About Gears

More

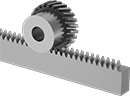

Metal Gears and Gear Racks—20° Pressure Angle

The current industry standard, these 20° pressure angle gears have thicker, stronger teeth than 14½° pressure angle gears. Compared to plastic gears and racks, they’re better for high-load, high-speed, and heavy duty applications. Also known as spur gears.

Combine gears with different numbers of teeth to change speed and torque in your assembly. Combine a gear and rack to convert rotary motion into linear motion. To minimize your footprint, mount one or more standard gears inside of an internal gear.

For components to mesh correctly, they must have the same pressure angle and pitch/module.

Brass gears and racks are easy to machine, so you can add your own mounting holes and make other alterations. They won't rust when exposed to water.

Carbon steel components have hard, strong, and wear-resistant teeth, although they will rust when exposed to moisture and corrosive chemicals. They're best for high-torque machines, like lifting equipment, and heavy duty applications, such as rock crushing. Some carbon steel gears have hardened teeth for even better wear resistance. Gears with teeth that are not hardened can be hardened to fit your application.

Stainless steel gears and racks resist rust in damp and wet environments, so they're commonly used in food-processing plants and other areas with frequent cleaning. Spacers (sold separately) work with our metric gear racks to take the measuring and guesswork out of installing two racks end-to-end, so your gear rolls smoothly from one rack to the next. With the first rack fastened in place, roughly position the second rack. Place the teeth of the spacer into the teeth of the gear racks like a puzzle piece, and then adjust the second rack until all of the teeth fit together cleanly. Not for use with inch size gear racks.

For technical drawings and 3-D models, click on a part number.

| Gear Pitch | Lg. | Pitch Ht. | Ht. | Face Wd. | Material | Teeth Heat Treatment | Each | |

| 64 | 11" | 0.464" | 1/2" | 1/4" | 416 Stainless Steel | Not Hardened | 0000000 | 0000000 |

| 64 | 2ft. | 0.11" | 1/8" | 1/8" | Brass | __ | 0000000 | 000000 |

| 48 | 18" | 0.459" | 1/2" | 1/4" | 416 Stainless Steel | Not Hardened | 0000000 | 000000 |

| 48 | 2ft. | 0.104" | 1/8" | 1/8" | Brass | __ | 0000000 | 000000 |

| 32 | 18" | 0.449" | 1/2" | 1/4" | 416 Stainless Steel | Not Hardened | 0000000 | 000000 |

| 32 | 2ft. | 0.156" | 3/16" | 3/16" | Brass | __ | 0000000 | 000000 |

| 24 | 18" | 0.438" | 1/2" | 1/4" | 416 Stainless Steel | Not Hardened | 0000000 | 000000 |

| 24 | 2ft. | 0.208" | 1/4" | 1/4" | Brass | __ | 0000000 | 000000 |

| 20 | 2ft. | 0.45" | 1/2" | 1/2" | 1018 Carbon Steel | Not Hardened | 000000 | 00000 |

| 20 | 4ft. | 0.45" | 1/2" | 1/2" | 1215 Carbon Steel | Not Hardened | 0000000 | 00000 |

| 20 | 6ft. | 0.45" | 1/2" | 1/2" | 1215 Carbon Steel | Not Hardened | 0000000 | 00000 |

| 16 | 2ft. | 0.687" | 3/4" | 3/4" | 1018 Carbon Steel | Not Hardened | 000000 | 00000 |

| 16 | 4ft. | 0.687" | 3/4" | 3/4" | 1215 Carbon Steel | Not Hardened | 0000000 | 00000 |

| 16 | 6ft. | 0.687" | 3/4" | 3/4" | 1215 Carbon Steel | Not Hardened | 0000000 | 000000 |

| 12 | 2ft. | 0.917" | 1" | 1" | 1018 Carbon Steel | Not Hardened | 000000 | 00000 |

| 12 | 4ft. | 0.917" | 1" | 1" | 1215 Carbon Steel | Not Hardened | 0000000 | 00000 |

| 12 | 6ft. | 0.917" | 1" | 1" | 1215 Carbon Steel | Not Hardened | 0000000 | 000000 |

| 10 | 2ft. | 1.15" | 1 1/4" | 1 1/4" | 1018 Carbon Steel | Not Hardened | 000000 | 00000 |

| 10 | 4ft. | 1.15" | 1 1/4" | 1 1/4" | 1215 Carbon Steel | Not Hardened | 0000000 | 000000 |

| 10 | 6ft. | 1.15" | 1 1/4" | 1 1/4" | 1215 Carbon Steel | Not Hardened | 0000000 | 000000 |

| 8 | 2ft. | 1.375" | 1 1/2" | 1 1/2" | 1018 Carbon Steel | Not Hardened | 000000 | 000000 |

| 8 | 4ft. | 1.375" | 1 1/2" | 1 1/2" | 1215 Carbon Steel | Not Hardened | 0000000 | 000000 |

| 8 | 6ft. | 1.375" | 1 1/2" | 1 1/2" | 1215 Carbon Steel | Not Hardened | 0000000 | 000000 |

Gear Racks | Tooth Spacers | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Module | Lg., mm | Pitch Ht., mm | Ht., mm | Face Wd., mm | Material | Teeth Heat Treatment | Each | Each | ||

With Non-Machined Ends | ||||||||||

| 0.5 | 100 | 11.5 | 12 | 5 | Black-Oxide1045 Carbon Steel | Not Hardened | 00000000 | 000000 | 000000 | 00 |

| 0.5 | 300 | 8.5 | 9 | 3 | Brass | __ | 00000000 | 00000 | 000000 | 00 |

| 0.8 | 100 | 11.5 | 12.3 | 8 | Black-Oxide1045 Carbon Steel | Not Hardened | 00000000 | 00000 | 000000 | 00 |

| 0.8 | 300 | 9.2 | 10 | 4 | Brass | __ | 00000000 | 00000 | 000000 | 00 |

| 1 | 100 | 11 | 12 | 10 | Black-Oxide1045 Carbon Steel | Not Hardened | 00000000 | 00000 | 000000 | 00 |

| 1 | 300 | 9 | 10 | 6 | Brass | __ | 00000000 | 00000 | 000000 | 00 |

| 1 | 300 | 11 | 12 | 10 | Black-Oxide1045 Carbon Steel | Not Hardened | 00000000 | 00000 | 000000 | 00 |

| 1 | 500 | 8.8 | 9.8 | 10 | 1045 Carbon Steel | Not Hardened | 00000000 | 00000 | 00000000 | 0000000 |

| 1 | 500 | 11 | 12 | 10 | 304 Stainless Steel | Hardened | 00000000 | 000000 | 000000 | 00 |

| 1 | 1,000 | 8.8 | 9.8 | 10 | 1045 Carbon Steel | Not Hardened | 00000000 | 000000 | 00000000 | 000000 |

| 1.5 | 100 | 18.5 | 20 | 15 | Black-Oxide1045 Carbon Steel | Not Hardened | 00000000 | 00000 | 000000 | 00 |

| 1.5 | 300 | 18.5 | 20 | 15 | Black-Oxide1045 Carbon Steel | Not Hardened | 00000000 | 00000 | 000000 | 00 |

| 1.5 | 500 | 13.3 | 14.8 | 15 | 1045 Carbon Steel | Not Hardened | 00000000 | 000000 | 00000000 | 000000 |

| 1.5 | 500 | 18.5 | 20 | 15 | 304 Stainless Steel | Hardened | 00000000 | 000000 | 000000 | 00 |

| 1.5 | 1,000 | 13.3 | 14.8 | 15 | 1045 Carbon Steel | Not Hardened | 00000000 | 000000 | 00000000 | 000000 |

| 2 | 100 | 23 | 25 | 20 | Black-Oxide1045 Carbon Steel | Not Hardened | 00000000 | 00000 | 000000 | 00 |

| 2 | 300 | 23 | 25 | 20 | Black-Oxide1045 Carbon Steel | Not Hardened | 00000000 | 00000 | 000000 | 00 |

| 2 | 500 | 17.8 | 19.8 | 20 | 1045 Carbon Steel | Not Hardened | 00000000 | 000000 | 000000 | 00 |

| 2 | 500 | 23 | 25 | 20 | 304 Stainless Steel | Hardened | 00000000 | 000000 | 000000 | 00 |

| 2 | 1,000 | 17.8 | 19.8 | 20 | 1045 Carbon Steel | Not Hardened | 00000000 | 000000 | 000000 | 00 |

With Machined Ends | ||||||||||

| 0.5 | 300 | 11.5 | 12 | 5 | Black-Oxide1045 Carbon Steel | Not Hardened | 00000000 | 00000 | 000000 | 00 |

| 1.5 | 1,000 | 13.5 | 15 | 15 | Black-Oxide1045 Carbon Steel | Not Hardened | 00000000 | 000000 | 000000 | 00 |

| 1.5 | 1,000 | 18.5 | 20 | 15 | 304 Stainless Steel | Hardened | 00000000 | 000000 | 000000 | 00 |

| 2 | 1,000 | 18 | 20 | 20 | Black-Oxide1045 Carbon Steel | Not Hardened | 00000000 | 000000 | 000000 | 00 |

| 2 | 1,000 | 23 | 25 | 20 | 304 Stainless Steel | Hardened | 00000000 | 000000 | 000000 | 00 |

| 2.5 | 1,000 | 22.5 | 25 | 25 | Black-Oxide1045 Carbon Steel | Not Hardened | 00000000 | 000000 | 000000 | 00 |

Metal Gears and Gear Racks—14 1/2° Pressure Angle

A former industry standard, 14½° pressure angle gears are often found on older machinery. Made of carbon steel, they have high strength and are better than plastic gears and gear racks for high-load, high-speed, and heavy duty applications.

Combine gears with different numbers of teeth to change speed and torque in your assembly. Combine a gear and rack to convert rotary motion into linear motion.

For components to mesh correctly, they must have the same pressure angle and pitch.

Gears with teeth that are not hardened can be hardened to fit your application. Hardening a gear's teeth increases its wear resistance.

For technical drawings and 3-D models, click on a part number.

| Gear Pitch | Lg. | Pitch Ht. | Ht. | Face Wd. | Material | Teeth Heat Treatment | Each | |

| 32 | 2ft. | 0.156" | 3/16" | 3/16" | 1018 Carbon Steel | Not Hardened | 0000000 | 000000 |

| 32 | 4ft. | 0.156" | 3/16" | 3/16" | 1215 Carbon Steel | Not Hardened | 00000000 | 00000 |

| 32 | 6ft. | 0.156" | 3/16" | 3/16" | 1215 Carbon Steel | Not Hardened | 00000000 | 00000 |

| 24 | 2ft. | 0.208" | 1/4" | 1/4" | 1018 Carbon Steel | Not Hardened | 0000000 | 00000 |

| 24 | 4ft. | 0.208" | 1/4" | 1/4" | 1215 Carbon Steel | Not Hardened | 00000000 | 00000 |

| 24 | 6ft. | 0.208" | 1/4" | 1/4" | 1215 Carbon Steel | Not Hardened | 00000000 | 00000 |

| 20 | 2ft. | 0.325" | 3/8" | 3/8" | 1018 Carbon Steel | Not Hardened | 0000000 | 00000 |

| 20 | 4ft. | 0.325" | 3/8" | 3/8" | 1215 Carbon Steel | Not Hardened | 00000000 | 00000 |

| 20 | 6ft. | 0.325" | 3/8" | 3/8" | 1215 Carbon Steel | Not Hardened | 00000000 | 00000 |

| 16 | 2ft. | 0.438" | 1/2" | 1/2" | 1018 Carbon Steel | Not Hardened | 0000000 | 00000 |

| 16 | 4ft. | 0.438" | 1/2" | 1/2" | 1215 Carbon Steel | Not Hardened | 00000000 | 00000 |

| 16 | 6ft. | 0.438" | 1/2" | 1/2" | 1215 Carbon Steel | Not Hardened | 00000000 | 00000 |

| 12 | 2ft. | 0.417" | 1/2" | 3/4" | 1018 Carbon Steel | Not Hardened | 0000000 | 00000 |

| 12 | 2ft. | 0.667" | 3/4" | 3/4" | 1018 Carbon Steel | Not Hardened | 0000000 | 00000 |

| 12 | 4ft. | 0.417" | 1/2" | 3/4" | 1018 Carbon Steel | Not Hardened | 00000000 | 00000 |

| 12 | 4ft. | 0.667" | 3/4" | 3/4" | 1215 Carbon Steel | Not Hardened | 00000000 | 00000 |

| 12 | 6ft. | 0.417" | 1/2" | 3/4" | 1018 Carbon Steel | Not Hardened | 00000000 | 00000 |

| 12 | 6ft. | 0.667" | 3/4" | 3/4" | 1215 Carbon Steel | Not Hardened | 00000000 | 000000 |

| 10 | 2ft. | 0.525" | 5/8" | 1" | 1018 Carbon Steel | Not Hardened | 0000000 | 00000 |

| 10 | 2ft. | 0.9" | 1" | 1" | 1018 Carbon Steel | Not Hardened | 0000000 | 00000 |

| 10 | 4ft. | 0.525" | 5/8" | 1" | 1215 Carbon Steel | Not Hardened | 00000000 | 00000 |

| 10 | 4ft. | 0.9" | 1" | 1" | 1215 Carbon Steel | Not Hardened | 00000000 | 000000 |

| 10 | 6ft. | 0.525" | 5/8" | 1" | 1215 Carbon Steel | Not Hardened | 00000000 | 000000 |

| 10 | 6ft. | 0.9" | 1" | 1" | 1215 Carbon Steel | Not Hardened | 00000000 | 000000 |

| 8 | 2ft. | 0.625" | 3/4" | 1 1/4" | 1018 Carbon Steel | Not Hardened | 0000000 | 00000 |

| 8 | 2ft. | 1.125" | 1 1/4" | 1 1/4" | 1018 Carbon Steel | Not Hardened | 0000000 | 00000 |

| 8 | 4ft. | 0.625" | 3/4" | 1 1/4" | 1215 Carbon Steel | Not Hardened | 00000000 | 000000 |

| 8 | 4ft. | 1.125" | 1 1/4" | 1 1/4" | 1215 Carbon Steel | Not Hardened | 00000000 | 000000 |

| 8 | 6ft. | 0.625" | 3/4" | 1 1/4" | 1215 Carbon Steel | Not Hardened | 00000000 | 000000 |

| 8 | 6ft. | 1.125" | 1 1/4" | 1 1/4" | 1215 Carbon Steel | Not Hardened | 00000000 | 000000 |

| 6 | 2ft. | 0.833" | 1" | 1 1/2" | 1018 Carbon Steel | Not Hardened | 0000000 | 00000 |

| 6 | 2ft. | 1.333" | 1 1/2" | 1 1/2" | 1018 Carbon Steel | Not Hardened | 0000000 | 000000 |

| 6 | 4ft. | 0.833" | 1" | 1 1/2" | 1215 Carbon Steel | Not Hardened | 00000000 | 000000 |

| 6 | 4ft. | 1.333" | 1 1/2" | 1 1/2" | 1215 Carbon Steel | Not Hardened | 00000000 | 000000 |

| 6 | 6ft. | 0.833" | 1" | 1 1/2" | 1215 Carbon Steel | Not Hardened | 00000000 | 000000 |

| 6 | 6ft. | 1.333" | 1 1/2" | 1 1/2" | 1215 Carbon Steel | Not Hardened | 00000000 | 000000 |

Mounting Hole | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gear Pitch | Lg. | Pitch Ht. | Ht. | Face Wd. | Material | Teeth Heat Treatment | Number of | Center-to-Center | Center-to-End | For Mounting Screw Size | Mounting Fasteners Included | Each | |

| 24 | 4ft. | 0.208" | 1/4" | 1/4" | 1018 Carbon Steel | Not Hardened | 12 | 4" | 2" | No. 0 | No | 000000 | 0000000 |

| 20 | 4ft. | 0.325" | 3/8" | 3/8" | 1018 Carbon Steel | Not Hardened | 12 | 4" | 2" | No. 3 | No | 000000 | 000000 |

| 16 | 4ft. | 0.437" | 1/2" | 1/2" | 1018 Carbon Steel | Not Hardened | 12 | 4" | 2" | No. 8 | No | 000000 | 000000 |

| 12 | 4ft. | 0.667" | 3/4" | 3/4" | 1018 Carbon Steel | Not Hardened | 12 | 4" | 2" | 1/4" | No | 000000 | 000000 |

High-Power Metal Gears

The helical teeth on these gears stay in contact for longer than straight teeth, which allows them to transmit higher loads at higher speeds than spur gears.

For gears to mesh correctly, they must have the same pressure angle and pitch. All of these gears transmit motion in a straight line—make sure to get one left-hand and one right-hand gear. To change speed and torque in your assembly, pair two gears with different numbers of teeth.

Parallel helical components have a 21 1/2° helix angle so they only transmit motion in a straight line since the helix angle is so small. Made from alloy steel, these gears resist abrasion and are stronger than carbon steel gears. Their teeth are ground, so they're more precise than gears with rolled teeth. Pair them with a rack or a gear that has a different tooth direction.

For technical drawings and 3-D models, click on a part number.

Plastic Gears and Gear Racks—20° Pressure Angle

The current industry standard, these 20° pressure angle gears have thicker, stronger teeth than 14½° pressure angle gears. Made of plastic, they run quieter than metal gears and have good corrosion and chemical resistance. They’re also known as spur gears.

Combine gears with different numbers of teeth to change speed and torque in your assembly. Combine a gear and rack to convert rotary motion into linear motion.

For components to mesh correctly, they must have the same pressure angle and pitch/module.

Acetal gear racks absorb less water than nylon racks, so they’re less likely to swell.

Nylon gear racks are lightweight and can be used without lubrication.

For technical drawings and 3-D models, click on a part number.

| Module | Lg., mm | Pitch Ht., mm | Ht., mm | Face Wd., mm | Material | Fabrication | Color | Each | |

| 0.5 | 250 | 5.9 | 6.3 | 4 | Acetal Plastic | Molded | Gray | 0000000 | 00000 |

| 0.8 | 250 | 6.4 | 7.3 | 5 | Acetal Plastic | Molded | Gray | 0000000 | 0000 |

| 1 | 315 | 7.9 | 10 | 10 | Acetal Plastic | Molded | Gray | 0000000 | 0000 |

| 1 | 500 | 11 | 12 | 10 | Acetal Plastic | Machined | White | 0000000 | 000000 |

| 1 | 500 | 11 | 12 | 10 | Nylon Plastic | Machined | Blue | 0000000 | 000000 |

| 1.5 | 500 | 18.5 | 20 | 15 | Acetal Plastic | Machined | White | 0000000 | 000000 |

| 2 | 500 | 23 | 25 | 20 | Acetal Plastic | Machined | White | 0000000 | 000000 |

| 2 | 500 | 23 | 25 | 20 | Nylon Plastic | Machined | Blue | 0000000 | 000000 |

| 2 | 1,000 | 23 | 25 | 20 | Nylon Plastic | Machined | Blue | 0000000 | 000000 |

Plastic Gears and Gear Racks—14 1/2° Pressure Angle

A former industry standard, 14½° pressure angle gears are often found on older machinery. Made of plastic, they run quieter than metal gears and have good corrosion and chemical resistance. They’re also known as spur gears.

Combine gears with different numbers of teeth to change speed and torque in your assembly. Combine a gear and rack to convert rotary motion into linear motion.

For components to mesh correctly, they must have the same pressure angle and pitch.

Machined gear racks may be slightly bowed but will straighten out when installed.

For technical drawings and 3-D models, click on a part number.

| Gear Pitch | Lg. | Pitch Ht. | Ht. | Face Wd. | Material | Fabrication | Color | Each | |

| 48 | 1ft. | 0.109" | 1/8" | 1/8" | Nylon Plastic | Molded | White | 00000000 | 00000 |

| 32 | 1ft. | 0.156" | 3/16" | 3/16" | Nylon Plastic | Molded | White | 00000000 | 0000 |

| 24 | 1ft. | 0.203" | 1/4" | 1/4" | Nylon Plastic | Molded | White | 00000000 | 00000 |

| 20 | 4ft. | 0.325" | 3/8" | 3/8" | Nylon Plastic | Machined | Green | 00000000 | 000000 |

| 16 | 1ft. | 0.25" | 5/16" | 5/16" | Nylon Plastic | Molded | White | 00000000 | 00000 |

| 16 | 4ft. | 0.438" | 1/2" | 1/2" | Nylon Plastic | Machined | Green | 00000000 | 000000 |

| 12 | 4ft. | 0.667" | 3/4" | 3/4" | Nylon Plastic | Machined | Green | 00000000 | 000000 |

| 10 | 4ft. | 0.9" | 1" | 1" | Nylon Plastic | Machined | Green | 00000000 | 000000 |