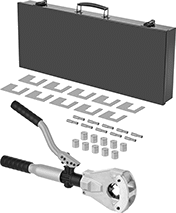

Hydraulic Compression Lug and Splice Crimpers

The high-pressure pumping system in these crimpers creates enough force to crimp large copper and aluminum lugs. They come with a replaceable pressure cartridge that lasts for 10,000 to 12,000 compressions. They crimp using dies, so they crimp a wider range of lug sizes and are less complicated than dieless crimpers. The head swivels 180°.

Dies are required. These crimpers accept U-type dies for Alcoa, Burndy, Panduit, T&B, and Blackburn 12-ton tools. We list lug markings for two common manufacturers to help choose the correct die for your compression lug.

Crimpers | Replacement Pressure Cartridges | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Jaw Opening | For Wire Type | Compression Force, tons | Lg. | Material | Handle Material | Includes | Each | Each | ||

| 1.00" | Solid, Stranded | 12 | 23" | Steel | Fiberglass | Plastic Carrying Case, Pressure Cartridge | 000000 | 000000000 | 000000 | 0000000 |

| 1.65" | Solid, Stranded | 12 | 25" | Steel | Fiberglass | Plastic Carrying Case, Pressure Cartridge | 000000 | 00000000 | 000000 | 000000 |

For Wire Gauge | For Lug Marking | |||||

|---|---|---|---|---|---|---|

| Copper | Aluminum | Color | T&B | Burndy | Each | |

| 6 | 8 | Blue | 24 | 7 | 0000000 | 0000000 |

| 4 | 6 | Gray | 29 | 8 | 0000000 | 000000 |

| 2 | __ | Brown | 33 | 10 | 0000000 | 000000 |

| 1 | 4 | Green | 37 | 11 | 0000000 | 000000 |

| 1/0 | 2 | Pink | 42 | 12 | 0000000 | 000000 |

| 2/0 | __ | Black | 45 | 13 | 0000000 | 000000 |

| 3/0 | __ | Orange | 50 | 14 | 0000000 | 000000 |

| 4/0 | __ | Purple | 54 | 15 | 0000000 | 000000 |

| 250 MCM | __ | Yellow | 62 | 16 | 0000000 | 000000 |

| 300 MCM | __ | White | 66, 66H | 17 | 0000000 | 000000 |

| 350 MCM | __ | Red | 71, 71H | 18 | 0000000 | 000000 |

| 400 MCM | __ | Blue | 76, 76H | 19 | 0000000 | 000000 |

| 500 MCM | __ | Brown | 087 | 21 | 0000000 | 000000 |

| 600 MCM | 400 MCM | Green | 94, 94H | 22 | 0000000 | 000000 |

| 750 MCM | __ | Black | 106, 106H | 24 | 0000000 | 000000 |

Dies for Cordless Compression Lug and Splice Crimpers

Attach these dies to your cordless crimper to secure compression lug and butt splice connectors onto cable. They’re easy to swap out, so you can quickly crimp across a range of connector sizes.

For Wire | 6 Ton Compression Force | 12 Ton Compression Force | ||||

|---|---|---|---|---|---|---|

| Gauge | Type | Material | Each | Each | ||

For Copper Connectors | ||||||

| 8 | Stranded | Steel | 0000000 | 0000000 | 0000000 | 0000000 |

| 6 | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 4 | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 2 | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 1 | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 1/0 | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 2/0 | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 3/0 | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 4/0 | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 250 MCM | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 300 MCM | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 350 MCM | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 400 MCM | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 500 MCM | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 600 MCM | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 750 MCM | Stranded | Steel | 000000 | 00 | 0000000 | 000000 |

For Aluminum Connectors | ||||||

| 8 | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 6 | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 4 | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 2 | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 1 | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 1/0 | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 2/0 | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 3/0 | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 4/0 | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 250 MCM | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 300 MCM | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 350 MCM | Stranded | Steel | 0000000 | 000000 | 0000000 | 000000 |

| 400 MCM | Stranded | Steel | 000000 | 00 | 0000000 | 000000 |

| 500 MCM | Stranded | Steel | 000000 | 00 | 0000000 | 000000 |

| 600 MCM | Stranded | Steel | 000000 | 00 | 0000000 | 000000 |

| 750 MCM | Stranded | Steel | 000000 | 00 | 0000000 | 000000 |

| No. of Pieces | For Wire Gauge | Type | Material | Container Type | Each | |

6 Ton Compression Force | ||||||

|---|---|---|---|---|---|---|

For Copper Connectors | ||||||

| 15 | 8, 6, 4, 2, 1, 1/0, 2/0, 3/0, 4/0, 250 MCM, 300 MCM, 350 MCM, 400 MCM, 500 MCM, 600 MCM | Stranded | Steel | Plastic Case | 0000000 | 000000000 |

For Aluminum Connectors | ||||||

| 12 | 8, 6, 4, 2, 1, 1/0, 2/0, 3/0, 4/0, 250 MCM, 300 MCM, 350 MCM | Stranded | Steel | Plastic Case | 0000000 | 00000000 |

12 Ton Compression Force | ||||||

For Copper Connectors | ||||||

| 15 | 6, 4, 2, 1, 1/0, 2/0, 3/0, 4/0, 250 MCM, 300 MCM, 350 MCM, 400 MCM, 500 MCM, 600 MCM, 750 MCM | Stranded | Steel | Plastic Case | 0000000 | 00000000 |

For Aluminum Connectors | ||||||

| 15 | 6, 4, 2, 1, 1/0, 2/0, 3/0, 4/0, 250 MCM, 300 MCM, 350 MCM, 400 MCM, 500 MCM, 600 MCM, 750 MCM | Stranded | Steel | Plastic Case | 0000000 | 00000000 |

Dieless Hydraulic Compression Lug and Splice Crimpers

| Four-Point Indent |

One-Point Indent |

The high-pressure pumping system in these crimpers creates enough force to crimp large copper and aluminum lugs without using dies. Instead of dies, adjust the settings for different compression connector sizes. The head rotates 350° so you can crimp at any angle and maneuver these tools in tight spaces. Each crimper includes 10 test kits for periodically testing that the pumping system activates at the proper pressure.

Crimpers with four-point indent form a more secure connection than crimpers with a one-point indent, but have a lower compression force and cannot be used with as large of lugs.

Crimpers with one-point indent form a consistent crimp that resembles a half-moon.

For Wire Gauge | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Copper | Aluminum | For Wire Type | Compression Force, tons | Lg. | Material | Handle Material | Grip Material | Includes | Each | |

Four-Point Indent | ||||||||||

| 4-750 MCM | 6-750 MCM | Solid, Stranded | 6 | 21" | Aluminum | Aluminum | Rubber | Metal Carrying Case | 0000000 | 000000000 |

One-Point Indent | ||||||||||

| 4-1000 MCM | 6-1000 MCM | Solid, Stranded | 12 | 26" | Aluminum | Fiberglass | Rubber | Plastic Carrying Case | 0000000 | 00000000 |

Hydraulic Compression Tools for Wire Rope Sleeves

Compress sleeves onto rope and wire rope with less effort than standard compression tools. Tools include a replaceable cartridge that lasts up to 10,000 compressions. Use the measuring gauge to confirm proper installation of the compressed sleeve.

Tools | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Handle | Replacement Dies | Replacement Cartridges | |||||||||

| For Compression Sleeve Material (Wire Rope Dia.) | For Stop Material (Wire Rope Dia.) | Material | Color | Overall Lg. | Includes | Each | Each | Each | |||

| Aluminum (5/16") | Aluminum (5/16") | Fiberglass | Yellow | 23" | Cartridge, Die, Measuring Gauge, Case | 00000000 | 000000000 | 0000000 | 0000000 | 0000000 | 0000000 |

| Aluminum (5/16") | __ | Fiberglass | Yellow | 23" | Cartridge, Die, Measuring Gauge, Case | 0000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 |

| Aluminum (7/16"); Copper (1/2") | __ | Fiberglass | Yellow | 23" | Cartridge, Die, Measuring Gauge, Case | 00000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 |

| Aluminum (1/2") | __ | Fiberglass | Yellow | 23" | Cartridge, Die, Measuring Gauge, Case | 00000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 |

| Copper (3/16") | __ | Fiberglass | Yellow | 23" | Cartridge, Die, Measuring Gauge, Case | 00000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 |

| Copper (1/4") | Copper (1/4", 5/16", 3/8") | Fiberglass | Yellow | 23" | Cartridge, Die, Measuring Gauge, Case | 00000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 |

| Copper (5/16") | __ | Fiberglass | Yellow | 23" | Cartridge, Die, Measuring Gauge, Case | 00000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 |

| Copper (3/8") | __ | Fiberglass | Yellow | 23" | Cartridge, Die, Measuring Gauge, Case | 00000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 |

| Copper (7/16”) | __ | Fiberglass | Yellow | 23" | Cartridge, Die, Measuring Gauge, Case | 000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 |

Hydraulic Bench-Top Compression Tools for Rope and Wire Rope Sleeves

Compress sleeves with more strength than hydraulic hand tools. Use the measuring gauge to confirm proper installation of the compressed sleeve.

Tools | Replacement Dies | |||||||

|---|---|---|---|---|---|---|---|---|

| For Compression Sleeve Material (Wire Rope Dia.) | For Compression Sleeve Material (Rope Dia.) | Handle Material | Overall Lg. | Includes | Each | Each | ||

| Aluminum (3/8") | Aluminum (3/8") | Steel | 29" | Case, Die, Measuring Gauge | 0000000 | 000000000 | 0000000 | 0000000 |

| Aluminum (1/2") | Aluminum (1/2") | Steel | 29" | Case, Die, Measuring Gauge | 0000000 | 00000000 | 0000000 | 000000 |

| Copper (9/16”) | __ | Steel | 29" | Case, Die, Measuring Gauge | 000000 | 00000000 | 0000000 | 000000 |

| Copper (5/8”) | __ | Steel | 29" | Case, Die, Measuring Gauge | 000000 | 00000000 | 0000000 | 000000 |

| Stainless Steel (1/4") | __ | Steel | 29" | Case, Die, Measuring Gauge | 00000000 | 00000000 | 0000000 | 000000 |

Wire Rope Compression Sleeves—For Lifting

Install with a compression tool to create a strong, permanent loop. Compression sleeves are also known as ferrules, crimps, swaging, and splicing sleeves. They're compatible with Nicopress compression tools.

Tin-plated copper sleeves have mild corrosion resistance.

Zinc-plated copper sleeves are more corrosion resistant than tin-plated or black-oxide copper.

18-8 stainless steel sleeves have excellent corrosion resistance to chemicals.

Warning: Fittings must match rope diameter and be installed correctly to obtain maximum holding power. Test all assemblies for required strength before use. Do not use with coated rope unless the coating is removed.

Sleeves | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

For Wire Rope | Compression Tools | ||||||||||

| Dia. | Construction | Sleeve Lg. | Required Number of Compressions | Capacity | Specifications Met | Pkg. Qty. | Pkg. | Compression Tool Type | Each | ||

Tin-Plated Copper | |||||||||||

For Steel and Stainless Steel Rope | |||||||||||

| 3/8" | 6 × 19 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 1 3/16" | 4 | 100% of the Rope's Capacity | ASME B30.9, MS51844 | 2 | 0000000 | 000000 | Hydraulic | 00000000 | 000000000 |

For Stainless Steel Rope | |||||||||||

| 1/2" | 6 × 19 IWRC 7 × 7 IWRC 7 × 19 IWRC | 1 7/8" | 3 | 100% of the Rope's Capacity | ASME B30.9, MS51844 | 1 | 0000000 | 00000 | Hydraulic | 00000000 | 00000000 |

Zinc-Plated Copper | |||||||||||

For Steel Rope | |||||||||||

| 3/8" | 6 × 19 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 1 1/4" | 4 | 100% of the Rope's Capacity | ASME B30.9, MS51844 | 2 | 0000000 | 00000 | Hydraulic | 00000000 | 00000000 |

| 1/2" | 6 × 19 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 1 7/8" | 6 | 100% of the Rope's Capacity | ASME B30.9, MS51844 | 1 | 000000 | 00000 | Hydraulic | 00000000 | 00000000 |

18-8 Stainless Steel | |||||||||||

For Steel and Stainless Steel Rope | |||||||||||

| 1/4" | 6 × 19 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 1 1/8" | 1 | 100% of the Rope's Capacity | ASME B30.9, MS51844 | 1 | 000000 | 0000 | Hydraulic Bench-Top | 00000000 | 00000000 |

For Stainless Steel Rope | |||||||||||

| 7/32" | 6 × 19 IWRC 7 × 7 IWRC 7 × 19 IWRC | 7/8" | 1 | 100% of the Rope's Capacity | ASME B30.9, MS51844 | 1 | 0000000 | 0000 | __ | 000000 | 00 |

Wire Rope Compression Sleeves—Not for Lifting

An economical option for light-duty tethering, securing, and suspending. Compression sleeves are also known as ferrules, crimps, swaging, and splicing sleeves. They're compatible with Nicopress compression tools.

Warning: Fittings must match rope diameter and be installed correctly to obtain maximum holding power. Test all assemblies for required strength before use. Do not use with coated rope unless the coating is removed.

Sleeves | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

For Wire Rope | Compression Tools | |||||||||

| Dia. | Construction | Sleeve Lg. | Required Number of Compressions | Capacity | Pkg. Qty. | Pkg. | Compression Tool Type | Each | ||

Aluminum | ||||||||||

For Steel Rope | ||||||||||

| 3/8" | 1 × 19 Strand Core 1 × 7 Strand Core 3 × 7 Hollow Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 7 × 19 IWRC 7 × 19 Strand Core 7 × 7 Strand Core 6 × 7 Fiber Core | 1 7/16" | 5 | 100% of the Rope's Capacity | 5 | 000000 | 00000 | Hydraulic | 00000000 | 000000000 |

| 1/2" | 1 × 19 Strand Core 1 × 7 Strand Core 3 × 7 Hollow Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 7 × 19 IWRC 7 × 19 Strand Core 7 × 7 Strand Core 6 × 7 Fiber Core | 2 1/8" | 4 | 100% of the Rope's Capacity | 5 | 0000000 | 00000 | Hydraulic | 00000000 | 00000000 |