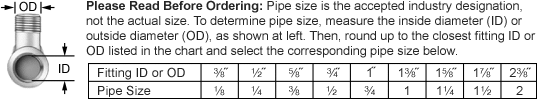

About Pipe Size and Spray Nozzles

More

About Loc-Line and Snap-Loc Coolant Hose

Assemble and disassemble Loc-Line and Snap-Loc coolant hose by snapping components together or pulling them apart. Assembly and separation tools (sold separately) are recommended.

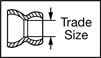

To ensure compatibility, select the color and trade size that match your current system. A system’s trade size is equal to the ID of its hose.

Food Industry Wide-Airflow Air Nozzles

These nozzles are made of FDA-listed materials. They have a flat shape that distributes air over a wider area than focused-airflow nozzles. All conform to OSHA 29 CFR 1910.95 requirements for noise.

For technical drawings and 3-D models, click on a part number.

Tip | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Air Consumption | Max. Temp., °F | Volume | Wd. | Thick. | O'all Lg. | Max. Inlet Pressure, psi | Specifications Met | Each | ||

1/4 NPT Male | ||||||||||

Polypropylene Plastic | ||||||||||

| A | 11 cfm @ 75 psi | 120° | 83 dBA @ 80 psi | 1 7/8" | 1/8" | 3 9/16" | 85 | FDA Compliant 21 CFR 177.1520, OSHA Compliant 29 CFR 1910.95 | 0000000 | 000000 |

Chemical Hose Nozzles

Adjust the flow while dispensing liquid chemicals. Nozzles are polypropylene, which is lightweight with excellent chemical resistance. They shut off manually.

Style A has a lever to turn flow on and off. It has a higher flow rate and bigger spout than Style B to dispense large quantities of liquid chemicals into drums and tanks quickly.

Style B has a trigger to turn flow on and off. It has an angled design, which reduces hose kinking for efficient fueling. Nozzle has a barbed connection; twist hose onto the barbed end and secure with a clamp. Use to transfer citric acid, nitric acid, phosphoric acid, and sodium hydroxide from pumps and processing equipment.

Warning: Do not leave nozzles unattended when in use.

For technical drawings and 3-D models, click on a part number.

Spout | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Max. Flow Rate, gpm | Pipe Size | For Hose ID | Connection | Max. Pressure | Temperature Range, °F | OD | Lg. | Material | Shut-Off Type | Each | |

For Use With Citric Acid, Ethyl Alcohol, Phosphoric Acid, and Sodium Hydroxide | ||||||||||||

| A | 180 | 1 1/2 | __ | Threaded NPT Female | 225 psi @ 72° F | -20° to 150° | 1 7/8" | 7" | Polypropylene Plastic | Manual | 00000000 | 000000 |

| A | 200 | 2 | __ | Threaded NPT Female | 200 psi @ 72° F | -20° to 150° | 2 3/8" | 7" | Polypropylene Plastic | Manual | 00000000 | 00000 |

| A | 240 | 2 | __ | Threaded NPT Female | 225 psi @ 72° F | -20° to 150° | 2 3/8" | 7" | Polypropylene Plastic | Manual | 00000000 | 00000 |

For Use With Citric Acid, Nitric Acid, Phosphoric Acid, and Sodium Hydroxide | ||||||||||||

| B | 40 | __ | 1/2" | Barbed Male | 150 psi @ 72° F | 32° to 105° | 31/32" | 4 1/2" | Polypropylene Plastic | Manual | 00000000 | 000000 |

| B | 40 | __ | 3/4" | Barbed Male | 150 psi @ 72° F | 32° to 105° | 31/32" | 4 1/2" | Polypropylene Plastic | Manual | 00000000 | 000000 |

| B | 40 | __ | 1" | Barbed Male | 150 psi @ 72° F | 32° to 105° | 31/32" | 4 1/2" | Polypropylene Plastic | Manual | 00000000 | 000000 |

Clamp-On Flat Spray Nozzles

Drill a hole anywhere along a pipe and snap on these nozzles. Spray tips can be removed for cleaning, but cannot be replaced with another tip. Made of reinforced plastic, all have a 300 Series stainless steel clamp that grips the pipe and an EPDM rubber gasket that prevents leaks. They're good for foam control and produce a flat, thin spray pattern.

For technical drawings and 3-D models, click on a part number.

Flow Rate, gpm | Each | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 100 psi | Orifice Dia. | For Hole Dia. | Overall Dia. | Lg. | Max. Pressure, psi | Max. Temp., °F | Reinforcement Material | Max. Swivel Angle | Spray Angle | 1-9 | 10-Up | |

Polypropylene Plastic | ||||||||||||||

For 1 Pipe Size | ||||||||||||||

| 0.7 | 1 | 1.5 | 0.07" | 9/16" | 1 13/16" | 2 1/2" | 100 | 175° | Glass | 52° | 80° | 000000000 | 000000 | 000000 |

| 1.4 | 2 | 3.2 | 0.1" | 9/16" | 1 13/16" | 2 1/2" | 100 | 175° | Glass | 52° | 65° | 000000000 | 00000 | 00000 |

| 2.1 | 3 | 4.7 | 0.12" | 9/16" | 1 13/16" | 2 1/2" | 100 | 175° | Glass | 52° | 65° | 000000000 | 00000 | 00000 |

| 2.8 | 4 | 6.3 | 0.14" | 9/16" | 1 13/16" | 2 1/2" | 100 | 175° | Glass | 52° | 65° | 000000000 | 00000 | 00000 |

| 3.5 | 5 | 7.9 | 0.16" | 9/16" | 1 13/16" | 2 1/2" | 100 | 175° | Glass | 52° | 65° | 000000000 | 00000 | 00000 |

For 1 1/4 Pipe Size | ||||||||||||||

| 0.7 | 1 | 1.5 | 0.07" | 9/16" | 1 13/16" | 2 1/2" | 100 | 175° | Glass | 52° | 80° | 000000000 | 00000 | 00000 |

| 1.4 | 2 | 3.2 | 0.1" | 9/16" | 1 13/16" | 2 1/2" | 100 | 175° | Glass | 52° | 65° | 000000000 | 00000 | 00000 |

| 2.1 | 3 | 4.7 | 0.12" | 9/16" | 1 13/16" | 2 1/2" | 100 | 175° | Glass | 52° | 65° | 000000000 | 00000 | 00000 |

| 2.8 | 4 | 6.3 | 0.14" | 9/16" | 1 13/16" | 2 1/2" | 100 | 175° | Glass | 52° | 65° | 000000000 | 00000 | 00000 |

| 3.5 | 5 | 7.9 | 0.16" | 9/16" | 1 13/16" | 2 1/2" | 100 | 175° | Glass | 52° | 65° | 000000000 | 00000 | 00000 |

| 4.9 | 7 | 11.1 | 0.19" | 9/16" | 1 13/16" | 2 1/2" | 100 | 175° | Glass | 52° | 65° | 000000000 | 00000 | 00000 |

For 1 1/2 Pipe Size | ||||||||||||||

| 2.1 | 3 | 4.7 | 0.12" | 9/16" | 1 13/16" | 2 1/2" | 100 | 175° | Glass | 52° | 65° | 000000000 | 00000 | 00000 |

| 2.8 | 4 | 6.3 | 0.14" | 9/16" | 1 13/16" | 2 1/2" | 100 | 175° | Glass | 52° | 65° | 000000000 | 00000 | 00000 |

| 3.5 | 5 | 7.9 | 0.16" | 9/16" | 1 13/16" | 2 1/2" | 100 | 175° | Glass | 52° | 65° | 000000000 | 00000 | 00000 |

| 4.9 | 7 | 11.1 | 0.19" | 9/16" | 1 13/16" | 2 1/2" | 100 | 175° | Glass | 52° | 65° | 000000000 | 00000 | 00000 |

For 2 Pipe Size | ||||||||||||||

| 4.9 | 7 | 11.1 | 0.19" | 9/16" | 1 13/16" | 2 1/2" | 100 | 175° | Glass | 52° | 65° | 000000000 | 00000 | 00000 |

Clamp-On Flat Spray Nozzles with Quick-Change Tip

These nozzles have replaceable tips that are removable with a quarter-turn. All tips have two O-rings to prevent leaks. Drill a hole anywhere along a pipe and snap on these nozzles. Made of reinforced plastic, all have a 300 Series stainless steel clamp that grips the pipe and an EPDM rubber gasket that prevents leaks. They're good for foam control and produce a flat, thin spray pattern.

For technical drawings and 3-D models, click on a part number.

Nozzles | Replacement Tips | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | Each | Each | |||||||||||||||

| @ 20 psi | @ 40 psi | @ 100 psi | Orifice Dia. | For Hole Dia. | Overall Dia. | Lg. | Max. Pressure, psi | Max. Temp., °F | Reinforcement Material | Max. Swivel Angle | Spray Angle | 1-9 | 10-Up | 1-9 | 10-Up | ||

Polypropylene Plastic | |||||||||||||||||

For 1 Pipe Size | |||||||||||||||||

| 0.7 | 1 | 1.5 | 0.07" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 80° | 00000000 | 000000 | 000000 | 0000000 | 000000 | 000000 |

| 1.4 | 2 | 3.2 | 0.1" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 65° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 2.1 | 3 | 4.7 | 0.12" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 65° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 2.8 | 4 | 6.3 | 0.14" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 65° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 3.5 | 5 | 7.9 | 0.16" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 65° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

For 1 1/4 Pipe Size | |||||||||||||||||

| 0.7 | 1 | 1.5 | 0.07" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 80° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 1.4 | 2 | 3.2 | 0.1" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 65° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 2.1 | 3 | 4.7 | 0.12" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 65° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 2.8 | 4 | 6.3 | 0.14" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 65° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 3.5 | 5 | 7.9 | 0.16" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 65° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 4.9 | 7 | 11.1 | 0.19" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 65° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

For 1 1/2 Pipe Size | |||||||||||||||||

| 2.1 | 3 | 4.7 | 0.12" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 65° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 2.8 | 4 | 6.3 | 0.14" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 65° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 3.5 | 5 | 7.9 | 0.16" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 65° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 4.9 | 7 | 11.1 | 0.19" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 65° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

For 2 Pipe Size | |||||||||||||||||

| 4.9 | 7 | 11.1 | 0.19" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 65° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

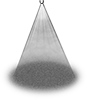

Clamp-On Full-Cone Spray Nozzles

Drill a hole anywhere along a pipe and snap on these nozzles. Spray tips can be quickly and easily removed with a quarter-turn for cleaning and replacement. Tips have two O-rings to prevent leaks. Made of reinforced plastic, all have a Series 300 stainless steel clamp that grips the pipe and an EPDM rubber gasket that prevents leaks. They provide a uniform distribution of droplets that are good for cooling and dust- and foam-control applications.

For technical drawings and 3-D models, click on a part number.

Nozzles | Replacement Tips | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | Each | Each | |||||||||||||||

| @ 20 psi | @ 40 psi | @ 100 psi | Orifice Dia. | For Hole Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Reinforcement Material | Max. Swivel Angle | Spray Angle | 1-9 | 10-Up | 1-9 | 10-Up | ||

Polypropylene Plastic | |||||||||||||||||

For 1 Pipe Size | |||||||||||||||||

| 0.1 | 0.2 | 0.3 | 0.03" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 55° | 00000000 | 000000 | 000000 | 0000000 | 000000 | 000000 |

| 0.4 | 0.5 | 0.8 | 0.05" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 105° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 0.4 | 0.6 | 0.9 | 0.05" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 53° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 0.7 | 1 | 1.5 | 0.06" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 75° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 2.8 | 4 | 6.3 | 0.1" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 120° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

For 1 1/4 Pipe Size | |||||||||||||||||

| 0.1 | 0.2 | 0.3 | 0.03" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 55° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 0.4 | 0.5 | 0.8 | 0.05" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 105° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 0.4 | 0.6 | 0.9 | 0.05" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 53° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 0.7 | 1 | 1.5 | 0.06" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 75° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 2.8 | 4 | 6.3 | 0.1" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 120° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

For 1 1/2 Pipe Size | |||||||||||||||||

| 0.7 | 1 | 1.5 | 0.06" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 75° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

| 2.8 | 4 | 6.3 | 0.1" | 9/16" | 1 13/16" | 3" | 100 | 175° | Glass | 52° | 120° | 00000000 | 00000 | 00000 | 0000000 | 00000 | 00000 |

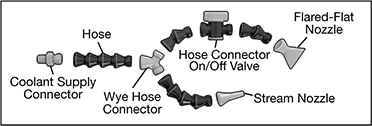

1/4" Snap-Loc Coolant Hose Kits

Kit contains lengths of hose, nozzles, connectors, and assembly pliers to build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there’s no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. Use the included assembly pliers; separation tool is sold separately. To ensure compatibility, select the color and trade size that match your current system. These components fit Snap-Loc hose with a 1/4" ID.

For technical drawings and 3-D models, click on a part number.

| No. of Pieces | Includes | Material | Max. Flow Rate, gph | For Max. SSU Viscosity Grade | Max. Pressure, psi | Max. Temp., °F | Each | |

| 27 | 2 Each 1" Flared Flat Nozzles 2 Each 1/16" Stream Nozzles 2 Each 1/4" Stream Nozzles 2 Each 1/8" Stream Nozzles 2 Each Female x Male x Male Wye Hose Connectors 3 Each 1/4 NPT Coolant Supply Connectors 3 Each 1/8 NPT Coolant Supply Connectors 8 Each 6" Long Hose Assembly Pliers Female x Female Straight Hose Connector Male x Female Straight Hose Connector | Acetal Plastic, Polypropylene Plastic | 500 | 200 | 30 | 200° | 0000000 | 000000 |

1/4" Snap-Loc Coolant Hose

Build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there’s no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. Assembly and separation tools (sold separately) are recommended. To ensure compatibility, select the color and trade size that match your current system. These components fit Snap-Loc hose with a 1/4" ID.

For technical drawings and 3-D models, click on a part number.

Orifices | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Shape | Spray Pattern | Gender | No. of | Dia. | Ht. | Wd. | O'all Lg. | Material | Max. Flow Rate, gph | For Max. SSU Viscosity Grade | Max. Pressure, psi | Max. Temp., °F | Pkg. Qty. | Pkg. | |

| 11 | Straight | Stream | Female | 1 | 1/16" | __ | __ | 1 3/16" | Polypropylene Plastic | 240 | 200 | 39 | 200° | 4 | 0000000 | 00000 |

| 11 | Straight | Stream | Female | 1 | 1/8" | __ | __ | 1 3/16" | Polypropylene Plastic | 240 | 200 | 39 | 200° | 4 | 0000000 | 0000 |

| 11 | Straight | Stream | Female | 1 | 1/4" | __ | __ | 1 3/16" | Polypropylene Plastic | 240 | 200 | 39 | 200° | 4 | 0000000 | 0000 |

| 12 | 90° Elbow | Stream | Female | 1 | 1/8" | __ | __ | 1 5/64" | Polypropylene Plastic | 240 | 200 | 39 | 200° | 2 | 0000000 | 0000 |

| 12 | 90° Elbow | Stream | Female | 1 | 1/4" | __ | __ | 1 5/64" | Polypropylene Plastic | 240 | 200 | 39 | 200° | 2 | 0000000 | 0000 |

| 13 | Straight | Flared Flat | Female | 1 | __ | 3/64" | 15/16" | 1" | Polypropylene Plastic | 240 | 200 | 39 | 200° | 2 | 0000000 | 0000 |

| 14 | 90° Elbow | Multiple Stream | Female | 6 | 1/16" | __ | __ | 1 5/16" | Polypropylene Plastic | 500 | 200 | 30 | 200° | 2 | 0000000 | 0000 |

1/2" Snap-Loc Coolant Hose

Build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there’s no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. Assembly and separation tools (sold separately) are recommended. To ensure compatibility, select the color and trade size that match your current system. These components fit Snap-Loc hose with a 1/2" ID.

For technical drawings and 3-D models, click on a part number.

Orifices | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Shape | Spray Pattern | Gender | No. of | Dia. | Ht. | Wd. | O'all Lg. | Material | Max. Flow Rate, gph | For Max. SSU Viscosity Grade | Max. Pressure, psi | Max. Temp., °F | Pkg. Qty. | Pkg. | |

| 12 | Straight | Stream | Female | 1 | 1/4" | __ | __ | 1 47/64" | Polypropylene Plastic | 480 | 200 | 19 | 200° | 4 | 0000000 | 00000 |

| 12 | Straight | Stream | Female | 1 | 3/8" | __ | __ | 1 47/64" | Polypropylene Plastic | 480 | 200 | 19 | 200° | 4 | 0000000 | 0000 |

| 12 | Straight | Stream | Female | 1 | 1/2" | __ | __ | 1 47/64" | Polypropylene Plastic | 480 | 200 | 19 | 200° | 4 | 0000000 | 0000 |

| 13 | 90° Elbow | Multiple Stream | Female | 7 | 1/8" | __ | __ | 2 3/16" | Polypropylene Plastic | 2,000 | 200 | 20 | 200° | 2 | 0000000 | 0000 |

| 14 | Straight | Flared Flat | Female | 1 | __ | 1/8" | 2 3/32" | 2" | Polypropylene Plastic | 480 | 200 | 19 | 200° | 2 | 0000000 | 00000 |

3/4" Snap-Loc Coolant Hose

Build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there’s no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. To ensure compatibility, select the color and trade size that match your current system. These components fit Snap-Loc hose with a 3/4" ID.

For technical drawings and 3-D models, click on a part number.

Orifices | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Spray Pattern | Gender | No. of | Ht. | Wd. | O'all Lg. | Material | Max. Flow Rate, gph | For Max. SSU Viscosity Grade | Max. Pressure, psi | Max. Temp., °F | Pkg. Qty. | Pkg. | |

| 7 | Flared Flat | Female | 1 | 1/8" | 2 29/32" | 3" | Polypropylene Plastic | 1,080 | 200 | 9 | 200° | 2 | 0000000 | 000000 |