About Hinges

More

About Rod Ends

More

Narrow-Profile Lift-Off Hinges without Holes

Range of

Motion

Hinge with 360°

Range of Motion

Also known as bullet hinges, these hinges are the right size for tight spaces and narrow frames. The hinge pin is permanently attached to the frame leaf so you can quickly lift the door off the hinge without removing the pin. Hinges with a 360° range of motion have a small triangular surface to weld to the door frame. Hinges with a 270° range of motion have a body that welds directly to the door frame.

Aluminum hinges are about half the weight of low-carbon steel. They have mild corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Hinges | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Door Leaf | Frame Leaf | Replacement Bushings | ||||||||||

| Ht. | Wd. | Ht. | Wd. | O'all Wd. | Range of Motion | Pin Dia. | Material | Pin Material | Each | Each | ||

Aluminum—Dull | ||||||||||||

| 2 31/32" | 13/16" | 2 31/32" | 13/16" | 13/16" | 360° | 1/2" | 5052 Aluminum | Stainless Steel | 000000 | 000000 | 00000000 | 00000 |

| 3 9/16" | 13/16" | 3 9/16" | 13/16" | 13/16" | 360° | 1/2" | 5052 Aluminum | Stainless Steel | 000000 | 00000 | 00000000 | 0000 |

Easy-Lube Narrow-Profile Lift-Off Hinges without Holes

Hinge with 360°

Range of Motion

A grease fitting makes these hinges easy to lubricate. Also known as bullet hinges, these hinges are the right size for tight spaces and narrow frames. The hinge pin is permanently attached to the frame leaf so you can quickly lift the door off the hinge without removing the pin. All of the hinges have a small triangular surface to weld to the door frame.

Aluminum hinges are about half the weight of low-carbon steel. They have mild corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Narrow-Profile Lift-Off Hinges with Holes

These hinges are the right size for tight spaces and narrow frames. The hinge pin is permanently attached to the frame leaf so you can quickly lift the door off the hinge without removing the pin. Mounting screws (not included) are concealed when the hinge is closed.

Hinges for inset doors are for doors that are flush with their frame when the door is closed. Capacity is per hinge. To choose a door mounting location, stand on the pull side of the door—use a right-side hinge if the hinge is on the right or a left-side hinge if it’s on the left.

For technical drawings and 3-D models, click on a part number.

Door Leaf | Frame Leaf | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Ht. | Wd. | O'all Wd. | Leaf Thick. | Range of Motion | Capacity, lbs. | Pin Dia. | Mounting Fasteners Included | No. of Mounting Holes | Mounting Screw Size | Each | ||

Left Side Door Mounting Location | ||||||||||||||

For Inset Door—Standard | ||||||||||||||

Black Painted Zinc | ||||||||||||||

| 4 | 1" | 13/16" | 5/8" | 3/8" | 13/16" | 0.375" | 180° | 250 | 3/16" | No | 4 | No. 6 | 00000000 | 000000 |

Right Side Door Mounting Location | ||||||||||||||

For Inset Door—Standard | ||||||||||||||

Black Painted Zinc | ||||||||||||||

| 4 | 1" | 13/16" | 5/8" | 3/8" | 13/16" | 0.375" | 180° | 250 | 3/16" | No | 4 | No. 6 | 00000000 | 00000 |

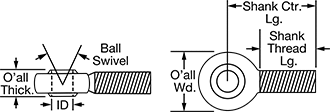

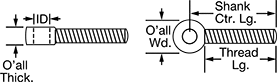

Mil. Spec. Ball Joint Rod Ends

Made of cadmium-plated steel, these rod ends generally handle higher loads than stainless steel, aluminum, and nylon rod ends. They provide moderate corrosion resistance. All have a PTFE liner that allows smooth ball rotation and eliminates the need for lubrication. Liner meets SAE AS81820.

Rod ends with an oversized shank have a shank that is one size larger than the ID to handle greater stress.

For technical drawings and 3-D models, click on a part number.

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Static Radial Load Cap., lbs. | Specifications Met | Material | Choose a Shank Thread Direction | Each | |

Ball Joints with Oversized Shank | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5/16"-24 | 3/16" | 15° | 13/16" | 7/16" | 1 9/16" | 15/16" | 2,350 | MIL-B-81935 SAE AS81820 SAE AS81935 | Cadmium-Plated Alloy Steel | Right Hand | 00000000 | 0000000 |

| 5/16"-24 | 1/4" | 15° | 13/16" | 7/16" | 1 9/16" | 15/16" | 4,850 | MIL-B-81935 SAE AS81820 SAE AS81935 | Cadmium-Plated Alloy Steel | 0000000 | 000000 | |

Internally Threaded Mil. Spec. Ball Joint Rod Ends

Made of cadmium-plated steel, these rod ends generally handle higher loads than stainless steel, aluminum, and nylon rod ends. They provide moderate corrosion resistance. All have a PTFE liner that allows smooth ball rotation and eliminates the need for lubrication. Liner meets SAE AS81820.

Rod ends with an oversized shank have a shank that is one size larger than the ID to handle greater stress.

For technical drawings and 3-D models, click on a part number.

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Static Radial Load Cap., lbs. | Specifications Met | Material | Shank Thread Direction | Each | |

Ball Joints with Oversized Shank | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5/16"-24 | 1/4" | 15° | 13/16" | 7/16" | 1 7/16" | 3/4" | 4,850 | MIL-B-81935 SAE AS81820 SAE AS81935 | Cadmium-Plated Alloy Steel | Right Hand | 00000000 | 0000000 |

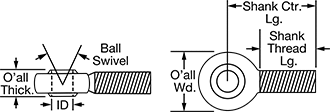

Internally Threaded Thrust-Rated Ball Joint Rod Ends

An innovative body design keeps the ball from being pushed out when supporting thrust loads. Rod ends are zinc-plated steel for moderate corrosion resistance and have a self-lubricating polyurethane insert.

For technical drawings and 3-D models, click on a part number.

Static Load Cap., lbs. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Radial | Thrust | Temp. Range, °F | Material | Shank Thread Direction | Each | |

| 1/4"-28 | 1/4" | 36° | 13/16" | 3/8" | 1 3/16" | 9/16" | 1,100 | 330 | -40° to 175° | Zinc-Plated Carbon Steel | Right Hand | 00000000 | 000000 |

Thrust-Rated Ball Joint Rod Ends

An innovative body design keeps the ball from being pushed out when supporting thrust loads. Rod ends are zinc-plated steel for moderate corrosion resistance and have a self-lubricating polyurethane insert.

For technical drawings and 3-D models, click on a part number.

Static Load Cap., lbs. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Radial | Thrust | Temp. Range, °F | Material | Shank Thread Direction | Each | |

| 1/4"-28 | 1/4" | 36° | 13/16" | 3/8" | 1 7/16" | 15/16" | 1,100 | 330 | -40° to 175° | Zinc-Plated Carbon Steel | Right Hand | 00000000 | 000000 |

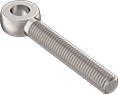

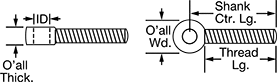

Corrosion-Resistant Fully Threaded Rod End Bolts

These rod end bolts are good for wet and corrosive environments—for maximum mounting flexibility, cut the fully threaded shaft to whatever length you need. Also known as swing bolts and eyebolts, rod end bolts have no moving parts. They're designed to make pivoting or hinge movements in applications that don't need to compensate for misalignment.

Brass rod end bolts resist corrosion in humid and wet environments, but not as well as stainless steel bolts. They're also not as strong. Often, brass bolts are chosen for their look, or to match other components, such as hinges.

303 and 304 stainless steel rod end bolts won't rust in humid, wet, and washdown environments. They're stronger than brass bolts and nearly as strong as steel. They will rust when exposed to salt water and chemicals, however. Black-oxide 303 stainless steel rod end bolts have a matte-black finish that adds some corrosion resistance but is mostly chosen for its looks.

17-4 PH stainless steel rod end bolts have the most tensile strength—a similar amount to high-strength alloy steel. They also won’t rust in humid, wet, and washdown environments. Even at high temperatures, they maintain their excellent strength and corrosion resistance, so they’re often used in automotive drive trains and heat exchangers. However, they’ll rust when exposed to salt water and chemicals.

316 stainless steel rod end bolts are our most corrosion resistant, and they're nearly as strong as steel rod end bolts. Use them in areas with salt water, chlorine, and chemicals without worrying about rust.

ASTM rod end bolts meet a standard for material.

For technical drawings and 3-D models, click on a part number.

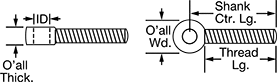

| Shank Thread Size | ID | O'all Wd. | Shank Center Lg. | Shank Thread Lg. | O'all Thick. | Tensile Strength, psi | Specifications Met | Fastener Strength Grade/Class | Each | |

Right-Hand Threaded Shank | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Brass | ||||||||||

| 3/8"-16 | 5/16" | 13/16" | 3" | 2 1/2" | 3/8" | 55,000 | ASTM B16 | __ | 00000000 | 000000 |

| 3/8"-16 | 3/8" | 13/16" | 2" | 1 1/2" | 3/8" | 55,000 | ASTM B16 | __ | 00000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 3 1/2" | 3" | 3/8" | 55,000 | ASTM B16 | __ | 00000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 5" | 4 1/2" | 3/8" | 55,000 | ASTM B16 | __ | 00000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 6" | 5 1/2" | 3/8" | 55,000 | ASTM B16 | __ | 00000000 | 00000 |

303 Stainless Steel | ||||||||||

| 3/8"-16 | 5/16" | 13/16" | 3" | 2 1/2" | 3/8" | 90,000 | ASTM A582 | __ | 00000000 | 00000 |

| 3/8"-16 | 5/16" | 13/16" | 4" | 3 1/2" | 3/8" | 90,000 | ASTM A582 | __ | 00000000 | 00000 |

| 3/8"-24 | 3/8" | 13/16" | 5" | 4 1/2" | 3/8" | 90,000 | ASTM A582 | __ | 00000000 | 00000 |

Black-Oxide 303 Stainless Steel | ||||||||||

| 3/8"-16 | 5/16" | 13/16" | 3" | 2 1/2" | 3/8" | 90,000 | ASTM A582 | __ | 00000000 | 00000 |

| 3/8"-16 | 5/16" | 13/16" | 4" | 3 1/2" | 3/8" | 90,000 | ASTM A582 | __ | 00000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 2" | 1 1/2" | 3/8" | 90,000 | ASTM A582 | __ | 00000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 3 1/2" | 3" | 3/8" | 90,000 | ASTM A582 | __ | 00000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 5" | 4 1/2" | 3/8" | 90,000 | ASTM A582 | __ | 00000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 6" | 5 1/2" | 3/8" | 90,000 | ASTM A582 | __ | 00000000 | 00000 |

| 3/8"-24 | 3/8" | 13/16" | 3 1/2" | 3" | 3/8" | 90,000 | ASTM A582 | __ | 00000000 | 00000 |

304 Stainless Steel | ||||||||||

| 3/8"-16 | 3/8" | 13/16" | 1 15/16" | 1 7/16" | 3/8" | 75,000 | ASTM A193 | ASTM Grade B8 | 0000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 3 1/2" | 3" | 3/8" | 75,000 | ASTM A193 | ASTM Grade B8 | 0000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 5" | 4 1/2" | 3/8" | 75,000 | ASTM A193 | ASTM Grade B8 | 0000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 6" | 5 1/2" | 3/8" | 75,000 | ASTM A193 | ASTM Grade B8 | 0000000 | 00000 |

| 3/8"-24 | 3/8" | 13/16" | 3 1/2" | 3" | 3/8" | 75,000 | ASTM A193 | ASTM Grade B8 | 0000000 | 00000 |

17-4 PH Stainless Steel | ||||||||||

| 3/8"-16 | 5/16" | 13/16" | 3" | 2 1/2" | 3/8" | 160,000 | ASTM A564 | __ | 00000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 2" | 1 1/2" | 3/8" | 160,000 | ASTM A564 | __ | 00000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 5" | 4 1/2" | 3/8" | 160,000 | ASTM A564 | __ | 00000000 | 00000 |

| 3/8"-24 | 3/8" | 13/16" | 3 1/2" | 3" | 3/8" | 160,000 | ASTM A564 | __ | 00000000 | 00000 |

316 Stainless Steel | ||||||||||

| 3/8"-16 | 5/16" | 13/16" | 3" | 2 1/2" | 3/8" | 75,000 | ASTM A276 | __ | 00000000 | 00000 |

| 3/8"-16 | 5/16" | 13/16" | 4" | 3 1/2" | 3/8" | 75,000 | ASTM A276 | __ | 00000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 2" | 1 1/2" | 3/8" | 75,000 | ASTM A276 | __ | 00000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 3 1/2" | 3" | 3/8" | 75,000 | ASTM A276 | __ | 00000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 5" | 4 1/2" | 3/8" | 75,000 | ASTM A276 | __ | 00000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 6" | 5 1/2" | 3/8" | 75,000 | ASTM A276 | __ | 00000000 | 00000 |

| 3/8"-24 | 3/8" | 13/16" | 3 1/2" | 3" | 3/8" | 75,000 | ASTM A276 | __ | 00000000 | 00000 |

| 3/8"-24 | 3/8" | 13/16" | 5" | 4 1/2" | 3/8" | 75,000 | ASTM A276 | __ | 00000000 | 00000 |

Fully Threaded Rod End Bolts

For maximum mounting flexibility, cut the fully threaded shaft to whatever length you need. Also known as swing bolts and eyebolts, rod end bolts have no moving parts. They're designed to make pivoting or hinge movements in applications that don't need to compensate for misalignment.

For technical drawings and 3-D models, click on a part number.

| Shank Thread Size | ID | O'all Wd. | Shank Center Lg. | Shank Thread Lg. | O'all Thick. | Tensile Strength, psi | Specifications Met | Material | Each | |

Right-Hand Threaded Shank | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 3/8"-16 | 3/8" | 13/16" | 1 15/16" | 1 7/16" | 3/8" | 60,000 | ASTM A521 Class CA | Black-Oxide Carbon Steel | 0000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 3 1/2" | 3" | 3/8" | 60,000 | ASTM A521 Class CA | Black-Oxide Carbon Steel | 0000000 | 0000 |

| 3/8"-16 | 3/8" | 13/16" | 5" | 4 1/2" | 3/8" | 60,000 | ASTM A521 Class CA | Black-Oxide Carbon Steel | 0000000 | 0000 |

| 3/8"-16 | 3/8" | 13/16" | 6" | 5 1/2" | 3/8" | 60,000 | ASTM A521 Class CA | Black-Oxide Carbon Steel | 0000000 | 0000 |

| 3/8"-24 | 3/8" | 13/16" | 3 1/2" | 3" | 3/8" | 60,000 | ASTM A521 Class CA | Black-Oxide Carbon Steel | 0000000 | 00000 |

High-Strength Fully Threaded Rod End Bolts

These alloy steel rod end bolts have the highest tensile strength of any steel fully threaded rod end bolt we offer. For maximum mounting flexibility, cut the fully threaded shaft to whatever length you need. Also known as swing bolts and eyebolts, rod end bolts have no moving parts. They're designed to make pivoting or hinge movements in applications that don't need to compensate for misalignment.

For technical drawings and 3-D models, click on a part number.

| Shank Thread Size | ID | O'all Wd. | Shank Center Lg. | Shank Thread Lg. | O'all Thick. | Tensile Strength, psi | Fastener Strength Grade/Class | Specifications Met | Material | Each | |

Right-Hand Threaded Shank | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3/8"-16 | 5/16" | 13/16" | 3" | 2 1/2" | 3/8" | 125,000 | ASTM Grade B7 | ASTM A193 | Black-Oxide Alloy Steel | 0000000 | 000000 |

| 3/8"-16 | 5/16" | 13/16" | 4" | 3 1/2" | 3/8" | 125,000 | ASTM Grade B7 | ASTM A193 | Black-Oxide Alloy Steel | 0000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 1 15/16" | 1 7/16" | 3/8" | 125,000 | ASTM Grade B7 | ASTM A193 | Black-Oxide Alloy Steel | 0000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 2" | 1 1/2" | 3/8" | 125,000 | ASTM Grade B7 | ASTM A193 | Black-Oxide Alloy Steel | 0000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 3 1/2" | 3" | 3/8" | 125,000 | ASTM Grade B7 | ASTM A193 | Black-Oxide Alloy Steel | 0000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 5" | 4 1/2" | 3/8" | 125,000 | ASTM Grade B7 | ASTM A193 | Black-Oxide Alloy Steel | 0000000 | 00000 |

| 3/8"-16 | 3/8" | 13/16" | 6" | 5 1/2" | 3/8" | 125,000 | ASTM Grade B7 | ASTM A193 | Black-Oxide Alloy Steel | 0000000 | 00000 |

| 3/8"-24 | 3/8" | 13/16" | 3 1/2" | 3" | 3/8" | 125,000 | ASTM Grade B7 | ASTM A193 | Black-Oxide Alloy Steel | 0000000 | 00000 |

| 3/8"-24 | 3/8" | 13/16" | 5" | 4 1/2" | 3/8" | 125,000 | ASTM Grade B7 | ASTM A193 | Black-Oxide Alloy Steel | 0000000 | 00000 |

Externally Threaded Clevis Rod Ends

A male-threaded shank lets you build a linkage with a tapped tube or any female-threaded connection. Good for a wide variety of pivot-point applications, all are zinc-plated steel for moderate corrosion resistance. Clevis pins are not included.

For technical drawings and 3-D models, click on a part number.

| Shank Thread Size | ID | Jaw Opening Wd. | O'all Wd. | Shank Center Lg. | Shank Thread Lg. | Jaw Center Lg. | Tensile Strength, psi | Choose a Shank Thread Direction | Each | |

Zinc-Plated Carbon Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1/2"-20 | 7/16" | 3/8" | 13/16" | 3 3/8" | 2" | 1 3/8" | 90,000 | 0000000 | 000000 | |

| 5/8"-18 | 3/8" | 3/8" | 13/16" | 3 3/8" | 2" | 1 3/8" | 90,000 | 0000000 | 00000 | |

| 5/8"-18 | 7/16" | 3/8" | 13/16" | 3 3/8" | 2" | 1 3/8" | 90,000 | 0000000 | 00000 | |

| 5/8"-18 | 1/2" | 3/8" | 13/16" | 3 3/8" | 2" | 1 3/8" | 90,000 | 0000000 | 00000 | |

| 3/4"-16 | 3/8" | 3/8" | 13/16" | 3 3/8" | 2" | 1 3/8" | 90,000 | Right Hand | 00000000 | 00000 |

| 3/4"-16 | 1/2" | 3/8" | 13/16" | 3 3/8" | 2" | 1 3/8" | 90,000 | 0000000 | 00000 | |