About Plastic and Rubber Tubing

More

About Hose

More

About Heat-Shrink Tubing

More

High-Temperature Medium-Pressure Chemical Hose

- Temperature Range: -40° to 350° F

- Maximum Vacuum: 29" of Hg @ 72° F

- Material:

1/2" and 3/4" ID Hose: PTFE with EPDM Rubber Cover

All Other Hose: FEP with EPDM Rubber Cover - Color: Green with Yellow Stripe

- Compatible Hose Fittings: Barbed

This hose can stand up to chemicals at high temperatures.

For technical drawings and 3-D models, click on a part number.

Per Ft. | |||||||

|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Max. Pressure | Max. Continuous Lg., ft. | 1-49 | 50-Up | |

| 1" | 1 9/16" | 5 3/4" | 450 psi @ 72° F | 50 | 000000000 | 000000 | 000000 |

| 1 1/4" | 1 3/4" | 8 1/2" | 375 psi @ 72° F | 50 | 000000000 | 00000 | 00000 |

| 1 1/2" | 2 1/8" | 10 1/2" | 350 psi @ 72° F | 50 | 000000000 | 00000 | 00000 |

| 2" | 2 11/16" | 13" | 300 psi @ 72° F | 50 | 000000000 | 000000 | 000000 |

| 3" | 3 7/8" | 21" | 250 psi @ 72° F | 50 | 000000000 | 000000 | 000000 |

| 4" | 5" | 39" | 175 psi @ 72° F | 50 | 000000000 | 000000 | 000000 |

High-Temperature Medium-Pressure Chemical Hose with Fittings

- Temperature Range: -40° to 350° F

- Maximum Vacuum: 29" of Hg @ 72° F

- Material: 1/2" and 3/4" ID hose is PTFE with EPDM Rubber Cover; 1" and 2" ID hose is FEP with EPDM Rubber Cover.

- Color: Green with Yellow Stripe

This hose can stand up to chemicals at high temperatures. 316 stainless steel fittings have excellent corrosion resistance; steel fittings have excellent strength.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | ID | OD | Bend Radius | Max. Pressure | 1 ft. | 2 ft. | 3 ft. | 4 ft. | 5 ft. | 10 ft. | 15 ft. | 20 ft. | 25 ft. | 50 ft. | |

Steel Threaded NPT Male × Steel Threaded NPT Male | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 × 1 | 1" | 1 9/16" | 5 3/4" | 450 psi @ 72° F | 00000000 | ||||||||||

| 2 × 2 | 2" | 2 11/16" | 13" | 300 psi @ 72° F | 000000000 | ||||||||||

316 Stainless Steel Threaded NPT Male × 316 Stainless Steel Threaded NPT Male | |||||||||||||||

| 1 × 1 | 1" | 1 9/16" | 5 3/4" | 450 psi @ 72° F | 00000000 | ||||||||||

| 2 × 2 | 2" | 2 11/16" | 13" | 300 psi @ 72° F | 00000000 | ||||||||||

UV-Resistant Hard Plastic Tubing for Chemicals

Ultraviolet light won’t cause this tubing to degrade or deteriorate.

FEP (fluorinated ethylene propylene) tubing is the most economical option.

Semi-clear tubing gives you a limited view inside the line. Clear tubing allows you to easily monitor flow. Opaque tubing does not allow you to see inside the line.

Semi-flexible tubing is good for gradual bends.

Tubing that meets USP Class VI adheres to specifications for material testing; it is not for use in medical applications. Tubing that meets UL 94 V-0 is flame retardant, so it delays the spread of flames to valuable equipment. Tubing that meets ASTM D2116 and ASTM D3296 adheres to specifications and testing requirements for material quality.

For technical drawings and 3-D models, click on a part number.

- Semi-Flexible

- Compatible with Compression and Push to Connect Tube Fittings

- Hard (Durometer 55D)

- Temperature Range: 32° to 212° F

| ID | OD | Wall Thick. | Bend Radius | Max. Pressure | Lengths, ft. | Specifications Met | Per Ft. | |

Blue | ||||||||

|---|---|---|---|---|---|---|---|---|

Inch | ||||||||

| 3/32" | 1/8" | 1/64" | 1" | 140 psi @ 72° F | UL 94 V-0 | 0000000 | 00000 | |

| 1/8" | 3/16" | 1/32" | 1 1/4" | 140 psi @ 72° F | UL 94 V-0 | 0000000 | 0000 | |

| 3/16" | 1/4" | 1/32" | 2" | 140 psi @ 72° F | UL 94 V-0 | 0000000 | 0000 | |

| 9/32" | 3/8" | 3/64" | 3 1/4" | 140 psi @ 72° F | UL 94 V-0 | 0000000 | 0000 | |

| 3/8" | 1/2" | 1/16" | 3 1/2" | 140 psi @ 72° F | UL 94 V-0 | 0000000 | 0000 | |

Metric | ||||||||

| 2mm | 4mm | 1mm | 15mm | 140 psi @ 72° F | UL 94 V-0 | 0000000 | 0000 | |

| 4mm | 6mm | 1mm | 35mm | 140 psi @ 72° F | UL 94 V-0 | 0000000 | 0000 | |

| 6mm | 8mm | 1mm | 60mm | 140 psi @ 72° F | UL 94 V-0 | 0000000 | 0000 | |

| 8mm | 10mm | 1mm | 100mm | 100 psi @ 72° F | UL 94 V-0 | 0000000 | 0000 | |

| 10mm | 12mm | 1mm | 130mm | 100 psi @ 72° F | UL 94 V-0 | 00000000 | 0000 | |

Red | ||||||||

Inch | ||||||||

| 3/32" | 1/8" | 1/64" | 1" | 140 psi @ 72° F | UL 94 V-0 | 0000000 | 0000 | |

| 9/64" | 3/16" | 1/32" | 1 1/4" | 140 psi @ 72° F | UL 94 V-0 | 0000000 | 0000 | |

| 3/16" | 1/4" | 1/32" | 2" | 140 psi @ 72° F | UL 94 V-0 | 0000000 | 0000 | |

| 9/32" | 3/8" | 3/64" | 3 1/4" | 140 psi @ 72° F | UL 94 V-0 | 0000000 | 0000 | |

| 3/8" | 1/2" | 1/16" | 3 1/2" | 140 psi @ 72° F | UL 94 V-0 | 0000000 | 0000 | |

Metric | ||||||||

| 2mm | 4mm | 1mm | 15mm | 140 psi @ 72° F | UL 94 V-0 | 0000000 | 0000 | |

| 4mm | 6mm | 1mm | 35mm | 140 psi @ 72° F | UL 94 V-0 | 0000000 | 0000 | |

| 6mm | 8mm | 1mm | 60mm | 140 psi @ 72° F | UL 94 V-0 | 0000000 | 0000 | |

| 8mm | 10mm | 1mm | 100mm | 100 psi @ 72° F | UL 94 V-0 | 0000000 | 0000 | |

| 10mm | 12mm | 1mm | 130mm | 100 psi @ 72° F | UL 94 V-0 | 00000000 | 0000 | |

- Semi-Flexible

- Compatible with Compression and Push to Connect Tube Fittings

- Hard (Durometer 60D)

- Temperature Range: -100° to 400° F

| ID | OD | Wall Thick. | Bend Radius | Max. Pressure | Max. Vacuum | Specifications Met | Color | Lengths, ft. | Per Ft. | |

Inch | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1/32" | 1/16" | 1/64" | 1/2" | 400 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 00000000 | 00000 | |

| 1/16" | 1/8" | 1/32" | 1/2" | 440 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 0000 | |

| 3/32" | 5/32" | 1/32" | 1/2" | 350 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 0000 | |

| 1/8" | 3/16" | 1/32" | 3/4" | 295 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 00000000 | 0000 | |

| 1/8" | 1/4" | 1/16" | 1/2" | 460 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 0000 | |

| 3/16" | 1/4" | 1/32" | 1" | 220 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 0000 | |

| 3/16" | 5/16" | 1/16" | 1" | 365 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 0000 | |

| 1/4" | 5/16" | 1/32" | 1 3/4" | 175 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 00000000 | 0000 | |

| 1/4" | 3/8" | 1/16" | 1" | 300 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 0000 | |

| 5/16" | 3/8" | 1/32" | 2 1/2" | 140 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 0000 | |

| 5/16" | 7/16" | 1/16" | 2" | 260 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 0000 | |

| 3/8" | 7/16" | 1/32" | 3 1/2" | 125 psi @ 72° F | 25 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 00000000 | 0000 | |

| 3/8" | 1/2" | 1/16" | 2" | 230 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 0000 | |

| 7/16" | 1/2" | 1/32" | 6" | 110 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 0000 | |

| 1/2" | 9/16" | 1/32" | 6 1/2" | 90 psi @ 72° F | 14 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 00000000 | 0000 | |

| 1/2" | 5/8" | 1/16" | 3" | 180 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 00000 | |

| 5/8" | 3/4" | 1/16" | 6" | 150 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 00000 | |

| 3/4" | 7/8" | 1/16" | 12" | 130 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 00000 | |

| 1" | 1 1/8" | 1/16" | 24" | 75 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 00000 | |

Metric | ||||||||||

| 2mm | 4mm | 1mm | 38mm | 460 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 0000 | |

| 3mm | 5mm | 1mm | 25mm | 370 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 0000 | |

| 4mm | 6mm | 1mm | 44mm | 300 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 0000 | |

| 6mm | 8mm | 1mm | 63mm | 230 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 0000 | |

| 8mm | 10mm | 1mm | 70mm | 180 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 0000 | |

| 10mm | 12mm | 1mm | 101mm | 150 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 0000 | |

| 12mm | 14mm | 1mm | 152mm | 140 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 0000 | |

| 14mm | 16mm | 1mm | 203mm | 100 psi @ 72° F | 29 in. of Hg @ 72° F | USP Class VI, ASTM D2116, ASTM D3296, NSF/ANSI 51, NSF/ANSI 372, NSF/ANSI 61, FDA Compliant 21 CFR 177.1550 | Clear | 0000000 | 0000 | |

- Semi-Flexible

- Compatible with Compression and Push to Connect Tube Fittings

- Hard (Durometer 55D)

- Temperature Range: 32° to 212° F

| ID | OD | Wall Thick. | Bend Radius | Color | Lengths, ft. | Per Ft. | |

Inch | |||||||

|---|---|---|---|---|---|---|---|

| 3/32" | 1/8" | 1/64" | 1" | Black | 0000000 | 00000 | |

| 1/8" | 3/16" | 1/32" | 1 1/4" | Black | 0000000 | 0000 | |

| 3/16" | 1/4" | 1/32" | 2" | Black | 0000000 | 0000 | |

| 9/32" | 3/8" | 3/64" | 3 1/4" | Black | 0000000 | 0000 | |

| 3/8" | 1/2" | 1/16" | 3 1/2" | Black | 0000000 | 0000 | |

Metric | |||||||

| 2mm | 4mm | 1mm | 15mm | Black | 0000000 | 0000 | |

| 4mm | 6mm | 1mm | 35mm | Black | 0000000 | 0000 | |

| 6mm | 8mm | 1mm | 60mm | Black | 0000000 | 0000 | |

| 8mm | 10mm | 1mm | 100mm | Black | 0000000 | 0000 | |

| 10mm | 12mm | 1mm | 130mm | Black | 00000000 | 0000 | |

Self-Retracting Hard Plastic Tubing for Chemicals

- Flexible

- Compatible with Compression and Push to Connect Tube Fittings

- Hard (Durometer 55D)

- Temperature Range: -400° to 200° F

- Specifications Met: UL 94 V-0, USP Class IV

Keep your work site safe and clutter free—this coiled FEP tubing extends when you need it and retracts out of the way when you don’t. Tubing has the chemical resistance to withstand a variety of acids and other harsh substances. It meets UL 94 V-0 for flame retardance, so it delays the spread of flames to valuable equipment. Tubing meets USP Class IV for material testing; it is not for use in medical applications. Tubing is semi-clear, so it gives you a limited view inside your line. It is flexible and bends easily around objects.

For technical drawings and 3-D models, click on a part number.

| ID | OD | Wall Thick. | Lg., ft. | Retracted Lg. | Coil OD | Bend Radius | Max. Pressure | Max. Vacuum | Color | Each | |

Semi-Clear FEP Plastic | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/8" | 1/4" | 1/16" | 1 | 3" | 1 1/2" | 1/2" | 470 psi @ 72° F | 27 in. of Hg @ 72° F | White | 0000000 | 0000000 |

| 1/8" | 1/4" | 1/16" | 2 | 6" | 1 1/2" | 1/2" | 470 psi @ 72° F | 27 in. of Hg @ 72° F | White | 0000000 | 000000 |

| 1/8" | 1/4" | 1/16" | 4 | 12" | 1 1/2" | 1/2" | 470 psi @ 72° F | 27 in. of Hg @ 72° F | White | 0000000 | 000000 |

| 1/8" | 1/4" | 1/16" | 6 | 18" | 1 1/2" | 1/2" | 470 psi @ 72° F | 27 in. of Hg @ 72° F | White | 0000000 | 000000 |

| 1/4" | 3/8" | 1/16" | 1 | 3" | 2 3/8" | 3/4" | 290 psi @ 72° F | 27 in. of Hg @ 72° F | White | 0000000 | 000000 |

| 1/4" | 3/8" | 1/16" | 2 | 6" | 2 3/8" | 3/4" | 290 psi @ 72° F | 27 in. of Hg @ 72° F | White | 0000000 | 000000 |

| 1/4" | 3/8" | 1/16" | 4 | 12" | 2 3/8" | 3/4" | 290 psi @ 72° F | 27 in. of Hg @ 72° F | White | 0000000 | 000000 |

| 1/4" | 3/8" | 1/16" | 6 | 18" | 2 3/8" | 3/4" | 290 psi @ 72° F | 27 in. of Hg @ 72° F | White | 0000000 | 000000 |

High-Strength Heat-Shrink Tubing

With excellent durability and chemical resistance, this tubing withstands demanding use.

FEP tubing is more chemical resistant than PVDF tubing, and withstands higher temperatures. It resists tears from stretching or flexing, but it’s softer than PVDF tubing and less resistant to cuts.

Dielectric strength is the maximum voltage a material can handle before it starts to breakdown. The higher the dielectric strength of a material, the better it is for preventing electricity, heat, or signal from dissipating from wire and cable.

For technical drawings and 3-D models, click on a part number.

- Shrink Ratio: See Table

- Dielectric Strength: 2,000 V/mil

- Shrink Temperature: 420° F

- Temperature Range: -400° to 400° F

ID | ||||||||

|---|---|---|---|---|---|---|---|---|

| Before Shrinking | Min. After Shrinking | Min. Wall Thick. After Shrinking | For Wire Gauge | For Wire Size | Color | Lengths, ft. | Per Ft. | |

1.3:1 Shrink Ratio | ||||||||

| 0.031" | 0.027" | 0.01" | 24 | __ | Clear | 00000000 | 00000 | |

| 0.036" | 0.032" | 0.01" | 22 | __ | Clear | 00000000 | 0000 | |

| 0.045" | 0.039" | 0.01" | 20 | __ | Clear | 00000000 | 0000 | |

| 0.06" | 0.049" | 0.01" | 18 | __ | Clear | 00000000 | 0000 | |

| 0.075" | 0.061" | 0.01" | 16 | __ | Clear | 00000000 | 0000 | |

| 0.092" | 0.072" | 0.01" | 14 | __ | Clear | 00000000 | 0000 | |

| 0.115" | 0.089" | 0.01" | 12 | __ | Clear | 00000000 | 0000 | |

| 0.141" | 0.114" | 0.01" | 10 | __ | Clear | 00000000 | 0000 | |

| 0.18" | 0.143" | 0.01" | 8 | __ | Clear | 00000000 | 0000 | |

| 0.225" | 0.18" | 0.01" | 6 | __ | Clear | 00000000 | 0000 | |

| 0.29" | 0.226" | 0.01" | 4 | __ | Clear | 00000000 | 0000 | |

| 0.365" | 0.28" | 0.01" | 2 | __ | Clear | 00000000 | 0000 | |

| 0.44" | 0.349" | 0.01" | 1/0 | __ | Clear | 00000000 | 0000 | |

| 0.58" | 0.448" | 0.02" | __ | 7/16" | Clear | 00000000 | 00000 | |

| 0.666" | 0.51" | 0.02" | __ | 1/2" | Clear | 00000000 | 00000 | |

| 0.83" | 0.637" | 0.03" | __ | 5/8" | Clear | 00000000 | 00000 | |

| 1" | 0.764" | 0.03" | __ | 3/4" | Clear | 00000000 | 00000 | |

| Each | ||||||||

1.6:1 Shrink Ratio | ||||||||

| 0.094" | 0.056" | 0.01" | __ | 3/32" | Clear | 4 | 00000000 | 00000 |

| 0.125" | 0.075" | 0.01" | __ | 1/8" | Clear | 4 | 00000000 | 00000 |

| 0.188" | 0.115" | 0.01" | __ | 3/16" | Clear | 4 | 00000000 | 00000 |

| 0.25" | 0.15" | 0.01" | __ | 1/4" | Clear | 4 | 00000000 | 00000 |

| 0.375" | 0.235" | 0.01" | __ | 3/8" | Clear | 4 | 00000000 | 00000 |

| 0.5" | 0.3" | 0.02" | __ | 1/2" | Clear | 4 | 00000000 | 00000 |

| 1" | 0.6" | 0.025" | __ | 1" | Clear | 4 | 00000000 | 00000 |

2:1 Shrink Ratio | ||||||||

| 0.034" | 0.017" | 0.013" | __ | __ | Clear | 4 | 00000000 | 000000 |

| 0.075" | 0.038" | 0.013" | __ | __ | Clear | 4 | 00000000 | 000000 |

| 0.125" | 0.063" | 0.013" | __ | __ | Clear | 4 | 00000000 | 000000 |

| 0.19" | 0.095" | 0.013" | __ | __ | Clear | 4 | 00000000 | 000000 |

| 0.29" | 0.145" | 0.013" | __ | __ | Clear | 4 | 00000000 | 000000 |

| 0.385" | 0.193" | 0.013" | __ | __ | Clear | 4 | 00000000 | 000000 |

- Shrink Ratio: See Table

- Dielectric Strength: See Table

- Shrink Temperature: See Table

- Temperature Range: See Table

ID | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Before Shrinking | Min. After Shrinking | Min. Wall Thick. After Shrinking | Shrink Temp., °F | Temp. Range, °F | Dielectric Strength | Color | 1 ft. | 2 ft. | 3 ft. | 4 ft. | 6 ft. | 8 ft. | |

1.3:1 Shrink Ratio | |||||||||||||

| 1.1" | 0.88" | 0.02" | 350° | -450° to 400° | 1,400 V/mil | Clear | 00000000 | ||||||

| 1.3" | 1" | 0.02" | 350° | -450° to 400° | 1,400 V/mil | Clear | 00000000 | ||||||

| 1.7" | 1.3" | 0.02" | 350° | -450° to 400° | 1,400 V/mil | Clear | 00000000 | ||||||

| 2.1" | 1.7" | 0.02" | 350° | -450° to 400° | 1,400 V/mil | Clear | 00000000 | ||||||

| 2.6" | 2.1" | 0.02" | 350° | -450° to 400° | 1,400 V/mil | Clear | 00000000 | ||||||

| 3.1" | 2.6" | 0.02" | 350° | -450° to 400° | 1,400 V/mil | Clear | 00000000 | ||||||

| 4.3" | 3.5" | 0.02" | 350° | -450° to 400° | 1,400 V/mil | Clear | 00000000 | ||||||

| 5.2" | 4.3" | 0.02" | 350° | -450° to 400° | 1,400 V/mil | Clear | 00000000 | ||||||

| 6.2" | 5.2" | 0.02" | 350° | -450° to 400° | 1,400 V/mil | Clear | 00000000 | ||||||

1.6:1 Shrink Ratio | |||||||||||||

| 1.5" | 0.9" | 0.03" | 420° | -400° to 400° | 2,000 V/mil | Clear | 00000000 | ||||||

| 2" | 1.2" | 0.03" | 420° | -400° to 400° | 2,000 V/mil | Clear | 00000000 | ||||||

Tight-Fit High-Strength Heat-Shrink Tubing

- Material: FEP Plastic

- Shrink Ratio: 1.3:1

- Dielectric Strength: 2,000 V/mil

- Shrink Temperature: 260° F

- Temperature Range: -100° to 400° F

Protect light bulbs, capacitors, and other electronics—this FEP tubing adds a tear- and cut-resistant layer that even contains shattered glass if the bulb breaks. Similar to shrink wrap, it tightly conforms to objects. It’s clear, so you won’t be blocking light, including UV light, from shining through if you use it on a bulb. This tubing also resists chemicals.

Dielectric strength is the maximum voltage a material can handle before it starts to breakdown. The higher the dielectric strength of a material, the better it is for preventing electricity, heat, or signal from dissipating from wire and cable.

For technical drawings and 3-D models, click on a part number.

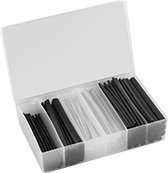

Harsh Environment Heat-Shrink Tubing Assortments

Maintain a supply of tubing in a variety of sizes and materials that withstands harsh conditions such as abrasion, moisture, and chemicals.

PVC tubing has excellent resistance to chemicals, oil, and acids.

Polyolefin is for general purpose use. Polyolefin with adhesive creates a water-resistant seal; the adhesive melts when heated and bonds to the underlying surface.

PTFE has excellent abrasion resistance and withstands higher temperatures than other tubing.

FEP tubing is high strength to resist abrasion, cuts, tears, and chemicals.

PVDF resists abrasion, cuts, and tears.

| Includes | Number of Pieces | Lg. | Shrink Ratio | Shrink Temp., °F | Colors Included | Each | |

| 0.05"-1" ID Before Shrinking of Polyolefin (49 pieces, 10 sizes) 0.25"-1" ID Before Shrinking of Polyolefin with Adhesive Lining (52 pieces, 5 sizes) 0.05"-0.75" ID Before Shrinking of PVC (18 pieces, 9 sizes) 0.05"-0.08" ID Before Shrinking of PTFE (17 pieces, 5 sizes) 0.05"-0.38" ID Before Shrinking of PVDF (14 pieces, 7 sizes) 0.03"-0.12" ID Before Shrinking of FEP (22 pieces, 6 sizes) 0.17"-0.25" ID Before Shrinking Nylon Butt Splices (3 sizes, 12 each) 0.29"-0.6" ID Before Shrinking Polyolefin End Caps (6 pieces, 3 sizes) | 181 | 1", 1/2ft. | 1.2:1, 1.5:1, 2:1, 2.5:1, 3:1 | 195° to 485° | Black, Blue, Brown, Clear, Gray, Green, Red, White, Yellow | 00000000 | 0000000 |

| 0.06"-0.5" ID Before Shrinking of Polyolefin (42 pieces, 7 sizes) 0.13"-1" ID Before Shrinking of Polyolefin with Adhesive Lining (16 pieces/6sizes) 0.06"-0.5" ID Before Shrinking of PVC (14 pieces, 7 sizes) 0.17"-0.5" ID Before Shrinking of PVDF (14 pieces, 7 sizes) 0.03"-0.12" ID Before Shrinking of FEP (14 pieces, 7 sizes) 0.17"-0.25" ID Before Shrinking Nylon Butt Splices (3 Sizes, 4 each) | 112 | 1/2ft. | 1.2:1, 2:1, 2.5:1, 3:1 | 195° to 395° | Black, Blue, Brown, Clear, Gray, Green, Green with Yellow Stripe, Red, White, Yellow | 00000000 | 000000 |