How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Low-Pressure Iron and Steel Threaded Pipe Fittings

Use these fittings for low-pressure applications in noncorrosive environments.

Saddle tap tees tap into existing pipe lines so you can install branch lines, valves, and other equipment. The gasket and clamps create a tight seal so the opening won’t leak. To install, shut down your line and secure the clamps, then drill a hole into the pipe.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water

- Temperature Range: -20° to 180° F

| Pipe Size (A) | For Pipe Size | For Pipe OD | Lg. | Max. Pressure | Max. Vacuum | Color | Material | Gasket Material | Each | ||

NPT Female | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 1 1/2, 1 1/4 | 1.9", 1.66" | 3 1/4" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 000000 |

| 1/2 | 2 | 2 3/8" | 3 1/4" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 00000 |

| 1/2 | 3 | 3 1/2" | 3 1/4" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 00000 |

| 1/2 | 4 | 4 1/2" | 3 5/8" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 00000 |

| 1/2 | 6 | 6 5/8" | 3 5/8" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 000000 |

| 1/2 | 8 | 8 5/8" | 3 5/8" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 000000 |

| 3/4 | 1 1/2, 1 1/4 | 1.9", 1.66" | 3 1/4" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 00000 |

| 3/4 | 2 | 2 3/8" | 3 1/4" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 00000 |

| 3/4 | 3 | 3 1/2" | 3 1/4" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 00000 |

| 3/4 | 4 | 4 1/2" | 3 5/8" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 00000 |

| 3/4 | 6 | 6 5/8" | 3 5/8" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 000000 |

| 3/4 | 8 | 8 5/8" | 3 5/8" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 000000 |

| 1 | 1 1/2, 1 1/4 | 1.9", 1.66" | 3 1/4" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 00000 |

| 1 | 2 | 2 3/8" | 3 1/4" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 00000 |

| 1 | 3 | 3 1/2" | 3 1/4" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 00000 |

| 1 | 4 | 4 1/2" | 3 5/8" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 00000 |

| 1 | 6 | 6 5/8" | 3 5/8" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 000000 |

| 1 | 8 | 8 5/8" | 3 5/8" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 000000 |

| 1 1/4 | 2 | 2 3/8" | 3 1/4" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 00000 |

| 1 1/4 | 3 | 3 1/2" | 3 1/4" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 000000 |

| 1 1/4 | 4 | 4 1/2" | 3 5/8" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 000000 |

| 1 1/4 | 6 | 6 5/8" | 3 5/8" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 000000 |

| 1 1/4 | 8 | 8 5/8" | 3 5/8" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 000000 |

| 1 1/2 | 2 | 2 3/8" | 3 1/4" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 00000 |

| 1 1/2 | 3 | 3 1/2" | 3 1/4" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 000000 |

| 1 1/2 | 4 | 4 1/2" | 3 5/8" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 000000 |

| 1 1/2 | 6 | 6 5/8" | 3 5/8" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 000000 |

| 1 1/2 | 8 | 8 5/8" | 3 5/8" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 000000 |

| 2 | 3 | 3 1/2" | 3 1/4" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 000000 |

| 2 | 4 | 4 1/2" | 3 5/8" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 000000 |

| 2 | 6 | 6 5/8" | 3 5/8" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 000000 |

| 2 | 8 | 8 5/8" | 3 5/8" | 100 psi @ 72° F | 15 in. of Hg @ 72° F | Blue | Epoxy-Coated | Iron | Buna-N Rubber | 00000000 | 000000 |

Aluminum Quick-Connect Pipe Fittings for Compressed Air

Twist these fittings onto aluminum pipe for quick, sealed connections—no threading, soldering, or welding necessary. Use them to build a compressed air system in half the time it would take to build a copper or steel system. Also known as Unipipe fittings, they’re part of a quick-connect system that’s compatible with pipe from Unipipe, Transair, and Infinity.

Finger tighten the collar on the end of these fittings, then use a wrench for the final quarter turn. The inside of these fittings has a compression ring and O-ring to seal against the pipe. They’re easy to take apart as needed to modify your setup.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Coolant, Nitrogen, Oil

- Temperature Range: 0° to 210° F

- Specifications Met: ASME B31.1, ASME B31.3, ASME B31.9

- Pipe Nipples and Pipe: Use Quick-Disconnect Aluminum

Saddle tap tees bolt onto pipe to add connections without requiring you to disassemble your system. You can use them to connect your ceiling-mounted pipe to equipment below. To install, drill through the threaded outlet into your pipe with a hole saw (sold separately).

Tees | |||||||||

|---|---|---|---|---|---|---|---|---|---|

For Pipe OD | Hole Saws | ||||||||

| (A) | (B) | Lg., mm | Material | Max. Pressure | Includes | Each | Each | ||

| 3/4" (20 mm) | 1" (25 mm) | 33 | Epoxy-Coated 6061 Aluminum | 580 psi @ 72° F | Cap | 0000000 | 000000 | 0000000 | 000000 |

| 3/4" (20 mm) | 1 1/2" (40 mm) | 38 | Epoxy-Coated 6061 Aluminum | 580 psi @ 72° F | Cap | 0000000 | 00000 | 0000000 | 00000 |

| 1" (25 mm) | 1 1/2" (40 mm) | 38 | Epoxy-Coated 6061 Aluminum | 580 psi @ 72° F | Cap | 0000000 | 00000 | 0000000 | 00000 |

- For Use With: Air, Coolant, Nitrogen, Oil

- Temperature Range: 0° to 210° F

- Specifications Met: ASME B31.1, ASME B31.3, ASME B31.9

- Pipe Nipples and Pipe: Use Quick-Disconnect Aluminum

Saddle tap tees bolt onto pipe to add connections without requiring you to disassemble your system. You can use them to connect your ceiling-mounted pipe to equipment below. To install, drill through the threaded outlet into your pipe with a hole saw (sold separately).

Threaded connections can be taken apart as needed for maintenance and repair.

Tees | Hole Saws | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size (A) | For Pipe OD (B) | Lg., mm | Material | Max. Pressure | Includes | Each | Each | ||

NPT Threads | |||||||||

| 1/2 | 1" (25 mm) | 33 | Epoxy-Coated 6061 Aluminum | 580 psi @ 72° F | __ | 0000000 | 000000 | 0000000 | 000000 |

| 1/2 | 1" (25 mm) | 33 | Epoxy-Coated 6061 Aluminum | 580 psi @ 72° F | Cap | 0000000 | 00000 | 0000000 | 00000 |

| 1/2 | 1 1/2" (40 mm) | 33 | Epoxy-Coated 6061 Aluminum | 580 psi @ 72° F | Cap | 0000000 | 00000 | 0000000 | 00000 |

| 1/2 | 1 1/2" (40 mm) | 47 | Epoxy-Coated 6061 Aluminum | 580 psi @ 72° F | __ | 0000000 | 00000 | 0000000 | 00000 |

| 3/4 | 1 1/2" (40 mm) | 38 | Epoxy-Coated 6061 Aluminum | 580 psi @ 72° F | Cap | 0000000 | 00000 | 0000000 | 00000 |

| 3/4 | 1 1/2" (40 mm) | 47 | Epoxy-Coated 6061 Aluminum | 580 psi @ 72° F | __ | 0000000 | 00000 | 0000000 | 00000 |

Use measuring tools to mark your pipe’s proper insertion depth so you know if it’s inserted far enough into the fitting.

| Max. Dp. Measured, mm | Lg., mm | Wd., mm | Material | Each | |

| 160 | 224 | 39 | Plastic | 0000000 | 000000 |

Standard-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 40 plastic pipe–they are the industry standard for residential and commercial low-pressure plumbing and water supply applications. They are plastic for good corrosion resistance.

Fittings for drinking water meet NSF/ANSI Standard 61.

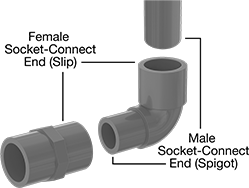

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a sealant to the male threads. For plastic threads, apply a non-hardening, plastic-compatible sealant. Tape or sealants with PTFE are not recommended for plastic-to-plastic connections. Fittings that meet ASTM D1784, ASTM D1785, and ASTM D4066 adhere to specifications and testing requirements for material quality.

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 Aluminum, Iron, PVC Plastic, Stainless Steel, Steel

- Flanges: Use Schedule 40 PVC Plastic

Saddle-tap tee adapters allow you to create additional outlets and connections in metal or plastic pipe. To install, shut down your line and drill a hole in the pipe where you want to create a connection. Position the saddle over the hole so the gasket and lip are fully engaged and secure with the included nuts, bolts, and washers.

| Pipe Size | Socket Depth | For Pipe Size | For Pipe OD | For Hole Dia. | OD | ID | Wall Thick. | Material | Color | Max. Pressure | Each | |

| 1 1/2 | 1/2" | 4 | 4 1/2" | 1 3/4" | 1 29/32" | 1.61" | 0.145" | PVC Plastic | White | 200 psi @ 72° F | 0000000 | 0000000 |

| 1 1/2 | 29/32" | 3 | 3 1/2" | 2 1/4" | 1 29/32" | 1.61" | 0.145" | PVC Plastic | White | 200 psi @ 72° F | 0000000 | 00000 |

| 2 | 3/8" | 3 | 3 1/2" | 2 1/4" | 2 3/8" | 2.067" | 0.154" | PVC Plastic | White | 200 psi @ 72° F | 0000000 | 00000 |

| 2 | 7/16" | 4 | 4 1/2" | 2 1/4" | 2 3/8" | 2.067" | 0.154" | PVC Plastic | White | 200 psi @ 72° F | 0000000 | 000000 |

| 2 | 11/16" | 6 | 6 5/8" | 2 1/4" | 2 3/8" | 2.067" | 0.154" | PVC Plastic | White | 200 psi @ 72° F | 0000000 | 000000 |

| 3 | 1/2" | 4 | 4 1/2" | 3" | 3 1/2" | 3.068" | 0.216" | PVC Plastic | White | 200 psi @ 72° F | 0000000 | 000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 Aluminum, Iron, PVC Plastic, Stainless Steel, Steel

- Flanges: Use Schedule 40 PVC Plastic

Fittings with stainless steel collar have a reinforcement on the female threads to prevent the threads from cracking.

Saddle-tap tee adapters allow you to create additional outlets and connections in metal or plastic pipe. To install, shut down your line and drill a hole in the pipe where you want to create a connection. Position the saddle over the hole so the gasket and lip are fully engaged and secure with the included nuts, bolts, and washers.

| Pipe Size | Socket Depth | For Pipe Size | For Pipe OD | For Hole Dia. | OD | ID | Wall Thick. | Material | Collar Material | Color | Max. Pressure | Each | |

NPT Threads | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 5/16" | 2 | 2 3/8" | 3/4" | 27/32" | 0.622" | 0.109" | PVC Plastic | Stainless Steel | White | 200 psi @ 72° F | 0000000 | 000000 |

| 3/4 | 5/16" | 2 | 2 3/8" | 7/8" | 1 3/64" | 0.824" | 0.113" | PVC Plastic | Stainless Steel | White | 200 psi @ 72° F | 0000000 | 00000 |

| 3/4 | 27/32" | 4 | 4 1/2" | 1 1/8" | 1 3/64" | 0.824" | 0.113" | PVC Plastic | Stainless Steel | White | 200 psi @ 72° F | 0000000 | 000000 |

| 1 | 5/16" | 2 | 2 3/8" | 1 1/8" | 1 5/16" | 1.049" | 0.133" | PVC Plastic | Stainless Steel | White | 200 psi @ 72° F | 0000000 | 00000 |

| 1 | 7/16" | 4 | 4 1/2" | 1 1/8" | 1 5/16" | 1.049" | 0.133" | PVC Plastic | Stainless Steel | White | 200 psi @ 72° F | 0000000 | 000000 |

| 2 | 11/16" | 6 | 6 5/8" | 2 1/4" | 2 3/8" | 2.067" | 0.154" | PVC Plastic | Stainless Steel | White | 200 psi @ 72° F | 0000000 | 000000 |

Thick-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 80 pipe–they have thicker, stronger walls than standard-wall fittings so they can handle heavy duty industrial plumbing and water supply applications, such as water processing, waste water treatment, and irrigation. Fittings are plastic for good corrosion resistance. They meet ASTM specifications and testing requirements for material quality.

Fittings for drinking water meet NSF/ANSI Standard 61.

To prevent leaks in threaded connections, apply a sealant to the male threads. For plastic threads, apply a non-hardening, plastic-compatible sealant. Tape or sealants with PTFE are not recommended for plastic-to-plastic connections.

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 Aluminum, Iron, PVC Plastic, Stainless Steel, Steel

- Flanges: Use Class 150 PVC Plastic

Saddle-tap tee adapters allow you to create additional outlets and connections in metal or plastic pipe. To install, shut down your line and drill a hole in the pipe where you want to create a connection. Position the saddle over the hole so the gasket and lip are fully engaged and secure with the included nuts, bolts, and washers.

| Pipe Size | For Pipe Size | For Pipe OD | For Hole Dia. | Material | Collar Material | Color | Max. Pressure | Each | |

NPT Threads | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 2 | 2 3/8" | 3/4" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 000000 |

| 1/2 | 3 | 3 1/2" | 7/8" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 00000 |

| 1/2 | 4 | 4 1/2" | 1 1/8" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 000000 |

| 3/4 | 2 | 2 3/8" | 7/8" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 00000 |

| 3/4 | 3 | 3 1/2" | 7/8" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 00000 |

| 3/4 | 4 | 4 1/2" | 1 1/8" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 000000 |

| 1 | 2 | 2 3/8" | 1 1/8" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 00000 |

| 1 | 3 | 3 1/2" | 1 1/8" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 00000 |

| 1 | 4 | 4 1/2" | 1 1/8" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 000000 |

| 1 1/2 | 3 | 3 1/2" | 2 1/4" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 00000 |

| 1 1/2 | 4 | 4 1/2" | 1 3/4" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 000000 |

| 2 | 4 | 4 1/2" | 2 1/4" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 000000 |

| 2 | 6 | 6 5/8" | 2 1/4" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 000000 |

CPVC Pipe Fittings for Hot Water

Made of CPVC, these fittings can handle high temperatures. They have thick, strong walls to handle heavy duty industrial plumbing and water supply applications, such as water processing and waste water treatment. They also have good corrosion resistance. These fittings are comparable to Corzan. Some meet ASTM D1784 specifications and testing requirements for material quality.

Fittings for drinking water meet NSF/ANSI Standard 61.

Schedule 80 fittings have thick, strong walls for heavy duty, industrial applications.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Saddle-tap tees allow you to create additional outlets and connections in metal or plastic pipe. They clamp on for an easy way to install and maintain systems.

| Pipe Size | For Pipe Size | For Pipe OD | For Hole Dia. | Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 2 | 2 3/8" | 3/4" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | 00000000 | 000000 |

| 1/2 | 3 | 3 1/2" | 7/8" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | 00000000 | 00000 |

| 1/2 | 4 | 4 1/2" | 1 1/8" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | 00000000 | 000000 |

| 3/4 | 2 | 2 3/8" | 7/8" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | 00000000 | 00000 |

| 3/4 | 3 | 3 1/2" | 7/8" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | 00000000 | 00000 |

| 3/4 | 4 | 4 1/2" | 1 1/8" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | 00000000 | 000000 |

| 1 | 2 | 2 3/8" | 1 1/8" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | 00000000 | 00000 |

| 1 | 3 | 3 1/2" | 1 1/8" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | 00000000 | 00000 |

| 1 | 4 | 4 1/2" | 1 1/8" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | 00000000 | 000000 |

| 1 1/2 | 3 | 3 1/2" | 2 1/4" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | 00000000 | 00000 |

| 1 1/2 | 4 | 4 1/2" | 1 3/4" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | 00000000 | 000000 |

| 2 | 4 | 4 1/2" | 2 1/4" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | 00000000 | 000000 |

| 2 | 6 | 6 5/8" | 2 1/4" | CPVC Plastic | 80 | Light Gray | 200 psi @ 72° F | 00000000 | 000000 |

Low-Pressure Clamp-On Connectors for Drain, Waste, and Vent

To make installing and maintaining systems easy, these connectors come with clamps that form a strong seal on pipe and fittings once tightened.

Saddle-tap adapters allow you to tap into an existing pipeline. They have wraparound clamps that provide nearly 360° contact with pipe; as the clamps are tightened, pressure is uniformly distributed around the pipe for maximum support. To install, shut down your line and drill a hole in the pipe where you want to create a connection. Position the saddle over the hole and tighten the clamps.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water

- Temperature Range: 0° to 110° F

- For Pipe Material: PVC Plastic

- For Use With: Air, Water

- Temperature Range: 0° to 110° F

- For Pipe Material: PVC Plastic