Filter by

Holding Capacity

Draw Arm Travel

Thread Size

Reach Length

Mounting Location

Draw Arm Adjustability

Projection

DFARS Specialty Metals

Export Control Classification Number (ECCN)

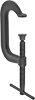

Fabricating and Machining

Containers, Storage, and Furniture

Material Handling