About Accident Prevention Signs

More

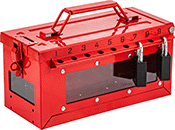

Lockout Organizing Stations

Keep padlocks, tags, and other lockout tools neatly stored and ready for use in these easy-to-spot stations. Set them up in a central location in your facility or place them near equipment that needs frequent maintenance. The bright colors and clear labeling remind your team to use lockout procedures when working. These stations help you comply with OSHA 29 CFR 1910.147, which requires you to lock out power sources during maintenance to prevent unexpected machine startups.

Racks and boards have open storage, so you can see and access your tools without the need for keys. These stations make inspections easier, since you can tell at a glance whether everything is in place. Mount them to a wall to create a permanent home for your lockout tools.

For extra security, use cabinets—they can be locked to limit access to your tools. Style E has a transparent window, so your tools remain visible while they are secured. Move the adjustable shelves on styles G and J to make room for large or odd-shaped devices, such as circuit-breaker and valve lockouts. Unlike the other cabinets, which are wall-mount only, style G also has a handle so you can carry them wherever they’re needed.

All stations resist some impact, but metal stations are stronger than plastic stations. Steel stations are plastic- or powder-coated to resist corrosion in damp areas. Plastic stations resist corrosion in damp areas better than steel stations. Stainless steel stations resist corrosion in damp areas better than regular steel stations.

Stations that meet UL 2809-2 are made of 100% recycled materials. They’re UL validated to meet ongoing purchasing requirements for LEED-certified facilities.

Boards | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Pegboard Hooks | |||||||||||||

| Style | Compartment Type | Ht. | Wd. | Dp. | For Max. No. of Padlocks | No. of Hooks Included | For No. of Hooks | No. of Bins | Bar Thick. | Specifications Met | Each | Each | ||

Plastic | ||||||||||||||

| B | Hook | 9" | 12" | 3" | 4 | 5 | 5 | __ | __ | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | 000000 | 00 |

| B | Hook | 19" | 12" | 3" | 10 | 13 | 13 | __ | __ | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | 000000 | 00 |

| B | Hook | 19" | 24" | 3" | 20 | 24 | 24 | __ | __ | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | 000000 | 00 |

| B | Hook | 32" | 24" | 3" | 50 | 54 | 54 | __ | __ | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | 000000 | 00 |

| C | Hook, Bin, Bar | 30" | 25" | 5 1/4" | 25 | 8 | 34 | 4 | 3/8" | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | 0000000 | 00000 |

Painted Stainless Steel | ||||||||||||||

| D | Bin, Bar | 10" | 8" | 5 1/2" | 7 | __ | __ | 1 | 1" | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 00000 | 000000 | 00 |

Cabinets | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Lock | Pegboard Hooks | |||||||||||||||

| Style | Compartment Type | Ht. | Wd. | Dp. | For Max. No. of Padlocks | No. of Hooks Included | For No. of Hooks | No. of Bins | Bar Thick. | No. of Shelves | Type | For Max. Padlock Shackle Dia. | No. of Keys Included | Each | Each | ||

Plastic | |||||||||||||||||

| E | Hook, Bin, Bar | 26" | 19 1/2" | 5" | 20 | 6 | 24 | 1 | 3/8" | __ | Padlockable | 3/16" | __ | 0000000 | 0000000 | 0000000 | 00000 |

| E | Hook, Bin, Bar | 30" | 25" | 5 1/4" | 25 | 8 | 34 | 4 | 3/8" | __ | Padlockable | 3/16" | __ | 0000000 | 000000 | 0000000 | 0000 |

| F | Shelf | 18" | 14" | 9 1/2" | __ | __ | __ | __ | __ | 3 | Padlockable | 9/32" | __ | 0000000 | 000000 | 000000 | 00 |

Powder-Coated Steel | |||||||||||||||||

| G | Shelf | 16" | 14" | 6" | __ | __ | __ | __ | __ | 2 | Padlockable | 9/32" | __ | 0000000 | 000000 | 000000 | 00 |

| H | Hook | 10" | 12" | 2" | 16 | 8 | 8 | __ | __ | __ | Keyed | __ | 2 | 0000000 | 000000 | 000000 | 00 |

| H | Hook | 15 1/2" | 18" | 2" | 36 | 18 | 18 | __ | __ | __ | Keyed | __ | 2 | 0000000 | 000000 | 000000 | 00 |

| J | Shelf | 30 1/4" | 15" | 9 1/2" | __ | __ | __ | __ | __ | 3 | Keyed | __ | 2 | 0000000 | 000000 | 000000 | 00 |

Wall-Mount Electrical and Valve Lockout Sets with Padlocks

Keep everything you need to lock out most electrical equipment and valves around your facility in a single spot against the wall. These sets have supplies for locking out circuit breakers, valves, plugs, wall switches, and other controls. The supplies are red or yellow to alert people to maintenance. They help you comply with OSHA 29 CFR 1910.147, which requires power sources and supply lines to be locked out to prevent injuries.

Cabinets are made of stainless steel, so they resist damage better than our plastic cases. They meet UL 2809-2, so they’re made of at least 90% recycled materials to meet purchasing requirements for LEED-certified facilities.

Cases have a clear plastic cover to protect lockout items against water and dust while still letting you see inside. They have a larger set of supplies than our cabinets, including a cable lockout for weaving through and around panel boxes, valve wheels, and other hard-to-secure equipment.

Mounting Holes | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Includes | Ht. | Wd. | Dp. | Fasteners Included | No. | Screw Size | Specifications Met | Each | |

Cabinets | |||||||||

| 1 Each: Gas Cylinder Lockout 1 Each: Wall Switch Lockout 2 Each: Plug Lockouts 2 Valve Wheel Lockouts (1 Each that fits 1"-2 1/2" and 2 1/2"-5" Diameter Wheels) 3 Each: Circuit Breaker Lockouts 4 Each: Lockout Hasps 4 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 10 Each: Tags 10 Each: Cable Ties | 16" | 15 1/4" | 5 1/2" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 0000000 |

Cases | |||||||||

| 1 Each: Cable Lockout 1 Each: Snap-On Lockout Hasp 2 Each: Plug Lockouts 2 Each: Lockout Hasps 2 Each: Valve Handle Lockouts (Fits 3/8 to 4 Pipe Size) 2 Each: Wall Switch Lockouts 4 Valve Wheel Lockouts (1 Each that fits 1"-3", 2"-5", 4"-6 1/2", and 6"-10" Diameter Wheels) 6 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 8 Each: Circuit Breaker Lockouts 24 Each: Tags 24 Each: Cable Ties | 27" | 23 1/2" | 4 1/2" | No | 8 | No. 10 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |

Wall-Mount Lockout Sets with Padlocks

Keep items for group lockouts organized and within reach with these sets. They mount to a wall and provide hangers for your lockout supplies. All padlocks and hasps are red, and the board or case is yellow plastic, so these sets are easy to see. They help you comply with OSHA 29 CFR 1910.147 requirements for the control of hazardous energy.

Cases have a clear plastic cover to protect lockout items against water and dust.

Sets that meet UL 2809-2 are made of 100% recycled materials and are sustainably sourced to meet purchasing requirements for LEED-certified facilities.

Mounting Holes | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Includes | Ht. | Wd. | Dp. | Fasteners Included | No. | Screw Size | Specifications Met | Each | |

Boards | |||||||||

| 3 Each: Cable Ties 2 Each: Lockout Hasps 3 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 3 Each: Tags | 11" | 11" | 2 1/2" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 0000000 |

| 10 Each: Cable Ties 2 Each: Lockout Hasps 8 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 10 Each: Tags | 15" | 15" | 2 1/2" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 000000 |

| 10 Each: Cable Ties 2 Each: Lockout Hasps 12 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 10 Each: Tags | 23" | 15" | 2 1/2" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 000000 |

| 2 Each: Lockout Hasps 16 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 10 Each: Tags | 13 1/2" | 14 1/2" | 3" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 |

Cases | |||||||||

| 12 Each: Cable Ties 2 Each: Lockout Hasps 4 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 12 Each: Tags | 12 1/4" | 16" | 1 3/4" | No | 4 | No. 6 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |

| 24 Each: Cable Ties 2 Each: Lockout Hasps 10 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 24 Each: Tags | 15 1/2" | 22" | 1 3/4" | No | 4 | No. 6 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |

Lockout Procedure Stations

Store all of your lockout safety procedure forms in one place. Mount them in a prominent spot in your facility or near equipment that’s either used often or that requires unique lockout procedures.

Using these stations helps you create a program for locking out energy sources such as electricity, hydraulics, and steam that adheres to OSHA 29 CFR 1910.147 standards. To keep your procedures current, you can update these forms to reflect changes to equipment.

Binder racks hold binders that you fill with one form for each piece of equipment—the form lists the equipment’s required lockouts.

Document displays help you display permits and procedures. They have space for storing additional forms and documents. Those that are plastic have a removable clipboard so you can fill out forms, checklists, and audits on the go. Those that are stainless steel are ideal for the outdoors and other wet environments—they resist corrosion better than plastic stations. They also have an IP03-rated gasket that seals your documents against water. A powder coating gives them even more corrosion resistance and ensures they don’t scuff the surfaces they touch. You can mount them to a wall or use the handle to carry them around. Use the included dry erase label to write down permit and work order numbers.

Mounting Holes | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Material | Mounting Fasteners Included | No. of | Dia. | Environmental Rating | Specifications Met | Features | Includes | Each | |

Binder Racks | ||||||||||||

| 20" | 14" | 4 1/2" | Plastic | Yes | 4 | 1/4" | __ | OSHA Compliant 29 CFR 1910.147 | __ | 1 Each: Lockout Safety Procedure Binder 25 Each: Lockout Procedure Template Forms | 0000000 | 000000 |

Document Displays | ||||||||||||

| 17" | 9 3/4" | 1 1/2" | Plastic | No | 2 | 3/16" | __ | OSHA Compliant 29 CFR 1910.147 | Removable Clipboard | __ | 00000000 | 000000 |

| 17 1/4" | 12 1/8" | 2 1/4" | Powder-Coated 430 Stainless Steel | No | 6 | 3/8" | IP03 | OSHA Compliant 29 CFR 1910.147 | Handle | 1 Each: Dry Erase Label | 00000000 | 000000 |

Pkg. | |||

|---|---|---|---|

| Pkg. Qty. | 1-4 | 5-Up | |

| 25 | 0000000 | 000000 | 000000 |

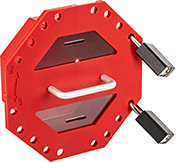

Portable/Wall-Mount Group Lockout Boxes

Carry these boxes from job to job and mount them near equipment to lock out valves, electrical controls, and other machines with fewer padlocks, saving your team time. With these lockout boxes, you only need one padlock to lock out a piece of equipment. When starting maintenance work, have each person lock their own padlock to the outside of the box and place their key inside. The keys are only accessible once everyone has removed their padlocks, keeping your team safe. Each box has hooks to keep your keys organized and easy to identify. Once these boxes are locked, you can still add keys through a slot. All boxes help you comply with OSHA 29 CFR 1910.147 procedures for controlling hazardous energy.

Plastic boxes are lightweight and corrosion resistant. They’re also nonconductive for use near electronics. While they’re a durable option, they aren’t as strong as steel and stainless steel boxes. Steel boxes are stronger than stainless steel boxes. They’re powder coated for corrosion protection. Stainless steel boxes resist corrosion better than steel boxes, and they’re powder coated for even more corrosion resistance. They’re stronger than plastic boxes, but weaker than steel boxes.

Boxes with a polycarbonate plastic window let you view the keys inside. Thanks to its material, the window protects your keys from water exposure and resists impact to prevent break-ins.

Boxes with a wall-mount bracket make it easy to secure your box to a wall and remove it. To secure and prevent unwanted removal, place the box against the mounted bracket and slide the locking mechanism inside of the box in place. To remove, unlock the cover of the box and slide the locking mechanism to the unlocked position.

Boxes with a document display let you view checklists and permits as you lock out equipment, reducing the risk of injury. Thanks to an IP-rated gasket, they’ll keep your documents protected in damp environments. The lock caddy is removable so it’s easy to transport your padlocks and keys during lockout. For easy retrieval of the keys you drop through the slot, the key cup that collects them is removable as well.

Boxes with a control-lock hole have a dedicated spot for supervisors to lock the box closed.

Boxes with a dry erase label are helpful to write down permit and work order numbers.

Mounting Holes | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Color | Lg. | Wd. | Ht. | For Max. No. of Padlocks (Hole Location) | For Max. Padlock Shackle Dia. | No. of Key Hooks | Fasteners Included | No. | Screw Size | Mounting Location | No. of Windows | Features | Environmental Rating | Each | |

(A) Plastic Box with Polycarbonate Plastic Window | |||||||||||||||

| Red | 13" | 3 1/2" | 13" | 44 (Outside of Box) | 5/16" | 16 | No | 2 | 1/4" | Freestanding, Wall | 1 | Control-Lock Hole, Handle, Key Slot | __ | 0000000 | 000000 |

(B) Powder-Coated Steel Box | |||||||||||||||

| Red | 6 3/8" | 3 1/2" | 12 3/4" | 14 (Outside of Box) | 9/32" | 12 | No | 4 | No. 8 | Freestanding, Wall | __ | Handle, Key Slot | __ | 00000000 | 00000 |

| Yellow | 6 3/8" | 3 1/2" | 12 3/4" | 14 (Outside of Box) | 9/32" | 12 | No | 4 | No. 8 | Freestanding, Wall | __ | Handle, Key Slot | __ | 00000000 | 00000 |

(C) Powder-Coated Steel Box with Polycarbonate Plastic Window | |||||||||||||||

| Red | 10 1/2" | 3 1/2" | 6 1/8" | 12 (Outside of Box) | 5/16" | 6 | No | 2 | No. 8 | Freestanding, Wall | 1 | Handle, Key Slot | __ | 0000000 | 00000 |

(D) Powder-Coated 430 Stainless Steel Box with Wall-Mount Bracket, Polycarbonate Plastic Window | |||||||||||||||

| Red | 8 3/8" | 4" | 6 7/8" | 8 (Outside of Box) | 3/8" | 4 | No | 3 | No. 10 | Freestanding, Wall | 1 | Dry Erase Label, Handle, Key Slot | __ | 0000000 | 00000 |

(E) Powder-Coated 430 Stainless Steel Box with Document Display, Polycarbonate Plastic Window | |||||||||||||||

| Red | 12 1/8" | 4 3/4" | 31" | 12 (Outside of Box); 12 (Removable Lock Caddy) | 9/32" | 12 | No | 8 | No. 8 | Wall | 2 | Control-Lock Hole, Dry Erase Label, Handle, Key Slot, Removable Key Cup | IP03 | 000000000 | 000000 |

Portable Group Lockout Boxes

Lock out a machine with fewer padlocks when a team is working. After locking one padlock to each electrical control and placing the keys in the box, each person can attach a padlock to the outside of the box before starting their work. The keys are only accessible once all padlocks have been removed, keeping everyone safe while maintenance is completed. Once these boxes are locked, you can still add keys through a slot. They help you comply with OSHA 29 CFR 1910.147 procedures for the control of energy sources that could cause injuries.

These lockout boxes resist corrosion. Plastic boxes are nonconductive. Stainless steel boxes have drain holes to keep moisture from building up inside. They're stackable for easy storage.

Styles A and C have a window, so you can view the keys inside. Made of polycarbonate plastic, the window protects your keys from water exposure and resists impact to prevent break-ins.

Boxes with a control-lock hole allow a supervisor to lock them with a control padlock. Boxes with a removable key cup make it easy to retrieve keys dropped in the key slot. Lift the cup out to access your keys.

| Style | Color | Lg. | Wd. | Ht. | For Max. No. of Padlocks (Hole Location) | Min. Padlock Vertical Shackle Clearance | For Max. Padlock Shackle Dia. | No. of Windows | Window Material | Features | Stackable | Each | |

Plastic | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | Red | 7 3/4" | 4" | 7 3/4" | 17 (Outside of Box) | 1 1/2" | 1/4" | 1 | Polycarbonate Plastic | Handle, Key Slot | No | 00000000 | 000000 |

Powder-Coated Steel | |||||||||||||

| B | Blue | 9" | 3 1/2" | 6" | 13 (Outside of Box) | 5/8" | 9/32" | __ | __ | Control-Lock Hole, Handle, Key Slot | No | 00000000 | 00000 |

| B | Red | 4 1/4" | 4 1/4" | 6 1/4" | 7 (Outside of Box) | 1" | 5/16" | __ | __ | Control-Lock Hole, Handle, Key Slot | No | 00000000 | 00000 |

| B | Red | 9" | 3 1/2" | 6" | 13 (Outside of Box) | 5/8" | 9/32" | __ | __ | Control-Lock Hole, Handle, Key Slot | No | 00000000 | 00000 |

| B | Yellow | 10" | 4" | 6" | 13 (Outside of Box) | 3/4" | 5/16" | __ | __ | Control-Lock Hole, Handle, Key Slot | No | 000000000 | 00000 |

| C | Red | 8" | 4 1/2" | 4 3/4" | 20 (Outside of Box) | 3/4" | 1/4" | 2 | Polycarbonate Plastic | Handle, Key Slot | No | 00000000 | 000000 |

| C | Red | 12" | 8 1/4" | 9" | 21 (Outside of Box) | 1/2" | 5/16" | 1 | Polycarbonate Plastic | Control-Lock Hole, Handle, Key Slot, Removable Key Cup | Yes | 00000000 | 000000 |

Powder-Coated Stainless Steel | |||||||||||||

| C | Red | 12" | 6 1/2" | 5 3/4" | 19 (Outside of Box) | 3/4" | 3/8" | 1 | Polycarbonate Plastic | Control-Lock Hole, Drain Holes, Handle, Key Slot, Removable Key Cup | Yes | 00000000 | 00000 |

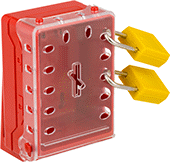

Wall-Mount Group Lockout Boxes

Lock out a machine with fewer padlocks when a team is working. After locking one padlock to each electrical control and placing the keys in the box, each person locks their own padlock to the outside of these boxes. The keys are only accessible once all the padlocks have been removed—keeping your group safe. Once these boxes are locked, you can still add keys through a slot. Made of plastic, they’re lightweight, durable, corrosion resistant, and nonconductive. A plastic window lets you view the keys inside while protecting them from water exposure. These boxes help you comply with OSHA 29 CFR 1910.147 procedures for the control of energy sources that could cause injuries.

Boxes with a control-lock hole allow a supervisor to lock them with a control padlock.

Boxes with a wall-mount bracket make it easy to remove your box from a wall. After you mount the bracket, these boxes slide on and off of it.

Mounting Holes | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Color | Lg. | Wd. | Ht. | For Max. No. of Padlocks (Hole Location) | For Max. Padlock Shackle Dia. | No. of Key Hooks | Fasteners Included | No. | Screw Size | Number of Windows | Window Material | Features | Includes | Each | |

Plastic | |||||||||||||||

| Red | 2 3/4" | 4" | 5 3/4" | 12 (Outside of Box) | 9/32" | 3 | No | 3 | No. 4 | 1 | Polycarbonate Plastic | Key Slot | Wall-Mount Bracket | 00000000 | 000000 |

| Red | 4" | 13" | 11" | 26 (Outside of Box) | 15/32" | 11 | No | 2 | No. 10 | 1 | Polycarbonate Plastic | Control-Lock Hole, Key Slot | __ | 000000000 | 000000 |

Three-Way View Lockout Signs

Mark your lockout station with a sign that employees will see from anywhere in the room. When mounted on the wall, these triangular signs pop out like a tent, so workers see them from straight-on as well as from either side of the sign. They'll always know where to find lockout tags, devices, procedures, and other equipment. The signs also serve as a reminder to use lockouts when performing maintenance.

Having a visible lockout station helps your organization comply with OSHA 29 CFR 1910.147, which requires energy sources to be locked out during maintenance.

Mounting | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Thick. | Flange Wd. | Material | Fasteners Included | Number of Holes | Hole Dia. | Specifications Met | Each | |

Lock-Out Center with Arrow (English)—Red with White Message | |||||||||||

| 6" | 9" | 4" | 1/8" | 1" | Vinyl Plastic | No | 2 | 3/16" | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |

Lock-Out Center with Arrow (English)—White with Red Message | |||||||||||

| 6" | 9" | 4" | 1/8" | 1" | Vinyl Plastic | No | 2 | 3/16" | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 |

Lockout Safety Center with Arrow (English)—White with Red Message | |||||||||||

| 6" | 9" | 4" | 1/8" | 1" | Acrylic Plastic | Yes | 2 | 3/16" | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 |

Tag Organizing Stations

Create a permanent home for keeping frequently used tags handy. These stations have bins that fit standard accident prevention, lockout/tagout, inspection, inventory, and 5S discard tags. You can also use them to display tags that log the status of current or scheduled maintenance.

Compartment | Mounting Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | For Max. No. of Tags | No. of | Type | Ht. | Wd. | Dp. | Color | Material | Mounting Fasteners Included | Dia. | No. of | Each | |

| 15 3/4" | 23 1/2" | 2" | 240 | 8 | Bin | 4 1/2" | 3 1/2" | 7/8" | Clear | Acrylic Plastic | No | 3/16" | 4 | 0000000 | 000000 |