1,500 | 3,600 | 690 in.-lbs. @ 300 rpm | 450 in.-lbs. @ 300 rpm | Pin and Block | Ball-Spring Oil Fitting | MIL-U-20625A Class C | 0000000 | 000000 |

| 7/8" | 1 5/16" | 1 1/2" | 4 1/4" | 35° | 1,500 | 7,200 | 1,385 in.-lbs. @ 300 rpm | 900 in.-lbs. @ 300 rpm | Pin and Block | Ball-Spring Oil Fitting | MIL-U-20625A Class C | 0000000 | 000000 |

| 1" | 1 9/16" | 1 3/4" | 5" | 35° | 1,500 | 10,700 | Not Rated | Not Rated | Pin and Block | Ball-Spring Oil Fitting | MIL-U-20625A Class C | 0000000 | 000000 |

| 1 3/16" | 1 5/8" | 2" | 5 7/16" | 35° | 1,500 | 15,500 | 2,980 in.-lbs. @ 300 rpm | 1,935 in.-lbs. @ 300 rpm | Pin and Block | Ball-Spring Oil Fitting | MIL-U-20625A Class C | 0000000 | 000000 |