Filter by

System of Measurement

Thread Size

Hex Nut Profile

Thread Direction

Material

Specifications Met

Fastener Strength Grade/Class

Thread Type

Fastener Strength Rating

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Thread Fit

Drive Style

Performance

Spanner Wrench Style

Thin-Profile Hex Nuts

About half the height of standard-profile nuts, these fit in spaces with low clearance. You can also use them as jam nuts by threading them against another hex nut to hold it in place.

Medium-Strength Steel

|

These Grade 5 or Class 04 nuts are your go-to for fastening most machinery and equipment. To avoid stripped threads during installation, make sure your screw has a comparable strength rating.

Zinc-Plated Steel—A step up from plain steel, the zinc plating withstands occasional exposure to moisture.

Zinc-Yellow-Chromate-Plated Steel—With a more durable finish than clear zinc plating, these nuts are suitable for most wet and outdoor environments. However, they won't hold up to the harsh chemicals that stainless steel can.

Steel—Best for dry environments since moisture will cause these nuts to rust.

Thread Size | Wd., mm | Ht., mm | Fastener Strength Grade/Class | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M22 × 1.5 mm | 32 | 11 | ISO Class 04 | DIN 439B, ISO 4035 | 10 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M22 × 2.5 mm | 32 | 11 | ISO Class 04 | DIN 439B, ISO 4035 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Yellow-Chromate-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M22 × 1.5 mm | 32 | 11 | ISO Class 04 | DIN 439B, ISO 4035 | 5 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M22 × 1.5 mm | 32 | 10 | — | DIN 936 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M22 × 1.5 mm | 32 | 11 | ISO Class 04 | DIN 439B, ISO 4035 | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M22 × 2.5 mm | 32 | 10 | — | DIN 936 | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M22 × 2.5 mm | 32 | 11 | — | DIN 439B, ISO 4035 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant Stainless Steel

|

18-8 Stainless Steel—The choice for wet and outdoor environments, these nuts resist rust. However, they won't hold up to the harsh chemicals that 316 stainless steel can.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these nuts won't degrade when exposed to harsh weather, salt water, and most chemicals.

Left-Hand-Thread Thin-Profile Hex Nuts

These nuts tighten when turned to the left. Use them with left-hand rods and screws to prevent counterclockwise-moving parts from loosening. About half the height of standard-profile nuts, these fit in spaces with low clearance. You can also use them as jam nuts by threading them against another hex nut to hold it in place.

Medium-Strength Steel

|

These Grade 5 or Class 04 nuts are your go-to for fastening most machinery and equipment. To avoid stripped threads during installation, make sure your screw has a comparable strength rating.

Black-Oxide Steel—Typically chosen for their appearance, these nuts have a dark, matte coating to create a finished look. They offer minimal corrosion resistance, so they're best for dry environments.

Corrosion-Resistant Stainless Steel

|

18-8 Stainless Steel—The choice for wet and outdoor environments, these nuts resist rust. However, they won't hold up to the harsh chemicals that 316 stainless steel can.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these nuts won't degrade when exposed to harsh weather, salt water, and most chemicals.

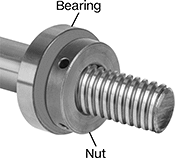

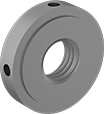

Thin-Profile Bearing Nuts

|

|

Used in pairs or with another bearing nut, these thin-profile nuts—often called shaft nuts—hold bearings, bushings, pulleys, and gears in place on your threaded shaft or spindle. Threading two nuts tightly against each other makes it harder for vibration to loosen your assembly than if you used only one nut. For the nut closer to the bearing, position the stepped face towards the bearing. These thin-profile nuts have holes on the side, so you can tighten and loosen them with a pin spanner wrench. All meet DIN 1816, an international standard for bearing locknut dimensions.

Carbon Steel—Carbon steel bearing nuts are strong and resist wear.

Thread Spacing—When choosing your thread spacing, consider the precision of your application. The finer the threads, the more control you have when making adjustments.

Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Spacing | OD, mm | Wd., mm | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stepped Face | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M22 × 1.5 mm | Fine | 40 | 9 | DIN 1816 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||