About Padlocks

More

Clamp-On Circuit Breaker Lockouts

A lockout for every style of circuit breaker switch—these lockouts clamp over your switch, so it doesn’t matter if it has a through hole. Secure these lockouts with a padlock. Less disruptive than locking access to an entire panel, they isolate a single circuit or group of circuits. These lockouts help you comply with OSHA 29 CFR 1910.147 requirements for the control of electrical circuits to prevent injuries.

Single-pole lockouts secure a single switch. Tie-bar multipole lockouts are wider than single-pole lockouts to fit onto most tie bars, which control multiple circuits.

Style B have a compact profile for breaker boxes with tight clearance. Use a flat-head screwdriver to tighten them onto your switch. These lockouts have a warning label on the front for visibility. Made of 100% recycled materials, they’re rated UL 2809-2 to meet purchasing requirements in LEED-certified facilities.

For Max. Switch | Overall | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Voltage | Wd. | Thick. | Lg. | Wd. | Dp. | For Circuit Breaker Type | For Manufacturer | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Temp. Range, °F | Color | Message | Each | |

Plastic | ||||||||||||||

| 120V AC 240V AC | 5/8" | 7/16" | 1" | 3/4" | 2" | Single Pole | American Circuit Breakers, Cutler-Hammer, GE, Merlin Gerin, Siemens, Square D | 1 | 9/32" | -40° to 250° | Red | Danger—Locked Out—Do Not Operate | 000000000 | 000000 |

| 120V AC 277V AC | 5/8" | 7/16" | 1" | 1 5/8" | 2" | Tie-Bar Multipole | American Circuit Breakers, Cutler-Hammer, GE, Merlin Gerin, Siemens, Square D | 1 | 9/32" | -40° to 250° | Red | Danger—Locked Out—Do Not Operate | 000000000 | 00000 |

Lockout Hasps

Lock out electrical panels, switches, and other power sources to keep machinery off during repairs. These hasps have multiple holes for multiple padlocks and tags, so each person can add their own as they start the job. Until the last padlock is removed, these hasps won’t open. They help you comply with OSHA 29 CFR 1910.147 requirements for the control of hazardous energy.

Aluminum hasps resist corrosion better than steel hasps, so they won’t wear as easily.

Hasps that meet UL 2809-2 are made of 100% recycled materials and are sustainably sourced to meet purchasing requirements for LEED-certified facilities.

For technical drawings and 3-D models, click on a part number.

Hasp Clearance | Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Vertical | Horizontal | Hasp Thick. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Specifications Met | Each | |

Aluminum | ||||||||||

Powder Coated | ||||||||||

| 1" | 1" | 1/2" | 6 | 3/8" | 4 7/16" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 000000000 | 000000 |

| 1 1/2" | 1 1/2" | 1/2" | 6 | 3/8" | 5" | 2 1/16" | Red | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 000000000 | 00000 |

Nonconductive Lockout Hasps

Ideal for circuit breakers and other electrical equipment, these hasps are made of nonconductive plastic to prevent shocks. They also resist corrosion better than hasps with a metal body. Use them to lock out controls to keep machinery off while completing repairs. They have multiple holes for multiple padlocks and tags, so each person can add their own as they start the job. Until the last padlock is removed, these hasps won’t open. They help you comply with OSHA 29 CFR 1910.147, which requires electrical controls to be locked out during maintenance to prevent injuries.

Style C have a flexible clasp that you can bend to fit around irregular shapes. They also have a prominent warning label on the body.

Hasps that meet UL 2809-2 are made of 100% recycled materials and are sustainably sourced to meet purchasing requirements for LEED-certified facilities.

Hasp Clearance | Overall | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Vertical | Horizontal | Hasp Thick. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Specifications Met | Each | |

Plastic | |||||||||||

| A | 1" | 1" | 1/2" | 6 | 3/8" | 5" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 000000000 | 000000 |

| A | 1 1/2" | 1 1/2" | 3/8" | 6 | 3/8" | 4 1/2" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 000000000 | 00000 |

| C | 1 15/16" | 1" | 1/4" | 3 | 1/4" | 8" | 1 3/4" | Red | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 000000000 | 00000 |

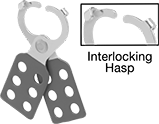

Pry-Resistant Interlocking-Hasp Lockouts

Clasps interlock when you close these lockouts to protect against prying. Use them to lock out controls so machinery stays off during repairs. They have multiple holes for multiple padlocks and lockout tags, so each person can add their own as they start the job. Each padlock adds another layer of security, and until the last is removed, these lockouts won’t open. They help you comply with OSHA 29 CFR 1910.147, which requires controls to be locked out during maintenance to prevent injuries.

Lockouts that meet UL-2809-2 are made of 100% recycled materials and are sustainably sourced to meet ongoing purchasing requirements for LEED-certified facilities.

For technical drawings and 3-D models, click on a part number.

Hasp Clearance | Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Vertical | Horizontal | Hasp Thick. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Specifications Met | Each | |

Powder-Coated Steel | ||||||||||

| 1" | 1" | 1/2" | 6 | 3/8" | 4 1/2" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 000000000 | 00000 |

| 1 1/2" | 1 1/2" | 1/2" | 6 | 3/8" | 5" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 000000000 | 0000 |

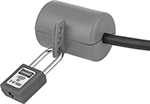

Electrical Plug Lockouts

Lock out a plug that powers machinery so no one starts it up during maintenance. Place a plug into the cylinder of these lockouts and secure with a padlock. All can fit a standard electrical plug that has a single cord. Made of plastic, they resist corrosion and are nonconductive for use with electronics. These lockouts help you comply with OSHA 29 CFR 1910.147, which requires electrical circuits to be locked out to prevent injury.

Lockouts for 2 or more padlocks let multiple people add their own padlock. This keeps everyone safe until all of the maintenance work is done and all padlocks are removed.

Lockouts with 2 holes for electrical plugs let you insert a cord from either end. That means you can lock out two devices at once, or lock out both the plug and socket of the same cord.

Lockouts with 5 holes for electrical plugs have a variety of hole sizes to handle different cord diameters. They’ll fit dual-cord battery plugs for forklifts, as well as standard single-cord plugs. Use them with gas-powered equipment, too—the largest hole on these lockouts fits a gas cylinder valve.

Lockouts with adjustable-fit closure let you secure any cord diameter up to 1 1/4”. Slide the two top lids against each other to change the hole size.

Lockouts with a message alert passersby that a plug has been locked out for safety.

Lockouts that meet UL 2809-2 are made of 100% recycled materials and are sustainably sourced to meet ongoing purchasing requirements for LEED-certified facilities.

For Plug | Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | For Max. Cord Dia. | No. of Holes for Electrical Plugs | Max. Lg. | Wd. | Lg. | Wd. | Ht. | Dia. | Temp. Range, ° F | Message | Features | Specifications Met | Each | |

Yellow Plastic (English/Spanish Message) | |||||||||||||||

| 3 | 9/16" | 1 1/4" | 1 | 5 1/2" | 1 1/2"-3" | 7" | __ | __ | 3 3/4" | -25° to 200° | Danger—Do Not Plug In/No Conectar | Adjustable-Fit Closure | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 000000000 | 000000 |

Red Plastic (English Message) | |||||||||||||||

| 3 | 9/16" | 1/2" | 2 | 3" | 3/4"-2" | 3 1/2" | __ | __ | 2 1/2" | -25° to 200° | Danger—Do Not Operate—Equipment Locked Out | __ | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 000000000 | 00000 |

| 6 | 9/32" | 1 1/8", 1", 1" | 5 | 6 3/4" | 1/2"-2 1/2" | 7 1/4" | 4 1/4" | 3" | __ | -40° to 300° | Danger—Do Not Operate—Equipment Locked Out | __ | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 00000 |

Gas Cylinder Lockouts

Prohibit access to the main valve on a gas cylinder. These lockouts secure with a padlock and lockout tag. They help you comply with OSHA 29 CFR 1910.147, which requires handles on pneumatic and hydraulic systems to be locked out during maintenance to prevent injuries.

Plastic lockouts are more corrosion resistant and lighter in weight than steel lockouts. However, they aren’t as strong. These lockouts have a warning label to alert passersby. Style A are for forklift gas cylinder handwheels. With holes for up to three padlocks, each person can add their own as they start a job. Each padlock adds another layer of security, and until the last is removed, these lockouts won’t open. Made of 100% recycled materials, they meet UL 2809-2 purchasing requirements for LEED-certified facilities.

For technical drawings and 3-D models, click on a part number.

| Style | For Hand Wheel Dia. Range | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Overall Lg. | Temp. Range, ° F | Color | Message | Specifications Met | Each | |

| A | 1 1/4" to 2 3/16" | 3 | 5/16" | 3 1/2" | Up to 200° | Yellow | Danger—Do Not Operate—Equipment Locked Out | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 000000 |

Wall-Mount Electrical and Valve Lockout Sets with Padlocks

Keep everything you need to lock out most electrical equipment and valves around your facility in a single spot against the wall. These sets have supplies for locking out circuit breakers, valves, plugs, wall switches, and other controls. The supplies are red or yellow to alert people to maintenance. They help you comply with OSHA 29 CFR 1910.147, which requires power sources and supply lines to be locked out to prevent injuries.

Cabinets are made of stainless steel, so they resist damage better than our plastic cases. They meet UL 2809-2, so they’re made of at least 90% recycled materials to meet purchasing requirements for LEED-certified facilities.

Mounting Holes | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Includes | Ht. | Wd. | Dp. | Fasteners Included | No. | Screw Size | Specifications Met | Each | |

Cabinets | |||||||||

| 1 Each: Gas Cylinder Lockout 1 Each: Wall Switch Lockout 2 Each: Plug Lockouts 2 Valve Wheel Lockouts (1 Each that fits 1"-2 1/2" and 2 1/2"-5" Diameter Wheels) 3 Each: Circuit Breaker Lockouts 4 Each: Lockout Hasps 4 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 10 Each: Tags 10 Each: Cable Ties | 16" | 15 1/4" | 5 1/2" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 0000000 |

Electrical Lockout Sets with Padlocks

Keep an assortment of padlocks, hasps, and other electrical lockouts on hand. Stored in a portable case, these sets have everything you need to lock out electrical equipment around your facility—just grab them and go. The lockouts are red or yellow to grab your attention and alert you to maintenance. Use them to help comply with OSHA 29 CFR 1910.147 requirements to prevent injuries caused by accidental startups during maintenance.

Sets in a carrying case store lockouts in a soft, portable bag.

Sets that meet UL 2809-2 are made of 100% recycled materials, so they meet purchasing requirements for LEED-certified facilities.

| For Use With | Includes | Specifications Met | Each | |

| Circuit Breakers, Electrical Plugs | 3 Each: Cable Ties 2 Each: Plug Lockouts 2 Each: Lockout Hasps 2 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 2 Each: Tags Carrying Case | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 0000000 |

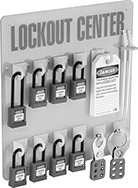

Wall-Mount Lockout Sets with Padlocks

Keep items for group lockouts organized and within reach with these sets. They mount to a wall and provide hangers for your lockout supplies. All padlocks and hasps are red, and the board or case is yellow plastic, so these sets are easy to see. They help you comply with OSHA 29 CFR 1910.147 requirements for the control of hazardous energy.

Sets that meet UL 2809-2 are made of 100% recycled materials and are sustainably sourced to meet purchasing requirements for LEED-certified facilities.

Mounting Holes | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Includes | Ht. | Wd. | Dp. | Fasteners Included | No. | Screw Size | Specifications Met | Each | |

Boards | |||||||||

| 3 Each: Cable Ties 2 Each: Lockout Hasps 3 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 3 Each: Tags | 11" | 11" | 2 1/2" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 0000000 |

| 10 Each: Cable Ties 2 Each: Lockout Hasps 8 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 10 Each: Tags | 15" | 15" | 2 1/2" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 000000 |

| 10 Each: Cable Ties 2 Each: Lockout Hasps 12 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 10 Each: Tags | 23" | 15" | 2 1/2" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 000000 |

Electrical and Valve Lockout Sets with Padlocks

Everything you need to lock out your electrical equipment or valves. These sets are your one stop shop for padlocks, hasps, and other lockout devices. Bright red, they alert others to service or repairs. Use them to comply with OSHA 29 CFR 1910.147 requirements to prevent injuries caused by accidental startups during maintenance.

Sets in a carrying case store lockout components in a soft, portable bag.

Sets in a fanny pack are strapped around your waist to keep lockout devices within reach.

Sets that meet UL 2809-2 are made of 100% recycled materials, so they meet purchasing requirements for LEED-certified facilities.

| Lockout Style | Includes | Specifications Met | Each | |

| Cover, Hasp | 1 Each: Plug Lockout 1 Each: Circuit Breaker Lockout 1 Valve Wheel Lockout (fits 2 1/2"-5" Diameter Wheels) 4 Each: Lockout Hasps 2 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 5 Each: Tags 5 Cable Ties Fanny Pack | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 0000000 |

| Cover, Hasp | 1 Each: Circuit Breaker Lockout 2 Valve Wheel Lockouts (1 Each that fits 1"-2 1/2" and 2 1/2"-4" Diameter Wheels) 2 Each: Lockout Hasps 2 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 2 Each: Tags 3 Cable Ties Carrying Case | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 000000 |

Lockout Organizing Stations

Keep padlocks, tags, and other lockout tools neatly stored and ready for use in these easy-to-spot stations. Set them up in a central location in your facility or place them near equipment that needs frequent maintenance. The bright colors and clear labeling remind your team to use lockout procedures when working. These stations help you comply with OSHA 29 CFR 1910.147, which requires you to lock out power sources during maintenance to prevent unexpected machine startups.

Racks and boards have open storage, so you can see and access your tools without the need for keys. These stations make inspections easier, since you can tell at a glance whether everything is in place. Mount them to a wall to create a permanent home for your lockout tools.

All stations resist some impact, but metal stations are stronger than plastic stations. Stainless steel stations resist corrosion in damp areas better than regular steel stations.

Stations that meet UL 2809-2 are made of 100% recycled materials. They’re UL validated to meet ongoing purchasing requirements for LEED-certified facilities.

Overall | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Style | Compartment Type | Ht. | Wd. | Dp. | For Max. No. of Padlocks | No. of Bins | Bar Thick. | Specifications Met | Each | |

Painted Stainless Steel | ||||||||||

| D | Bin, Bar | 10" | 8" | 5 1/2" | 7 | 1 | 1" | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 000000 |

Weather-Resistant Extra-Clearance

Choose-a-Color Lockout Padlocks with Labels

Fit the extra-long shackle of these padlocks around oversized hasps and chains to lock out equipment outdoors. They come in a variety of colors that catch your eye and display a warning label that alerts you to locked-out machines. Assign colors to individuals or functions, such as blue for plumbing and red for electrical, to meet lockout identification standards. To prevent accidental startups during maintenance, pair them with a lockout device. This helps you comply with OSHA 29 CFR 1910.147 standards for safe lockouts. Made from materials that resist corrosion from rain and snow, these locks will operate smoothly even when exposed to the elements. They have a plastic cover that protects the lock body and prevents them from damaging nearby surfaces.

These padlocks don’t let you remove the key from the lock until you close the shackle. This makes sure you properly secure locks before walking away with the key. These locks are keyed differently, so they each open with a different key.

Aluminum-body locks are stronger and hold up better against break-in attempts than brass-body locks. They’re made of at least 70% recycled materials to help meet UL 2809-2 requirements for LEED-certified facilities.

Steel shackles are stronger than stainless steel shackles. Hardened steel shackles are stronger than unhardened steel and stainless steel shackles. Stainless steel shackles are more resistant to corrosion than steel or hardened steel shackles. Plastic-coated shackles help resist corrosion. The plastic also makes them less conductive, keeping you safe when locking out electrical panels or other equipment.

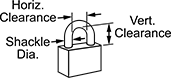

Shackle | Body | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vertical Clearance | Horizontal Clearance | Dia. | Material | Ht. | Wd. | Thick. | Message | No. of Keys Included | Choose a Cover Color | Specifications Met | Each | |

Solid Aluminum Body | ||||||||||||

| 3" | 3/4" | 1/4" | Plastic-Coated Steel | 1 3/4" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove | 1 | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 0000000 | 000000 | |

| 3" | 3/4" | 1/4" | Plastic-Coated Hardened Steel | 1 3/4" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove | 1 | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 0000000 | 00000 | |

Solid Aluminum Body with Plastic Keyhole Cover | ||||||||||||

| 3" | 7/8" | 3/16" | Stainless Steel | 1 3/4" | 1 1/2" | 3/4" | Danger—Locked Out Do Not Remove | 1 | Red | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 00000 |