How to Measure Threaded Pipe Size

More

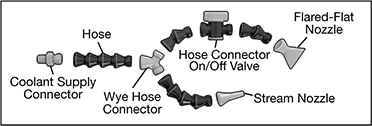

About Loc-Line and Snap-Loc Coolant Hose

Assemble and disassemble Loc-Line and Snap-Loc coolant hose by snapping components together or pulling them apart. Assembly and separation tools (sold separately) are recommended.

To ensure compatibility, select the color and trade size that match your current system. A system’s trade size is equal to the ID of its hose.

How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

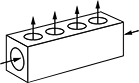

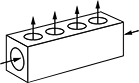

Right-Angle Flow Rectangular Manifolds

Distribute air or fluid to multiple locations from a single supply source with these manifolds. They are also known as headers. They have mounting holes, so you can mount from the top or side.

Stainless steel manifolds have the best corrosion resistance of all our metal manifolds. They can handle a wider temperature range than other plastic and metal manifolds. 316 stainless steel manifolds have better corrosion resistance than 303 stainless steel manifolds to handle fuel and gasoline in addition to coolant and other harsh substances.

Use a plug (sold separately) to close off any unused inlets and outlets.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water, Hydraulic Fluid, Alcohol, Coolant, Cutting Oil, Deionized Water, Diesel Fuel, Fuel Oil, Gasoline, Mineral Oil, Nitrogen

- Temperature Range: -100° to 500° F

- Maximum Pressure:

Air: 1,000 psi @ 72° F

Water: 5,000 psi @ 72° F

Hydraulic Fluid: 5,000 psi @ 72° F

Alcohol, Coolant, Cutting Oil, Deionized Water, Diesel Fuel, Fuel Oil, Gasoline, Mineral Oil, Nitrogen: 3,000 psi @ 72° F

Inlet | Outlet | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Pipe Size | Dash Size | Pipe Size | Dash Size | Lg. | Wd. | Ht. | Outlet Ctr.-to-Ctr. | Each | |

Outlets on One Side—Standard Outlet Spacing | ||||||||||

| 2 | 1/4 | 04 | 1/8 | 02 | 1 3/4" | 1" | 1" | 3/4" | 00000000 | 000000 |

| 2 | 3/8 | 06 | 1/4 | 04 | 2 1/8" | 1 1/4" | 1 1/4" | 1 1/8" | 00000000 | 000000 |

| 2 | 1/2 | 08 | 3/8 | 06 | 2 3/4" | 1 1/2" | 1 1/2" | 1" | 00000000 | 000000 |

| 4 | 1/4 | 04 | 1/8 | 02 | 3 1/4" | 1" | 1" | 3/4" | 00000000 | 000000 |

| 4 | 3/8 | 06 | 1/4 | 04 | 3 7/8" | 1 1/4" | 1 1/4" | 7/8" | 00000000 | 000000 |

| 4 | 1/2 | 08 | 3/8 | 06 | 4 3/4" | 1 1/2" | 1 1/2" | 1" | 00000000 | 000000 |

- For Use With: Air, Water, Hydraulic Fluid, Alcohol, Coolant, Cutting Oil, Deionized Water, Diesel Fuel, Fuel Oil, Gasoline, Mineral Oil, Nitrogen

- Temperature Range: -65° to 250° F

- Maximum Pressure: 3,500 psi @ 72° F

- Maximum Vacuum: 27 in. of Hg @ 72° F

Inlet | Outlet | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Pipe Size | Dash Size | Pipe Size | Dash Size | Lg. | Wd. | Ht. | Outlet Ctr.-to-Ctr. | Each | |

Outlets on One Side—Standard Outlet Spacing | ||||||||||

| 2 | 1/4 | 04 | 1/8 | 02 | 1 3/4" | 1" | 1" | 3/4" | 00000000 | 0000000 |

| 3 | 1/4 | 04 | 1/8 | 02 | 2 1/2" | 1" | 1" | 3/4" | 00000000 | 000000 |

| 3 | 3/4 | 12 | 1/2 | 08 | 5 1/2" | 2" | 2" | 1 1/2" | 00000000 | 000000 |

| 3 | 1 | 16 | 3/4 | 12 | 7" | 2 1/2" | 2 1/2" | 2" | 00000000 | 000000 |

| 4 | 3/4 | 12 | 1/2 | 08 | 7" | 2" | 2" | 1 1/2" | 00000000 | 000000 |

| 6 | 1/4 | 04 | 1/8 | 02 | 4 3/4" | 1" | 1" | 3/4" | 00000000 | 000000 |

| 6 | 3/8 | 06 | 1/4 | 04 | 5 7/8" | 1 1/4" | 1 1/4" | 7/8" | 00000000 | 000000 |

| 6 | 3/4 | 12 | 1/2 | 08 | 10" | 2" | 2" | 1 1/2" | 00000000 | 000000 |

| 6 | 1 | 16 | 3/4 | 12 | 13" | 2 1/2" | 2 1/2" | 2" | 00000000 | 000000 |

- For Use With: Air, Water, Hydraulic Fluid, Alcohol, Coolant, Cutting Oil, Deionized Water, Diesel Fuel, Fuel Oil, Gasoline, Mineral Oil, Nitrogen

- Temperature Range: -65° to 250° F

- Maximum Pressure: 3,500 psi @ 72° F

- Maximum Vacuum: 27 in. of Hg @ 72° F

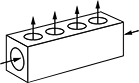

Straight-Flow Rectangular Manifolds

Unlike other manifolds, which have an inlet on either end, these have one inlet on the opposite side from the outlets. This design allows fluid or air to follow a straight path, improving flow through your system. It also frees up the ends of the manifold, so you can mount it in corners and in narrow spaces. Manifolds are also known as headers. They have mounting holes, so you can mount from the top or side.

316 stainless steel manifolds have excellent corrosion resistance. They can handle fuel, gasoline, coolant, and other harsh substances.

Use a plug (sold separately) to close off any unused inlets and outlets.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water, Hydraulic Fluid, Alcohol, Coolant, Cutting Oil, Deionized Water, Diesel Fuel, Fuel Oil, Gasoline, Mineral Oil, Nitrogen

- Temperature Range: -60° to 250° F

- Maximum Pressure:

Air: 3,500 psi @ 72° F

Water: 3,500 psi @ 72° F

Hydraulic Fluid: 3,500 psi @ 72° F

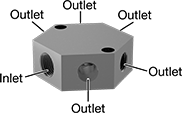

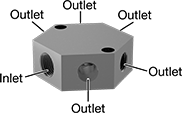

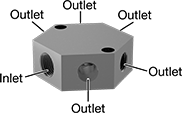

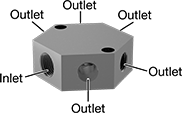

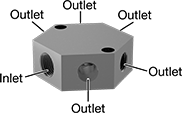

Low-Profile Hex Manifolds

When you’re short on vertical space, these manifolds are a good fit—they have outlets on the side instead of on top, so they have a lower profile than rectangular manifolds. Use them to distribute air, water, or hydraulic fluid to five locations from a single supply source. Manifolds have mounting holes, so you can mount from the top.

316 stainless steel manifolds have excellent corrosion resistance and can handle fuel, gasoline, coolant and other harsh substances.

Use a plug (sold separately) to close off any unused inlets and outlets.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water, Hydraulic Fluid, Alcohol, Coolant, Cutting Oil, Deionized Water, Diesel Fuel, Fuel Oil, Gasoline, Mineral Oil, Nitrogen

- Temperature Range: -100° to 500° F

- Maximum Pressure: 3,500 psi @ 72° F

- Maximum Vacuum: 27 in. of Hg @ 72° F

Inlet | Outlet | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Pipe Size | Dash Size | Pipe Size | Dash Size | Wd. | Ht. | Outlet Spacing | Each | |

| 5 | 1/8 | 02 | 1/16 | 01 | 1 5/8" | 3/4" | Standard | 00000000 | 0000000 |

| 5 | 1/4 | 04 | 1/8 | 02 | 1 5/8" | 3/4" | Standard | 00000000 | 000000 |

| 5 | 3/8 | 06 | 1/4 | 04 | 1 7/8" | 1" | Standard | 00000000 | 000000 |

| 5 | 1/2 | 08 | 3/8 | 06 | 2" | 1 1/4" | Standard | 00000000 | 000000 |

| 5 | 3/4 | 12 | 1/2 | 08 | 2 1/4" | 1 1/2" | Standard | 00000000 | 000000 |

| 5 | 1 | 16 | 3/4 | 12 | 3" | 1 3/4" | Standard | 00000000 | 000000 |

- For Use With: Air, Water, Hydraulic Fluid, Alcohol, Coolant, Cutting Oil, Deionized Water, Diesel Fuel, Fuel Oil, Gasoline, Mineral Oil, Nitrogen

- Temperature Range: -100° to 500° F

- Maximum Pressure: 3,500 psi @ 72° F

- Maximum Vacuum: 27 in. of Hg @ 72° F

Inlet | Outlet | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Thread Size | Dash Size | Thread Size | Dash Size | Wd. | Ht. | Outlet Spacing | Each | |

| 5 | 7/16"-20 | 4 | 5/16"-18 | 2 | 1 5/8" | 3/4" | Standard | 00000000 | 0000000 |

| 5 | 9/16"-18 | 6 | 7/16"-20 | 4 | 1 7/8" | 3/4" | Standard | 00000000 | 000000 |

| 5 | 3/4"-16 | 8 | 9/16"-18 | 6 | 2" | 1" | Standard | 00000000 | 000000 |

| 5 | 1 1/16"-12 | 12 | 3/4"-16 | 8 | 3" | 1 1/4" | Standard | 00000000 | 000000 |

| 5 | 1 5/16"-12 | 16 | 1 1/16"-12 | 12 | 2 1/2" | 1 1/2" | Standard | 00000000 | 000000 |

| 5 | 1 5/8"-20 | 20 | 1 5/16"-12 | 16 | 4 1/2" | 2 3/4" | Standard | 00000000 | 000000 |

- For Use With: Air, Water, Hydraulic Fluid, Alcohol, Coolant, Cutting Oil, Deionized Water, Diesel Fuel, Fuel Oil, Gasoline, Mineral Oil, Nitrogen

- Temperature Range: -100° to 500° F

- Maximum Pressure: 3,500 psi @ 72° F

- Maximum Vacuum: 27 in. of Hg @ 72° F

- For Use With: Air, Water, Hydraulic Fluid, Alcohol, Coolant, Cutting Oil, Deionized Water, Diesel Fuel, Fuel Oil, Gasoline, Mineral Oil, Nitrogen

- Temperature Range: -100° to 500° F

- Maximum Pressure: 3,500 psi @ 72° F

- Maximum Vacuum: 27 in. of Hg @ 72° F

- For Use With: Air, Water, Hydraulic Fluid, Alcohol, Coolant, Cutting Oil, Deionized Water, Diesel Fuel, Fuel Oil, Gasoline, Mineral Oil, Nitrogen

- Temperature Range: -100° to 500° F

- Maximum Pressure: 3,500 psi @ 72° F

- Maximum Vacuum: 27 in. of Hg @ 72° F

Inlet | Outlet | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Thread Size | Thread Pitch, mm | Thread Size | Thread Pitch, mm | Wd., mm | Ht., mm | Outlet Spacing | Each | |

| 5 | M6 | 1 | M3 | 0.5 | 45 | 19 | Standard | 00000000 | 0000000 |

| 5 | M8 | 1 | M6 | 1 | 45 | 19 | Standard | 00000000 | 000000 |

| 5 | M10 | 1 | M8 | 1 | 45 | 19 | Standard | 00000000 | 000000 |

| 5 | M12 | 1.5 | M10 | 1 | 47 | 19 | Standard | 00000000 | 000000 |

| 5 | M14 | 1.5 | M12 | 1.5 | 47 | 19 | Standard | 00000000 | 000000 |

| 5 | M16 | 1.5 | M14 | 1.5 | 47 | 25 | Standard | 00000000 | 000000 |

| 5 | M20 | 1.5 | M18 | 1.5 | 50 | 31 | Standard | 00000000 | 000000 |

| 5 | M22 | 1.5 | M20 | 1.5 | 50 | 38 | Standard | 00000000 | 000000 |

| Pipe Size | Max. Pressure | Each | |

316 Stainless Steel—BSPP | |||

|---|---|---|---|

| 1/8 | 2,000 psi @ 72° F | 00000000 | 000000 |

| 1/4 | 2,000 psi @ 72° F | 00000000 | 00000 |

316 Stainless Steel—BSPT | |||

| 1/8 | 2,000 psi @ 72° F | 00000000 | 00000 |

| 1/4 | 2,000 psi @ 72° F | 00000000 | 00000 |

| 3/8 | 2,000 psi @ 72° F | 00000000 | 00000 |

| 1/2 | 2,000 psi @ 72° F | 00000000 | 00000 |

| Pipe Size | Max. Pressure | Pressure Class | Each | |

316 Stainless Steel—NPT | ||||

|---|---|---|---|---|

| 1/8 | 3,000 psi @ 72° F | 3000 | 00000000 | 00000 |

| 1/4 | 3,000 psi @ 72° F | 3000 | 00000000 | 0000 |

| 3/8 | 3,000 psi @ 72° F | 3000 | 00000000 | 00000 |

| 1/2 | 3,000 psi @ 72° F | 3000 | 00000000 | 00000 |

| 3/4 | 3,000 psi @ 72° F | 3000 | 00000000 | 00000 |

| 1 | 3,000 psi @ 72° F | 3000 | 00000000 | 00000 |

316 Stainless Steel—BSPP | ||||

| 1/8 | 2,000 psi @ 72° F | __ | 00000000 | 00000 |

| 1/4 | 2,000 psi @ 72° F | __ | 00000000 | 00000 |

| 3/8 | 2,000 psi @ 72° F | __ | 00000000 | 00000 |

| 1/2 | 2,000 psi @ 72° F | __ | 00000000 | 00000 |

| Pipe Size | Max. Pressure | Pressure Class | Each | |

316 Stainless Steel—NPT | ||||

|---|---|---|---|---|

| 1/8 | 3,000 psi @ 72° F | 3000 | 00000000 | 00000 |

| 1/4 | 3,000 psi @ 72° F | 3000 | 00000000 | 0000 |

| 3/8 | 3,000 psi @ 72° F | 3000 | 00000000 | 00000 |

| 1/2 | 3,000 psi @ 72° F | 3000 | 00000000 | 00000 |

| 3/4 | 3,000 psi @ 72° F | 3000 | 00000000 | 00000 |

| 1 | 3,000 psi @ 72° F | 3000 | 00000000 | 00000 |

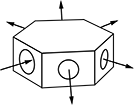

Low-Profile Square Manifolds

With outlets on the side instead of on top, these manifolds have a lower profile than rectangular manifolds and fit well in cramped spaces. Use them to distribute air, water, or hydraulic fluid to three locations from a single supply source. Manifolds have mounting holes, so you can mount from the top.

316 stainless steel manifolds have excellent corrosion resistance and can handle fuel, gasoline, coolant and other harsh substances.

Use a plug (sold separately) to close off any unused inlets and outlets.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water, Hydraulic Fluid, Alcohol, Coolant, Cutting Oil, Deionized Water, Diesel Fuel, Fuel Oil, Gasoline, Mineral Oil, Nitrogen

- Temperature Range: -100° to 500° F

- Maximum Pressure: 3,500 psi @ 72° F

- Maximum Vacuum: 27 in. of Hg @ 72° F

| Pipe Size | Drive | Length | Max. Pressure | Each | |

316 Stainless Steel—NPT | |||||

|---|---|---|---|---|---|

| 1/8 | External Hex | 5/8" | 3,000 psi @ 72° F | 00000000 | 00000 |

| 1/8 | External Square | 17/64" | 3,000 psi @ 72° F | 00000000 | 0000 |

| 1/4 | External Hex | 47/64" | 3,000 psi @ 72° F | 00000000 | 0000 |

| 1/4 | External Square | 25/64" | 3,000 psi @ 72° F | 00000000 | 0000 |

| 3/8 | External Hex | 7/8" | 3,000 psi @ 72° F | 00000000 | 00000 |

| 3/8 | External Square | 15/32" | 3,000 psi @ 72° F | 00000000 | 00000 |

| 1/2 | External Hex | 59/64" | 3,000 psi @ 72° F | 00000000 | 00000 |

| 1/2 | External Square | 35/64" | 3,000 psi @ 72° F | 00000000 | 00000 |

| 3/4 | External Hex | 1 3/64" | 3,000 psi @ 72° F | 00000000 | 00000 |

| 3/4 | External Square | 21/32" | 3,000 psi @ 72° F | 00000000 | 00000 |

| 1 | External Hex | 1 1/8" | 3,000 psi @ 72° F | 00000000 | 00000 |

| 1 | External Square | 13/16" | 3,000 psi @ 72° F | 00000000 | 00000 |

Round Manifolds for Hose Lines

Mount these manifolds on the end of a hose line to distribute air, water, or hydraulic fluid to three locations from a single supply source.

316 stainless steel manifolds have excellent corrosion resistance and can handle fuel, gasoline, coolant and other harsh substances.

- Temperature Range: -60° to 500° F

- Maximum Pressure:

Air: 1,000 psi @ 72° F

Water: 3,500 psi @ 72° F

Hydraulic Fluid: 3,500 psi @ 72° F - Maximum Vacuum: 27 in. of Hg @ 72° F

Inlet | Outlet | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Pipe Size | Dash Size | Pipe Size | Dash Size | Lg. | OD | Outlet Ctr.-to-Ctr. | Outlet Spacing | Each | |

NPT Inlets × NPT Outlets | ||||||||||

| 3 | 1/4 | 04 | 1/4 | 04 | 1 1/2" | 1 5/8" | 1" | Standard | 00000000 | 000000 |

| 3 | 3/8 | 06 | 1/4 | 04 | 1 1/2" | 1 5/8" | 1" | Standard | 00000000 | 00000 |

| 3 | 1/2 | 08 | 1/4 | 04 | 1 1/2" | 1 5/8" | 1" | Standard | 00000000 | 000000 |

| 3 | 1/2 | 08 | 3/8 | 06 | 1 3/4" | 2" | 1 1/4" | Standard | 00000000 | 000000 |

| 3 | 3/4 | 12 | 1/2 | 08 | 2 1/2" | 3" | 1 3/4" | Standard | 00000000 | 000000 |

BSPT Inlets × BSPT Outlets | ||||||||||

| 3 | 1/4 | 04 | 1/4 | 04 | 1 1/2" | 1 5/8" | 1" | Standard | 00000000 | 00000 |

| 3 | 3/8 | 06 | 1/4 | 04 | 1 1/2" | 1 5/8" | 1" | Standard | 00000000 | 00000 |

| 3 | 1/2 | 08 | 1/4 | 04 | 1 1/2" | 1 5/8" | 1" | Standard | 00000000 | 000000 |

| 3 | 1/2 | 08 | 3/8 | 06 | 1 3/4" | 2" | 1 1/4" | Standard | 00000000 | 000000 |

Straight-Flow Junction Blocks

Use these junction blocks to organize and separate multiple lines in your system. They have threaded holes that allow air, water, or hydraulic fluid to flow straight through the block. They have mounting holes, so you can mount from the side.

316 stainless steel junction blocks have excellent corrosion resistance and can handle fuel, gasoline, coolant, and other harsh substances.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water, Hydraulic Fluid, Alcohol, Coolant, Cutting Oil, Deionized Water, Diesel Fuel, Fuel Oil, Gasoline, Mineral Oil, Nitrogen

- Temperature Range: -100° to 500° F

- Maximum Pressure:

Air: 1,000 psi @ 72° F

Water: 3,500 psi @ 72° F

Hydraulic Fluid: 3,500 psi @ 72° F - Maximum Vacuum: Not Rated

Inlet | Outlet | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Pipe Size | Dash Size | Pipe Size | Dash Size | Lg. | Wd. | Ht. | Outlet Ctr.-to-Ctr. | Outlet Spacing | Each | |

| 2 | 1/8 | 02 | 1/8 | 02 | 1 3/4" | 1" | 1" | 3/4" | Standard | 00000000 | 0000000 |

| 2 | 1/4 | 04 | 1/4 | 04 | 1 3/4" | 1" | 1" | 7/8" | Standard | 00000000 | 000000 |

| 4 | 1/8 | 02 | 1/8 | 02 | 3 1/4" | 1" | 1" | 3/4" | Standard | 00000000 | 000000 |

| 4 | 1/4 | 04 | 1/4 | 04 | 4 1/8" | 1" | 1" | 7/8" | Standard | 00000000 | 000000 |

| 4 | 3/8 | 06 | 3/8 | 06 | 7 3/4" | 1 1/2" | 1 1/2" | 1 1/2" | Standard | 00000000 | 000000 |

1/4" Snap-Loc Coolant Hose

Build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there’s no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. Assembly and separation tools (sold separately) are recommended. To ensure compatibility, select the color and trade size that match your current system. These components fit Snap-Loc hose with a 1/4" ID.

For technical drawings and 3-D models, click on a part number.

Threaded Pipe Inlet Connection | Threaded Pipe Outlet Connection | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | No. of | Size | Thread Type | Gender | No. of | Size | Thread Type | Gender | O'all Ht. | OD | Material | Max. Flow Rate, gph | For Max. SSU Viscosity Grade | Max. Pressure, psi | Max. Temp., °F | Each | |

| 15 | 1 | 1/4 | NPT | Female | 1 | 1/4 | NPT | Female | 1 3/4" | 2 1/2" | Polypropylene Plastic | 240 | 200 | 39 | 200° | 0000000 | 000000 |

1/4" Snap-Loc Coolant Hose Kits

Kit contains lengths of hose, nozzles, connectors, and assembly pliers to build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there’s no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. Use the included assembly pliers; separation tool is sold separately. To ensure compatibility, select the color and trade size that match your current system. These components fit Snap-Loc hose with a 1/4" ID.

For technical drawings and 3-D models, click on a part number.

| No. of Pieces | Includes | Material | Max. Flow Rate, gph | For Max. SSU Viscosity Grade | Max. Pressure, psi | Max. Temp., °F | Each | |

| 27 | 2 Each 1" Flared Flat Nozzles 2 Each 1/16" Stream Nozzles 2 Each 1/4" Stream Nozzles 2 Each 1/8" Stream Nozzles 2 Each Female x Male x Male Wye Hose Connectors 3 Each 1/4 NPT Coolant Supply Connectors 3 Each 1/8 NPT Coolant Supply Connectors 8 Each 6" Long Hose Assembly Pliers Female x Female Straight Hose Connector Male x Female Straight Hose Connector | Acetal Plastic, Polypropylene Plastic | 500 | 200 | 30 | 200° | 0000000 | 000000 |

1/2" Snap-Loc Coolant Hose

Build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there’s no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. Assembly and separation tools (sold separately) are recommended. To ensure compatibility, select the color and trade size that match your current system. These components fit Snap-Loc hose with a 1/2" ID.

Manifolds can be joined with connectors.

For technical drawings and 3-D models, click on a part number.

For style 15 manifold, use a style 2 or 3 coolant supply connector to connect a style 10 wye-shaped hose connector.

Threaded Pipe Inlet Connection | Threaded Pipe Outlet Connections | O'all | Mounting Holes | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Size (No. of) | Thread Type | Gender | Size (No. of) | Thread Type | Gender | Ht. | Wd. | Dp. | Material | Max. Flow Rate, gph | Max. Pressure, psi | Max. Temp., °F | No. of | Dia. | Mounting Fasteners Included | Each | |

| 15 | 1/2 (1) | NPT | Female | 3/8 (3), 1/2 (1) | NPT | Female | 1 3/4" | 5 1/2" | 1" | Acetal Plastic | 480 | 19 | 200° | 4 | 1/4" | No | 0000000 | 000000 |

1/4" Loc-Line Coolant Hose

Build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there's no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. Assembly pliers (sold separately) are recommended. To ensure compatibility, select the color and trade size that match your current system. These components fit Loc-Line hose with a 1/4” ID.

Manifolds can be joined with connectors.

For technical drawings and 3-D models, click on a part number.

For styles 31 and 32 manifolds, add style 13 tee-shaped hose connectors.

Inlet Hose Connection | Outlet Hose Connections | O'all | Mounting Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | No. of | Gender | No. of | Gender | Ht. | Wd. | Dp. | Valve Operation | Material | Max. Flow Rate, gph | Max. Pressure, psi | Max. Temp., °F | No. of | Dia. | Mounting Fasteners Included | Each | |

| 31 | 1 | Female | 4 | Male | 2 15/16" | 5 3/16" | 1 9/16" | Handle | Acetal Plastic | 250 | 50 | 170° | 2 | 1/4" | No | 000000000 | 000000 |

| 32 | 1 | Female | 4 | Male | 1 13/16" | 4 1/4" | 1" | __ | Acetal Plastic | 250 | 30 | 170° | 2 | 1/4" | No | 00000000 | 00000 |

O'all | Hose Connector Mounting | Bracket Mounting | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Ht. | Dp. | Lg. | Material | Max. Temp., °F | No. of Holes | Screw Size | No. of Holes | Hole Dia. | Mounting Fasteners Included | Pkg. Qty. | Pkg. | |

| 33 | 7/8" | 5/8" | 2 15/16" | Acetal Plastic | 170° | 3 | No. 8 | 2 | 1/4" | No | 2 | 000000000 | 00000 |

For styles 34 and 35 manifolds, use a style 2 coolant supply connector to connect a style 12 wye-shaped hose connector.

Barbed Tube Inlet Connection | Threaded Pipe Outlet Connections | O'all | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | No. of | For Tube ID | No. of | Size | Thread Type | Gender | Ht. | Wd. | Lg. | OD | Material | Fitting Material | Max. Flow Rate, gph | Max. Pressure, psi | Max. Temp., °F | Includes | Each | |

| 34 | 1 | 1/2" | 2 | 1/4 | NPT | Female | 2 9/16" | 1 3/16" | 1 7/16" | __ | Aluminum | Brass | 250 | 50 | 335° | One 1/4 NPT Plug | 000000000 | 000000 |

| 35 | 1 | 3/8" | 4 | 1/4 | NPT | Female | 1 3/16" | __ | __ | 2 1/8" | Aluminum | Brass | 250 | 30 | 170° | Three 1/4 NPT Plugs | 00000000 | 00000 |

1/4" Loc-Line Coolant Hose Kits

Kits contain lengths of hose, nozzles, valves, and caps to build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there’s no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. Assembly pliers (sold separately) are recommended. To ensure compatibility, select the color and trade size that match your current system. These components fit Loc-Line hose with a 1/4” ID.

For technical drawings and 3-D models, click on a part number.

| No. of Pieces | Includes | Material | Max. Flow Rate, gph | Max. Pressure, psi | Max. Temp., °F | Each | |

| 11 | 1" Flared Flat Nozzle 1/4 NPT Coolant Supply Connection Valve 1/4" Stream Nozzle 1/8" Stream Nozzle 2 Each 5 3/4" Long Hose 3 Each Caps Magnetic Manifold Mount with Barbed Tube Fitting | Acetal Plastic | 250 | 50 | 170° | 000000000 | 000000 |

| 25 | 2 Each 1" Flared Flat Nozzles 2 Each 1/16" Stream Nozzles 2 Each 1/4" Stream Nozzles 2 Each 1/8" Stream Nozzles 3 Each Caps 5 Each 1/4 NPT Coolant Supply Connection Valves 8 Each 5 3/4" Long Hose Magnetic Manifold Mount with Barbed Tube Fitting | Acetal Plastic | 250 | 50 | 170° | 000000000 | 00000 |

1/2" Loc-Line Coolant Hose

Build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there’s no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. Assembly pliers (sold separately) are recommended. To ensure compatibility, select the color and trade size that match your current system. These components fit Loc-Line hose with a 1/2" ID.

Manifolds can be joined with connectors.

For technical drawings and 3-D models, click on a part number.

For style 29 manifold, add style 9 tee-shaped hose connectors.

Inlet Hose Connection | Outlet Hose Connections | O'all | Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | No. of | Gender | No. of | Gender | Ht. | Wd. | Dp. | Material | Max. Flow Rate, gph | Max. Pressure, psi | Max. Temp., °F | No. of | Dia. | Mounting Fasteners Included | Each | |

| 29 | 1 | Female | 4 | Male | 2 1/8" | 6" | 1 1/4" | Acetal Plastic | 478 | 20 | 170° | 2 | 1/4" | No | 00000000 | 000000 |