About Paint and Ink Markers

Paint markers work well even on dirty, rusty, wet, and oily surfaces. They leave textured marks you can feel with your hand.

Ink markers work best on a clean, dry surface. Marks dry faster than paint and are smooth to the touch.

Both paint and ink markers are permanent.

More

About Selecting Pipe Markers

More

Paint Markers

Choose only the colors you need. These paint markers work well even on dirty, rusty, and oily surfaces.

Paint Crayons

These paint crayons work well even on dirty, rusty, and oily surfaces.

Optional holder makes it easier to write and keeps the crayon from drying out.

NEMA-Color Assorted-Character Slip-On Wire Markers

Slip these markers onto wires that are open on one end. They come furnished on dispensers for easy storage and installation. Place the dispenser over the end of a wire and slip the marker onto it. Each color comes on its own dispenser. They correspond to the following international color code for numbering: black (0), brown (1), red (2), orange (3), yellow (4), green (5), blue (6), purple (7), gray (8), and white (9). Gray, orange, white, and yellow markers have black characters. Black, blue, brown, green, purple, and red markers have white characters.

For Wire | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Character | Quantity of Each Marker | Gauge | OD | Color (Message Color) | Material | Includes | Pkg. Qty. | Pkg. | |

| 0-9 | 25 | 16-9 | 0.05"-0.12" | Gray/Orange/White/Yellow (Black); Black/Blue/Brown/Green/Purple/Red (White) | PVC Plastic | Dispensers | 250 | 0000000 | 000000 |

| 0-9 | 25 | 10-4 | 0.1"-0.2" | Gray/Orange/White/Yellow (Black); Black/Blue/Brown/Green/Purple/Red (White) | PVC Plastic | Dispensers | 250 | 0000000 | 00000 |

NEMA-Color Assorted-Character Slip-On Wire Markers with Holder

Keep wire markers organized and ready for use. The holder comes with 20 dispensers for easy installation; two for each color. Place the dispenser over the end of a wire and slip the marker onto it. Markers correspond to the following international color code for numbering: black (0), brown (1), red (2), orange (3), yellow (4), green (5), blue (6), purple (7), gray (8), and white (9). Gray, orange, white, and yellow markers have black characters. Black, blue, brown, green, purple, and red markers have white characters.

For Wire | Holder | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Character | Quantity of Each Marker | Gauge | OD | Dia. | Material | Overall Lg. | Color (Message Color) | Material | Includes | Each | |

| 0-9 | 50 | 16-9 | 0.05"-0.12" | 2 1/4" | Plastic | 6" | Gray/Orange/White/Yellow (Black); Black/Blue/Brown/Green/Purple/Red/White (White) | PVC Plastic | Dispensers, Belt Loop Hook | 0000000 | 000000 |

| 0-9 | 50 | 10-4 | 0.1"-0.2" | 2 1/4" | Plastic | 6" | Gray/Orange/White/Yellow (Black); Black/Blue/Brown/Green/Purple/Red/White (White) | PVC Plastic | Dispensers, Belt Loop Hook | 0000000 | 00000 |

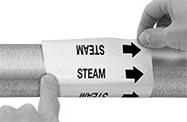

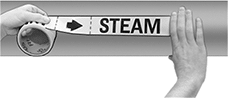

Adhesive-Back Pipe Markers

Apply directly onto clean, dry pipes for clear identification of contents.

Style A have an alternating message. Wrap them around the pipe and you can read the contents whether the arrow points left or right.

Style B have a removable arrow; apply the message to a pipe and then turn the arrow to match your system’s flow direction. For a more secure hold, pair these with pipe marker tape—just layer the tape over the edge of your markers then wrap it around the full diameter of a pipe.

Pipe markers that meet ASME A13.1 adhere to requirements that, for a given pipe size, they have the proper minimum character height, identify contents with a message, indicate flow direction with an arrow, and designate hazardous classifications with a specific marker color. For messages with multiple marker color options, choose the color that best identifies the hazardous properties of the contents according to the ASME designations.

Pipe markers that meet CGA-9 standards adhere to strict requirements for color and message uniformity to identify gas lines and equipment in medical and pharmaceutical industries. When placed according to NFPA 99 standards, they also help you meet safety standards for medical gases in your facility.

For technical drawings and 3-D models, click on a part number.

| Style | For Pipe OD | Flow-Direction Arrow | Character Ht. | Ht. | Wd. | Thick. | Material | Temp. Range, °F | Specifications Met | Pkg. Qty. | Pkg. | |

Helium (English)—Brown with White Message | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 1/4"-3/4" | Yes | 1/4" | 3" | 3" | 0.004" | Vinyl Plastic | -50° to 180° | ASME A13.1, CGA C-9, NFPA 99 | 5 | 000000000 | 00000 |

| B | 3/4"-2" | Yes | 3/4" | 1" | 8" | 0.005" | Vinyl Plastic | 32° to 140° | CGA C-9, NFPA 99 | 10 | 000000000 | 0000 |

| B | 2 1/4"-7 7/8" | Yes | 1 1/4" | 2" | 12" | 0.005" | Vinyl Plastic | 32° to 140° | CGA C-9, NFPA 99 | 10 | 000000000 | 00000 |

Made-to-Order Adhesive-Back Pipe Markers

Specify the message you need to label the contents of a pipe (two lines maximum, up to 28 characters per line, including spaces). Apply these markers directly onto clean, dry pipes.

Wraparound-mount markers are secured in place with an included adhesive strip.

Adhesive-back only markers can be paired with pipe marker tape for a more secure hold. Just stick the tape over the edge of your marker then wrap it around the full diameter of the pipe. These markers don't have flow arrows—use them with flow arrow pipe markers to indicate flow and meet ASME A13.1.

For technical drawings and 3-D models, click on a part number.

| For Pipe OD | Character Ht. | Ht. | Wd. | Thick. | Flow-Direction Arrow | Mount Type | Material | Temp. Range, °F | Pkg. Qty. | Pkg. | |

Brown with White Message | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/4"-3/4" | 1/4" | 3" | 3" | 0.004" | Yes | Adhesive Back, Wraparound | Vinyl Plastic | -40° to 170° | 10 | 00000000 | 000000 |

| 3/4"-2 1/4" | 3/4" | 2" | 8" | 0.004" | No | Adhesive Back | Vinyl Plastic | -40° to 170° | 10 | 00000000 | 00000 |

| 2 1/2"-7 7/8" | 1 3/4" | 2 1/4" | 13" | 0.004" | No | Adhesive Back | Vinyl Plastic | -40° to 170° | 5 | 00000000 | 00000 |

| 8"-10" | 2 1/2" | 4" | 24" | 0.004" | No | Adhesive Back | Vinyl Plastic | -40° to 170° | 1 | 00000000 | 0000 |

Flow Arrow Pipe Marker Tape

Secure peeling edges of adhesive pipe markers. For the most secure hold, layer this tape over the edge of your pipe markers then wrap it around the full diameter of a pipe. Printed arrows on the tape's surface indicate the flow direction of your pipe's contents. Also known as pipe banding tape.

For technical drawings and 3-D models, click on a part number.

Roll | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Pipe OD | Wd. | Thick. | Lg., ft. | ID | Arrow Spacing | Material | Temp. Range, °F | Specifications Met | Color | Message Color | Each | |

| 3/4"-2" | 1" | 0.004" | 108 | 3" | 2 3/4" | Vinyl Plastic | -50° to 140° | ASME A13.1 | Brown | White | 0000000 | 000000 |

Pipe Marker Tape

Also known as pipe banding tape, use this tape to secure peeling edges of adhesive pipe markers. For the most secure hold, layer this tape over the edge of your pipe markers then wrap it around the full diameter of a pipe.

For technical drawings and 3-D models, click on a part number.

Choose-a-Color Cable Ties

Identify bundles at a glance.

Narrow ties are highly flexible and conform to irregularly shaped material better than standard and wide cable ties.

Standard ties balance flexibility and strength, making them good for most bundling applications.

Wide ties are stronger but less flexible than narrow and standard cable ties. Use them for heavy duty applications that require extra strength.

For technical drawings and 3-D models, click on a part number.

Pkg. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | For Max. Bundle Dia. | Breaking Strength, lbs. | Wd. | Thick. | For Use Outdoors | Temp. Range, °F | Color | Pkg. Qty. | 1-9 | 10-Up | |

Solid—Nylon Plastic | |||||||||||

Narrow | |||||||||||

| 7 7/8" | 2" | 18 | 0.10" | 0.04" | No | -40° to 180° | Brown | 100 | 000000000 | 00000 | 00000 |

Standard | |||||||||||

| 5 1/2" | 1 1/4" | 40 | 0.14" | 0.05" | No | -40° to 180° | Brown | 100 | 000000000 | 0000 | 0000 |

| 11 3/4" | 2 7/8" | 50 | 0.19" | 0.05" | No | -40° to 180° | Brown | 100 | 000000000 | 00000 | 00000 |

Wide | |||||||||||

| 14 3/4" | 4" | 120 | 0.30" | 0.08" | No | -40° to 180° | Brown | 25 | 00000000 | 0000 | 0000 |

Choose-a-Color Reusable Cable Ties

Use different colored ties to identify bundles at a glance. A release tab makes these ties easy to remove and use again. Since the head sticks out, you can squeeze the tab and pull to release with one hand, even while wearing gloves. Tuck the excess tail into the slot to avoid having to cut it, which can leave sharp edges that may nick you.

For technical drawings and 3-D models, click on a part number.

| Lg. | For Max. Bundle Dia. | Breaking Strength, lbs. | Width | Thickness | For Use Outdoors | Specifications Met | Temp. Range, °F | Features | Color | Pkg. Qty. | Pkg. | |

Squeeze Release—Nylon Plastic | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Narrow | ||||||||||||

| 6" | 1 7/16" | 18 | 0.09" | 0.04" | Yes | UL 62275 Type 21, UL 94 V-2 | -40° to 180° | Tuck-Back Head | Brown | 100 | 0000000 | 000000 |

Choose-a-Color Fine-Adjustment Cable Tie Assortments

The cable ties in these assortments have a smooth body and metal-toothed head, so they cinch close to your bundle. They include different colors to help you identify bundles, equipment, and materials at a glance.

For technical drawings and 3-D models, click on a part number.

| Total No. of Pieces | Includes | For Use Outdoors | Specifications Met | Temp. Range, °F | Color | Each | |

Nylon Plastic | |||||||

|---|---|---|---|---|---|---|---|

| 100 | 10 narrow cable ties of each color—3" Lg. x 0.09" Wd. (for 5/8" max. bundle dia., 17 lbs. breaking strength) | No | UL 62275 Type 2, UL 62275 Type 21, UL 94 V-2 | -40° to 180° | Black, Blue, Brown, Gray, Green, Orange, Purple, Red, White, Yellow | 0000000 | 000000 |

| 100 | 10 standard cable ties of each color—5" Lg. x 0.14" Wd. (for 1 3/8" max. bundle dia., 40 lbs. breaking strength) | No | UL 62275 Type 2, UL 62275 Type 21, UL 94 V-2 | -40° to 180° | Black, Blue, Brown, Gray, Green, Orange, Purple, Red, White, Yellow | 0000000 | 00000 |

| 100 | 10 standard cable ties of each color—7" Lg. x 0.19" Wd. (for 1 7/8" max. bundle dia., 49 lbs. breaking strength) | No | UL 62275 Type 21S, UL 62275 Type 2S, UL 94 V-2 | -40° to 180° | Black, Blue, Brown, Gray, Green, Orange, Purple, Red, White, Yellow | 0000000 | 00000 |

| 100 | 10 standard cable ties of each color—14" Lg. x 0.19" Wd. (for 4" max. bundle dia., 49 lbs. breaking strength) | No | UL 62275 Type 21S, UL 62275 Type 2S, UL 94 V-2 | -40° to 180° | Black, Blue, Brown, Gray, Green, Orange, Purple, Red, White, Yellow | 0000000 | 00000 |

Choose-a-Color Identification Bands for Hose and Tube

Color code hose and tube lines in your facility to identify them at a glance. Fit these bands around lines up to 6” in diameter. They require an installation tool (sold separately) to secure them.

For technical drawings and 3-D models, click on a part number.