How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Metal Barbed Hose Fittings for Air and Water

Slide the barbed end into rubber hose and secure with the appropriate clamp or crimp-on hose ferrule.

Brass fittings are softer than other metal fittings, so they’re easier to thread together. Plain brass fittings have good corrosion resistance. Fittings with a threaded end are also known as hose nipples.

Fittings with a 45° flared end are also known as refrigeration and SAE fittings.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: 250 psi @ 72° F

- Temperature Range: -40° to 160° F

- Attachment Type: Use Crimp-On Hose Ferrules, except For 1/2" Hose ID: Use Band-and-Buckle Clamps

- Specifications Met: SAE J476

Metal Push-On Barbed Hose Fittings for Air and Water

Fittings have sharper barbs than standard barbed hose fittings to grip rubber push-on hose with no clamps or ferrules required. The more you pull on the fittings, the tighter the hose will grip.

Brass fittings are softer than other metal fittings, so they’re easier to thread together. They have good corrosion resistance.

Fittings with a flared end meet JIC or SAE standards for dimensions. Fittings with a 45° flared end are also known as refrigeration and SAE fittings.The optional installation tool (sold separately) allows you to connect large quantities of barbed fittings to push-on hose. Use the built-in cutter to squarely cut the hose without fraying. Next, lubricate either the push-on hose, fitting or both. Then, clamp the hose into the tool’s vise and apply light pressure on the handle to drive into the fitting.

Note: To ensure proper connection, the barbed end has to be pushed in all the way, with the hose end concealed by the ring.

For technical drawings and 3-D models, click on a part number.

Mounting Hole | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Hose ID Range | Lg. | Ht. | Dp. | Dia. | No. of | Mounting Fasteners Included | Each | |

| 1/4" to 3/4" | 13 1/2" | 7" | 2 3/8" | 5/8" | 4 | No | 00000000 | 0000000 |

Screw-On Hose Fittings for D.O.T. Hose

Create or repair D.O.T. hose assemblies in the field with just a wrench and a vise, no crimper required. To install, separate the two pieces of these fittings. Screw the hose-end portion onto your hose, then thread the nipple portion into the hose-end portion. When assembled, these fittings compress against the hose to form a strong seal. Also known as reusable fittings, they can be unscrewed from your hose and used on a new one. All meet labeling and performance requirements for motor vehicle brake hose fittings.

Fittings with a flared tube connection swivel 360° until tightened for easy installation.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: See table

- Temperature Range: -40° to 300° F

- Specifications Met: D.O.T. FMVSS 106, SAE J517 100R5

- For Hose Manufacturer Series: Parker 201 SAE J517 100R5

For Hose | ||||||||

|---|---|---|---|---|---|---|---|---|

| ID | OD | For Tube OD | Thread Size | Thread Type | Dash Size | Max. Pressure | Each | |

Zinc-Plated Steel—Parker 20 Series | ||||||||

| 5/16" | 11/16" | 3/8" | 5/8"-18 | UN/UNF (SAE 45°) | 06 | 2,250 psi @ 72° F | 0000000 | 000000 |

Threaded Hose Fittings for Compressed Gas

Use these fittings to connect welding hose to pressure regulators and torches. They are also known as CGA (Compressed Gas Association) fittings. Fittings are brass for good corrosion resistance.

Fittings with left-hand threads are identified with a notch in the nut.

Note: Fittings have a CGA number that corresponds to a specific type of gas. Choose a fitting with the same CGA number as your tank and other system components.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: 200 psi @ 72° F

- Maximum Temperature: 120° F

| CGA Number | Gas Fitting Size | Thread Size | Thread Type | Thread Direction | For Use With | Each | |

Brass | |||||||

|---|---|---|---|---|---|---|---|

| 032 x 022 | B | 5/8"-18 x 9/16"-18 | UN/UNF (CGA) | Right Hand | Argon, Helium, Krypton, Neon, Nitrogen, Oxygen, Xenon | 0000000 | 000000 |

- Maximum Pressure: 200 psi @ 72° F

- Maximum Temperature: 120° F

Female Hose Connection | Female Pipe Connection | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CGA Number | Gas Fitting Size | Thread Size | Thread Type | Thread Direction | Pipe Size | Thread Type | Thread Direction | For Use With | Each | |

Brass | ||||||||||

| 032 | B | 5/8"-18 | UN/UNF (CGA) | Right Hand | 1/4 | NPT | Right Hand | Argon, Helium, Krypton, Neon, Nitrogen, Xenon | 0000000 | 000000 |

- Maximum Pressure: 200 psi @ 72° F

- Maximum Temperature: 120° F

| CGA Number | Gas Fitting Size | Thread Size | Thread Type | Thread Direction | For Use With | Each | |

Brass | |||||||

|---|---|---|---|---|---|---|---|

| 032 x 022 | B | 5/8"-18 x 9/16"-18 | UN/UNF (CGA) | Right Hand | Argon, Helium, Krypton, Neon, Nitrogen, Oxygen, Xenon | 0000000 | 000000 |

- Maximum Pressure: 200 psi @ 72° F

- Maximum Temperature: 120° F

Male Hose Connection | Male Pipe Connection | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CGA Number | Gas Fitting Size | Thread Size | Thread Type | Thread Direction | Pipe Size | Thread Type | Thread Direction | For Use With | Each | |

Brass | ||||||||||

| 032 | B | 5/8"-18 | UN/UNF (CGA) | Right Hand | 1/4 | NPT | Right Hand | Argon, Helium, Krypton, Neon, Nitrogen, Xenon | 0000000 | 000000 |

- Maximum Pressure: 200 psi @ 72° F

- Maximum Temperature: 120° F

| CGA Number | Gas Fitting Size | Thread Size | Thread Type | Thread Direction | For Use With | Each | |

Brass | |||||||

|---|---|---|---|---|---|---|---|

| 032 | B | 5/8"-18 | UN/UNF (CGA) | Right Hand | Argon, Helium, Krypton, Neon, Nitrogen, Xenon | 0000000 | 000000 |

Nuts for Barbed Hose Fittings for Compressed Gas

Also known as CGA (Compressed Gas Association) nuts, these are designed for low-pressure welding applications downstream of your tank and pressure regulator. Slide a barbed hose adapter for compressed gas into a male or female nut to make a threaded connection to torches or pressure regulators.

Nuts with left-hand threads are identified with a notch.

Brass nuts have good corrosion resistance. Note: Nuts have a CGA number that corresponds to a specific type of gas. Choose a nut with the same CGA number as your tank and other system components.

For technical drawings and 3-D models, click on a part number.

Nuts for High-Pressure Nipples for Compressed Gas

Slide a high-pressure hose nipple for compressed gas into one of these nuts to connect a pipe to the inlet of a pressure regulator. They are also known as CGA (Compressed Gas Association) nuts and inlet nuts.

Brass nuts have good corrosion resistance and are softer than 316 stainless steel nuts, so they're easier to thread together. Aluminum-plated brass nuts have better corrosion and wear resistance than unplated brass.

Note: Nuts have a CGA, BS, or DIN number that corresponds to a specific type of gas. Choose a nut with the same number as your tank and other system components.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: See table

- Maximum Temperature: 120° F, except DIN 477 No. 9: 250° F

| Number | Thread Size | Thread Type | Thread Direction | Max. Pressure | For Use With | Each | |

Aluminum-Plated Brass | |||||||

|---|---|---|---|---|---|---|---|

| CGA 180 | 5/8"-18 | UN/UNF (CGA) | Right Hand | 3,000 psi @ 72° F | Air, Argon, Butane, Carbon Dioxide, Helium, Krypton, Methane, Natural Gas, Neon, Nitrogen, Oxygen, Propane, Propylene | 000000000 | 000000 |

Welding Gas Hose with Fittings

- Material:

Grade R Hose: EPDM Rubber

Grade T Hose: Blended Rubber - Color: Green, Red, or Green/Red

- Temperature Range:

Male Fittings: -40° to 120° F

Female Fittings: -40° to 180° F

Hose is abrasion, weather, and ozone resistant.

Hose for use with argon and carbon dioxide conveys these gases for shielding while TIG and MIG welding.

Green hose has right-hand threads on the fittings.

For technical drawings and 3-D models, click on a part number.

Air Conditioning Hose

- Temperature Range: -20° to 180° F

- Material: Kevlar with Buna-N Rubber Cover

- Color: Black, Blue, Red, or Yellow

Use hose to charge and test your air conditioning units.

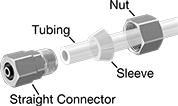

Tight-Seal Brass Compression Tube Fittings for Air and Water

- Temperature Range: -65° to 250° F

- Tubing: Use with firm (Durometer 95A) EVA plastic or polyurethane rubber

- Specifications Met: SAE J512

A built-in tube support slips inside the tubing to prevent collapsing and provides a sturdy connection for an extra-tight seal. Fittings have a single sleeve (ferrule) that compresses the tubing as you tighten the nut. The nut and sleeve are included. Fittings are also known as flareless fittings. They are brass for good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Fittings with 45° female flared tube end have an internal flare that mates with a male 45° flared fitting.

| For Tube OD | Material | Max. Pressure | Each | |

UN/UNF (SAE 45°) Threads | ||||

|---|---|---|---|---|

| 3/8" | Brass | 90 psi @ 72° F | 00000000 | 00000 |

| For Tube OD | Nut Material | Max. Pressure | Pkg. Qty. | Pkg. | |

| 3/8" | Brass | 90 psi @ 72° F | 25 | 00000000 | 000000 |

Sleeve | ||||||

|---|---|---|---|---|---|---|

| For Tube OD | Material | Color | Max. Pressure | Pkg. Qty. | Pkg. | |

| 3/8" | Acetal Plastic | White | 90 psi @ 72° F | 25 | 00000000 | 00000 |

Push-to-Connect Tube Fittings for Drinking Water

- Temperature Range: 35° to 150° F

- Tubing: See table

- Specifications Met: NSF/ANSI 61

Made of moisture-resistant acetal, these fittings won't absorb water and lose strength, even in high-humidity environments. Also known as instant fittings, they connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect, push on the release ring and pull the tubing out of the fitting. All meet NSF/ANSI 61 for use in drinking water systems.

For technical drawings and 3-D models, click on a part number.

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD | Material | Color | Release Ring Color | Max. Pressure | Material | Hardness Rating | Each | |

| 3/8" | Acetal Plastic | Gray | Gray | 150 psi @ 72° F | Nylon Plastic, Polyethylene Plastic | Firm, Hard | 000000000 | 00000 |

Fittings with female 45° flared end are also known as faucet connectors; they attach directly to a faucet threaded inlet or water line.

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD | Material | Color | Release Ring Color | Max. Pressure | Material | Hardness Rating | Each | |

| 3/8" | Acetal Plastic | Gray | Gray | 150 psi @ 72° F | Nylon Plastic, Polyethylene Plastic | Firm, Hard | 000000000 | 00000 |

Tube supports are recommended if you want to use fittings with soft nylon, polyethylene, and PVC tubing to prevent the tube from collapsing.

For Tube | Tube Support | |||||||

|---|---|---|---|---|---|---|---|---|

| OD | ID | Material | Color | Max. Pressure | Pkg. Qty. | Environment | Pkg. | |

| 3/8" | 5/16" | Acetal Plastic | Gray | 150 psi @ 72° F | 10 | Food Industry | 000000000 | 00000 |

Locking clips secure the release ring to prevent the fitting from accidentally disconnecting.

| For Tube OD | Material | Color | Pkg. Qty. | Pkg. | |

| 3/8" | Acetal Plastic | Red | 10 | 000000000 | 00000 |

Stainless Steel Barbed Tube Fittings for Food and Beverage

- Temperature Range: -20° to 750° F

- Tubing: Use with soft or firm (Durometer 65A-90A) polyurethane rubber or PVC plastic

- Specifications Met: See table

Made of stainless steel, these fittings are more durable than plastic barbed tube fittings for food and beverage. They have single or multiple barbs that grip onto tubing.

Fittings with female 45° flared end connect to the male flared end of another fitting.

For technical drawings and 3-D models, click on a part number.

45° Flared Fittings for Copper and Brass Tubing

- Temperature Range: -65° to 250° F

- Tubing: Use with seamless brass and copper that meets ASTM B280

No sleeve is required to assemble these fittings, which makes for a faster, more convenient installation compared to 37° flared fittings. They require a nut (sold separately) for each tube end. Fittings are also known as refrigeration and SAE fittings. They are brass for good corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads.

UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water; except adapters for 1/8" and 1" tube OD are not for use with fuel oil

- Specifications Met: See table

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Specifications Met | Each | |

NPTF Threads | |||||||

| 3/8" | 0.032" | 1/8 | Brass | 1,000 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 00000 |

| 3/8" | 0.032" | 1/4 | Brass | 1,000 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 0000 |

| 3/8" | 0.032" | 3/8 | Brass | 1,000 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 0000 |

| 3/8" | 0.032" | 1/2 | Brass | 1,000 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 0000 |

| 3/8" | 0.032" | 3/4 | Brass | 1,000 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 00000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water; except adapters for 5/8" and 3/4" tube OD are not for use with fuel oil

- Specifications Met: See table

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Specifications Met | Each | |

NPTF Threads | |||||||

| 3/8" | 0.032" | 1/8 | Brass | 1,000 psi @ 72° F | SAE J512, SAE J513, UL Listed | 00000000 | 000000 |

| 3/8" | 0.032" | 1/4 | Brass | 1,000 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 0000 |

| 3/8" | 0.032" | 3/8 | Brass | 1,000 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 0000 |

| 3/8" | 0.032" | 1/2 | Brass | 1,000 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 00000 |

| 3/8" | 0.032" | 3/4 | Brass | 1,000 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 00000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: See table

For Tube | Socket Connection | |||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Copper Tube Size | For Tube OD | Material | Max. Pressure | Specifications Met | Each | |

| 3/8" | 0.032" | __ | 1/4" | Brass | 1,000 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 000000 |

| 3/8" | 0.032" | __ | 5/16" | Brass | 1,000 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 00000 |

| 3/8" | 0.032" | 1/4 | 3/8" | Brass | 1,000 psi @ 72° F | SAE J512, SAE J513 | 000000000 | 0000 |

| 3/8" | 0.032" | 3/8 | 1/2" | Brass | 1,000 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 00000 |

| 3/8" | 0.032" | 1/2 | 5/8" | Brass | 1,000 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 00000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Each | |

| 3/8" | 0.032" | Brass | 1,000 psi @ 72° F | 000000000 | 00000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

- For Use With:

Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water - Specifications Met: SAE J512, SAE J513, UL Listed

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Each | |

NPTF Threads | ||||||

| 3/8" | 0.032" | 1/8 | Brass | 1,000 psi @ 72° F | 000000000 | 000000 |

| 3/8" | 0.032" | 1/4 | Brass | 1,000 psi @ 72° F | 000000000 | 0000 |

| 3/8" | 0.032" | 3/8 | Brass | 1,000 psi @ 72° F | 000000000 | 00000 |

| 3/8" | 0.032" | 1/2 | Brass | 1,000 psi @ 72° F | 000000000 | 00000 |

| 3/8" | 0.032" | 3/4 | Brass | 1,000 psi @ 72° F | 000000000 | 00000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

Fittings that swivel until tightened rotate 360° for easy installation.

| For Tube OD | Thread Size | Material | Gasket Material | Max. Pressure | Each | |

UN/UNF (SAE Straight) Threads | ||||||

|---|---|---|---|---|---|---|

| 3/8" | 5/8"-18 | Brass | Fluoroelastomer Rubber | 1,000 psi @ 72° F | 000000000 | 000000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Each | |

| 3/8" | 0.032" | Brass | 1,000 psi @ 72° F | 000000000 | 000000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

Inline tees are also known as branch tees.

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

Inline tees are also known as branch tees.

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

Right-angle tees are also known as run tees.

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Each | |

| 3/8" | 0.032" | Brass | 1,000 psi @ 72° F | 000000000 | 000000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water;

except caps for 1/8" tube OD are only for use with refrigerant - Specifications Met: See table

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Specifications Met | Each | |

| 3/8" | 0.032" | Brass | 1,000 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 00000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Each | |

| 3/8" | 0.032" | Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water; except nuts for 1" tube OD are not for use with fuel oil

- Specifications Met: SAE J512, SAE J513, UL Listed; except nuts for 1" tube OD meet SAE J512 and SAE J513 only

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Lg. | Each | ||

Short Nuts | |||||||

| A | 1/4" | 0.049" | Brass | 1,400 psi @ 72° F | 3/4" | 000000000 | 00000 |

| A | 5/16" | 0.049" | Brass | 1,200 psi @ 72° F | 7/8" | 000000000 | 0000 |

| A | 3/8" | 0.032" | Brass | 1,000 psi @ 72° F | 29/32" | 000000000 | 0000 |

| A | 3/8" | 0.065" | Brass | 1,000 psi @ 72° F | 1" | 000000000 | 0000 |

| A | 1/2" | 0.032" | Brass | 750 psi @ 72° F | 1" | 000000000 | 0000 |

| A | 1/2" | 0.083" | Brass | 750 psi @ 72° F | 1 1/8" | 000000000 | 0000 |

| A | 5/8" | 0.035" | Brass | 650 psi @ 72° F | 1 1/16" | 000000000 | 00000 |

| A | 5/8" | 0.095" | Brass | 650 psi @ 72° F | 1 5/16" | 000000000 | 00000 |

| B | 1/4" | 0.03" | Brass | 1,400 psi @ 72° F | 5/8" | 00000000 | 0000 |

| B | 1/2" | 0.032" | Brass | 750 psi @ 72° F | 27/32" | 000000000 | 0000 |

| B | 5/8" | 0.035" | Brass | 650 psi @ 72° F | 31/32" | 000000000 | 00000 |

Long Nuts | |||||||

| A | 1/4" | 0.049" | Brass | 1,400 psi @ 72° F | 15/16" | 000000000 | 0000 |

| A | 5/16" | 0.049" | Brass | 1,200 psi @ 72° F | 1 1/8" | 000000000 | 0000 |

| A | 3/8" | 0.065" | Brass | 1,000 psi @ 72° F | 1 5/16" | 000000000 | 0000 |

| A | 1/2" | 0.083" | Brass | 750 psi @ 72° F | 1 5/8" | 000000000 | 00000 |

| A | 5/8" | 0.095" | Brass | 650 psi @ 72° F | 1 7/8" | 000000000 | 00000 |

Supported 45° Flared Fittings for Copper and Brass Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Temperature Range: -65° to 250° F

- Tubing: Use with seamless brass and copper

- Specifications Met:

Metric: SAE J512, SAE J513, UL Listed

All other fittings: SAE J512, UL Listed; except tee connectors for 1/2" tube OD

The flared end nests inside the fitting body, providing extra support to the tubing. Fittings are also known as inverted 45° flared fittings, refrigeration fittings, and SAE fittings. To assemble, place the nut (sold separately) on the tubing, flare the end of the tubing, then insert the tubing into the fitting and tighten the nut. Fittings are brass for good corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads.

For technical drawings and 3-D models, click on a part number.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Each | |

NPTF Threads | ||||||

| 3/8" | 0.032" | 1/4 | 360 Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Each | |

| 3/8" | 0.032" | 360 Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Each | |

| 3/8" | 0.032" | 360 Brass | 1,000 psi @ 72° F | 00000000 | 000000 |

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Each | |

| 3/8" | 0.032" | 360 Brass | 1,000 psi @ 72° F | 00000000 | 00000 |