About Rod Ends

More

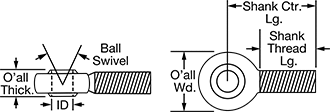

Corrosion-Resistant Ball Joint Rod Ends

Made of stainless steel, these rod ends provide excellent corrosion resistance. A PTFE liner allows smooth ball rotation and eliminates the need for lubrication.

For technical drawings and 3-D models, click on a part number.

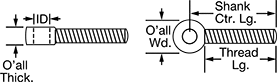

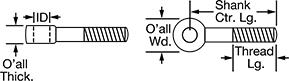

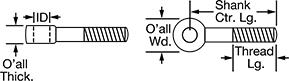

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Static Radial Load Cap., lbs. | Material | Shank Thread Direction | Each | |

| M4 × 0.7 mm | 4mm | 33.5° | 14mm | 6.9mm | 30mm | 19mm | Not Rated | 303 Stainless Steel | Right Hand | 00000000 | 000000 |

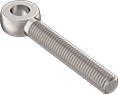

Corrosion-Resistant Fully Threaded Rod End Bolts

These rod end bolts are good for wet and corrosive environments—for maximum mounting flexibility, cut the fully threaded shaft to whatever length you need. Also known as swing bolts and eyebolts, rod end bolts have no moving parts. They're designed to make pivoting or hinge movements in applications that don't need to compensate for misalignment.

303 and 304 stainless steel rod end bolts won't rust in humid, wet, and washdown environments. They're stronger than brass bolts and nearly as strong as steel. They will rust when exposed to salt water and chemicals, however. 316 stainless steel rod end bolts are our most corrosion resistant, and they're nearly as strong as steel rod end bolts. Use them in areas with salt water, chlorine, and chemicals without worrying about rust.

ASTM rod end bolts meet a standard for material.

DIN 444 rod end bolts meet an international standard for rod end dimensions.

For technical drawings and 3-D models, click on a part number.

| Shank Thread Size | ID | O'all Wd. | Shank Center Lg. | Shank Thread Lg. | O'all Thick. | Tensile Strength, psi | Specifications Met | Each | |

Right-Hand Threaded Shank | |||||||||

|---|---|---|---|---|---|---|---|---|---|

303 Stainless Steel | |||||||||

| M6 × 1 mm | 6mm | 14mm | 70mm | 56mm | 7mm | Not Rated | DIN 444 | 00000000 | 000000 |

304 Stainless Steel | |||||||||

| M6 × 1 mm | 6mm | 14mm | 30mm | 21mm | 7mm | 70,000 | DIN 444 | 00000000 | 00000 |

| M6 × 1 mm | 6mm | 14mm | 40mm | 31mm | 7mm | 70,000 | DIN 444 | 00000000 | 00000 |

| M6 × 1 mm | 6mm | 14mm | 50mm | 41mm | 7mm | 70,000 | DIN 444 | 00000000 | 00000 |

316 Stainless Steel | |||||||||

| M6 × 1 mm | 6mm | 14mm | 45mm | 36mm | 7mm | 75,000 | DIN 444 | 00000000 | 00000 |

| M6 × 1 mm | 6mm | 14mm | 50mm | 41mm | 7mm | 75,000 | DIN 444 | 00000000 | 00000 |

| M6 × 1 mm | 6mm | 14mm | 60mm | 51mm | 7mm | 75,000 | DIN 444 | 00000000 | 00000 |

| M6 × 1 mm | 6mm | 14mm | 70mm | 56mm | 7mm | 75,000 | ASTM A276, DIN 444 | 00000000 | 00000 |

Left-Hand Threaded Shank | |||||||||

303 Stainless Steel | |||||||||

| M6 × 1 mm | 6mm | 14mm | 30mm | 18mm | 7mm | 90,000 | ASTM A582, DIN 444 | 00000000 | 00000 |

| M6 × 1 mm | 6mm | 14mm | 35mm | 22mm | 7mm | 90,000 | ASTM A582, DIN 444 | 00000000 | 00000 |

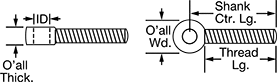

Fully Threaded Rod End Bolts

For maximum mounting flexibility, cut the fully threaded shaft to whatever length you need. Also known as swing bolts and eyebolts, rod end bolts have no moving parts. They're designed to make pivoting or hinge movements in applications that don't need to compensate for misalignment.

For technical drawings and 3-D models, click on a part number.

| Shank Thread Size | ID | O'all Wd. | Shank Center Lg. | Shank Thread Lg. | O'all Thick. | Tensile Strength, psi | Specifications Met | Material | Each | |

Right-Hand Threaded Shank | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| M6 × 1 mm | 6mm | 14mm | 30mm | 18mm | 7mm | 78,000 | DIN 444 | Black-Oxide Carbon Steel | 00000000 | 000000 |

| M6 × 1 mm | 6mm | 14mm | 40mm | 26mm | 7mm | 78,000 | DIN 444 | Black-Oxide Carbon Steel | 00000000 | 00000 |

| M6 × 1 mm | 6mm | 14mm | 50mm | 36mm | 7mm | Not Rated | DIN 444 | Black-Oxide Carbon Steel | 0000000 | 0000 |

| M6 × 1 mm | 6mm | 14mm | 60mm | 46mm | 7mm | Not Rated | DIN 444 | Black-Oxide Carbon Steel | 0000000 | 0000 |

| M6 × 1 mm | 6mm | 14mm | 80mm | 66mm | 7mm | Not Rated | DIN 444 | Black-Oxide Carbon Steel | 0000000 | 0000 |

High-Strength Fully Threaded Rod End Bolts

These alloy steel rod end bolts have the highest tensile strength of any steel fully threaded rod end bolt we offer. For maximum mounting flexibility, cut the fully threaded shaft to whatever length you need. Also known as swing bolts and eyebolts, rod end bolts have no moving parts. They're designed to make pivoting or hinge movements in applications that don't need to compensate for misalignment.

For technical drawings and 3-D models, click on a part number.

| Shank Thread Size | ID | O'all Wd. | Shank Center Lg. | Shank Thread Lg. | O'all Thick. | Tensile Strength, psi | Fastener Strength Grade/Class | Specifications Met | Material | Each | |

Right-Hand Threaded Shank | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| M6 × 1 mm | 6mm | 14mm | 30mm | 16mm | 9mm | 125,000 | ASTM Grade B7 | ASTM A193 | Black-Oxide Alloy Steel | 0000000 | 000000 |

| M6 × 1 mm | 6mm | 14mm | 40mm | 26mm | 9mm | 125,000 | ASTM Grade B7 | ASTM A193 | Black-Oxide Alloy Steel | 0000000 | 00000 |

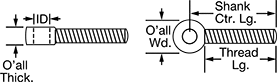

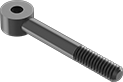

Partially Threaded Rod End Bolts

Create pivoting connections in applications that require high shear strength—the partially threaded shank of these rod end bolts withstands more side force than a fully threaded shank. Also known as swing bolts and eyebolts, they are used to create hinges, turnbuckles, and tie downs. Unlike ball joint rod ends, these rod end bolts are made from a single piece of metal, so they wear down more slowly and have a more controlled swing. However, because they do not have a moving ball joint, they do not compensate for angular misalignment.

Made from steel, they are stronger and more wear resistant than stainless steel rod end bolts, but they are not as corrosion resistant. Rod end bolts with a black-oxide finish have a dark, matte coating that keeps the steel from rusting in dry environments.

Rod end bolts that meet DIN 444 adhere to international dimensional standards, ensuring they are compatible with other parts and tools.

For technical drawings and 3-D models, click on a part number.

| Shank Thread Size | ID | O'all Wd. | Shank Center Lg. | Shank Thread Lg. | O'all Thick. | Tensile Strength, psi | Specifications Met | Material | Pkg. Qty. | Pkg. | |

Right-Hand Threaded Shank | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| M6 × 1 mm | 6mm | 14mm | 25mm | 11mm | 7mm | 55,000 | DIN 444 | Carbon Steel | 5 | 00000000 | 00000 |

| M6 × 1 mm | 6mm | 14mm | 30mm | 18mm | 7mm | 55,000 | DIN 444 | Carbon Steel | 5 | 00000000 | 00000 |

| M6 × 1 mm | 6mm | 14mm | 35mm | 18mm | 7mm | 55,000 | DIN 444 | Carbon Steel | 5 | 00000000 | 0000 |

| M6 × 1 mm | 6mm | 14mm | 40mm | 18mm | 7mm | 55,000 | DIN 444 | Carbon Steel | 5 | 00000000 | 0000 |

| M6 × 1 mm | 6mm | 14mm | 45mm | 18mm | 7mm | 55,000 | DIN 444 | Carbon Steel | 5 | 00000000 | 00000 |

| M6 × 1 mm | 6mm | 14mm | 50mm | 18mm | 7mm | 55,000 | DIN 444 | Carbon Steel | 5 | 00000000 | 00000 |

| Each | |||||||||||

| M6 × 1 mm | 6mm | 14mm | 50mm | 18mm | 7mm | 75,000 | DIN 444 | Black-Oxide Carbon Steel | __ | 00000000 | 00000 |

| M6 × 1 mm | 6mm | 14mm | 50mm | 32mm | 7mm | 75,000 | DIN 444 | Black-Oxide Carbon Steel | __ | 0000000 | 00000 |

| Pkg. | |||||||||||

| M6 × 1 mm | 6mm | 14mm | 60mm | 18mm | 7mm | 55,000 | DIN 444 | Carbon Steel | 5 | 00000000 | 00000 |

| M6 × 1 mm | 6mm | 14mm | 70mm | 18mm | 7mm | 55,000 | DIN 444 | Carbon Steel | 5 | 00000000 | 00000 |

| Each | |||||||||||

| M6 × 1 mm | 6mm | 14mm | 75mm | 18mm | 7mm | 75,000 | DIN 444 | Black-Oxide Carbon Steel | __ | 00000000 | 00000 |

| Pkg. | |||||||||||

| M6 × 1 mm | 6mm | 14mm | 80mm | 18mm | 7mm | 55,000 | DIN 444 | Carbon Steel | 5 | 00000000 | 00000 |

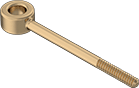

Corrosion-Resistant Partially Threaded Rod End Bolts

Pivot and hinge components in wet and corrosive environments with these stainless steel or brass rod end bolts. They're commonly known as swing bolts and eyebolts. With no moving parts, they're less likely to wear out than ball joint rod ends, although they don't compensate for misalignment as effectively. Use them to guide and connect components, such as tubing, or as a turnbuckle to tension wire and cable. They can also be used as tie downs and hinges.

With external threads, these bolts hold fast to female threaded components in applications where high shear strength is required, such as water pumps, alternators, and motor mounts. Because the shank is only partially threaded, they handle a greater amount of force from the side than bolts with a fully threaded shank.

Brass rod end bolts resist corrosion in humid and wet environments, but not as well as stainless steel bolts. They're also not as strong. Often, brass bolts are chosen for their look, or to match other components, such as hinges.

303 and 304 stainless steel rod end bolts won't rust in humid, wet, and washdown environments. They're stronger than brass bolts and nearly as strong as steel. They will rust when exposed to salt water and chemicals, however. DIN 444 rod end bolts meet an international standard for rod end dimensions.

For technical drawings and 3-D models, click on a part number.

| Shank Thread Size | ID | O'all Wd. | Shank Center Lg. | Shank Thread Lg. | O'all Thick. | Tensile Strength, psi | Specifications Met | Each | |

Right-Hand Threaded Shank | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Brass | |||||||||

| M6 × 1 mm | 6mm | 14mm | 40mm | 18mm | 7mm | 50,000 | DIN 444 | 00000000 | 00000 |

| M6 × 1 mm | 6mm | 14mm | 50mm | 18mm | 7mm | 50,000 | DIN 444 | 00000000 | 0000 |

| M6 × 1 mm | 6mm | 14mm | 60mm | 18mm | 7mm | 50,000 | DIN 444 | 00000000 | 0000 |

303 Stainless Steel | |||||||||

| M6 × 1 mm | 6mm | 14mm | 50mm | 32mm | 7mm | 85,000 | DIN 444 | 0000000 | 00000 |

304 Stainless Steel | |||||||||

| M6 × 1 mm | 6mm | 14mm | 30mm | 18mm | 7mm | 85,000 | DIN 444 | 00000000 | 0000 |

| M6 × 1 mm | 6mm | 14mm | 35mm | 18mm | 7mm | 85,000 | DIN 444 | 00000000 | 0000 |

| M6 × 1 mm | 6mm | 14mm | 40mm | 18mm | 7mm | 85,000 | DIN 444 | 00000000 | 0000 |

| M6 × 1 mm | 6mm | 14mm | 45mm | 18mm | 7mm | 85,000 | DIN 444 | 00000000 | 0000 |

| M6 × 1 mm | 6mm | 14mm | 50mm | 18mm | 7mm | 85,000 | DIN 444 | 00000000 | 0000 |

| M6 × 1 mm | 6mm | 14mm | 60mm | 18mm | 7mm | 85,000 | DIN 444 | 00000000 | 0000 |