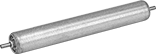

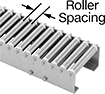

Small-Diameter Conveyor Rollers

Galvanized steel rollers are strong and have some corrosion resistance. Aluminum rollers are lightweight and more corrosion resistant than galvanized steel.

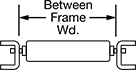

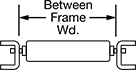

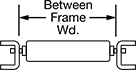

Roller | |||||||

|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Gauge | Cap., lbs. | Overall Wd. | Temp. Range, °F | Each | |

1/4" Round Axle | |||||||

3/4" Dia. Galvanized Steel Roller | |||||||

| 3" | 2 3/4" | 20 | 30 | 3 3/4" | -15° to 220° | 0000000 | 000000 |

| 4" | 3 3/4" | 20 | 30 | 4 3/4" | -15° to 220° | 0000000 | 00000 |

| 4 7/8" | 4 5/8" | 20 | 30 | 5 5/8" | -15° to 220° | 0000000 | 00000 |

| 6" | 5 3/4" | 20 | 30 | 6 3/4" | -15° to 220° | 0000000 | 00000 |

| 7" | 6 3/4" | 20 | 30 | 7 3/4" | -15° to 220° | 0000000 | 00000 |

| 8" | 7 3/4" | 20 | 30 | 8 3/4" | -15° to 220° | 0000000 | 00000 |

| 9" | 8 3/4" | 20 | 30 | 9 3/4" | -15° to 220° | 0000000 | 00000 |

| 10" | 9 3/4" | 20 | 30 | 10 3/4" | -15° to 220° | 0000000 | 00000 |

| 10 3/8" | 10 1/8" | 20 | 30 | 11 1/8" | -15° to 220° | 0000000 | 00000 |

| 11" | 10 3/4" | 20 | 30 | 11 3/4" | -15° to 220° | 0000000 | 00000 |

| 12" | 11 3/4" | 20 | 30 | 12 3/4" | -15° to 220° | 0000000 | 00000 |

| 13" | 12 3/4" | 20 | 30 | 13 3/4" | -15° to 220° | 0000000 | 00000 |

| 13 7/8" | 13 5/8" | 20 | 30 | 14 5/8" | -15° to 220° | 0000000 | 00000 |

| 15" | 14 3/4" | 20 | 30 | 15 3/4" | -15° to 220° | 0000000 | 00000 |

| 16" | 15 3/4" | 20 | 30 | 16 3/4" | -15° to 220° | 0000000 | 00000 |

| 17" | 16 3/4" | 20 | 30 | 17 3/4" | -15° to 220° | 0000000 | 00000 |

| 19" | 18 3/4" | 20 | 30 | 19 3/4" | -15° to 220° | 0000000 | 00000 |

| 20" | 19 3/4" | 20 | 30 | 20 3/4" | -15° to 220° | 0000000 | 00000 |

| 21" | 20 3/4" | 20 | 30 | 21 3/4" | -15° to 220° | 0000000 | 00000 |

| 22" | 21 3/4" | 20 | 30 | 22 3/4" | -15° to 220° | 0000000 | 00000 |

| 23" | 22 3/4" | 20 | 30 | 23 3/4" | -15° to 220° | 0000000 | 00000 |

| 24" | 23 3/4" | 20 | 30 | 24 3/4" | -15° to 220° | 0000000 | 00000 |

| 25" | 24 3/4" | 20 | 30 | 25 3/4" | -15° to 220° | 0000000 | 00000 |

| 26" | 25 3/4" | 20 | 30 | 26 3/4" | -15° to 220° | 0000000 | 00000 |

| 27" | 26 3/4" | 20 | 30 | 27 3/4" | -15° to 220° | 0000000 | 00000 |

| 28" | 27 3/4" | 20 | 30 | 28 3/4" | -15° to 220° | 0000000 | 00000 |

| 29" | 28 3/4" | 20 | 30 | 29 3/4" | -15° to 220° | 0000000 | 00000 |

| 30" | 29 3/4" | 20 | 30 | 30 3/4" | -15° to 220° | 0000000 | 00000 |

3/4" Dia. Aluminum Roller | |||||||

| 3" | 2 3/4" | 20 | 20 | 3 3/4" | -15° to 220° | 0000000 | 00000 |

| 4" | 3 3/4" | 20 | 20 | 4 3/4" | -15° to 220° | 0000000 | 00000 |

| 4 7/8" | 4 5/8" | 20 | 20 | 5 5/8" | -15° to 220° | 0000000 | 00000 |

| 6" | 5 3/4" | 20 | 20 | 6 3/4" | -15° to 220° | 0000000 | 00000 |

| 8" | 7 3/4" | 20 | 20 | 8 3/4" | -15° to 220° | 0000000 | 00000 |

| 10" | 9 3/4" | 20 | 20 | 10 3/4" | -15° to 220° | 0000000 | 00000 |

| 10 3/8" | 10 1/8" | 20 | 20 | 11 1/8" | -15° to 220° | 0000000 | 00000 |

| 12" | 11 3/4" | 20 | 20 | 12 3/4" | -15° to 220° | 0000000 | 00000 |

| 13 7/8" | 13 5/8" | 20 | 20 | 14 5/8" | -15° to 220° | 0000000 | 00000 |

| 16" | 15 3/4" | 20 | 20 | 16 3/4" | -15° to 220° | 0000000 | 00000 |

| 17 7/8" | 17 5/8" | 20 | 20 | 18 5/8" | -15° to 220° | 0000000 | 00000 |

| 20" | 19 3/4" | 20 | 20 | 20 3/4" | -15° to 220° | 0000000 | 00000 |

| 22" | 21 3/4" | 20 | 20 | 22 3/4" | -15° to 220° | 0000000 | 00000 |

| 24" | 23 3/4" | 20 | 20 | 24 3/4" | -15° to 220° | 0000000 | 00000 |

| 26" | 25 3/4" | 20 | 20 | 26 3/4" | -15° to 220° | 0000000 | 00000 |

| 28" | 27 3/4" | 20 | 20 | 28 3/4" | -15° to 220° | 0000000 | 00000 |

Small-Diameter Corrosion-Resistant Conveyor Rollers

Made from stainless steel, these rollers are suitable for washdown applications.

Conveyor Rollers | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Roller | Replacement Bearings | |||||||||

| For Between Frame Wd. | Wd. | Gauge | Cap., lbs. | Overall Wd. | Bearing Material | Temp. Range, °F | Each | Each | ||

1/4" Round Axle | ||||||||||

3/4" Dia. Stainless Steel Roller | ||||||||||

| 3" | 2 1/16" | 16 | 60 | 4" | Plastic | -120° to 215° | 00000000 | 000000 | 000000 | 00 |

| 4" | 3 1/8" | 20 | 20 | 5" | Plastic | 30° to 150° | 0000000 | 00000 | 0000000 | 00000 |

| 4 7/8" | 4" | 20 | 20 | 5 7/8" | Plastic | 30° to 150° | 0000000 | 00000 | 0000000 | 0000 |

| 6" | 5 1/8" | 20 | 20 | 7" | Plastic | 30° to 150° | 0000000 | 00000 | 0000000 | 0000 |

| 8" | 7 1/8" | 20 | 20 | 9" | Plastic | 30° to 150° | 0000000 | 00000 | 0000000 | 0000 |

| 10" | 9 1/8" | 20 | 20 | 11" | Plastic | 30° to 150° | 0000000 | 00000 | 0000000 | 0000 |

| 10 3/8" | 9 1/2" | 20 | 20 | 11 3/8" | Plastic | 30° to 150° | 0000000 | 00000 | 0000000 | 0000 |

| 12" | 11 1/8" | 20 | 20 | 13" | Plastic | 30° to 150° | 0000000 | 00000 | 0000000 | 0000 |

| 13 7/8" | 13" | 20 | 20 | 14 7/8" | Plastic | 30° to 150° | 0000000 | 00000 | 0000000 | 0000 |

| 16" | 15 1/8" | 20 | 20 | 17" | Plastic | 30° to 150° | 0000000 | 00000 | 0000000 | 0000 |

| 17 7/8" | 17" | 20 | 20 | 18 7/8" | Plastic | 30° to 150° | 0000000 | 00000 | 0000000 | 0000 |

| 20" | 19 1/8" | 20 | 20 | 21" | Plastic | 30° to 150° | 0000000 | 00000 | 0000000 | 0000 |

| 22" | 21 1/8" | 20 | 20 | 23" | Plastic | 30° to 150° | 0000000 | 00000 | 0000000 | 0000 |

| 24" | 23 1/8" | 20 | 20 | 25" | Plastic | 30° to 150° | 0000000 | 00000 | 0000000 | 0000 |

| 26" | 25 1/8" | 20 | 20 | 27" | Plastic | 30° to 150° | 0000000 | 00000 | 0000000 | 0000 |

| 28" | 27 1/8" | 20 | 20 | 29" | Plastic | 30° to 150° | 0000000 | 00000 | 0000000 | 0000 |

| 30" | 29 1/8" | 20 | 20 | 31" | Plastic | 30° to 150° | 0000000 | 00000 | 0000000 | 0000 |

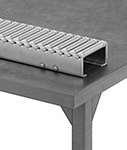

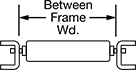

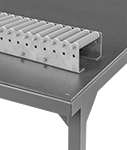

Bench-Top Roller Conveyors

Designed to rest on a work surface, these conveyors have two sets of axle holes so you can position the conveying surface 1/8" above the frame or 3/4" below the frame (position below to use the frame as a guide rail).

Galvanized steel conveyors are stronger than aluminum and have some corrosion resistance.

Aluminum conveyors are lightweight and corrosion resistant.

Note: Capacities are based on an evenly distributed load. The length of the material you're conveying should be at least three times the roller spacing.

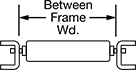

Wd. | Roller | 5 ft. Lg. | 10 ft. Lg. | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Spacing | Projection | Dp. Below Frame | Frame Ht. | Cap., lbs./ft. | Each | Cap., lbs./ft. | Each | ||

3/4" Dia. Galvanized Steel Rollers—1/4" Round Axle | |||||||||||

| 5 3/4" | 4 7/8" | 1" | 1/8" | 3/4" | 2 1/2" | 120 | 0000000 | 0000000 | 35 | 0000000 | 0000000 |

| 5 3/4" | 4 7/8" | 2" | 1/8" | 3/4" | 2 1/2" | 120 | 0000000 | 000000 | 35 | 0000000 | 000000 |

| 11 1/4" | 10 3/8" | 1" | 1/8" | 3/4" | 2 1/2" | 120 | 0000000 | 000000 | 35 | 0000000 | 00000000 |

| 11 1/4" | 10 3/8" | 2" | 1/8" | 3/4" | 2 1/2" | 120 | 0000000 | 000000 | 35 | 0000000 | 000000 |

| 14 3/4" | 13 7/8" | 1" | 1/8" | 3/4" | 2 1/2" | 120 | 0000000 | 000000 | 35 | 0000000 | 00000000 |

| 18 3/4" | 17 7/8" | 1" | 1/8" | 3/4" | 2 1/2" | 120 | 0000000 | 000000 | 35 | 0000000 | 00000000 |

3/4" Dia. Aluminum Rollers—1/4" Round Axle | |||||||||||

| 5 3/4" | 4 7/8" | 1" | 1/8" | 3/4" | 2 1/2" | 100 | 0000000 | 000000 | 25 | 0000000 | 000000 |

| 11 1/4" | 10 3/8" | 1" | 1/8" | 3/4" | 2 1/2" | 100 | 0000000 | 000000 | 25 | 0000000 | 000000 |

| 14 3/4" | 13 7/8" | 1" | 1/8" | 3/4" | 2 1/2" | 100 | 0000000 | 000000 | 25 | 0000000 | 000000 |

| 18 3/4" | 17 7/8" | 1" | 1/8" | 3/4" | 2 1/2" | 100 | 0000000 | 000000 | 25 | 0000000 | 00000000 |

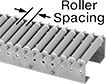

Stainless Steel Bench-Top Roller Conveyors

Push small items from person to person in areas with frequent washdowns. Made of stainless steel with polypropylene bearings, these conveyors won’t rust from exposure to water or chemicals. They’re lightweight and don’t require a power source, so you can set them up on any flat surface to move material over short distances. The rollers convey objects with either flat or uneven bottoms.

Note: Capacities are based on an evenly distributed load. The length of the material you're conveying should be at least three times the roller spacing.

Wd. | Roller | |||||||

|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Spacing | Projection | Dp. Below Frame | Frame Ht. | Cap., lbs./ft. | Each | |

5 ft. Lg. | ||||||||

3/4" Dia. Stainless Steel Rollers—1/4" Round Axle | ||||||||

| 5 7/8" | 4 7/8" | 1" | 1/8" | 3/4" | 2 1/2" | 120 | 0000000 | 000000000 |

| 11 3/8" | 10 3/8" | 1" | 1/8" | 3/4" | 2 1/2" | 120 | 0000000 | 00000000 |

| 14 7/8" | 13 7/8" | 1" | 1/8" | 3/4" | 2 1/2" | 120 | 0000000 | 00000000 |

| 19 7/8" | 17 7/8" | 1" | 1/8" | 3/4" | 2 1/2" | 120 | 0000000 | 00000000 |

10 ft. Lg. | ||||||||

3/4" Dia. Stainless Steel Rollers—1/4" Round Axle | ||||||||

| 5 7/8" | 4 7/8" | 1" | 1/8" | 3/4" | 2 1/2" | 35 | 0000000 | 00000000 |

| 11 3/8" | 10 3/8" | 1" | 1/8" | 3/4" | 2 1/2" | 35 | 0000000 | 00000000 |

| 14 7/8" | 13 7/8" | 1" | 1/8" | 3/4" | 2 1/2" | 35 | 0000000 | 00000000 |

| 19 7/8" | 17 7/8" | 1" | 1/8" | 3/4" | 2 1/2" | 35 | 0000000 | 00000000 |

Abrasion-Resistant Bench-Top Roller Conveyors

|  |

|

Push glass, painted objects, and other delicate material from one workstation to the next. These conveyors rest on a flat surface instead of a stand, and they have PVC rollers that won’t mark or dent your material. They have two sets of axle holes for the rollers, so you can position the conveying surface 1/8" above the frame or 3/4" below. The frame serves as a guide rail when rollers are mounted below it.

Note: Capacities are based on an evenly distributed load. The length of the material you're conveying should be at least three times the roller spacing.

Wd. | Roller | 5 ft. Lg. | 10 ft. Lg. | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Spacing | Projection | Dp. Below Frame | Frame Ht. | Cap., lbs./ft. | Each | Cap., lbs./ft. | Each | ||

0.78" Dia. PVC Plastic Rollers—1/4" Round Axle | |||||||||||

| 5" | 4" | 1" | 1/8" | 3/4" | 2 1/2" | 120 | 0000000 | 0000000 | 35 | 0000000 | 0000000 |

| 9" | 8" | 1" | 1/8" | 3/4" | 2 1/2" | 120 | 0000000 | 000000 | 35 | 0000000 | 00000000 |

| 13" | 12" | 1" | 1/8" | 3/4" | 2 1/2" | 120 | 0000000 | 000000 | 35 | 0000000 | 00000000 |

Protective Covers for Conveyor Rollers

Reduce noise, absorb impact, and extend roller life. The higher the hardness rating, the longer the covers will protect rollers in demanding applications.

Slide-on covers slip over the roller. For easier installation, use lubricant and an air nozzle.

Polyurethane has a high-friction surface for high speeds and inclines.

Lubricant is water based and loses its lubrication properties upon drying to ensure covers retain a snug fit.

Connect air nozzles to a source of compressed air to create a cushion for sliding covers onto the roller.