How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

How to Measure Threaded Pipe Size

More

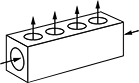

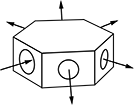

Right-Angle Flow Rectangular Manifolds

Distribute air or fluid to multiple locations from a single supply source with these manifolds. They are also known as headers. They have mounting holes, so you can mount from the top or side.

Aluminum manifolds are the industry standard for the most common types of applications. They are lighter in weight than other metal manifolds and have good corrosion resistance. Anodized aluminum manifolds have a black finish and nickel-plated aluminum manifolds have a shiny finish.

Stainless steel manifolds have the best corrosion resistance of all our metal manifolds. They can handle a wider temperature range than other plastic and metal manifolds. 316 stainless steel manifolds have better corrosion resistance than 303 stainless steel manifolds to handle fuel and gasoline in addition to coolant and other harsh substances.

Use a plug (sold separately) to close off any unused inlets and outlets.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water, Hydraulic Fluid

- Temperature Range: -65° to 250° F

- Maximum Pressure:

Air: 1,000 psi @ 72° F

Water: 1,000 psi @ 72° F

Hydraulic Fluid: 3,000 psi @ 72° F - Maximum Vacuum: 27 in. of Hg @ 72° F

Inlet | Outlet | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Pipe Size | Dash Size | Pipe Size | Dash Size | Lg. | Wd. | Ht. | Outlet Ctr.-to-Ctr. | Color | Each | |

Outlets on One Side—Standard Outlet Spacing | |||||||||||

| 2 | 1/4 | 04 | 1/8 | 02 | 1 3/4" | 1" | 1" | 3/4" | Black | 00000000 | 000000 |

| 3 | 1/4 | 04 | 1/8 | 02 | 2 1/2" | 1" | 1" | 3/4" | Black | 00000000 | 00000 |

| 3 | 3/8 | 06 | 1/4 | 04 | 3" | 1 1/4" | 1 1/4" | 7/8" | Black | 00000000 | 00000 |

| 3 | 1/2 | 08 | 3/8 | 06 | 3 3/4" | 1 1/2" | 1 1/2" | 1" | Black | 00000000 | 00000 |

| 4 | 1/4 | 04 | 1/8 | 02 | 3 1/4" | 1" | 1" | 3/4" | Black | 00000000 | 00000 |

| 4 | 3/8 | 06 | 1/4 | 04 | 3 7/8" | 1 1/4" | 1 1/4" | 7/8" | Black | 00000000 | 00000 |

| 4 | 1/2 | 08 | 3/8 | 06 | 4 3/4" | 1 1/2" | 1 1/2" | 1" | Black | 00000000 | 00000 |

| 6 | 1/4 | 04 | 1/8 | 02 | 4 3/4" | 1" | 1" | 3/4" | Black | 00000000 | 00000 |

| 6 | 3/8 | 06 | 1/4 | 04 | 5 5/8" | 1 1/4" | 1 1/4" | 7/8" | Black | 00000000 | 00000 |

| 6 | 1/2 | 08 | 3/8 | 06 | 6 3/4" | 1 1/2" | 1 1/2" | 1" | Black | 00000000 | 00000 |

- For Use With: Air, Water, Hydraulic Fluid

- Temperature Range: -65° to 250° F

- Maximum Pressure:

Air: 1,000 psi @ 72° F

Water: 3,000 psi @ 72° F

Hydraulic Fluid: 1,000 psi @ 72° F - Maximum Vacuum: 27 in. of Hg @ 72° F

Inlet | Outlet | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Pipe Size | Dash Size | Pipe Size | Dash Size | Lg. | Wd. | Ht. | Outlet Ctr.-to-Ctr. | Color | Each | |

Outlets on One Side—Standard Outlet Spacing | |||||||||||

| 3 | 1/4 | 04 | 1/8 | 02 | 2 1/2" | 1" | 1" | 3/4" | Black | 00000000 | 000000 |

| 3 | 3/8 | 06 | 1/4 | 04 | 3" | 1 1/4" | 1 1/4" | 7/8" | Black | 00000000 | 00000 |

| 3 | 1/2 | 08 | 3/8 | 06 | 3 3/4" | 1 1/2" | 1 1/2" | 1" | Black | 00000000 | 00000 |

| 3 | 3/4 | 12 | 1/2 | 08 | 5 1/2" | 2" | 2" | 1 1/2" | Black | 00000000 | 00000 |

| 6 | 3/4 | 12 | 1/2 | 08 | 10" | 2" | 2" | 1 1/2" | Black | 00000000 | 000000 |

| 6 | 1 | 16 | 3/4 | 12 | 13" | 2 1/2" | 2 1/2" | 2" | Black | 00000000 | 000000 |

- For Use With: Air, Water, Hydraulic Fluid

- Temperature Range: -65° to 250° F

- Maximum Pressure:

Air: 1,000 psi @ 72° F

Water: 1,000 psi @ 72° F

Hydraulic Fluid: 3,000 psi @ 72° F - Maximum Vacuum: 27 in. of Hg @ 72° F

Inlet | Outlet | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Pipe Size | Dash Size | Pipe Size | Dash Size | Lg. | Wd. | Ht. | Outlet Ctr.-to-Ctr. | Color | Each | |

Outlets on One Side—Standard Outlet Spacing | |||||||||||

| 4 | 3/8 | 06 | 1/4 | 04 | 3 7/8" | 1 1/4" | 1 1/4" | 7/8" | Black | 00000000 | 000000 |

- For Use With: Air, Water, Hydraulic Fluid

- Temperature Range: -10° to 200° F

- Maximum Pressure:

Air: 1,000 psi @ 72° F

Water: 3,000 psi @ 72° F

Hydraulic Fluid: 3,000 psi @ 72° F - Maximum Vacuum: 29 in. of Hg @ 72° F

Inlet | Outlet | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Pipe Size | Dash Size | Pipe Size | Dash Size | Lg. | Wd. | Ht. | Outlet Ctr.-to-Ctr. | Each | |

Outlets on One Side—Standard Outlet Spacing | ||||||||||

| 2 | 1/4 | 04 | 1/8 | 02 | 1 3/4" | 1" | 1" | 3/4" | 0000000 | 000000 |

| 2 | 3/8 | 06 | 1/4 | 04 | 2 3/8" | 1 1/4" | 1 1/4" | 7/8" | 0000000 | 00000 |

| 2 | 1/2 | 08 | 3/8 | 06 | 2 3/4" | 1 1/2" | 1 1/2" | 1" | 0000000 | 00000 |

| 4 | 1/4 | 04 | 1/8 | 02 | 3 1/4" | 1" | 1" | 3/4" | 0000000 | 00000 |

| 4 | 3/8 | 06 | 1/4 | 04 | 4 1/8" | 1 1/4" | 1 1/4" | 7/8" | 0000000 | 00000 |

| 4 | 1/2 | 08 | 3/8 | 06 | 4 3/4" | 1 1/2" | 1 1/2" | 1" | 0000000 | 00000 |

| 6 | 1/4 | 04 | 1/8 | 02 | 4 3/4" | 1" | 1" | 3/4" | 0000000 | 00000 |

| 6 | 3/8 | 06 | 1/4 | 04 | 5 7/8" | 1 1/4" | 1 1/4" | 7/8" | 0000000 | 00000 |

| 6 | 1/2 | 08 | 3/8 | 06 | 6 3/4" | 1 1/2" | 1 1/2" | 1" | 0000000 | 00000 |

- For Use With: Air, Water, Hydraulic Fluid, Alcohol, Coolant, Cutting Oil, Deionized Water, Diesel Fuel, Fuel Oil, Gasoline, Mineral Oil, Nitrogen

- Temperature Range: -65° to 250° F

- Maximum Pressure: 3,500 psi @ 72° F

- Maximum Vacuum: 27 in. of Hg @ 72° F

Inlet | Outlet | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Pipe Size | Dash Size | Pipe Size | Dash Size | Lg. | Wd. | Ht. | Outlet Ctr.-to-Ctr. | Each | |

Outlets on One Side—Standard Outlet Spacing | ||||||||||

| 2 | 1/4 | 04 | 1/8 | 02 | 1 3/4" | 1" | 1" | 3/4" | 00000000 | 0000000 |

| 3 | 1/4 | 04 | 1/8 | 02 | 2 1/2" | 1" | 1" | 3/4" | 00000000 | 000000 |

| 3 | 1 | 16 | 3/4 | 12 | 7" | 2 1/2" | 2 1/2" | 2" | 00000000 | 000000 |

| 4 | 3/4 | 12 | 1/2 | 08 | 7" | 2" | 2" | 1 1/2" | 00000000 | 000000 |

| 6 | 1/4 | 04 | 1/8 | 02 | 4 3/4" | 1" | 1" | 3/4" | 00000000 | 000000 |

| 6 | 3/8 | 06 | 1/4 | 04 | 5 7/8" | 1 1/4" | 1 1/4" | 7/8" | 00000000 | 000000 |

| 6 | 3/4 | 12 | 1/2 | 08 | 10" | 2" | 2" | 1 1/2" | 00000000 | 000000 |

| Pipe Size | Drive | Pressure Class | Max. Pressure | Each | |

Aluminum—NPT | |||||

|---|---|---|---|---|---|

| 3/8 | External Square | 150 | 150 psi @ 72° F | 000000000 | 00000 |

Aluminum—BSPT | |||||

| 1/8 | Hex | 150 | 150 psi @ 72° F | 00000000 | 0000 |

| 1/8 | External Square | __ | 250 psi @ 72° F | 0000000 | 0000 |

| 1/4 | Hex | 150 | 150 psi @ 72° F | 00000000 | 0000 |

| 1/4 | External Square | __ | 250 psi @ 72° F | 0000000 | 0000 |

| 3/8 | Hex | 150 | 150 psi @ 72° F | 00000000 | 0000 |

| 3/8 | External Square | __ | 250 psi @ 72° F | 0000000 | 00000 |

| 1/2 | Hex | 150 | 150 psi @ 72° F | 00000000 | 00000 |

| 1/2 | External Square | __ | 250 psi @ 72° F | 0000000 | 00000 |

Straight-Flow Rectangular Manifolds

Unlike other manifolds, which have an inlet on either end, these have one inlet on the opposite side from the outlets. This design allows fluid or air to follow a straight path, improving flow through your system. It also frees up the ends of the manifold, so you can mount it in corners and in narrow spaces. Manifolds are also known as headers. They have mounting holes, so you can mount from the top or side.

Anodized aluminum manifolds are the industry standard for the most common types of applications. They are lighter in weight than other metal manifolds and have good corrosion resistance. These manifolds are anodized for a black finish.

Use a plug (sold separately) to close off any unused inlets and outlets.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water, Hydraulic Fluid

- Temperature Range: See Table

- Maximum Pressure:

Air: 1,000 psi @ 72° F

Water: 1,000 psi @ 72° F

Hydraulic Fluid: 3,000 psi @ 72° F

Inlet | Outlet | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Pipe Size | Dash Size | Pipe Size | Dash Size | Lg. | Wd. | Ht. | Outlet Ctr.-to-Ctr. | Color | Temperature Range, °F | Each | |

Standard Outlet Spacing | ||||||||||||

| 4 | 1/4 | 4 | 1/8 | 2 | 3 1/4" | 1" | 1" | 3/4" | Black | -60° to 250° | 00000000 | 000000 |

| 4 | 3/8 | 6 | 1/4 | 4 | 4 1/8" | 1 1/4" | 1 1/4" | 7/8" | Black | -60° to 250° | 00000000 | 00000 |

| 4 | 1/2 | 8 | 3/8 | 6 | 4 3/4" | 1 1/2" | 1 1/2" | 1" | Black | -60° to 250° | 00000000 | 00000 |

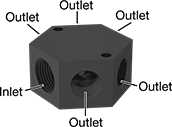

Low-Profile Hex Manifolds

When you’re short on vertical space, these manifolds are a good fit—they have outlets on the side instead of on top, so they have a lower profile than rectangular manifolds. Use them to distribute air, water, or hydraulic fluid to five locations from a single supply source. Manifolds have mounting holes, so you can mount from the top.

Anodized aluminum manifolds are the industry standard for the most common types of applications. They are lighter in weight than other metal manifolds and have good corrosion resistance. These manifolds are anodized for a black finish.

316 stainless steel manifolds have excellent corrosion resistance and can handle fuel, gasoline, coolant and other harsh substances.

Use a plug (sold separately) to close off any unused inlets and outlets.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water, Hydraulic Fluid

- Temperature Range: -10° to 200° F

- Maximum Pressure: 1,000 psi @ 72° F

- Maximum Vacuum: 27 in. of Hg @ 72° F

- For Use With: Air, Water, Hydraulic Fluid, Alcohol, Coolant, Cutting Oil, Deionized Water, Diesel Fuel, Fuel Oil, Gasoline, Mineral Oil, Nitrogen

- Temperature Range: -100° to 500° F

- Maximum Pressure: 3,500 psi @ 72° F

- Maximum Vacuum: 27 in. of Hg @ 72° F

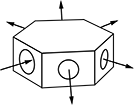

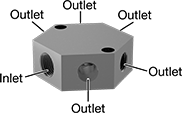

Low-Profile Square Manifolds

With outlets on the side instead of on top, these manifolds have a lower profile than rectangular manifolds and fit well in cramped spaces. Use them to distribute air, water, or hydraulic fluid to three locations from a single supply source. Manifolds have mounting holes, so you can mount from the top.

Anodized aluminum manifolds are the industry standard for the most common types of applications. They are lighter in weight than other metal manifolds and have good corrosion resistance. These manifolds are anodized for a black finish.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water, Hydraulic Fluid

- Temperature Range: -10° to 200° F

- Maximum Pressure: 1,000 psi @ 72° F

- Maximum Vacuum: 27 in. of Hg @ 72° F

Round Manifolds for Hose Lines

Mount these manifolds on the end of a hose line to distribute air, water, or hydraulic fluid to three locations from a single supply source.

Aluminum manifolds are lighter in weight than stainless steel manifolds and have good corrosion resistance.

- Temperature Range: See Table

- Maximum Pressure: See Table

- Maximum Vacuum: 27 in. of Hg @ 72° F

Inlet | Outlet | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Pipe Size | Dash Size | Pipe Size | Dash Size | Lg. | OD | Outlet Ctr.-to-Ctr. | Outlet Spacing | Max. Pressure | Temp. Range, °F | Each | |

BSPP Inlets × BSPP Outlets | ||||||||||||

| 3 | 1/4 | 04 | 1/4 | 04 | 1 1/2" | 1 5/8" | 1" | Standard | 300 psi @ 72° F | -10° to 200° | 00000000 | 000000 |

| 3 | 3/8 | 06 | 1/4 | 04 | 1 1/2" | 1 5/8" | 1" | Standard | 300 psi @ 72° F | -10° to 200° | 00000000 | 00000 |

| 3 | 1/2 | 08 | 1/4 | 04 | 1 1/2" | 1 5/8" | 1" | Standard | 300 psi @ 72° F | -10° to 200° | 00000000 | 00000 |

| 3 | 3/4 | 12 | 1/2 | 08 | 2 1/2" | 3" | 1 3/4" | Standard | 300 psi @ 72° F | -10° to 200° | 00000000 | 00000 |

Straight-Flow Junction Blocks

Use these junction blocks to organize and separate multiple lines in your system. They have threaded holes that allow air, water, or hydraulic fluid to flow straight through the block. They have mounting holes, so you can mount from the side.

Anodized aluminum junction blocks are lightweight with good corrosion and wear resistance.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water, Hydraulic Fluid

- Temperature Range: -10° to 200° F

- Maximum Pressure:

Air: 1,000 psi @ 72° F

Water: 1,000 psi @ 72° F

Hydraulic Fluid: 3,000 psi @ 72° F - Maximum Vacuum: Not Rated

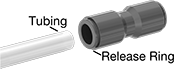

Push-to-Connect Tube Fittings for Air

- Temperature Range: 0° to 170° F, except polybutylene plastic fittings are 32° to 140° F

- Tubing: Use with firm (Durometer 95A-45D) polyethylene plastic or polyurethane rubber

- Specifications Met: ISO 14743, except cartridges and polybutylene plastic fittings

Insert tubing into these fittings and an internal gripping ring and O-ring hold the tubing tight. They are also known as instant fittings. To disconnect, push on the release ring and pull the tubing out of the fitting. Fittings have good corrosion resistance. Use them in low-pressure applications.

Identification rings (sold separately) snap over the release ring so you can color-code your lines.

Clips (sold separately) align and organize your tubing and fittings.

BSPP and UN/UNF (SAE Straight) male threads have a gasket to protect against leaks. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

For technical drawings and 3-D models, click on a part number.

Use plugs to close off unused manifold holes.

Release Ring | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Inlets | Pipe Size | Number of Outlets | For Tube OD | Material | Material | Color | Max. Pressure | Mount Type | Mounting Fasteners Included | Each | |

BSPP Threads | |||||||||||

| 2 | 1/4 | 8 | 4mm | Aluminum | Plastic | Black | 290 psi @ 72° F | Screw On | No | 00000000 | 000000 |

| 2 | 1/4 | 8 | 6mm | Aluminum | Plastic | Black | 290 psi @ 72° F | Screw On | No | 00000000 | 00000 |

| 2 | 3/8 | 6 | 8mm | Aluminum | Plastic | Black | 290 psi @ 72° F | Screw On | No | 00000000 | 00000 |

| 2 | 1/2 | 6 | 10mm | Aluminum | Plastic | Black | 290 psi @ 72° F | Screw On | No | 00000000 | 000000 |

| 2 | 1/2 | 6 | 12mm | Aluminum | Plastic | Black | 290 psi @ 72° F | Screw On | No | 00000000 | 000000 |

Universal-Thread Push-to-Connect Tube Fittings for Air and Water

Threads

with Gasket

- Temperature Range: 0° to 175° F

- Tubing: Use with firm (Durometer 85A-100A) nylon plastic or polyurethane rubber

- Specifications Met: ISO 14743

Make lightweight connections without the hassle of matching the exact thread type—these fittings connect to NPT, NPTF, BSPP, BSPT, and other universal threads. With a nylon body and nickel-plated brass threads, these fittings are lighter than most metal fittings, and withstand corrosion better than plain brass threads. They also have a reusable gasket to guard against leaks. Connect the tube ends to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect them, push the release ring and pull the tubing out of the fitting. These fittings are sometimes known as instant fittings. All meet ISO 14743, which is an international standard for push-to-connect fittings for plastic tubing.

For technical drawings and 3-D models, click on a part number.

Threads

with Gasket

Release Ring | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Inlets | For Tube OD (Inlet) | Pipe Size (Inlet) | Number of Outlets | For Tube OD (Outlet) | Pipe Connection Material | Tube Connection Material | Gasket Material | Color | Material | Color | Maximum Pressure | Each | |

BSPP, BSPT, NPT, NPTF, Universal Threads | |||||||||||||

| 2 | 1/4" | 1/8 | 3 | 5/32" | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Blue | 250 psi @ 72° F | 00000000 | 000000 |

| 2 | 1/4" | 1/4 | 3 | 5/32" | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Blue | 250 psi @ 72° F | 00000000 | 00000 |

| 2 | 5/16" | 1/8 | 3 | 5/32" | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Blue | 250 psi @ 72° F | 00000000 | 00000 |

| 2 | 5/16" | 1/8 | 3 | 1/4" | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Blue | 250 psi @ 72° F | 00000000 | 00000 |

| 2 | 5/16" | 1/4 | 3 | 5/32" | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Blue | 250 psi @ 72° F | 00000000 | 00000 |

| 2 | 5/16" | 1/4 | 3 | 1/4" | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Blue | 250 psi @ 72° F | 00000000 | 00000 |

| 2 | 3/8" | 1/4 | 3 | 1/4" | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Blue | 250 psi @ 72° F | 00000000 | 00000 |

| 2 | 3/8" | 1/4 | 3 | 5/16" | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Blue | 250 psi @ 72° F | 00000000 | 00000 |

| 2 | 3/8" | 3/8 | 3 | 1/4" | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Blue | 250 psi @ 72° F | 00000000 | 00000 |

| 2 | 3/8" | 3/8 | 3 | 5/16" | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Blue | 250 psi @ 72° F | 00000000 | 00000 |

| 2 | 6mm | 1/8 | 3 | 4mm | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Black | 250 psi @ 72° F | 00000000 | 00000 |

| 2 | 6mm | 1/4 | 3 | 4mm | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Black | 250 psi @ 72° F | 00000000 | 00000 |

| 2 | 8mm | 1/8 | 3 | 4mm | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Black | 250 psi @ 72° F | 00000000 | 00000 |

| 2 | 8mm | 1/8 | 3 | 6mm | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Black | 250 psi @ 72° F | 00000000 | 00000 |

| 2 | 8mm | 1/4 | 3 | 4mm | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Black | 250 psi @ 72° F | 00000000 | 00000 |

| 2 | 8mm | 1/4 | 3 | 6mm | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Black | 250 psi @ 72° F | 00000000 | 00000 |

| 2 | 10mm | 1/4 | 3 | 6mm | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Black | 250 psi @ 72° F | 00000000 | 00000 |

| 2 | 10mm | 1/4 | 3 | 8mm | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Black | 250 psi @ 72° F | 00000000 | 00000 |

| 2 | 10mm | 3/8 | 3 | 6mm | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Black | 250 psi @ 72° F | 00000000 | 00000 |

| 2 | 10mm | 3/8 | 3 | 8mm | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Black | 250 psi @ 72° F | 00000000 | 00000 |

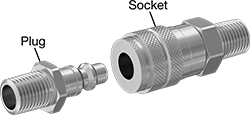

Industrial Quick-Disconnect Hose Couplings for Air

A complete coupling consists of a plug and a socket (both sold separately or in a set) that connect and disconnect quickly. Use them if you need frequent access to a line. They are also known as industrial interchange couplings. All Industrial plugs are compatible with any of the Industrial sockets of the same coupling size, regardless of the pipe size or barbed hose ID.

Steel is stronger and more durable than other metals. Zinc-plated steel has fair corrosion resistance and should be used primarily in dry environments. Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: 230 psi @ 72° F

- Temperature Range: 0° to 212° F

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Manifolds distribute air to multiple lines.

Push-to-connect sockets join by forcefully pushing the plug and socket together until you hear a click. Unlike sleeve-lock sockets, you should not slide back the sleeve to connect. To disconnect, slide the sleeve on the socket forward until the plug ejects.

For Plug Tip | |||||||

|---|---|---|---|---|---|---|---|

| Coupling Size | Lg. | Dia. | Pipe Size | Thread Material | Number of Mounting Holes | Each | |

Zinc-Plated Steel | |||||||

| 1/4 | 3/16" | 5/16" | 1/2 | Zinc-Plated Steel | 4 | 0000000 | 000000 |

- Maximum Pressure: 230 psi @ 72° F

- Temperature Range: 0° to 212° F

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Manifolds distribute air to multiple lines.

Push-to-connect sockets join by forcefully pushing the plug and socket together until you hear a click. Unlike sleeve-lock sockets, you should not slide back the sleeve to connect. To disconnect, slide the sleeve on the socket forward until the plug ejects.

For Plug Tip | |||||||

|---|---|---|---|---|---|---|---|

| Coupling Size | Lg. | Dia. | Pipe Size | Thread Material | Number of Mounting Holes | Each | |

Zinc-Plated Steel | |||||||

| 1/4 | 3/16" | 5/16" | 1/2 | Zinc-Plated Steel | 4 | 0000000 | 0000000 |

- Maximum Pressure: 230 psi @ 72° F

- Temperature Range: 0° to 212° F

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Manifolds distribute air to multiple lines.

Push-to-connect sockets join by forcefully pushing the plug and socket together until you hear a click. Unlike sleeve-lock sockets, you should not slide back the sleeve to connect. To disconnect, slide the sleeve on the socket forward until the plug ejects.

For Plug Tip | |||||||

|---|---|---|---|---|---|---|---|

| Coupling Size | Lg. | Dia. | Pipe Size | Thread Material | Number of Mounting Holes | Each | |

Zinc-Plated Steel | |||||||

| 1/4 | 3/16" | 5/16" | 1/2 | Zinc-Plated Steel | 4 | 0000000 | 0000000 |

- Maximum Pressure: 230 psi @ 72° F

- Temperature Range: 0° to 212° F

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Manifolds distribute air to multiple lines.

Push-to-connect sockets join by forcefully pushing the plug and socket together until you hear a click. Unlike sleeve-lock sockets, you should not slide back the sleeve to connect. To disconnect, slide the sleeve on the socket forward until the plug ejects.

For Plug Tip | |||||||

|---|---|---|---|---|---|---|---|

| Coupling Size | Lg. | Dia. | Pipe Size | Thread Material | Number of Mounting Holes | Each | |

Zinc-Plated Steel | |||||||

| 1/4 | 3/16" | 5/16" | 1/2 | Zinc-Plated Steel | 4 | 0000000 | 0000000 |

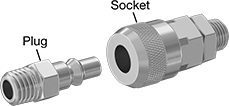

ARO Quick-Disconnect Hose Couplings for Air

A complete coupling consists of a plug and a socket (both sold separately or in a set) that connect and disconnect quickly. Use them if you need frequent access to a line. All ARO plugs are compatible with any of the ARO sockets of the same coupling size, regardless of the pipe size or barbed hose ID.

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Push-to-connect sockets are easier to connect than sleeve-lock sockets. Connect by pushing the plug into the socket until you hear a click. To disconnect, slide the sleeve on the socket forward until the plug ejects.

Manifolds give you a centralized and mounted location for plugging in your air tool line.

Steel is stronger and more durable than other metals. Zinc-plated steel has fair corrosion resistance and should be used primarily in dry environments.Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: 230 psi @ 72° F

- Maximum Vacuum: Not Rated

- Temperature Range: 0° to 212° F

Number Of | For Plug Tip | |||||||

|---|---|---|---|---|---|---|---|---|

| Inlets | Outlets | Coupling Size | Lg. | Dia. | Pipe Size | Thread Type | Each | |

Zinc-Plated Steel | ||||||||

| 1 | 4 | 1/4 | 5/16" | 5/16" | 1/2 | BSPP | 0000000 | 0000000 |