About Hammers

More

Manual Tools for Blind Rivets

This tool has changeable nosepieces—use the nosepiece that matches your rivet's diameter. To install a rivet, insert the mandrel into the nosepiece of the tool. Place the rivet in the material and squeeze the handles. The tool pulls the mandrel through the rivet's body, creating a secure hold on both sides of the material, and breaks off the excess mandrel.

Nose | |||||

|---|---|---|---|---|---|

| Dia. | Lg. | Lg. | Includes | Each | |

| 3/4" | 1" | 9 1/2" | Four nosepieces (3/32", 1/8", 5/32", and 3/16") | 0000000 | 000000 |

| Retaining Screw for Jaw Pusher Spring | 00000000 | Each | 00000 |

| 3/32", 1/8", 5/32", 3/16" Jaw Pusher Spring | 00000000 | Each | 000 |

| 5/32" Nosepiece | 00000000 | Each | 0000 |

| 1/8" Nosepiece | 00000000 | Each | 0000 |

| Jaw Pusher | 00000000 | Each | 0000 |

| Opening Spring | 00000000 | Each | 000 |

| 3/32", 1/8", 5/32", 3/16" Jaw (Two Jaw Parts) | 00000000 | Each | 0000 |

| 3/16" Nosepiece | 00000000 | Each | 0000 |

| 3/32" Nosepiece | 00000000 | Each | 0000 |

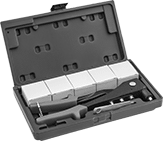

Manual Tool and Blind Rivet Kits

Kit includes a tool and domed and flush-mount rivets for 0.063"-0.125" and 0.188"-0.25" material thickness ranges. The tool has changeable nosepieces—use the nosepiece that matches your rivet's diameter. To install a rivet, insert the mandrel into the nosepiece of the tool. Place the rivet in the material and squeeze the handles. The tool pulls the mandrel through the rivet's body, creating a secure hold on both sides of the material, and breaks off the excess mandrel.

Nose | |||||

|---|---|---|---|---|---|

| Dia. | Lg. | Lg. | Includes | Each | |

| 5/8" | 1" | 9 1/2" | 25 aluminum with steel mandrel domed rivets for 0.020”-0.125” thickness (3/16” dia.) 25 steel flush-mount rivets for 0.188”-0.250” thickness (1/8” dia.) 50 aluminum domed rivets for 0.063”-0.125” thickness (1/8” dia.) 50 steel domed rivets for 0.063”-0.125” thickness (1/8” dia.) 50 steel domed rivets for 0.188”-0.250” thickness (1/8” dia.) Four nosepieces (3/32", 1/8", 5/32", and 3/16") | 0000000 | 000000 |

| 3/32" Nosepiece | 00000000 | Each | 00000 |

| Opening Spring | 00000000 | Each | 000 |

| 1/8" Nosepiece | 00000000 | Each | 0000 |

| 3/16" Nosepiece | 00000000 | Each | 0000 |

| Jaw Pusher Spring | 00000000 | Each | 000 |

| 5/32" Nosepiece | 00000000 | Each | 0000 |

| Retaining Screw for Jaw Pusher Spring | 00000000 | Each | 0000 |

| Jaw Pusher | 00000000 | Each | 0000 |

| Jaw (Two Jaw Parts) | 00000000 | Each | 0000 |

Comfort-Grip Manual Tools for Blind Rivets

Contoured handles provide comfort and a secure grip. This tool has changeable nosepieces—use the nosepiece that matches your rivet's diameter. To install a rivet, insert the mandrel into the nosepiece of the tool. Place the rivet in the material and squeeze the handles. The tool pulls the mandrel through the rivet's body, creating a secure hold on both sides of the material, and breaks off the excess mandrel.

3/32" nosepiece (sold separately) is required to install 3/32" dia. blind rivets.

Nose | |||||

|---|---|---|---|---|---|

| Dia. | Lg. | Lg. | Includes | Each | |

| 13/16" | 1 1/4" | 10" | Three nosepieces (1/8", 5/32", and 3/16") | 0000000 | 000000 |

360° Swivel-Head Manual Tools for Blind Rivets

Swivel the head to install blind rivets at any angle. This tool has changeable nosepieces—use the nosepiece that matches your rivet's diameter. To install a rivet, insert the mandrel into the nosepiece of the tool. Place the rivet in the material and squeeze the handles. The tool pulls the mandrel through the rivet's body, creating a secure hold on both sides of the material, and breaks off the excess mandrel.

Nose | |||||

|---|---|---|---|---|---|

| Dia. | Lg. | Lg. | Includes | Each | |

| 7/8" | 1" | 11" | Four nosepieces (3/32", 1/8", 5/32", and 3/16") | 000000000 | 000000 |

Manual Tools for Plastic Blind Rivets

Nose | ||||||

|---|---|---|---|---|---|---|

| For Blind Rivet Type | For Rivet Dia. | Dia. | Lg. | Lg. | Each | |

| Standard | 0.157", 0.195", 0.197", 0.236", 0.246" | 7/8" | 2 1/2" | 6 1/2" | 000000000 | 000000 |

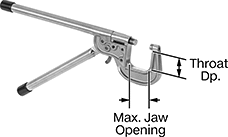

Extra-Leverage Manual Tools for Blind Rivets

Long handles provide additional leverage to install large-diameter rivets. They also extend your reach to access areas other tools can't. This tool has changeable nosepieces—use the nosepiece that matches your rivet's diameter. To install a rivet, insert the mandrel into the nosepiece of the tool. Place the rivet in the material and squeeze the handles. The tool pulls the mandrel through the rivet's body, creating a secure hold on both sides of the material, and breaks off the excess mandrel.

1/8" nosepiece (sold separately) is required to install 1/8" dia. blind rivets.

Optional nose extension (sold separately) adds 2 1/2" of reach.

Nose | |||||

|---|---|---|---|---|---|

| Dia. | Lg. | Lg. | Includes | Each | |

| 1" | 2 1/2" | 21" | Three nosepieces (5/32", 3/16", and 1/4") | 000000000 | 0000000 |

Mandrel-Collecting Extra-Leverage Manual Tools for Blind Rivets

A built-in receptacle collects spent mandrels. This tool has long handles for additional leverage to install large-diameter rivets. They also extend your reach to access areas other tools can't. The nosepieces are changeable—use the nosepiece that matches your rivet's diameter. To install a rivet, insert the mandrel into the nosepiece of the tool. Place the rivet in the material and squeeze the handles. The tool pulls the mandrel through the rivet's body, creating a secure hold on both sides of the material, and breaks off the excess mandrel.

1/8" nosepiece (sold separately) is required to install 1/8" dia. blind rivets.

Optional nose extension (sold separately) adds 2 1/2" of reach.

Nose | |||||

|---|---|---|---|---|---|

| Dia. | Lg. | Lg. | Includes | Each | |

| 1" | 2 1/2" | 21" | Three nosepieces (5/32", 3/16", and 1/4") | 000000000 | 0000000 |

Easy-Squeeze Manual Tools for Blind Rivets

Install rivets with up to 40% less force than other manual tools. This tool has changeable nosepieces—use the nosepiece that matches your rivet's diameter. To install a rivet, insert the mandrel into the nosepiece of the tool. Place the rivet in the material and squeeze the handles. The tool pulls the mandrel through the rivet's body, creating a secure hold on both sides of the material, and breaks off the excess mandrel.

3/32" nosepiece (sold separately) is required to install 3/32" dia. blind rivets.

Nose | |||||||

|---|---|---|---|---|---|---|---|

| Dia. | Lg. | Lg. | Ht. | Features | Includes | Each | |

| 1" | 1 1/2" | 8 1/4" | 8 1/2" | Mandrel Collector | Three nosepieces (1/8", 5/32", and 3/16") | 000000000 | 0000000 |

Nosepieces, Jaws, and Replacement Parts for Blind Rivet Tools

| For Manufacturer Model Number | For Rivet Dia. | Each | |

For Marson Tools | |||

|---|---|---|---|

| Big Daddy, Big Daddy II | 1/8" | 000000000 | 00000 |

| Big Daddy, Big Daddy II | 5/32" | 000000000 | 0000 |

| Big Daddy, Big Daddy II | 3/16" | 000000000 | 0000 |

| Big Daddy, Big Daddy II | 1/4" | 000000000 | 0000 |

| Klik-Fast HP-2 | 3/32" | 00000000 | 0000 |

| Klik-Fast HP-2 | 1/8" | 00000000 | 0000 |

| Klik-Fast HP-2 | 5/32" | 00000000 | 0000 |

| Klik-Fast HP-2 | 3/16" | 00000000 | 0000 |

For Huck Tools | |||

| HK-150C | 3/32", 1/8" | 0000000 | 0000 |

| HK-150C | 5/32", 3/16" | 00000000 | 0000 |

| HK-150C | 1/4" | 0000000 | 00000 |

For Gesipa Tools | |||

| Flipper, NTX-F | 3/32" | 00000000 | 00000 |

| Flipper, NTX-F | 1/8" | 00000000 | 00000 |

| Flipper, NTX-F | 5/32" | 00000000 | 00000 |

| Flipper, NTX-F | 3/16" | 00000000 | 00000 |

| For Manufacturer Model Number | Lg. | Each | |

For Marson Tools | |||

|---|---|---|---|

| Big Daddy, Big Daddy II | 4 13/16" | 000000000 | 000000 |

| For Manufacturer Model Number | Lg. | Each | |

For Marson Tools | |||

|---|---|---|---|

| Big Daddy, Big Daddy II | 2 5/16" | 000000000 | 000000 |

| For Manufacturer Model Number | Each | |

For Marson Tools | ||

|---|---|---|

| Klik-Fast HP-2 | 00000000 | 00000 |

Removal Tools for Push-In Rivets

Slide these tools under the head of plastic push-in rivets and squeeze the handles to pop the rivet out. They are also known as panel clip pliers.

| Lg. | Wd. | Ht. | Max. Jaw Opening | Material | Grip Material | Each | |

| 9" | 2 1/2" | 4 1/2" | 1 1/2" | Steel | Rubber | 000000000 | 000000 |

Tools for Hollow Rivets

One of these tools and a hammer are all you need to expand the base of hollow (tubular) and hollow-end (semi-tubular) rivets. Place the tool over the hollow end of the rivet, then strike with a hammer. The rivet’s end will flare out to fasten your material.

For technical drawings and 3-D models, click on a part number.

| For Rivet Dia. | For Rivet Material | Dia. | Lg. | Material | Each | |

| 1/16" | Aluminum, Steel, Copper, Brass | 5/16" | 3 1/2" | Steel | 00000000 | 000000 |

| 0.087" | Aluminum, Steel, Copper, Brass | 3/8" | 4 1/4" | Steel | 00000000 | 00000 |

| 1/8" | Aluminum, Steel, Copper, Brass | 3/8" | 4 1/4" | Steel | 000000 | 00000 |

| 9/64" | Aluminum, Steel, Copper, Brass | 1/2" | 5" | Steel | 000000 | 00000 |

| 5/32" | Aluminum, Steel, Copper, Brass | 1/2" | 5" | Steel | 000000 | 00000 |

| 3/16" | Aluminum, Steel, Copper, Brass | 1/2" | 5" | Steel | 000000 | 00000 |

| 7/32" | Aluminum, Steel, Copper, Brass | 1/2" | 5" | Steel | 000000 | 00000 |

| 1/4" | Aluminum, Steel, Copper, Brass | 1/2" | 5" | Steel | 000000 | 00000 |

| 5/16" | Aluminum, Steel, Copper, Brass | 5/8" | 5" | Steel | 000000 | 00000 |

Bucking Bars

Place against the back side of your rivet while hammering the head.

For technical drawings and 3-D models, click on a part number.

Solid Rivet Cutters

Trim solid rivets to the length you need without changing their shape. For clean, uniform cuts, you can choose a length from 1/4" to 3/4" in 1/16" increments.

| For Rivet Dia. | Cut Lg. | Overall Lg. | Material | Handle Color | Grip Material | Each | |

For Use On Aluminum | |||||||

|---|---|---|---|---|---|---|---|

| 3/32", 1/8", 5/32", 3/16", 7/32", 1/4" | 1/4"-3/4" | 9 1/2" | Steel | Red | Plastic | 0000000 | 000000 |

Tools for Solid Rivets with Washer

Set solid copper rivets with washer (also known as belt rivets) using one of these tools and a hammer. Press the washer into place, then strike the end of the tool to clinch the back of the rivet tight with the washer.

| For Rivet Size | For Rivet Dia. | For Rivet Material | Setter Hole Dia. | Lg. | Material | Each | |

| No. 3 | 0.28"-0.307" | Copper | 0.312" | 4 1/2" | Steel | 0000000 | 000000 |

| No. 4, No. 5 | 0.233"-0.275" | Copper | 0.281" | 4 1/2" | Steel | 0000000 | 00000 |

| No. 6 | 0.212"-0.229" | Copper | 0.234" | 4 1/2" | Steel | 0000000 | 00000 |

| No. 7 | 0.19"-0.209" | Copper | 0.213" | 4 1/2" | Steel | 0000000 | 00000 |

| No. 8 | 0.165"-0.187" | Copper | 0.191" | 4 1/2" | Steel | 0000000 | 00000 |

| No. 9, No. 10 | 0.148"-0.163" | Copper | 0.166" | 4 1/2" | Steel | 0000000 | 00000 |

| No. 11 | 0.14"-0.146" | Copper | 0.149" | 4 1/2" | Steel | 0000000 | 00000 |

| No. 12 | 0.124"-0.138" | Copper | 0.14" | 4 1/2" | Steel | 0000000 | 00000 |

| No. 13 | 0.108"-0.123" | Copper | 0.125" | 4 1/2" | Steel | 0000000 | 00000 |

| No. 14 | 0.098"-0.107" | Copper | 0.109" | 4 1/2" | Steel | 0000000 | 00000 |

Manual Squeeze Tools for Solid Rivets

Squeeze the handles to set solid aluminum rivets. The head rotates 360° for installation from any angle. Do not use these tools with steel or stainless steel rivets.

| For Max. Domed Rivet Lg. | For Max. Flat Rivet Lg. | Max. Jaw Opening | Lg. | Handle Lg. | Wt., lbs. | Material | Includes | Each | |

| 1.65" | 1.713" | 2" | 15 1/2" | 9 1/2" | 3 | Stainless Steel | 11 Piece Die Set | 0000000 | 0000000 |

| For Max. Domed Rivet Lg. | For Max. Flat Rivet Lg. | Max. Jaw Opening | Lg. | Handle Lg. | Wt., lbs. | Material | Includes | Each | |

| 7/8" | 15/16" | 1 3/8" | 15 1/2" | 9 1/2" | 6 | Stainless Steel | 11 Piece Die Set | 0000000 | 0000000 |

Tools for Blind Rivets and Rivet Nuts

This tool has changeable nosepieces, anvils, and pull-up studs for installing rivets and rivet nuts. A self-contained hydraulic system delivers additional force to make installation easier. Choose the attachment that matches your rivet's diameter or nut thread size. To install a rivet, insert the mandrel into the nosepiece of the tool. Place the rivet in the material and squeeze the handles. The tool pulls the mandrel through the rivet's body, creating a secure hold on both sides of the material, and breaks off the excess mandrel.

Pull-up studs and driving anvils for 6-32 to 3/8"-16 and M3 to M10 rivet nuts are sold separately.

For technical drawings and 3-D models, click on a part number.

Nose | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Lg. | Lg. | Ht. | For Rivet Nut Thread Size | For Rivet Nut Body Type | For Rivet Nut Material | Hydraulic Oil Included | Includes | Each | |

| 1 1/16" | 2 1/4" | 9 1/2" | 6 3/8" | 1/4"-20, 1/4"-28, 10-24, 10-32, 3/8"-16, 5/16"-18, 6-32, 8-32, M10, M3, M4, M5, M6, M8 | Bulbed, Sleeve, Smooth, Hex, Ribbed | Aluminum, Steel | Yes | Five nosepieces (3/32", 1/8", 5/32", 3/16", and 1/4") Two anvils (10-24 and 1/4"-20) Two pull-up studs (10-24 and 1/4"-20) | 0000000 | 0000000 |

| For Rivet Nut Thread Size | Lg. | Each | |

| 6-32 | 1 9/16" | 00000000 | 000000 |

| 8-32 | 1 1/4" | 00000000 | 00000 |

| 10-24 | 1 1/2" | 00000000 | 00000 |

| 10-32 | 1 1/2" | 00000000 | 00000 |

| 1/4"-20 | 1 13/16" | 00000000 | 00000 |

| 1/4"-28 | 1 1/2" | 00000000 | 00000 |

| 5/16"-18 | 2 1/8" | 00000000 | 00000 |

| 3/8"-16 | 2 1/8" | 0000000 | 00000 |

| M3 | 1 1/2" | 0000000 | 00000 |

| M4 | 1 7/16" | 00000000 | 00000 |

| M5 | 1 3/8" | 00000000 | 00000 |

| M6 | 1 13/16" | 00000000 | 00000 |

| M8 | 2" | 00000000 | 00000 |

| M10 | 1 7/16" | 00000000 | 00000 |

Riveting Hammers

Set solid rivets by hand. These tools are also known as paneing, setting, and seaming hammers. Use the flat end of the head to drive rivets and pins. The other end of the head has a wedge shape for creating corners and seams in sheet metal. For replacement handles, see Hickory Hammer Handles.

Hickory handles resist vibration. Steel handles are stronger than hickory handles but have less vibration resistance. Fiberglass handles combine the strength of steel with the vibration resistance of hickory.

Textured grips provide slip resistance.

| Head Wt., lbs. | Face Dia. | Face Lg. | Face Wd. | Overall Lg. | Face Material | Handle Replaceable | Each | ||

Hickory Handle with Plain Grip | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| A | 1/2 | 11/16" | __ | __ | 11" | Steel | Replaceable | 000000 | 000000 |

| A | 3/4 | 13/16" | __ | __ | 13 1/2" | Steel | Replaceable | 000000 | 00000 |

| A | 1 | 7/8" | __ | __ | 14" | Steel | Replaceable | 000000 | 00000 |

| B | 1 | __ | 13/16" | 13/16" | 13 1/2" | Steel | Replaceable | 000000 | 00000 |

Steel Handle with Textured Grip | |||||||||

| C | 3/4 | __ | 13/16" | 3/4" | 11" | Steel | Nonreplaceable | 000000 | 00000 |

| C | 1 1/4 | __ | 15/16" | 7/8" | 12" | Steel | Nonreplaceable | 000000 | 00000 |

Fiberglass Handle with Textured Grip | |||||||||

| D | 1 | 1" | __ | __ | 12 1/2" | Steel | Nonreplaceable | 0000000 | 00000 |