About Gears

More

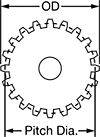

Metal Ratcheting Gears

Compared to plastic gears, these metal ratcheting gears are better for high-load, high-speed, and heavy duty applications. Used to prevent unwanted motion in jacks, tie downs, clutches, and winches, ratchet gears have sloped teeth that allow motion in one direction and prevent it in the other.

Gears with hardened teeth are more wear resistant than gears with teeth that are not hardened. Gears with teeth that are not hardened can be hardened to fit your application. Hardening a gear’s teeth increases its wear resistance.

A pawl is required to prevent backward motion.

For technical drawings and 3-D models, click on a part number.

Hub | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Face Wd. | Number of Teeth | OD | For Shaft Dia. | Mounting Distance | Material | Teeth Heat Treatment | Overall Wd. | Dia. | Wd. | Each | |

Round Bore | |||||||||||

| 1/4" | 18 | 0.75" | 3/8" | 0.74" | 303 Stainless Steel | Not Hardened | __ | __ | __ | 0000000 | 000000 |

| 1/4" | 24 | 1" | 3/8" | 0.83" | 303 Stainless Steel | Not Hardened | __ | __ | __ | 0000000 | 00000 |

| 1/4" | 30 | 1.25" | 1/4" | 0.92" | 303 Stainless Steel | Not Hardened | __ | __ | __ | 0000000 | 00000 |

| 3/8" | 24 | 1.5" | 11/16" | 1.6" | 303 Stainless Steel | Not Hardened | __ | __ | __ | 0000000 | 00000 |

| 3/8" | 32 | 2" | 11/16" | 1.75" | 303 Stainless Steel | Not Hardened | __ | __ | __ | 0000000 | 00000 |

| 3/8" | 48 | 3" | 11/16" | 2.1" | 303 Stainless Steel | Not Hardened | __ | __ | __ | 0000000 | 00000 |

| 3/8" | 64 | 4" | 11/16" | 2.5" | 303 Stainless Steel | Not Hardened | __ | __ | __ | 0000000 | 000000 |

| 6mm | 50 | 33.3mm | 10mm | 33.8mm | 1045 Carbon Steel | Hardened | 6 mm | __ | __ | 0000000 | 00000 |

| 6mm | 50 | 33.3mm | 10mm | 33.8mm | 1045 Carbon Steel | Hardened | 16 mm | 25 mm | 10 mm | 0000000 | 00000 |

| 6mm | 60 | 40mm | 10mm | 35.5mm | 1045 Carbon Steel | Hardened | 6 mm | __ | __ | 0000000 | 00000 |

| 6mm | 80 | 53.3mm | 12mm | 39.5mm | 1045 Carbon Steel | Hardened | 16 mm | 35 mm | 10 mm | 0000000 | 00000 |

| 6mm | 100 | 66.6mm | 12mm | 44.1mm | 1045 Carbon Steel | Hardened | 6 mm | __ | __ | 0000000 | 00000 |

| 6mm | 100 | 66.6mm | 12mm | 44.1mm | 1045 Carbon Steel | Hardened | 16 mm | 40 mm | 10 mm | 0000000 | 00000 |

| 12mm | 50 | 50mm | 12mm | 45.5mm | 1045 Carbon Steel | Hardened | 12 mm | __ | __ | 0000000 | 00000 |

| 12mm | 50 | 50mm | 12mm | 45.5mm | 1045 Carbon Steel | Hardened | 24 mm | 35 mm | 12 mm | 0000000 | 00000 |

| 12mm | 60 | 60mm | 15mm | 48.2mm | 1045 Carbon Steel | Hardened | 12 mm | __ | __ | 0000000 | 00000 |

| 12mm | 60 | 60mm | 15mm | 48.2mm | 1045 Carbon Steel | Hardened | 24 mm | 40 mm | 12 mm | 0000000 | 00000 |

| 12mm | 80 | 80mm | 15mm | 54.7mm | 1045 Carbon Steel | Hardened | 12 mm | __ | __ | 0000000 | 00000 |

| 12mm | 80 | 80mm | 15mm | 54.7mm | 1045 Carbon Steel | Hardened | 24 mm | 50 mm | 12 mm | 0000000 | 00000 |

| 12mm | 100 | 100mm | 15mm | 62.2mm | 1045 Carbon Steel | Hardened | 12 mm | __ | __ | 0000000 | 00000 |

| 12mm | 100 | 100mm | 15mm | 62.2mm | 1045 Carbon Steel | Hardened | 24 mm | 50 mm | 12 mm | 0000000 | 00000 |

| 15mm | 30 | 60mm | 15mm | 61.2mm | 1045 Carbon Steel | Hardened | 15 mm | __ | __ | 0000000 | 00000 |

| 15mm | 60 | 120mm | 15mm | 79.1mm | 1045 Carbon Steel | Hardened | 15 mm | __ | __ | 0000000 | 000000 |

| 20mm | 30 | 90mm | 15mm | 76.3mm | 1045 Carbon Steel | Hardened | 20 mm | __ | __ | 0000000 | 00000 |

| 20mm | 40 | 120mm | 20mm | 85.2mm | 1045 Carbon Steel | Hardened | 20 mm | __ | __ | 0000000 | 000000 |

| 20mm | 50 | 150mm | 20mm | 95.5mm | 1045 Carbon Steel | Hardened | 20 mm | __ | __ | 0000000 | 000000 |

| 25mm | 30 | 120mm | 20mm | 95.7mm | 1045 Carbon Steel | Hardened | 25 mm | __ | __ | 0000000 | 000000 |

| 25mm | 50 | 200mm | 20mm | 122.4mm | 1045 Carbon Steel | Hardened | 43 mm | 100 mm | 18 mm | 00000000 | 000000 |

| For Face Wd. | For Shaft Dia. | Overall Lg. | Material | Center-to-End Lg. | Each | |

Round Bore | ||||||

|---|---|---|---|---|---|---|

| 1/4" | 3/32" | 3/4" | 303 Stainless Steel | 9/16" | 0000000 | 000000 |

| 3/8" | 1/4" | 1 9/16" | 17-4 PH Stainless Steel | 1 5/16" | 0000000 | 00000 |

| 6mm | 5mm | 38mm | 1045 Carbon Steel | 30mm | 0000000 | 00000 |

| 12mm | 8mm | 49mm | 1045 Carbon Steel | 39mm | 0000000 | 00000 |

| 15mm | 10mm | 67.5mm | 1045 Carbon Steel | 55mm | 0000000 | 00000 |

| 20mm | 12mm | 80mm | 1045 Carbon Steel | 65mm | 0000000 | 00000 |

| 25mm | 13mm | 98mm | 1045 Carbon Steel | 80mm | 0000000 | 00000 |

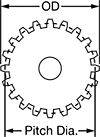

Plastic Ratcheting Gears

A light duty alternative to metal, these plastic ratcheting gears run quieter than metal gears and have good corrosion and chemical resistance. Used to prevent unwanted motion in spools, clocks, and printers, ratchet gears have sloped teeth that allow motion in one direction and prevent it in the other.

A pawl is required to prevent backward motion.

For technical drawings and 3-D models, click on a part number.

| For Face Wd. | For Shaft Dia. | Overall Lg. | Material | Fabrication | Color | Center-to-End Lg. | Each | |

Round Bore | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4" | 3/32" | 3/4" | Nylon Plastic | Machined | White | 9/16" | 0000000 | 000000 |

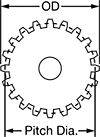

Metal Worms and Worm Gears

Worm gears use screw threads to make large reductions to shaft speed while transmitting motion at a right angle. They transmit motion from worm to gear and cannot be reversed. For gears and worms to mesh correctly, they must have the same pressure angle, pitch/module, number of thread starts, and thread direction. These worms are compatible with plastic worm gears.

Speed ratio is the ratio by which output shaft speed is reduced. As speed decreases, torque increases.

Cast iron gears are strong and durable.

Bronze gears have low friction and dissipate heat better than cast iron gears to provide a long service life for both the gear and the worm. They’re also more corrosion resistant than cast iron gears.

For technical drawings and 3-D models, click on a part number.

Hub | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gear Pitch | Speed Ratio | Number of Teeth | Pressure Angle | Gear Pitch Dia. | For Number of Thread Starts | OD | Face Wd. | Overall Wd. | For Shaft Dia. | Dia. | Wd. | Material | For Thread Direction | Teeth Heat Treatment | Teeth Fabrication | Each | |

Round Bore—Cast Iron | |||||||||||||||||

| 12 | 18:1 | 18 | 14 1/2° | 1 1/2" | 1 | 1.69" | 1/2" | 1.125" | 1/2" | 1.25" | 0.625" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 12 | 20:1 | 20 | 14 1/2° | 1.67" | 1 | 1.85" | 1/2" | 1.125" | 1/2" | 1.25" | 0.625" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 12 | 30:1 | 30 | 14 1/2° | 2 1/2" | 1 | 2.69" | 1/2" | 1.125" | 1/2" | 1.25" | 0.625" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 12 | 40:1 | 40 | 14 1/2° | 3.33" | 1 | 3.52" | 1/2" | 1.25" | 5/8" | 1.5" | 0.75" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 12 | 60:1 | 60 | 14 1/2° | 5" | 1 | 5.19" | 1/2" | 1.25" | 5/8" | 1.75" | 0.75" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 10 | 20:1 | 20 | 14 1/2° | 2" | 1 | 2.22" | 5/8" | 1.375" | 1/2" | 1.25" | 0.75" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 10 | 30:1 | 30 | 14 1/2° | 3" | 1 | 3.22" | 5/8" | 1.375" | 5/8" | 1.75" | 0.75" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 10 | 40:1 | 40 | 14 1/2° | 4" | 1 | 4.22" | 5/8" | 1.375" | 5/8" | 1.75" | 0.75" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 10 | 50:1 | 50 | 14 1/2° | 5" | 1 | 5.22" | 5/8" | 1.375" | 3/4" | 2" | 0.75" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 10 | 100:1 | 100 | 14 1/2° | 10" | 1 | 10.22" | 5/8" | 1.375" | 3/4" | 2.5" | 0.75" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 8 | 20:1 | 20 | 14 1/2° | 2 1/2" | 1 | 2.78" | 3/4" | 1.5" | 3/4" | 1.75" | 0.75" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 8 | 30:1 | 30 | 14 1/2° | 3 3/4" | 1 | 4.03" | 3/4" | 1.5" | 3/4" | 1.75" | 0.75" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 8 | 40:1 | 40 | 14 1/2° | 5" | 1 | 5.28" | 3/4" | 1.625" | 1" | 2.375" | 0.875" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 6 | 20:1 | 20 | 14 1/2° | 3.33" | 1 | 3.71" | 1" | 1.875" | 3/4" | 1.875" | 0.875" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 6 | 24:1 | 24 | 14 1/2° | 4" | 1 | 4.37" | 1" | 1.875" | 3/4" | 1.875" | 0.875" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 6 | 30:1 | 30 | 14 1/2° | 5" | 1 | 5.37" | 1" | 1.875" | 7/8" | 2.25" | 0.875" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 6 | 40:1 | 40 | 14 1/2° | 6.67" | 1 | 7.04" | 1" | 1.875" | 1" | 2.5" | 0.875" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 6 | 72:1 | 72 | 14 1/2° | 12" | 1 | 12.37" | 1" | 2.25" | 1 1/4" | 3" | 1.25" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

Round Bore—Bronze | |||||||||||||||||

| 12 | 20:1 | 20 | 14 1/2° | 1.67" | 1 | 1.87" | 1/2" | 1" | 1/2" | 1.25" | 0.5" | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 12 | 30:1 | 30 | 14 1/2° | 2 1/2" | 1 | 2.7" | 1/2" | 1.12" | 1/2" | 1.19" | 0.62" | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 12 | 40:1 | 40 | 14 1/2° | 3.33" | 1 | 3.54" | 1/2" | 1.12" | 5/8" | 1.44" | 0.62" | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 10 | 20:1 | 20 | 14 1/2° | 2" | 1 | 2.24" | 5/8" | 1.245" | 1/2" | 1.25" | 0.62" | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 10 | 30:1 | 30 | 14 1/2° | 3" | 1 | 3.24" | 5/8" | 1.245" | 5/8" | 1.69" | 0.62" | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 10 | 40:1 | 40 | 14 1/2° | 4" | 1 | 4.24" | 5/8" | 1.245" | 5/8" | 1.69" | 0.62" | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 10 | 50:1 | 50 | 14 1/2° | 5" | 1 | 5.24" | 5/8" | 1.375" | 3/4" | 1.94" | 0.75" | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

Hub | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Module | Speed Ratio | Number of Teeth | Pressure Angle | Gear Pitch Dia., mm | For Number of Thread Starts | OD, mm | Face Wd., mm | Overall Wd., mm | For Shaft Dia., mm | Dia., mm | Wd., mm | Material | For Thread Direction | Teeth Heat Treatment | Teeth Fabrication | Each | |

Round Bore—Cast Iron | |||||||||||||||||

| 1 | 120:1 | 120 | 20° | 120 | 1 | 123 | 10 | 20 | 10 | 40 | 10 | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 1 | 60:1 | 60 | 20° | 60 | 1 | 63 | 10 | 20 | 10 | 30 | 10 | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1 | 100:1 | 100 | 20° | 100 | 1 | 103 | 10 | 20 | 10 | 40 | 10 | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1 | 80:1 | 80 | 20° | 80 | 1 | 83 | 10 | 20 | 10 | 35 | 10 | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1.5 | 30:1 | 30 | 20° | 45 | 1 | 49.5 | 12 | 22 | 10 | 30 | 10 | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1.5 | 40:1 | 40 | 20° | 60 | 1 | 64.5 | 12 | 22 | 12 | 30 | 10 | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 2 | 20:1 | 20 | 14 1/2° | 40 | 1 | 46 | 22 | 35 | 12 | 33 | 13 | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 2 | 10:1 | 20 | 14 1/2° | 40 | 2 | 46 | 22 | 35 | 12 | 33 | 13 | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 2.5 | 10:1 | 20 | 20° | 50 | 2 | 57.5 | 22 | 36 | 12 | 35 | 14 | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

Round Bore—Bronze | |||||||||||||||||

| 0.5 | 15:1 | 30 | 20° | 15 | 2 | 16 | 5 | 12 | 4 | 12 | 7 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 0.5 | 20:1 | 20 | 20° | 10 | 1 | 11 | 5 | 12 | 4 | 9 | 7 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 0.5 | 30:1 | 30 | 20° | 15 | 1 | 16 | 5 | 12 | 4 | 12 | 7 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 0.5 | 40:1 | 40 | 20° | 20 | 1 | 21 | 5 | 12 | 5 | 15 | 7 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 0.5 | 50:1 | 50 | 20° | 25 | 1 | 26 | 5 | 12 | 5 | 20 | 7 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 0.5 | 60:1 | 60 | 20° | 30 | 1 | 31 | 5 | 12 | 5 | 25 | 7 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 0.5 | 10:1 | 20 | 20° | 10 | 2 | 11 | 5 | 12 | 4 | 9 | 7 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 0.8 | 20:1 | 20 | 20° | 16 | 1 | 17.6 | 9 | 18 | 5 | 12 | 9 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 0.8 | 30:1 | 30 | 20° | 24 | 1 | 25.6 | 9 | 18 | 5 | 18 | 9 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 0.8 | 40:1 | 40 | 20° | 32 | 1 | 33.6 | 9 | 18 | 6 | 20 | 9 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 0.8 | 10:1 | 20 | 20° | 16 | 2 | 17.6 | 9 | 18 | 5 | 12 | 9 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1 | 30:1 | 30 | 20° | 30 | 1 | 33 | 10 | 20 | 6 | 20 | 10 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1 | 10:1 | 20 | 20° | 20 | 2 | 23 | 10 | 20 | 6 | 16 | 10 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1.25 | 20:1 | 20 | 20° | 25 | 1 | 28.75 | 10 | 20 | 6 | 20 | 10 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1.5 | 15:1 | 30 | 20° | 45 | 2 | 49.5 | 12 | 22 | 10 | 30 | 10 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1.5 | 20:1 | 20 | 20° | 30 | 1 | 34.5 | 12 | 22 | 8 | 22 | 10 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1.5 | 30:1 | 30 | 20° | 45 | 1 | 49.5 | 12 | 22 | 10 | 30 | 10 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1.5 | 10:1 | 20 | 20° | 30 | 2 | 34.5 | 12 | 22 | 8 | 22 | 10 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

Plastic Worm Gears

These plastic gears are lighter and quieter than metal gears—pair them with metal worms for lubrication-free operation. Worm gears use screw threads to make large reductions to shaft speed while transmitting motion at a right angle. They transmit motion from worm to gear and cannot be reversed. For gears and worms to mesh correctly, they must have the same pressure angle, pitch/module, number of thread starts, and thread direction.

Speed ratio is the ratio by which output shaft speed is reduced. As speed decreases, torque increases.

Acetal gears are lightweight, and resist corrosion and chemicals. They absorb less moisture than nylon gears, so they’re less prone to dimensional changes. They’re best suited for light duty applications, such as prototyping.

Nylon gears are lightweight and stronger than acetal gears.

For technical drawings and 3-D models, click on a part number.

Hub | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Module | Speed Ratio | Number of Teeth | Pressure Angle | Gear Pitch Dia., mm | For Number of Thread Starts | OD, mm | Face Width, mm | Overall Width, mm | For Shaft Diameter, mm | Material | Fabrication | Color | Diameter, mm | Width, mm | For Thread Direction | Each | |

Round Bore | |||||||||||||||||

| 0.5 | 10:1 | 20 | 20° | 10 | 2 | 11 | 5 | 12 | 4 | Acetal Plastic | Molded | White | 9 | 7 | Right Hand | 00000000 | 000000 |

| 0.5 | 20:1 | 20 | 20° | 10 | 1 | 11 | 5 | 12 | 4 | Acetal Plastic | Molded | White | 9 | 7 | Right Hand | 00000000 | 00000 |

| 0.5 | 30:1 | 30 | 20° | 15 | 1 | 16 | 5 | 12 | 4 | Acetal Plastic | Molded | White | 12 | 7 | Right Hand | 00000000 | 00000 |

| 0.5 | 40:1 | 40 | 20° | 20 | 1 | 21 | 5 | 12 | 5 | Acetal Plastic | Molded | White | 15 | 7 | Right Hand | 00000000 | 00000 |

| 0.5 | 50:1 | 50 | 20° | 25 | 1 | 26 | 5 | 12 | 5 | Acetal Plastic | Molded | White | 20 | 7 | Right Hand | 00000000 | 00000 |

| 0.5 | 60:1 | 60 | 20° | 30 | 1 | 31 | 5 | 12 | 5 | Acetal Plastic | Molded | White | 25 | 7 | Right Hand | 00000000 | 00000 |

| 0.8 | 10:1 | 20 | 20° | 16 | 2 | 17.6 | 9 | 18 | 5 | Acetal Plastic | Molded | White | 12 | 9 | Right Hand | 00000000 | 00000 |

| 0.8 | 50:1 | 50 | 20° | 40 | 1 | 41.6 | 9 | 18 | 8 | Acetal Plastic | Molded | White | 25 | 9 | Right Hand | 00000000 | 00000 |

| 0.8 | 60:1 | 60 | 20° | 48 | 1 | 49.6 | 9 | 18 | 8 | Acetal Plastic | Molded | White | 25 | 9 | Right Hand | 00000000 | 00000 |

| 1 | 10:1 | 20 | 20° | 20 | 2 | 23 | 10 | 20 | 6 | Nylon Plastic | Molded | Blue | 16 | 10 | Right Hand | 00000000 | 00000 |

| 1 | 30:1 | 30 | 20° | 30 | 1 | 33 | 10 | 20 | 6 | Nylon Plastic | Molded | Blue | 20 | 10 | Right Hand | 00000000 | 00000 |

| 1 | 50:1 | 50 | 20° | 50 | 1 | 53 | 10 | 20 | 8 | Nylon Plastic | Molded | Blue | 30 | 10 | Right Hand | 00000000 | 00000 |

| 1.5 | 10:1 | 20 | 20° | 30 | 2 | 34.5 | 12 | 22 | 8 | Nylon Plastic | Molded | Blue | 22 | 10 | Right Hand | 00000000 | 00000 |