How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

How to Measure Threaded Pipe Size

More

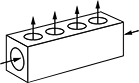

Right-Angle Flow Rectangular Manifolds

Distribute air or fluid to multiple locations from a single supply source with these manifolds. They are also known as headers. They have mounting holes, so you can mount from the top or side.

Zinc-plated steel manifolds have the best strength and durability of all our plastic and metal manifolds and can handle the highest pressures. Use them in noncorrosive environments.

Use a plug (sold separately) to close off any unused inlets and outlets.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water, Hydraulic Fluid

- Temperature Range: -60° to 300° F

- Maximum Pressure:

Air: 1,000 psi @ 72° F

Water: 5,000 psi @ 72° F

Hydraulic Fluid: 5,000 psi @ 72° F

Inlet | Outlet | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Pipe Size | Dash Size | Pipe Size | Dash Size | Lg. | Wd. | Ht. | Outlet Ctr.-to-Ctr. | Each | |

Outlets on One Side—Standard Outlet Spacing | ||||||||||

| 2 | 1/4 | 04 | 1/8 | 02 | 1 3/4" | 1" | 1" | 3/4" | 0000000 | 000000 |

| 2 | 3/8 | 06 | 1/4 | 04 | 2 1/8" | 1 1/4" | 1 1/4" | 1 1/8" | 0000000 | 00000 |

| 2 | 1/2 | 08 | 3/8 | 06 | 2 3/4" | 1 1/2" | 1 1/2" | 1" | 0000000 | 00000 |

| 3 | 1/4 | 04 | 1/8 | 02 | 2 1/2" | 1" | 1" | 3/4" | 0000000 | 00000 |

| 3 | 3/8 | 06 | 1/4 | 04 | 3" | 1 1/4" | 1 1/4" | 7/8" | 0000000 | 00000 |

| 3 | 1/2 | 08 | 3/8 | 06 | 3 3/4" | 1 1/2" | 1 1/2" | 1" | 0000000 | 00000 |

| 4 | 1/4 | 04 | 1/8 | 02 | 3 1/4" | 1" | 1" | 3/4" | 0000000 | 00000 |

| 4 | 3/8 | 06 | 1/4 | 04 | 3 7/8" | 1 1/4" | 1 1/4" | 7/8" | 0000000 | 00000 |

| 4 | 1/2 | 08 | 3/8 | 06 | 4 3/4" | 1 1/2" | 1 1/2" | 1" | 0000000 | 00000 |

| 5 | 1/4 | 04 | 1/8 | 02 | 4" | 1" | 1" | 3/4" | 0000000 | 00000 |

| 5 | 3/8 | 06 | 1/4 | 04 | 4 3/4" | 1 1/4" | 1 1/4" | 7/8" | 0000000 | 00000 |

| 6 | 1/4 | 04 | 1/8 | 02 | 4 3/4" | 1" | 1" | 3/4" | 0000000 | 00000 |

| 6 | 3/8 | 06 | 1/4 | 04 | 5 5/8" | 1 1/4" | 1 1/4" | 7/8" | 0000000 | 00000 |

| 6 | 1/2 | 08 | 3/8 | 06 | 6 3/4" | 1 1/2" | 1 1/2" | 1" | 0000000 | 00000 |

| 8 | 1/4 | 04 | 1/8 | 02 | 6 1/4" | 1" | 1" | 3/4" | 0000000 | 00000 |

| 8 | 3/8 | 06 | 1/4 | 04 | 7 3/8" | 1 1/4" | 1 1/4" | 7/8" | 0000000 | 00000 |

| 8 | 1/2 | 08 | 3/8 | 06 | 8 3/4" | 1 1/2" | 1 1/2" | 1" | 0000000 | 00000 |

| 10 | 1/4 | 04 | 1/8 | 02 | 7 3/4" | 1" | 1" | 3/4" | 0000000 | 00000 |

| 10 | 3/8 | 06 | 1/4 | 04 | 9 1/8" | 1 1/4" | 1 1/4" | 7/8" | 0000000 | 00000 |

| 10 | 1/2 | 08 | 3/8 | 06 | 10 3/4" | 1 1/2" | 1 1/2" | 1" | 0000000 | 00000 |

Straight-Flow Rectangular Manifolds

Unlike other manifolds, which have an inlet on either end, these have one inlet on the opposite side from the outlets. This design allows fluid or air to follow a straight path, improving flow through your system. It also frees up the ends of the manifold, so you can mount it in corners and in narrow spaces. Manifolds are also known as headers. They have mounting holes, so you can mount from the top or side.

Zinc-plated steel manifolds have the best strength and durability of all our metal manifolds and can handle the highest pressures. Use them in noncorrosive environments.

Use a plug (sold separately) to close off any unused inlets and outlets.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water, Hydraulic Fluid

- Temperature Range: -10° to 200° F

- Maximum Pressure:

Air: 1,000 psi @ 72° F

Water: 5,000 psi @ 72° F

Hydraulic Fluid: 5,000 psi @ 72° F

Inlet | Outlet | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Pipe Size | Dash Size | Pipe Size | Dash Size | Lg. | Wd. | Ht. | Outlet Ctr.-to-Ctr. | Each | |

Standard Outlet Spacing | ||||||||||

| 2 | 1/4 | 4 | 1/8 | 2 | 1 3/4" | 1" | 1" | 3/4" | 00000000 | 000000 |

| 2 | 3/8 | 6 | 1/4 | 4 | 2 1/8" | 1 1/4" | 1 1/4" | 7/8" | 00000000 | 00000 |

| 2 | 1/2 | 8 | 3/8 | 6 | 2 3/4" | 1 1/2" | 1 1/2" | 1" | 00000000 | 00000 |

| 2 | 3/4 | 12 | 1/2 | 8 | 4" | 2" | 2" | 1 1/2" | 00000000 | 00000 |

| 3 | 3/4 | 12 | 1/2 | 8 | 5 1/2" | 2" | 2" | 1 1/2" | 00000000 | 000000 |

| 3 | 1 | 16 | 3/4 | 12 | 7" | 2 1/2" | 2 1/2" | 2" | 00000000 | 000000 |

| 4 | 1/4 | 4 | 1/8 | 2 | 3 1/4" | 1" | 1" | 3/4" | 00000000 | 00000 |

| 4 | 3/8 | 6 | 1/4 | 4 | 3 7/8" | 1 1/4" | 1 1/4" | 7/8" | 00000000 | 00000 |

| 4 | 1/2 | 8 | 3/8 | 6 | 4 3/4" | 1 1/2" | 1 1/2" | 1" | 00000000 | 00000 |

| 4 | 3/4 | 12 | 1/2 | 8 | 7" | 2" | 2" | 1 1/2" | 00000000 | 000000 |

| 4 | 1 | 16 | 3/4 | 12 | 9" | 2 1/2" | 2 1/2" | 2" | 00000000 | 000000 |

| 6 | 1/4 | 4 | 1/8 | 2 | 4 3/4" | 1" | 1" | 3/4" | 00000000 | 00000 |

| 6 | 1/2 | 8 | 3/8 | 6 | 6 3/4" | 1 1/2" | 1 1/2" | 1" | 00000000 | 00000 |

| 6 | 3/4 | 12 | 1/2 | 8 | 10" | 2" | 2" | 1 1/2" | 0000000 | 000000 |

| 8 | 3/8 | 6 | 1/4 | 4 | 7 3/8" | 1 1/4" | 1 1/4" | 7/8" | 00000000 | 00000 |

| 8 | 1/2 | 8 | 3/8 | 6 | 8 3/4" | 1 1/2" | 1 1/2" | 1" | 00000000 | 00000 |

| 8 | 1 | 16 | 3/4 | 12 | 17" | 2 1/2" | 2 1/2" | 2" | 00000000 | 000000 |

Extra-Wide Outlet Spacing | ||||||||||

| 4 | 3/8 | 6 | 1/4 | 4 | 5 3/4" | 1 1/4" | 1 1/4" | 1 1/2" | 00000000 | 00000 |

| 4 | 1/2 | 8 | 3/8 | 6 | 6 1/4" | 1 1/2" | 1 1/2" | 1 1/2" | 00000000 | 00000 |

| 4 | 3/4 | 12 | 1/2 | 8 | 11 1/2" | 2" | 2" | 3" | 00000000 | 000000 |

| 4 | 1 | 16 | 3/4 | 12 | 12" | 2 1/2" | 2 1/2" | 3" | 00000000 | 000000 |

| Pipe Size | Drive | Pressure Class | Max. Pressure | Each | |

Steel—NPT | |||||

|---|---|---|---|---|---|

| 1/8 | Hex | 150 | 150 psi @ 72° F | 000000000 | 00000 |

| 1/8 | Square | 150 | 150 psi @ 72° F | 000000000 | 000 |

| 1/8 | External Square | Not Rated | Not Rated | 000000000 | 000 |

| 1/4 | Hex | 150 | 150 psi @ 72° F | 000000000 | 000 |

| 1/4 | Square | 150 | 150 psi @ 72° F | 000000000 | 000 |

| 1/4 | External Square | Not Rated | Not Rated | 000000000 | 000 |

| 3/8 | Hex | 150 | 150 psi @ 72° F | 000000000 | 000 |

| 3/8 | Square | 150 | 150 psi @ 72° F | 000000000 | 000 |

| 3/8 | External Square | Not Rated | Not Rated | 000000000 | 000 |

| 1/2 | Hex | 150 | 150 psi @ 72° F | 000000000 | 000 |

| 1/2 | Square | 150 | 150 psi @ 72° F | 000000000 | 000 |

| 1/2 | External Square | Not Rated | Not Rated | 000000000 | 000 |

| 3/4 | Hex | 150 | 150 psi @ 72° F | 000000000 | 000 |

| 3/4 | Square | 150 | 150 psi @ 72° F | 000000000 | 000 |

| 3/4 | External Square | Not Rated | Not Rated | 000000000 | 0000 |

| 1 | Square | 150 | 150 psi @ 72° F | 000000000 | 0000 |

| 1 | External Square | Not Rated | Not Rated | 000000000 | 0000 |

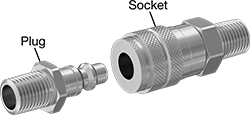

Industrial Quick-Disconnect Hose Couplings for Air

A complete coupling consists of a plug and a socket (both sold separately or in a set) that connect and disconnect quickly. Use them if you need frequent access to a line. They are also known as industrial interchange couplings. All Industrial plugs are compatible with any of the Industrial sockets of the same coupling size, regardless of the pipe size or barbed hose ID.

Steel is stronger and more durable than other metals. Zinc-plated steel has fair corrosion resistance and should be used primarily in dry environments. Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: 230 psi @ 72° F

- Temperature Range: 0° to 212° F

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Manifolds distribute air to multiple lines.

Push-to-connect sockets join by forcefully pushing the plug and socket together until you hear a click. Unlike sleeve-lock sockets, you should not slide back the sleeve to connect. To disconnect, slide the sleeve on the socket forward until the plug ejects.

For Plug Tip | |||||||

|---|---|---|---|---|---|---|---|

| Coupling Size | Lg. | Dia. | Pipe Size | Thread Material | Number of Mounting Holes | Each | |

Zinc-Plated Steel | |||||||

| 1/4 | 3/16" | 5/16" | 1/2 | Zinc-Plated Steel | 4 | 0000000 | 000000 |

- Maximum Pressure: 230 psi @ 72° F

- Temperature Range: 0° to 212° F

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Manifolds distribute air to multiple lines.

Push-to-connect sockets join by forcefully pushing the plug and socket together until you hear a click. Unlike sleeve-lock sockets, you should not slide back the sleeve to connect. To disconnect, slide the sleeve on the socket forward until the plug ejects.

For Plug Tip | |||||||

|---|---|---|---|---|---|---|---|

| Coupling Size | Lg. | Dia. | Pipe Size | Thread Material | Number of Mounting Holes | Each | |

Zinc-Plated Steel | |||||||

| 1/4 | 3/16" | 5/16" | 1/2 | Zinc-Plated Steel | 4 | 0000000 | 0000000 |

- Maximum Pressure: 230 psi @ 72° F

- Temperature Range: 0° to 212° F

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Manifolds distribute air to multiple lines.

Push-to-connect sockets join by forcefully pushing the plug and socket together until you hear a click. Unlike sleeve-lock sockets, you should not slide back the sleeve to connect. To disconnect, slide the sleeve on the socket forward until the plug ejects.

For Plug Tip | |||||||

|---|---|---|---|---|---|---|---|

| Coupling Size | Lg. | Dia. | Pipe Size | Thread Material | Number of Mounting Holes | Each | |

Zinc-Plated Steel | |||||||

| 1/4 | 3/16" | 5/16" | 1/2 | Zinc-Plated Steel | 4 | 0000000 | 0000000 |

- Maximum Pressure: 230 psi @ 72° F

- Temperature Range: 0° to 212° F

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Manifolds distribute air to multiple lines.

Push-to-connect sockets join by forcefully pushing the plug and socket together until you hear a click. Unlike sleeve-lock sockets, you should not slide back the sleeve to connect. To disconnect, slide the sleeve on the socket forward until the plug ejects.

For Plug Tip | |||||||

|---|---|---|---|---|---|---|---|

| Coupling Size | Lg. | Dia. | Pipe Size | Thread Material | Number of Mounting Holes | Each | |

Zinc-Plated Steel | |||||||

| 1/4 | 3/16" | 5/16" | 1/2 | Zinc-Plated Steel | 4 | 0000000 | 0000000 |

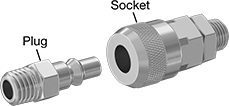

ARO Quick-Disconnect Hose Couplings for Air

A complete coupling consists of a plug and a socket (both sold separately or in a set) that connect and disconnect quickly. Use them if you need frequent access to a line. All ARO plugs are compatible with any of the ARO sockets of the same coupling size, regardless of the pipe size or barbed hose ID.

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Push-to-connect sockets are easier to connect than sleeve-lock sockets. Connect by pushing the plug into the socket until you hear a click. To disconnect, slide the sleeve on the socket forward until the plug ejects.

Manifolds give you a centralized and mounted location for plugging in your air tool line.

Steel is stronger and more durable than other metals. Zinc-plated steel has fair corrosion resistance and should be used primarily in dry environments.Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: 230 psi @ 72° F

- Maximum Vacuum: Not Rated

- Temperature Range: 0° to 212° F

Number Of | For Plug Tip | |||||||

|---|---|---|---|---|---|---|---|---|

| Inlets | Outlets | Coupling Size | Lg. | Dia. | Pipe Size | Thread Type | Each | |

Zinc-Plated Steel | ||||||||

| 1 | 4 | 1/4 | 5/16" | 5/16" | 1/2 | BSPP | 0000000 | 0000000 |

Grease Fitting Junction Blocks

Choose these blocks if you need to lubricate multiple points but need to control how each is greased. Unlike grease fitting manifolds, these blocks have multiple fittings, so you control what each point receives and when. Use the compression fittings on the outlets to connect tubing (not included) between the grease fittings and lubrication points.

Magnetic-mount blocks stick to machines and other steel surfaces.

Zinc-plated steel blocks have mild corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Zinc-Plated Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Number of Inlets | Number of Outlets | For Tube OD | For NLGI Viscosity Grade | Overall Wd. | Overall Dp. | Overall Ht. | Max. Pressure, psi | Each | |

Junction Blocks | |||||||||

| 3 | 3 | 1/4" | 00, 0, 1, 2 | 2 3/4" | 3/4" | 2 3/4" | 1,800 | 000000 | 000000 |

| 6 | 6 | 1/4" | 00, 0, 1, 2 | 5 3/4" | 3/4" | 2 3/4" | 1,800 | 000000 | 000000 |

| 10 | 10 | 1/4" | 00, 0, 1, 2 | 9 3/4" | 3/4" | 2 1/2" | 5,000 | 000000 | 000000 |

Magnetic-Mount Junction Blocks | |||||||||

| 3 | 3 | 1/4" | 00, 0, 1, 2 | 5 5/8" | 1 11/16" | 2 11/16" | 5,000 | 000000 | 000000 |

| 6 | 6 | 1/4" | 00, 0, 1, 2 | 6 5/8" | 1 11/16" | 2 11/16" | 5,000 | 000000 | 000000 |

| 10 | 10 | 1/4" | 00, 0, 1, 2 | 10 5/8" | 1 11/16" | 2 3/4" | 5,000 | 000000 | 000000 |