About Structural Adhesives

More

About Paint and Protective Coatings

More

Epoxy Potting Compounds

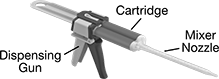

Encase electronic assemblies in a layer of epoxy for protection from dust, chemicals, moisture, mechanical shock, and vibration. The strongest of the potting compounds, epoxies are rigid and wear resistant. They have excellent chemical and moisture resistance, withstand a wide range of temperatures, and provide excellent electrical insulation. All require a mixer nozzle and gun to dispense.

Loctite® ES1001™, ES1902™, and ES2500™ come with a mixer nozzle.

Compounds that cannot be sold to Canada are restricted by product labeling requirements.

Dry Time | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch | Overall | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Temp. Range, °F | Specifications Met | For Use On | Choose a Color | Each | |

| DP270 | 1.64 | Thick Liquid | 3 hrs. | 48 hrs. | 850 | 0.18 | -65° to 210° | UL 94 HB | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Rubber, Glass | 00000000 | 000000 | |

| DP270 | 6.8 | Thick Liquid | 3 hrs. | 48 hrs. | 850 | 0.18 | -65° to 210° | UL 94 HB | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Rubber, Glass | 00000000 | 00000 | |

| DP270 | 13.5 | Thick Liquid | 3 hrs. | 48 hrs. | 850 | 0.18 | -65° to 210° | UL 94 HB | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Rubber, Glass | Black | 00000000 | 000000 |

| Mixer Nozzle for 1.64 fl. oz. Cartridges | 0000000 | Each | 00000 |

| Dispensing Gun for 1.64 fl. oz. and 1.69 fl. oz. Cartridges | 0000000 | Each | 000000 |

| Mixer Nozzle for 1.64 fl. oz. and 1.69 fl. oz. Cartridges (Mixing Elements: 16) | 0000000 | Each | 0000 |

| Dispensing Gun for 6.8 fl. oz. Cartridges | 0000000 | Each | 000000 |

| Mixer Nozzle for 6.8 fl. oz. Cartridges | 0000000 | Each | 0000 |

| Dispensing Gun for 13.5 fl. oz. Cartridges | 00000000 | Each | 000000 |

| Mixer Nozzle for 13.5 fl. oz. Cartridges | 00000000 | Each | 0000 |

Dry Time | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch, min. | Overall, hrs. | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Temp. Range, °F | Specifications Met | For Use On | Color | Each | |

| ES1001 | 1.7 | Thick Liquid | 60 | 24 | 1,100 | 0.29 | -10° to 220° | __ | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Ceramic, Glass | Black | 0000000 | 000000 |

| ES2500 | 1.7 | Thin Liquid | 10 | 16 | 410 | 0.28 | -40° to 220° | UL 94 HB | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Ceramic, Glass | Black | 0000000 | 00000 |

| Dispensing Gun for 1.7 fl. oz. Cartridges | 00000000 | Each | 000000 |

Dry Time | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Container Size, fl. oz. | Consistency | Touch, min. | Overall, hrs. | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Temp. Range, °F | For Use On | Color | Cannot Be Sold To | Each | |

| 1.69 | Thick Liquid | 45 | 24 | 400 | 0.3 | -40° to 300° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Silver, Plastic, Rubber, Composites, Fiberglass, Ceramic, Glass | Black | Canada | 0000000 | 000000 |

High-Temperature Epoxy Potting Compounds

Protect circuit boards and other electronics where high heat is a concern but you don’t need to transfer that heat elsewhere. These compounds are a good middle ground between standard epoxy compounds and heat-transfer compounds. They work at temperatures twice as high as standard epoxy compounds. However, they don't conduct heat as well as heat-transfer compounds so they're not the best choice for circuit boards that run for long periods of time. Harden these compounds at room temperature—they don’t require an oven to harden like heat-transfer compounds do.

Since they’re an epoxy compound, they won’t break down from chemicals or moisture. They’re also excellent electrical insulators and withstand a wide range of temperatures. Use them to shield components from dust, moisture, chemicals, mechanical shock, and vibration.

Jar and syringe compounds are the consistency of honey once they’re mixed, so they’ll seep into the crevices of a circuit board and encapsulate intricate components. Use the syringe for precise application.

Bottle compounds are easier to apply in higher volumes than jar and syringe compounds. Mix them together and pour them over components inside containers, such as a potting box. If air bubbles occur after mixing, you can put the mixture in a vacuum chamber to remove them. They cannot be sold to Canada due to product labeling requirements.

Dry Time | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Container Size, fl. oz. | Consistency | Viscosity, cP | Touch | Overall, hrs. | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Max. Temp., °F | For Use On | Cannot Be Sold To | Each | |

Jar and Syringe Compounds—Extra Hard | |||||||||||

| 1 | Thick Liquid | 3,600 | 12 hrs. | 24 | 450 | 0.22 | 500° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Rubber, Composites, Fiberglass, Ceramic, Glass | __ | 0000000 | 000000 |

Bottle Compounds—Extra Hard | |||||||||||

| 12.6 | Paste | 22,000 | 60 min. | 24 | 470 | 0.3 | 435° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Rubber, Composites, Fiberglass, Ceramic, Glass | Canada | 0000000 | 00000 |

Epoxy Potting Compounds for Harsh Environments

Tough enough to be permanently submersed in seawater, these compounds protect sensitive electronics, such as circuit boards, semiconductors, and sensors in harsh environments. They resist moisture, salt, and chemicals, so you can use them in corrosive oil, marine, and mining applications. These compounds can also be used within autoclaves. Because they are epoxies, they are rigid, resist wear, and create excellent electrical insulation. They withstand a wide range of temperatures, and this formulation won’t crack or split as components heat up and cool down.

They come in a cartridge, so you can apply them precisely. To dispense, they require a mixer nozzle and gun (both sold separately).

Dry Time | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Container Size, fl. oz. | Consistency | Touch, hrs. | Overall, hrs. | Hardness Rating | Dielectric Strength, V/mil | Temp. Range, °F | Environment | For Use On | Autoclavable | Each | |

| 1.69 | Thick Liquid | 12 | 24 | Extra Hard | 500 | -50° to 350° | Corrosive, Salt Spray, Submersible | Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium, Polystyrene Plastic, Polycarbonate Plastic, Polyurethane Rubber, ABS Plastic, PVC Plastic, CPVC Plastic, PVDF Plastic, Polyimide Plastic, HDPE Plastic, Nylon Plastic, PEEK Plastic, Polyethylene Plastic, UHMW Plastic, Polypropylene Plastic, Glass | Yes | 0000000 | 000000 |

| For Cartridge Size | Each | |

| 1.69 fl. oz. | 00000000 | 000000 |

| For Cartridge Size | Each | |

| 1.69 fl. oz. | 00000000 | 00000 |

Flexible Epoxy Potting Compounds

Combine the flexibility of silicone with the durability of standard epoxy—these compounds are great for protecting sensitive electronics that need to flex or expand and contract. Because they’re an epoxy, they still have excellent moisture, chemical, and abrasion resistance. They withstand a wide range of temperatures, and this formulation won’t crack or split as components heat up and cool down. These compounds are excellent electrical insulators, and they’ll shield your components from moisture and dust. You can also use them as an adhesive since they’re also tacky.

They come in a cartridge, so you can apply them precisely. To dispense, they require a mixer nozzle and gun (both sold separately).

Dry Time | ||||||||

|---|---|---|---|---|---|---|---|---|

| Container Size, fl. oz. | Consistency | Touch, hrs. | Overall, hrs. | Hardness Rating | Temp. Range, °F | For Use On | Each | |

| 1.69 | Thick Liquid | 24 | 72 | Soft | -85° to 275° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Titanium, Plastic, Rubber, Composites, Fiberglass, Ceramic, Glass | 0000000 | 000000 |

| For Cartridge Size | Each | |

| 1.69 fl. oz. | 00000000 | 000000 |

| For Cartridge Size | Each | |

| 1.69 fl. oz. | 00000000 | 00000 |

Flame-Retardant Epoxy Potting Compounds

Protect circuit boards and other electronics from fire and heat. These self-extinguishing compounds meet UL 94V-0 for flame retardance and withstand temperatures up to nearly 400° F. Use them to shield components from dust, moisture, chemicals, mechanical shock, and vibration. Since they’re epoxies, they won’t break down from chemicals or moisture. They’re also excellent electrical insulators. These compounds have the consistency of honey once they’re mixed, so they seep into crevices to encase intricate components. They’re not for sale in Canada.

Cartridge compounds dispense through a mixer nozzle for precise application. Use them with a dispensing gun.

Can compounds are easier to apply in high volumes than cartridge compounds. Mix them together and pour them over components inside containers, such as a potting box. If you see air bubbles after mixing, put the mixture in a vacuum chamber to remove them.

Dry Time | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Container Size | Consistency | Touch, hrs. | Overall, hrs. | Mixer Nozzle Included | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Temp. Range, °F | Specifications Met | For Use On | Cannot Be Sold To | Each | |

Cartridge Compounds—Extra Hard | ||||||||||||

| 15.2 oz. | Thick Liquid | 2 | 48 | Yes | 395 | 0.5 | -110° to 390° | UL 94 V-0 | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Fiberglass, Ceramic, Glass, Composites, Plastic, Rubber, Silver | Canada | 0000000 | 000000 |

Can Compounds—Extra Hard | ||||||||||||

| 3 qt. | Thick Liquid | 2 | 48 | __ | 395 | 0.5 | -110° to 390° | UL 94 V-0 | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Fiberglass, Ceramic, Glass, Composites, Plastic, Rubber, Silver | Canada | 0000000 | 000000 |

| For Cartridge Size, oz. | Includes | Each | |

| 15.2 | Built-In Plunger for 1:1 and 2:1 Mix Ratios | 0000000 | 0000000 |

Heat-Transfer Potting Compounds

Formulated to draw heat away from sensitive electronic components, these potting compounds have higher thermal conductivity than standard potting compounds. Use them to encase electronic assemblies for protection from dust, chemicals, moisture, mechanical shock, and vibration. Rigid and wear resistant, epoxies are the strongest of the potting compounds. They have excellent chemical and moisture resistance, withstand a wide range of temperatures, and provide excellent electrical insulation.

Cartridge potting compound requires a gun and mixer nozzle (each sold separately) to dispense.

Dry Time | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Container Size, gal. | Consistency | Touch, min. | Overall, hrs. | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Max. Temp., °F | For Use On | Color | Each | |

| 1 | Thick Liquid | 25 | 24 | 450 | 1.87 | 500° | Steel, Ceramic, Glass | Black | 0000000 | 0000000 |

Dry Time | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Container Size, fl. oz. | Consistency | Touch, min. | Overall, hrs. | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Temp. Range, °F | For Use On | Color | Each | |

| 1.7 | Thick Liquid | 15 | 8 | 520 | 1.01 | -40° to 210° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Silver, Titanium, Plastic, Composites, Fiberglass | Black | 0000000 | 000000 |

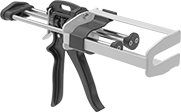

Two-Part Adhesive Dispensing Guns | |||

|---|---|---|---|

| Dispensing Gun for 1.7 fl. oz. Cartridges | 00000000 | Each | 000000 |

Mixer Nozzles for Two-Part Adhesive Cartridges | |||

|---|---|---|---|

| Mixer Nozzle for 1.7 fl. oz. Cartridges | 00000000 | Each | 00000 |

Dry Time | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Container Size, fl. oz. | Consistency | Touch | Overall, hrs. | Mix Ratio | Tensile Strength, psi | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Max. Temp., °F | Heating Requirements to Reach Full Strength | For Use On | Color | Each | |

| 19 | Thick Liquid | 25 min. | 24 | 12:1 | 10,900 | 450 | 1.87 | 500° | __ | Steel, Ceramic, Glass | Black | 0000000 | 0000000 |

| 20 | Gel | 4 hrs. | 6 | 4:1 | 11,000 | Not Rated | 1.87 | 600° | 4 hrs. @ 250° F then 2 hrs. @ 350° F | Steel, Ceramic, Glass | Black | 0000000 | 000000 |

Heavy Duty EMI/RFI Shielding Coatings for Electronics

Coat electronics for durability in tough conditions while blocking EMI/RFI signals. Made of epoxy mixed with silver-coated copper, these coatings are stronger than acrylic EMI/RFI coatings. They are rigid enough to withstand the wear of access panels and industrial cabinets. You can also use them in engine compartments because they resist damage from high temperatures and chemicals. Also known as conductive paint, they shield your parts from interference that could cause circuit malfunction and data loss. Mix the two parts of these compounds together and paint them on components. These coatings cannot be sold to Canada due to product labeling requirements.

Dry Time | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Container Size, fl. oz. | Consistency | Touch, min. | Overall, hrs. | Interference Reduction @ Frequency | Surface Resistivity | Temperature Range, °F | Heating Requirements to Reach Full Strength | For Use On | Color | Cannot Be Sold To | Each | |

| 27 | Thin Liquid | 5 | 4 | 55 dB @ 1 GHz | 0.31 ohms/sq. | -40° to 245° | 4 hrs. @ 150° F | Aluminum, Steel, Stainless Steel, Ceramic, Glass, Plastic, Chrome, Galvanized Steel | Brown | Canada | 0000000 | 0000000 |

Heavy Duty High-Purity Coatings for Electronics

This coating is formulated for use in sensitive applications such as manufacturing semiconductors. Thinner than potting compounds, the coating flows easily into small spaces between electrical components. Use it to secure and insulate hardware on printed circuit boards. Rigid and wear resistant, has excellent chemical and moisture resistance, withstands a wide range of temperatures, and provides excellent electrical insulation. It requires a gun and a mixer nozzle (each sold separately) to dispense.

Dry Time | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Container Size | Consistency | Touch, min. | Overall, hrs. | Dielectric Strength, V/mil | Temp. Range, °F | For Use On | Color | Each | |

Loctite® Coatings—Extra Hard | ||||||||||

| M-21HP | 1.7 fl. oz. | Paste | 20 | 24 | 500 | -65° to 300° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Titanium, Silver, Plastic, Composites, Fiberglass | Off-White | 0000000 | 000000 |

Mixer Nozzles for Two-Part Adhesive Cartridges | |||

|---|---|---|---|

| Mixer Nozzle for 1.7 fl. oz. Cartridges | 00000000 | Each | 00000 |

Two-Part Adhesive Dispensing Guns | |||

|---|---|---|---|

| Dispensing Gun for 1.7 fl. oz. Cartridges | 00000000 | Each | 000000 |

Harsh Environment Coatings for Electronics

High humidity, harsh chemicals, water submersions, and salt are no match for these electronic coatings. They also resist UV light, so they’ll work outdoors. Use them on circuit boards, sensors, and LED drivers in heavy machinery. Also known as conformal coatings, they’re thinner than potting compounds, so they flow into the smallest contours of your components to cover them completely.

Epoxy coatings resist impact and wear better than PVDF coatings, and they work in higher temperatures. You can also use them as an adhesive. For controlled pouring, they’re thickened with silicate. These coatings are autoclavable, and they’ll even cure underwater. Dispense them with a mixer nozzle and a gun (each sold separately).

Dry Time | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Container Size, fl. oz. | Consistency | Touch | Overall | Mixing Required | Mix Ratio | Mixer Nozzle Included | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Temp. Range, °F | For Use On | Color | Autoclavable | Each | |

Epoxy Coatings—Extra Hard | ||||||||||||||

Cartridge | ||||||||||||||

| 1.69 | Thick Liquid | 12 hrs. | 24 hrs. | Yes | 2:1 | No | 500 | Not Rated | -50° to 350° | Aluminum, Brass, Bronze, Steel, Stainless Steel, Titanium, Cast Iron, Iron, Silver, Plastic, Rubber, Composites, Fiberglass | Clear | Yes | 0000000 | 000000 |

| For Cartridge Size | Each | |

| 1.69 oz. | 00000000 | 000000 |

| For Cartridge Size | Each | |

| 1.69 oz. | 00000000 | 00000 |

Conductive Adhesives for Electronics

An alternative to solder, these flexible, silver-filled adhesives accommodate joint movement. Use them to bond electrical components and repair circuits.

Epoxy adhesives are two-part adhesives that need to be mixed together. The size listed is the combined total of the two parts.

Container | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Size, fl. oz. | Net Weight, oz. | Begins to Harden | Reaches Full Strength | Thermal Conductivity, W/m-K | Surface Resistivity, ohms-cm | Mix Ratio | Consistency | Temp. Range, °F | For Joining | Each | |

One-Time-Use Packet | |||||||||||

| __ | 0.09 | 3 hrs. | 24 hrs. | 1.55 | 0.05 | 1:1.15 | Paste | -75° to 230° | Ceramic, Glass, Metal | 0000000 | 000000 |

Can | |||||||||||

| 0.5 | __ | 4 hrs. | 5 days | 7.93 | 0.0004 | 1:1 | Paste | 80° to 265° | Metal | 0000000 | 000000 |

| 1 | __ | 4 hrs. | 5 days | 7.93 | 0.0004 | 1:1 | Paste | 80° to 265° | Metal | 0000000 | 000000 |

Epoxy Structural Adhesives

Epoxies are the strongest and most weather- and chemical-resistant structural adhesives. They work especially well on metals. The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

DP110, 14310, 14260, and 305-1/2 bond dissimilar materials.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

| DP110 | 6.76 | Cartridge | 8 min. | 48 hrs. | 2,500 | 20 | 1:1 | Thick Liquid (65,000 cP) | -65° to 350° | Gray | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 0000000 | 000000 |

| DP190 | 6.76 | Cartridge | 60 min. | 14 days | 850 | 20 | 1:1 | Thick Liquid (8,000 cP) | -65° to 350° | Clear | Metal, Plastic, Rubber, Masonry | 00000000 | 00000 |

Quick-Set Epoxy Structural Adhesives

For quick repairs, these epoxies begin to harden in 6 minutes or less. Epoxies are the strongest and most weather- and chemical-resistant structural adhesives.

The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

| DP100 | 6.76 | Cartridge | 5 min. | 48 hrs. | 750 | 2 | 1:1 | Thick Liquid (12,000 cP) | -65° to 320° | Clear | Metal, Plastic, Rubber | 0000000 | 000000 |

Toughened Epoxy Structural Adhesives

Toughened adhesives are blended with rubber particles for better impact resistance than standard epoxies. They form flexible, resilient bonds. The most weather- and chemical-resistant structural adhesives, epoxies work especially well on metals. Choose an adhesive that hardens quickly for fast repairs, or one that hardens slowly to allow more time for positioning.

The size listed is the combined total of the two parts. Use with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

| DP420 | 6.76 | Cartridge | 20 min. | 24 hrs. | 280 | 50 | 2:1 | Thick Liquid (30,000 cP) | -65° to 350° | Off-White | Metal, Plastic, Composites | 0000000 | 0000000 |

| DP460 | 6.76 | Cartridge | 60 min. | 24 hrs. | 2,500 | 60 | 2:1 | Thick Liquid (30,000 cP) | -65° to 350° | Off-White | Metal, Plastic, Composites | 0000000 | 000000 |

Slow-Set Epoxy Structural Adhesives

To allow time to adjust and position parts, these epoxies remain workable for at least 90 minutes. The strongest and most weather- and chemical-resistant structural adhesives, epoxies work especially well on metals.

The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

Container | Strength | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | For Joining | Each | |

| DP190 | 6.76 fl. oz. | Cartridge | 90 min. | 7 days | 1,400 | 20 | 1:1 | Thick Liquid (86,250 cP) | -65° to 350° | Metal, Plastic, Rubber, Masonry | 0000000 | 000000 |

Mixer Nozzles for Two-Part Adhesive Cartridges

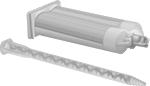

To simultaneously mix and dispense two-part adhesives, attach these mixer nozzles to a dual cartridge. Mixing elements help combine the two parts of an adhesive as it flows through the nozzle. A short nozzle with many mixing elements combines adhesive while minimizing the adhesive left in the nozzle after dispensing. Choose a nozzle that matches the connection type, size, and mix ratio of your adhesive cartridge.

A taper tip has a small opening for controlled dispensing.

A step tip allows you to trim the opening to the diameter you need.

Each | |||||||

|---|---|---|---|---|---|---|---|

| For Cartridge Size, oz. | Mix Ratio | Opening ID | Lg. | Mixing Elements | Material | Each | |

Taper Tip | |||||||

| 1.42, 1.69 | 1:1, 2:1, 4:1, 10:1 | 0.07" | 5.9" | 20 | Polypropylene Plastic | 00000000 | 00000 |

Each | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Cartridge Size, oz. | Mix Ratio | Opening ID | Lg. | Mixing Elements | Mfr. | Material | Each | |

4-Step Tip | ||||||||

| 7.8 | 10:1 | 0.394" | 8.7" | 18 | SciGrip | Polypropylene Plastic | 000000000 | 00000 |

Conductive Surface Fillers for Electronics

A high silver content allows these surface fillers to conduct electricity and heat. Use them to fill gaps and rebuild missing material on electrical connections or to assemble new components. They come as two parts. The size listed is the combined total of the two parts.

Volume resistivity measures how well a material opposes the flow of electricity. The lower the rating, the more electricity it conducts.

Thermal conductivity measures a material’s ability to transfer heat. The higher the rating, the more heat it transfers.

Container | Temp. Range, °F | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Net Weight, oz. | Type | Begins to Harden | Reaches Full Strength | Thermal Conductivity, W/m-K | Volume Resistivity, ohms-cm | Mix Ratio | Min. | Max. | For Use On | Each | |

Loctite® Surface Fillers | |||||||||||||

| 3888 | __ | 0.09 | One-Time-Use Packet | 90 min. | 24 hrs. | 1.44 | 0.001 | 100:6 | -40° | 170° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Titanium, Polycarbonate Plastic | 0000000 | 000000 |

Surface Fillers | |||||||||||||

| __ | __ | 0.09 | One-Time-Use Packet | 90 min. | 24 hrs. | 6.05 | 0.009 | 100:6 | -75° | 250° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Titanium, Ceramic, Glass | 0000000 | 00000 |

| __ | __ | 0.35 | One-Time-Use Packet | 90 min. | 24 hrs. | 6.05 | 0.009 | 100:6 | -75° | 250° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Titanium, Ceramic, Glass | 0000000 | 000000 |

| __ | 0.5 | __ | Jar | 4 hrs. | 5 days | 5.77 | 0.0004 | 1:1 | Not Rated | 300° | Aluminum, Brass, Copper, Steel, Stainless Steel | 0000000 | 000000 |

| __ | 1 | __ | Jar | 4 hrs. | 5 days | 5.77 | 0.0004 | 1:1 | Not Rated | 300° | Aluminum, Brass, Copper, Steel, Stainless Steel | 0000000 | 000000 |

Conductive Surface Filler Pens for Electronics

Dispense ready-to-use conductive liquid to fill pits and small gaps on circuit board components. These pens are also used to sketch and repair conductive pathways.

Product labeling requirements restrict sales to the listed areas.

Carbon acrylic pens should be used where only a small amount of conductivity is needed, such as circuit boards in keyboards. Their high surface resistivity only allows a small current to pass.

Nickel acrylic pens are best for general purpose repairs, such as bridges and traces in printed circuit boards. They have a medium surface resistivity, so they're a good balance between carbon acrylic and silver epoxy pens.

Silver epoxy pens are the most versatile—use them for any type of repair as well as for repairs that require excellent conductivity, such as connecting through holes on circuit boards without adding jumpers, wiring, or solder. Since they have the lowest surface resistivity, they allow the most current to pass.

Tip | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Container Size, fl. oz. | Dia. | Shape | Begins to Harden, min. | Reaches Full Strength | Surface Resistivity, ohms/sq. | Consistency | Max. Thick. | For Use Outdoors | Temp. Range, °F | Color | For Use On | Cannot Be Sold To | Each | |

Carbon Acrylic | ||||||||||||||

| 0.2 | 0.06" | Point | 2 | 24 hrs. | 100 | Thin Liquid | 0.003" | Yes | -40° to 245° | Black | Plastic | Canada | 0000000 | 000000 |

Nickel Acrylic | ||||||||||||||

| 0.2 | 0.06" | Point | 2 | 24 hrs. | 0.49 | Thin Liquid | 0.004" | Yes | -40° to 245° | Gray | Plastic | Canada | 0000000 | 00000 |

Silver Epoxy | ||||||||||||||

| 0.2 | 0.03" | Point | 3 | 60 min. | 0.050 | Thin Liquid | Not Rated | No | -65° to 300° | Silver | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Titanium | Outside United States and Canada | 0000000 | 00000 |