About On/Off Valves

More

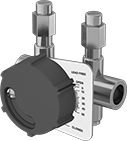

Flow-Indicating Threaded On/Off Valves

- Valve Type: Ball

- For Use With: Argon, Helium, Krypton, Neon, Oil, Steam, Water, Xenon

- Seal Material: Fluoroelastomer Rubber

- Specifications Met: CSA Certified, CSA-US Certified, FM Approved, UL Listed

An easy-to-read flow-indicating handle shows the percentage the valve is open. These valves are full port, so they do not restrict flow. UL Listed for use with liquefied-petroleum gas, they meet U.S. safety standards.

Nickel-plated brass valves are more corrosion resistant than plain brass valves.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | Each | |

Brass Body | ||||||||

|---|---|---|---|---|---|---|---|---|

NPT Female × NPT Female | ||||||||

| 1/4 | 7.7 | 600 psi @ 320° F | 150 psi @ 365° F | -40° to 365° | 29.89 | 1 13/16" | 0000000 | 000000 |

| 3/8 | 7.8 | 600 psi @ 320° F | 150 psi @ 365° F | -40° to 365° | 29.89 | 1 7/8" | 0000000 | 00000 |

| 1/2 | 16.8 | 600 psi @ 235° F | 150 psi @ 365° F | -40° to 365° | 29.89 | 2 1/2" | 0000000 | 00000 |

| 3/4 | 34.8 | 600 psi @ 235° F | 150 psi @ 365° F | -40° to 365° | 29.89 | 2 3/4" | 0000000 | 00000 |

| 1 | 52.2 | 500 psi @ 275° F | 150 psi @ 365° F | -40° to 365° | 29.89 | 3 5/16" | 0000000 | 00000 |

| 1 1/2 | 174 | 500 psi @ 275° F | 150 psi @ 365° F | -40° to 365° | 29.89 | 4 3/16" | 0000000 | 000000 |

| 2 | 255.2 | 500 psi @ 275° F | 150 psi @ 365° F | -40° to 365° | 29.89 | 5" | 0000000 | 000000 |

Nickel-Plated Brass Body | ||||||||

NPT Female × NPT Female | ||||||||

| 1/4 | 7.7 | 600 psi @ 235° F | 150 psi @ 365° F | -40° to 365° | 29.89 | 1 13/16" | 0000000 | 00000 |

| 3/8 | 7.8 | 600 psi @ 235° F | 150 psi @ 365° F | -40° to 365° | 29.89 | 1 7/8" | 0000000 | 00000 |

| 1/2 | 16.8 | 600 psi @ 235° F | 150 psi @ 365° F | -40° to 365° | 29.89 | 2 1/2" | 0000000 | 00000 |

| 3/4 | 34.8 | 600 psi @ 235° F | 150 psi @ 365° F | -40° to 365° | 29.89 | 2 3/4" | 0000000 | 00000 |

| 1 | 52.2 | 500 psi @ 275° F | 150 psi @ 365° F | -40° to 365° | 29.89 | 3 5/16" | 0000000 | 00000 |

| 1 1/2 | 174 | 500 psi @ 275° F | 150 psi @ 365° F | -40° to 365° | 29.89 | 4 3/16" | 0000000 | 000000 |

| 2 | 255.2 | 500 psi @ 275° F | 150 psi @ 365° F | -40° to 365° | 29.89 | 5" | 0000000 | 000000 |

Easy-to-Install Threaded On/Off Valves for Chemicals

For fast installation and removal from pipelines, these valves have union fittings that disassemble into multiple pieces. All have a plastic body that can stand up to aggressive and corrosive solutions in chemical-processing applications.

Flow-indicating T-handles show the percentage the valve is open.

Standard-port valves slightly restrict flow.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Ball

- For Use With: See table

- Ball Material: PVC Plastic

- Seal Material: Fluoroelastomer Rubber

- Seat Material: PTFE Plastic

| Pipe Size | Max. Pressure | Temperature Range, °F | Port Type | End-to-End Lg. | For Use With | Each | |

Threaded Union × Threaded Union with Flow-Indicating T-Handle | |||||||

|---|---|---|---|---|---|---|---|

| 1/2 | 150 psi @ 65° F | 35° to 140° | Standard | 4 1/8" | Ammonia, Butane, Carbon Dioxide, Citric Acid, Hydrochloric Acid, Methanol, Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Salt Water, Sodium Hydroxide, Water | 000000 | 0000000 |

Threaded Balancing Valves

- Valve Type: Ball

- For Use With: Water

- Seal Material: EPDM Rubber

- Specifications Met: CSA Certified

Thread these balancing valves onto pipe—they help you measure the pressure differential across the valve as well as change the flow rate to components in your system. Sometimes called circuit setters, they’re used in HVAC systems and other systems that require even flow distribution. To see what percentage they’re open, there’s an arrow on these valves that’s connected to their measuring plate. Readout ports on both sides let you attach flow measurement tools, such as pressure gauges and probes, which help you track how much the valves reduce flow. Open these valves to a saved percentage by using their memory shutoff function.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Flow Coefficient (Cv) | Maximum Pressure | Temperature Range, °F | End-to-End Length | Each | |

Brass Body | ||||||

|---|---|---|---|---|---|---|

NPT Female × NPT Female | ||||||

| 1/2 | 1.52 | 400 psi @ 250° F | 0° to 250° | 3" | 0000000 | 0000000 |

| 3/4 | 2.75 | 400 psi @ 250° F | 0° to 250° | 3 1/16" | 0000000 | 000000 |

| 1 | 5.75 | 400 psi @ 250° F | 0° to 250° | 3 13/16" | 0000000 | 000000 |

| 1 1/4 | 12.5 | 400 psi @ 250° F | 0° to 250° | 4 7/16" | 0000000 | 000000 |

| 1 1/2 | 19.9 | 400 psi @ 250° F | 0° to 250° | 4 7/16" | 0000000 | 000000 |

| 2 | 40 | 400 psi @ 250° F | 0° to 250° | 5 3/16" | 0000000 | 000000 |

| 2 1/2 | 65 | 400 psi @ 250° F | 0° to 250° | 6" | 0000000 | 000000 |

| 3 | 112 | 400 psi @ 250° F | 0° to 250° | 6 1/2" | 0000000 | 00000000 |

Solder-Connect Balancing Valves

- Valve Type: Ball

- For Use With: Water

- Seal Material: EPDM Rubber

- Specifications Met: CSA Certified

Attach these balancing valves using solder—they help you measure the difference in pressure across the valve and adjust the flow rate to system components. Also known as circuit setters, they’re often used in systems that need an even distribution of flow, such as HVAC systems. To check what percentage they’re open, there’s an arrow on these valves that’s connected to their measuring plate. There are readout ports on both sides for connecting flow measurement tools, such as pressure gauges and probes, which help you track how much the valves reduce flow. Use the memory shutoff function to open them to a saved setting.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | Flow Coefficient (Cv) | Maximum Pressure | Temperature Range, °F | End-to-End Length | Stem Type | Each | |

Brass Body | |||||||

|---|---|---|---|---|---|---|---|

Solder Connect × Solder Connect | |||||||

| 1/2" | 1.75 | 200 psi @ 250° F, 250 psi @ 225° F, 300 psi @ 200° F | 0° to 250° | 2 15/16" | Nonrising | 0000000 | 0000000 |

| 3/4" | 3.4 | 200 psi @ 250° F, 250 psi @ 225° F, 300 psi @ 200° F | 0° to 250° | 3 9/16" | Nonrising | 0000000 | 000000 |

| 1" | 5.75 | 200 psi @ 250° F, 250 psi @ 225° F, 300 psi @ 200° F | 0° to 250° | 4 5/16" | Nonrising | 0000000 | 000000 |

Easy-to-Install Plastic Threaded Flow-Adjustment Valves

- Valve Type: Ball

- For Use With: Ammonia, Carbon Dioxide, Citric Acid, Methanol, Nitrogen, Oxygen, Salt Water, Water

- Seal Material: EPDM Rubber

A threaded union on these valves makes them easy to install and remove without disrupting your line. They’re a good choice for lines that require frequent maintenance or cleaning. They thread together or apart with only a turn to the union fitting, unlike other threaded flow-adjustment valves that require repositioning your pipe or valve. The union fitting slides over your pipe, and the threaded fitting sits inside. Ideal for metering, sampling, and other applications, these valves gradually open and close to adjust flow as you turn the handle. A dial displays the percentage you’ve opened them. With a standard port, they’ll slightly restrict flow even when fully open. These valves come with socket-connect fittings for making threaded-to-threaded connections or adapting threaded to socket connections.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Port Type | End-to-End Lg. | Includes | Each | |

Dark Gray PVC Plastic Body | ||||||||

|---|---|---|---|---|---|---|---|---|

NPT Female × NPT Female | ||||||||

| 1/2 | 1.4 | 150 psi @ 65° F | 35° to 140° | Standard | 4 1/8" | Socket-Connect Connectors | 000000 | 0000000 |

Dual Shut-Off Threaded Diverting Valves

Female x Male x Male |  Female x Female x Female |

|

- Valve Type: Ball

- For Use With:

NPT Female × NPT Female × NPT Female: Air, Water

NPT Female × NPT Male × NPT Male: Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon - Seal Material: PTFE Plastic

Control flow in two directions from a single source—these valves have two handles for independent operation of each outlet. They can direct flow from the center-port inlet to one side-port outlet at full capacity, direct flow to both side-port outlets simultaneously at reduced capacity, or shut off flow to both outlet ports completely. Valves are standard port, so they slightly restrict flow.

For technical drawings and 3-D models, click on a part number.

| Inlet Pipe Size | Outlet Pipe Sizes | Flow Pattern | Max. Pressure | Temp. Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | Each | |

Brass Body | ||||||||

|---|---|---|---|---|---|---|---|---|

NPT Female × NPT Male × NPT Male | ||||||||

| 1 | 3/4 × 3/4 | Y-Pattern | 600 psi @ 200° F | -40° to 365° | 29 | 3 1/4" | 0000000 | 000000 |

Bronze Body | ||||||||

NPT Female × NPT Female × NPT Female | ||||||||

| 1 | 3/4 × 3/4 | Y-Pattern | 550 psi @ 150° F | Not Rated | 29 | 3 7/16" | 0000000 | 000000 |

| 1 1/4 | 3/4 × 3/4 | Y-Pattern | 550 psi @ 150° F | Not Rated | 29 | 3 7/16" | 0000000 | 000000 |