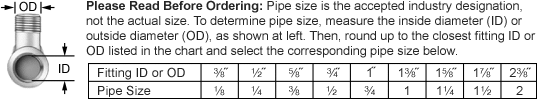

About Pipe Size and Spray Nozzles

More

About Fire-Fighting Hose Threads

More

Flat Spray Nozzles

Steel, and 316

Stainless Steel

These nozzles produce a flat, thin spray pattern. They're good for general cleaning, washing, etching, foam control, and applying coatings.

Brass nozzles have good corrosion resistance.

303 stainless steel nozzles are more chemical, corrosion, and abrasion resistant than brass nozzles.

Spray nozzle fittings and manifolds are also available.

For technical drawings and 3-D models, click on a part number.

Clamp-On Flat Spray Nozzles

Drill a hole anywhere along a pipe and snap on these nozzles. Spray tips can be removed for cleaning, but cannot be replaced with another tip. Made of reinforced plastic, all have a 300 Series stainless steel clamp that grips the pipe and an EPDM rubber gasket that prevents leaks. They're good for foam control and produce a flat, thin spray pattern.

For technical drawings and 3-D models, click on a part number.

Flow Rate, gpm | Each | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 100 psi | Orifice Dia. | For Hole Dia. | Overall Dia. | Lg. | Max. Pressure, psi | Max. Temp., °F | Reinforcement Material | Max. Swivel Angle | Spray Angle | 1-9 | 10-Up | |

Polypropylene Plastic | ||||||||||||||

For 1 Pipe Size | ||||||||||||||

| 0.7 | 1 | 1.5 | 0.07" | 9/16" | 1 13/16" | 2 1/2" | 100 | 175° | Glass | 52° | 80° | 000000000 | 000000 | 000000 |

| 1.4 | 2 | 3.2 | 0.1" | 9/16" | 1 13/16" | 2 1/2" | 100 | 175° | Glass | 52° | 65° | 000000000 | 00000 | 00000 |

| 2.1 | 3 | 4.7 | 0.12" | 9/16" | 1 13/16" | 2 1/2" | 100 | 175° | Glass | 52° | 65° | 000000000 | 00000 | 00000 |

| 2.8 | 4 | 6.3 | 0.14" | 9/16" | 1 13/16" | 2 1/2" | 100 | 175° | Glass | 52° | 65° | 000000000 | 00000 | 00000 |

| 3.5 | 5 | 7.9 | 0.16" | 9/16" | 1 13/16" | 2 1/2" | 100 | 175° | Glass | 52° | 65° | 000000000 | 00000 | 00000 |

Clamp-On Flat Spray Nozzles with Quick-Change Tip

These nozzles have replaceable tips that are removable with a quarter-turn. All tips have two O-rings to prevent leaks. Drill a hole anywhere along a pipe and snap on these nozzles. Made of reinforced plastic, all have a 300 Series stainless steel clamp that grips the pipe and an EPDM rubber gasket that prevents leaks. They're good for foam control and produce a flat, thin spray pattern.

For technical drawings and 3-D models, click on a part number.

Nozzles | Replacement Tips | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | Each | Each | |||||||||||||||

| @ 20 psi | @ 40 psi | @ 100 psi | Orifice Dia. | For Hole Dia. | Overall Dia. | Lg. | Max. Pressure, psi | Max. Temp., °F | Reinforcement Material | Max. Swivel Angle | Spray Angle | 1-9 | 10-Up | 1-9 | 10-Up | ||

Polypropylene Plastic | |||||||||||||||||

For 1 Pipe Size | |||||||||||||||||

| 0.7 | 1 | 1.5 | 0.07" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 80° | 00000000 | 000000 | 000000 | 0000000 | 000000 | 000000 |

| 1.4 | 2 | 3.2 | 0.1" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 65° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 2.1 | 3 | 4.7 | 0.12" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 65° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 2.8 | 4 | 6.3 | 0.14" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 65° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 3.5 | 5 | 7.9 | 0.16" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 65° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

Full-Cone Spray Nozzles

A low flow rate makes these nozzles good for distributing fluids, cooling, washing, rinsing, and dust- and foam-control applications. They provide a uniform distribution of droplets.

Brass nozzles have good corrosion resistance.

303 stainless steel nozzles are more chemical, corrosion, and abrasion resistant than brass nozzles.

Spray nozzle fittings and manifolds are also available.

For technical drawings and 3-D models, click on a part number.

Male | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | Each | |||||||||||

| @ 20 psi | @ 40 psi | @ 100 psi | @ 400 psi | Orifice Dia. | Max. Pressure, psi | Max. Temp., °F | Spray Angle | Overall Wd. | Lg. | 1-9 | 10-Up | |

1 NPT | ||||||||||||

| 10.8 | 15 | 23.1 | 44.3 | 0.32" | 400 | 450° | 60° | 1 3/8" | 2 3/16" | 000000000 | 000000 | 000000 |

| 10.8 | 15 | 23.1 | 44.3 | 0.32" | 400 | 450° | 90° | 1 3/8" | 2 3/16" | 000000000 | 00000 | 00000 |

| 10.8 | 15 | 23.1 | 44.3 | 0.32" | 400 | 450° | 120° | 1 3/8" | 2 3/16" | 000000000 | 00000 | 00000 |

| 14.4 | 20 | 30.8 | 59 | 0.37" | 400 | 450° | 60° | 1 3/8" | 2 3/16" | 000000000 | 00000 | 00000 |

| 14.4 | 20 | 30.8 | 59 | 0.37" | 400 | 450° | 90° | 1 3/8" | 2 3/16" | 000000000 | 00000 | 00000 |

| 14.4 | 20 | 30.8 | 59 | 0.37" | 400 | 450° | 120° | 1 3/8" | 2 3/16" | 000000000 | 00000 | 00000 |

Male | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | Each | |||||||||||

| @ 20 psi | @ 40 psi | @ 100 psi | @ 400 psi | Orifice Dia. | Max. Pressure, psi | Max. Temp., °F | Spray Angle | Overall Wd. | Lg. | 1-9 | 10-Up | |

1 NPT | ||||||||||||

| 10.8 | 15 | 23.1 | 44.3 | 0.32" | 400 | 800° | 60° | 1 3/8" | 2 3/16" | 000000000 | 0000000 | 0000000 |

| 10.8 | 15 | 23.1 | 44.3 | 0.32" | 400 | 800° | 90° | 1 3/8" | 2 3/16" | 000000000 | 000000 | 000000 |

| 10.8 | 15 | 23.1 | 44.3 | 0.32" | 400 | 800° | 120° | 1 3/8" | 2 3/16" | 000000000 | 000000 | 000000 |

| 14.4 | 20 | 30.8 | 59 | 0.37" | 400 | 800° | 60° | 1 3/8" | 2 3/16" | 000000000 | 000000 | 000000 |

| 14.4 | 20 | 30.8 | 59 | 0.37" | 400 | 800° | 90° | 1 3/8" | 2 3/16" | 000000000 | 000000 | 000000 |

| 14.4 | 20 | 30.8 | 59 | 0.37" | 400 | 800° | 120° | 1 3/8" | 2 3/16" | 000000000 | 000000 | 000000 |

High-Volume Clog-Resistant Full-Cone Spray Nozzles

Particles in liquid won’t clog these nozzles because of their unique internal and external design. They're good for cooling, humidification, and dust- and foam-control applications. All provide a uniform distribution of droplets. However, these nozzles produce larger droplets and a less precise spray pattern than standard full-cone spray nozzles.

Brass nozzles have good corrosion resistance.

316 stainless steel nozzles are more chemical and corrosion resistant than brass nozzles.

PTFE nozzles have excellent resistance to chemicals and corrosion.

Spray nozzle fittings and manifolds are also available.

For technical drawings and 3-D models, click on a part number.

Flow Rate, gpm | Each | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 100 psi | @ 400 psi | Orifice Dia. | For Max. Particle Dia. | Overall Wd. | Max. Pressure, psi | Max. Temp., °F | Lg. | 1-9 | 10-Up | |

60° Spray Angle | ||||||||||||

1 NPT Male | ||||||||||||

| 47.4 | 67 | 106 | 212 | 0.63" | 0.25" | 1 3/8" | 400 | 450° | 3 5/8" | 00000000 | 000000 | 000000 |

| 67.2 | 95 | 150 | 300 | 0.75" | 0.25" | 1 3/8" | 400 | 450° | 3 5/8" | 00000000 | 00000 | 00000 |

90° Spray Angle | ||||||||||||

1 NPT Male | ||||||||||||

| 47.4 | 67 | 106 | 212 | 0.63" | 0.25" | 1 3/8" | 400 | 450° | 3 5/8" | 00000000 | 00000 | 00000 |

| 67.2 | 95 | 150 | 300 | 0.75" | 0.25" | 1 3/8" | 400 | 450° | 3 5/8" | 00000000 | 00000 | 00000 |

120° Spray Angle | ||||||||||||

1 NPT Male | ||||||||||||

| 47.4 | 67 | 106 | 212 | 0.63" | 0.25" | 1 3/8" | 400 | 450° | 3 5/8" | 00000000 | 00000 | 00000 |

| 67.2 | 95 | 150 | 300 | 0.75" | 0.25" | 1 3/8" | 400 | 450° | 3 5/8" | 00000000 | 00000 | 00000 |

150° Spray Angle | ||||||||||||

1 NPT Male | ||||||||||||

| 47.4 | 67 | 106 | 212 | 0.63" | 0.25" | 1 3/8" | 400 | 450° | 4 3/8" | 00000000 | 00000 | 00000 |

| 67.2 | 95 | 150 | 300 | 0.75" | 0.25" | 1 3/8" | 400 | 450° | 4 3/8" | 00000000 | 00000 | 00000 |

Flow Rate, gpm | Each | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 100 psi | @ 400 psi | Orifice Dia. | For Max. Particle Dia. | Overall Wd. | Max. Pressure, psi | Max. Temp., °F | Lg. | 1-9 | 10-Up | |

60° Spray Angle | ||||||||||||

1 NPT Male | ||||||||||||

| 47.4 | 67 | 106 | 212 | 0.63" | 0.25" | 1 3/8" | 400 | 800° | 3 5/8" | 00000000 | 0000000 | 0000000 |

| 67.2 | 95 | 150 | 300 | 0.75" | 0.25" | 1 3/8" | 400 | 800° | 3 5/8" | 00000000 | 000000 | 000000 |

90° Spray Angle | ||||||||||||

1 NPT Male | ||||||||||||

| 47.4 | 67 | 106 | 212 | 0.63" | 0.25" | 1 3/8" | 400 | 800° | 3 5/8" | 00000000 | 000000 | 000000 |

| 67.2 | 95 | 150 | 300 | 0.75" | 0.25" | 1 3/8" | 400 | 800° | 3 5/8" | 00000000 | 000000 | 000000 |

120° Spray Angle | ||||||||||||

1 NPT Male | ||||||||||||

| 47.4 | 67 | 106 | 212 | 0.63" | 0.25" | 1 3/8" | 400 | 800° | 3 5/8" | 00000000 | 000000 | 000000 |

| 67.2 | 95 | 150 | 300 | 0.75" | 0.25" | 1 3/8" | 400 | 800° | 3 5/8" | 00000000 | 000000 | 000000 |

Flow Rate, gpm | Each | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | Orifice Dia. | For Max. Particle Dia. | Overall Wd. | Max. Pressure, psi | Max. Temp., °F | Lg. | 1-9 | 10-Up | |

60° Spray Angle | ||||||||||

1 NPT Male | ||||||||||

| 47.4 | 67 | 0.63" | 0.25" | 1 3/8" | 60 | 300° | 3 5/8" | 00000000 | 0000000 | 0000000 |

| 67.2 | 95 | 0.75" | 0.25" | 1 3/8" | 60 | 300° | 3 5/8" | 00000000 | 000000 | 000000 |

90° Spray Angle | ||||||||||

1 NPT Male | ||||||||||

| 47.4 | 67 | 0.63" | 0.25" | 1 3/8" | 60 | 300° | 3 5/8" | 00000000 | 000000 | 000000 |

| 67.2 | 95 | 0.75" | 0.25" | 1 3/8" | 60 | 300° | 3 5/8" | 00000000 | 000000 | 000000 |

120° Spray Angle | ||||||||||

1 NPT Male | ||||||||||

| 47.4 | 67 | 0.63" | 0.25" | 1 3/8" | 60 | 300° | 3 5/8" | 00000000 | 000000 | 000000 |

| 67.2 | 95 | 0.75" | 0.25" | 1 3/8" | 60 | 300° | 3 5/8" | 00000000 | 000000 | 000000 |

Clamp-On Full-Cone Spray Nozzles

Drill a hole anywhere along a pipe and snap on these nozzles. Spray tips can be quickly and easily removed with a quarter-turn for cleaning and replacement. Tips have two O-rings to prevent leaks. Made of reinforced plastic, all have a Series 300 stainless steel clamp that grips the pipe and an EPDM rubber gasket that prevents leaks. They provide a uniform distribution of droplets that are good for cooling and dust- and foam-control applications.

For technical drawings and 3-D models, click on a part number.

Nozzles | Replacement Tips | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | Each | Each | |||||||||||||||

| @ 20 psi | @ 40 psi | @ 100 psi | Orifice Dia. | For Hole Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Reinforcement Material | Max. Swivel Angle | Spray Angle | 1-9 | 10-Up | 1-9 | 10-Up | ||

Polypropylene Plastic | |||||||||||||||||

For 1 Pipe Size | |||||||||||||||||

| 0.1 | 0.2 | 0.3 | 0.03" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 55° | 00000000 | 000000 | 000000 | 0000000 | 000000 | 000000 |

| 0.4 | 0.5 | 0.8 | 0.05" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 105° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 0.4 | 0.6 | 0.9 | 0.05" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 53° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 0.7 | 1 | 1.5 | 0.06" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 75° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 2.8 | 4 | 6.3 | 0.1" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 120° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

Rotating Tank-Washing Nozzles

By circulating their spray, these nozzles clean faster with more even coverage and less water than stationary tank-washing nozzles. The force of the liquid flowing through is what causes them to rotate, so the higher the pressure, the faster they will rotate. They spray in multiple directions to effectively rinse down tanks, drums, and small vessels.

316 stainless steel and PVDF nozzles have good resistance to chemicals and corrosion. PTFE nozzles have excellent resistance to chemicals and corrosion.

For technical drawings and 3-D models, click on a part number.

Flow Rate, gpm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Pattern | Spray Angle | Each | ||

1 NPT Female | |||||||||||||

| E | 35.5 | 50 | 61.1 | 11 | 0.17" | 3 7/8" | 2 15/16" | 60 | 190° | Multiple Solid Stream | 360° | 0000000 | 0000000 |

Flow Rate, gpm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Pattern | Spray Angle | Each | ||

1 NPT Female | |||||||||||||

| G | 33 | 47 | 57.5 | 10 | 0.15" | 3" | 4" | 60 | 200° | Multiple Solid Stream | 360° | 0000000 | 0000000 |

| G | 49.5 | 70 | 86 | 10 | 0.21" | 3" | 4" | 60 | 200° | Multiple Solid Stream | 360° | 0000000 | 000000 |

| G | 49.5 | 70 | 86 | 10 | 0.28" | 3" | 4" | 60 | 200° | Multiple Solid Stream | 180° | 0000000 | 000000 |

High-Impact Rotating Tank-Washing Nozzles

Internal gears create controlled motion as fluid moves through these nozzles, maintaining speed and producing large droplets to efficiently clean heavily soiled or large-diameter tanks. These nozzles rotate, so they produce more even coverage and clean faster than stationary tank nozzles while using less water. A multi-directional spray pattern makes these nozzles good for rinsing.

For technical drawings and 3-D models, click on a part number.

Flow Rate, gpm | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Angle | Each | |

316 Stainless Steel | |||||||||||

1 NPT Female | |||||||||||

| 30 | 42 | 51 | 26 | 1.73" | 2 11/16" | 5 7/16" | 215 | 200° | 360° | 0000000 | 000000000 |

Tank-Washing Nozzles

To effectively rinse tanks, drums, and small vessels, these nozzles spray in multiple directions. The simplest style of tank-cleaning nozzle, they don't have any moving parts that will wear or need maintenance.

316 stainless steel nozzles have excellent chemical and corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Flow Rate, gpm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 30 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Angle | Each | |

1 NPT Female | ||||||||||||

| 57 | 70 | 81 | 99 | 17 | 0.08" | 2 1/2" | 3 5/16" | 60 | 390° | 360° | 00000000 | 0000000 |

Clog-Resistant Tank-Washing Nozzles

Avoid clogs while rinsing tanks, drums, and small vessels. These nozzles have a unique internal and external design, so particles in liquid pass through instead of getting stuck. To effectively rinse down tanks and other containers, they spray in multiple directions. But, compared to standard tank-washing nozzles, they produce larger droplets and have a less precise spray pattern. These nozzles don't have any moving parts that will wear or need maintenance.

316 stainless steel nozzles are more chemical and corrosion resistant than brass nozzles.

For technical drawings and 3-D models, click on a part number.

Flow Rate, gpm | 360° Spray Angle | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 60 psi | @ 400 psi | For Max. Tank Dia., ft. | Orifice Dia. | For Max. Particle Dia. | Overall Wd. | Max. Pressure, psi | Max. Temp., °F | Lg. | Each | |

316 Stainless Steel | ||||||||||||

1 NPT Female | ||||||||||||

| 70.6 | 100 | Not Rated | Not Rated | 10 | 0.25" | 0.3" | 2 3/8" | 40 | 200° | 4" | 00000000 | 0000000 |

Fire-Suppressing Spray Nozzles

FM approved for use in fire-protection applications, these nozzles produce a heavy, coarse spray to quickly put out fires. They come with a protective cover to keep dust and debris from clogging the nozzle’s opening. You don’t have to remove the cover—when water starts flowing, it is blown off the nozzle.

For technical drawings and 3-D models, click on a part number.

Flow Rate, gpm | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 100 psi | @ 400 psi | Orifice Dia. | For Max. Particle Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Angle | Features | Specifications Met | Each | |

Brass | ||||||||||||||

1 NPT Male | ||||||||||||||

| 29.7 | 42 | 66.4 | 132.8 | 0.6" | 0.19" | 1 3/8" | 3 5/8" | 400 | 450° | 120° | Protective Cap | FM Approved, UL Listed | 0000000 | 0000000 |

| 47.4 | 67 | 106 | 212 | 0.77" | 1/4" | 1 3/8" | 3 5/8" | 400 | 450° | 120° | Protective Cap | FM Approved, UL Listed | 0000000 | 000000 |

Spray and Stream Nozzles for Fire-Fighting Hose

Twist the barrel to adjust water flow. Nozzles have a textured barrel for grip and a rubber bumper for impact resistance.

Polycarbonate nozzles are durable and lightweight.

Brass nozzles are more durable than aluminum nozzles.

Aluminum nozzles are lighter than brass nozzles.

Quick-Flow Stream Nozzles for Fire-Fighting Hose

There’s no shut-off valve on these nozzles, so they provide instant water flow.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Flow Rate | Dia. | Lg. | Spray End Dia. | Each | |

NPSH Female | ||||||

|---|---|---|---|---|---|---|

Brass | ||||||

| 1 | 28 gpm @ 100 psi | 1 19/64" | 8" | 5/16" | 0000000 | 000000 |

Diesel-Fuel Hose Nozzles

Control the flow while dispensing diesel fuel. Nozzles are aluminum, which is lightweight with good corrosion resistance.

Nozzles with automatic shut-off will stop dispensing when the tank is full or if the nozzle falls from the tank. They have a built-in check valve that reduces spillage when withdrawing the nozzle from tank. Nozzles have an angled design, which reduces hose kinking for efficient fueling. They come with a plastic scuff guard to protect the nozzle from damage.

Nozzles with manual shut-off have a trigger to stop the flow. Do not leave the nozzle unattended when in use.

Nozzles with three-position hold-open clip allow you to dispense fuel without holding the trigger.

Styles B and C are also known as truck-stop nozzles. They have higher flow rates than Style A to dispense large quantities of fuel quickly. Style C includes a splash guard to protect your hands from spray.

Use hold-open clip kits to replace a broken clip. Install with pliers.

For technical drawings and 3-D models, click on a part number.

Nozzles | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Spout | Scuff Guard | Threaded Swivels | Replacement Hold-Open Clip Kits | ||||||||||||||

| Style | Max. Flow Rate, gpm | Pipe Size | Connection | Max. Pressure | Temperature Range, °F | OD | Lg. | Material | Color | Shut-Off Type | Specifications Met | Each | Each | Each | |||

Nozzles | |||||||||||||||||

| B | 25 | 1 | Threaded NPT Female | 50 psi @ 72° F | -20° to 125° | 1 1/8" | 6 13/16" | Aluminum | Green | Automatic, Manual | UL Listed | 0000000 | 0000000 | 0000000 | 0000000 | 000000 | 00 |

Nozzles with Three-Position Hold-Open Clip | |||||||||||||||||

| C | 75 | 1 | Threaded NPT Female | 50 psi @ 72° F | -20° to 125° | 1 3/8" | 7" | Aluminum | Green | Automatic, Manual | UL Listed | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 |

Hydraulic Hose Nozzles

Nozzles allow you to control the flow while dispensing hydraulic fluid. They shut off manually, so you’ll have to release the trigger to stop the flow. Nozzles are aluminum, which is lightweight with good corrosion resistance.

Style B is UL listed. It has an angled design, which reduces hose kinking for efficient fueling.

Warning: Do not leave nozzles unattended when in use.

For technical drawings and 3-D models, click on a part number.

Coolant Hose Nozzles

Dispense and control the flow of coolant with these nozzles. They have a built-in check valve to reduce spillage when withdrawing the nozzle from the tank. Nozzles shut off manually, so you’ll have to release the trigger to stop the flow. They are brass for good corrosion resistance.

Warning: Do not leave nozzles unattended when in use.

For technical drawings and 3-D models, click on a part number.

Threaded Swivels for Hose Nozzles

To prevent hose from twisting, kinking, and wearing prematurely, these swivels rotate before and after installation as needed. Connect them to the threaded end of your dispensing hose.

45° offset swivels rotate at the male connection point and at the elbow. They are UL listed.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Connection | Max. Pressure | Temperature Range, °F | Lg. | Gasket Material | Specifications Met | Each | |

For Use With Gasoline and Diesel Fuel | ||||||||

|---|---|---|---|---|---|---|---|---|

Aluminum | ||||||||

| 1 × 1 | Threaded NPT Female × Threaded NPT Male | 50 psi @ 72° F | -20° to 120° | 4 3/4" | Buna-N Rubber | UL Listed | 0000000 | 0000000 |

Container | |||||

|---|---|---|---|---|---|

| Size, fl. oz. | Type | Max. Pressure for Fluids, psi | Temp. Range, °F | Each | |

For Use With Gasoline, Diesel Fuel, Hydraulic Oil, and Coolant | |||||

| 4 | Brush-Top Can | 10,000 | -100° to 600° | 00000000 | 000000 |

Barbed Swivels for Hose Nozzles

Slide the barbed end of these swivels into your dispensing hose and connect with a clamp. They rotate before and after installation as needed to prevent hose from twisting, kinking, and wearing prematurely. They are also known as inline swivels. Swivels are anodized aluminum, which is lightweight with good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Anodized Aluminum | |||||||

|---|---|---|---|---|---|---|---|

| For Hose ID | Pipe Size | Connection | Max. Pressure | Temperature Range, °F | Lg. | Each | |

For Use With Gasoline, Hydraulic Fluid, and Coolant | |||||||

| 1" | 1 | Barbed Male × Threaded NPT Male | 150 psi @ 72° F | -65° to 250° | 2 13/16" | 0000000 | 000000 |