Filter by

Anchors for Block and Brick

|

Also known as double expansion anchors, these expand from both sides for full contact with your hole’s walls. They’re often used to mount handrails, shelving, and light fixtures. Since the gripping force is distributed along the entire length of the anchor, it won’t crack soft materials like block and brick. You can use these anchors as an alternative to drop-in anchors in concrete near edges, corners, or other weak points, but they are not as strong.

To install, hammer into a drilled hole and position your component. Then, insert a screw or threaded rod and tighten. For maximum expansion, the anchor should protrude slightly above the surface before threading the screw. All create a permanent female-threaded connection that lets you remove and reinstall a screw or threaded rod. They cannot be used in overhead applications.

Ultimate Strength, lbf | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg. | Drill Bit Size | Min. Installation Dp. | Material | Pull-Out | Shear | Conditions Tested In | Pkg. Qty. | Pkg. | ||

| 1/2"-13 | 2 1/2" | 7/8" | 2 1/4" | Zinc | 3,480 | 4,000 | 4,000 psi Concrete | 1 | 000000000 | 00000 | |

High-Strength Anchors for Block and Brick

|

Offering up to twice the strength of double expansion anchors, these US-made anchors expand in four directions for a superior grip in floors, walls, and ceilings. You can even use them to mount heavy machinery with constant motion, such as conveyors and vibrating feeders, because their ridges lock them in place to resist vibration. All of these anchors expand along their full length to distribute the gripping force, so they won’t crack soft materials. You can use them in concrete near edges, corners, or other weak points as an alternative to drop-in anchors.

To install, tap the anchor into a drilled hole. Insert a screw or threaded rod through your machinery and into the anchor. Then, tighten to expand the anchor. All create a permanent female-threaded connection that lets you remove and reinstall a screw or threaded rod.

Ultimate Strength, lbf | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg. | Drill Bit Size | Min. Installation Dp. | Material | Pull-Out | Shear | Conditions Tested In | Pkg. Qty. | Pkg. | ||

| 1/2"-13 | 2 1/4" | 7/8" | 2 1/4" | Zinc | 4,800 | 8,000 | 3,000 psi Concrete | 4 | 000000000 | 000000 | |

Anchors for Hollow Block and Brick

|

Requiring minimal installation depth, these anchors are best for thin cinder block and hollow core panel walls and ceilings. All expand

when fastened to create permanent female-threaded connections that let you remove and reinstall a screw or threaded rod. They fit into smaller holes than toggle anchors for hollow block and brick but are not as strong.

To install, place the anchor into a drilled hole, cone end first. Tap the anchor into the hole until it's flush with the surface. Then, position your component, insert a screw or threaded rod, and tighten.

Ultimate Strength, lbf | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg. | Drill Bit Size | Min. Installation Dp. | Sleeve Material | Material | Pull-Out | Shear | Conditions Tested In | Certification | Pkg. Qty. | Pkg. | ||

| 1/2"-13 | 1 3/4" | 3/4" | 1 1/2" | Zinc | Steel | 4,000 | 4,000 | 4,000 psi Concrete | FM Approved, UL Listed | 1 | 000000000 | 00000 | |

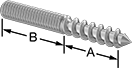

Thread-Mount Studs for Wood

|

Also known as hanger bolts, use these studs to hang, mount, and fasten parts to wood structures. Install them with a stud driver, or create wrench flats by threading two nuts onto the stud and jamming them together.

Zinc-Plated Steel—The most common choice for areas with occasional exposure to moisture.

18-8 Stainless Steel—The choice for wet and outdoor environments, these studs resist rust. However, they won't hold up to the harsh chemicals that 316 stainless steel can.

(A) | (B) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Screw Size | Thread Lg. | Thread Size | Thread Lg. | Lg. | Tensile Strength | Hardness | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3" | 1/2"-13 | 2 1/2" | 6" | Not Rated | Not Rated | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3" | 1/2"-13 | 2 1/2" | 12" | Not Rated | Not Rated | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 2" | 1/2"-13 | 1" | 3" | Not Rated | Not Rated | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 2" | 1/2"-13 | 1 1/2" | 3 1/2" | Not Rated | Not Rated | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 2" | 1/2"-13 | 2" | 4" | Not Rated | Not Rated | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3" | 1/2"-13 | 2" | 5" | Not Rated | Not Rated | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3" | 1/2"-13 | 2 1/2" | 6" | Not Rated | Not Rated | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3" | 1/2"-13 | 2 1/2" | 8" | Not Rated | Not Rated | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||