About Door Closers

When replacing an existing closer, remove the cover and match the model number and/or mounting hole pattern to a closer in our offering. Or, use one of our closers and a universal mounting plate that matches most hole patterns.

If you are installing a new closer, choose one that works for your door width. Due to added resistance from wind, closers typically accommodate smaller exterior doors than interior doors.

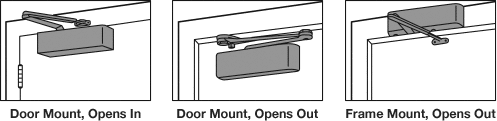

There are three typical mounting positions for door closers; many of our closers are versatile and can be mounted in any of these positions. To determine opening direction, stand on the side of the door where the closer will be mounted. If the door opens towards you it opens in; opens away from you it opens out.

Door Mount, Opens In—Also known as regular arm mount, this position allows the door to open in toward the closer.

Door Mount, Opens Out—Also known as parallel arm mount, the arm lays parallel with the door in the closed position.

Frame Mount, Opens Out—Also known as top frame mount, this position is often used for exterior doors.

Galvanized Iron and Steel Slip-On Framing and Fittings

To provide corrosion resistance in wet environments, this framing is galvanized. Slip the fittings over rails to construct custom railings, guard rails, storage racks, and shelving. Tighten the included set screws for a secure hold.

Galvanized iron fittings are malleable iron.

For technical drawings and 3-D models, click on a part number.

Adjustable-angle fittings can be positioned at any angle. Tighten the set screw to secure.

| For Rail OD | For Pipe Size | Material | Includes | Each | |

Adjustable-Angle Elbow | |||||

|---|---|---|---|---|---|

| 1 7/8" | 1 1/2 | Galvanized Iron | Set Screws | 00000000 | 000000 |

Through-hole fittings allow rails to run all the way through.

Adjustable-angle fittings can be positioned at any angle. Tighten the set screw to secure.

| For Rail OD | For Pipe Size | No. of Through Holes | Material | Includes | Each | |

Four-Way Adjustable-Angle Elbow | ||||||

|---|---|---|---|---|---|---|

| 1" | 3/4 | 1 | Galvanized Iron | Set Screws | 00000000 | 000000 |

| 1 3/8" | 1 | 1 | Galvanized Iron | Set Screws | 0000000 | 00000 |

| 1 5/8" | 1 1/4 | 1 | Galvanized Iron | Set Screws | 0000000 | 00000 |

| 1 7/8" | 1 1/2 | 1 | Galvanized Iron | Set Screws | 00000000 | 00000 |

| 2 3/8" | 2 | 1 | Galvanized Iron | Set Screws | 00000000 | 00000 |

Adjustable-Angle Cross | ||||||

| 1" | 3/4 | 1 | Galvanized Iron | Set Screws | 00000000 | 00000 |

| 1 3/8" | 1 | 1 | Galvanized Iron | Set Screws | 0000000 | 00000 |

| 1 5/8" | 1 1/4 | 1 | Galvanized Iron | Set Screws | 0000000 | 00000 |

| 1 7/8" | 1 1/2 | 1 | Galvanized Iron | Set Screws | 0000000 | 00000 |

| 2 3/8" | 2 | 1 | Galvanized Iron | Set Screws | 00000000 | 000000 |

Adjustable-Angle Wye | ||||||

| 1" | 3/4 | 1 | Galvanized Iron | Set Screws | 00000000 | 00000 |

| 1 3/8" | 1 | 1 | Galvanized Iron | Set Screws | 0000000 | 00000 |

| 1 5/8" | 1 1/4 | 1 | Galvanized Iron | Set Screws | 0000000 | 00000 |

| 1 7/8" | 1 1/2 | 1 | Galvanized Iron | Set Screws | 0000000 | 00000 |

| 2 3/8" | 2 | 1 | Galvanized Iron | Set Screws | 0000000 | 00000 |

Rail ends attach to rails on one end and have a flange on the other end to attach to floors, walls, and ceilings.

Flange | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Rail OD | For Pipe Size | Lg. | Wd. | Overall Ht. | Material | Includes | Each | |

Rectangular Adjustable-Angle | ||||||||

| 1" | 3/4 | 4 3/8" | 2" | 3 3/4" | Galvanized Iron | Set Screws | 00000000 | 000000 |

| 1 3/8" | 1 | 4 3/8" | 2" | 3 3/4" | Galvanized Iron | Set Screws | 0000000 | 00000 |

| 1 5/8" | 1 1/4 | 4 3/8" | 2" | 4 1/8" | Galvanized Iron | Set Screws | 0000000 | 00000 |

| 1 7/8" | 1 1/2 | 4 3/8" | 2" | 4 3/8" | Galvanized Iron | Set Screws | 0000000 | 00000 |

| 2 3/8" | 2 | 4 3/8" | 2" | 4 5/8" | Galvanized Iron | Set Screws | 00000000 | 00000 |

High-Traffic Door Closers

For frequently used doors, these closers last twice as long as standard door closers. They can replace Yale, Dorma, Falcon, Stanley, Parker, and Cal-Royal models with the same mounting hole pattern. All meet ANSI A156.4 Grade 1 durability, strength, and performance standards for door controls. Closers that meet UL 10C for fire-rated doors meet positive pressure fire test standards.

To determine door swing direction, stand on the side of the door where it swings away from you. If it opens to the right, select a right closer; if it opens to the left, select a left closer. Reversible closers are for right or left door-swing directions.

Free-moving closers pull doors shut after you've opened them.

Hold-open closers hold doors open until you close them with a slight push or pull on the door.

Closers with a delayed close hold doors open for a set amount of time before closing.

For Door Wd. | Opening Direction | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Interior | Exterior | For Door Swing Direction | Opening/Closing Action | Delayed Closing Time, sec. | Door Mount | Frame Mount | Range of Motion | Mounting Hardware Included | Specifications Met | Choose a Finish | Each | |

LCN 1261 | ||||||||||||

| 24"-54" | 24"-42" | Reversible | Free Moving | __ | Opens In, Opens Out | Opens Out | 180° | Yes | ANSI A156.4 Grade 1 UL 10C UL Listed | 0000000 | 0000000 | |

| 24"-54" | 24"-42" | Reversible | Hold Open | __ | Opens In, Opens Out | Opens Out | 180° | Yes | ANSI A156.4 Grade 1 | 0000000 | 000000 | |

LCN 1460/1461 | ||||||||||||

| 24"-60" | 24"-48" | Reversible | Free Moving | __ | Opens In, Opens Out | Opens Out | 180° | Yes | ANSI A156.4 Grade 1 UL 10C UL Listed | 0000000 | 000000 | |

| 24"-60" | 24"-48" | Reversible | Hold Open | __ | Opens In, Opens Out | Opens Out | 180° | Yes | ANSI A156.4 Grade 1 | 0000000 | 000000 | |

| 24"-60" | 24"-48" | Reversible | Hold Open Delayed Close | 5 to 60 | Opens In, Opens Out | Opens Out | 180° | Yes | ANSI A156.4 Grade 1 | 0000000 | 000000 | |

| 24"-60" | 24"-48" | Reversible | Delayed Close | 5 to 60 | Opens In, Opens Out | Opens Out | 180° | Yes | ANSI A156.4 Grade 1 UL 10C UL Listed | 0000000 | 000000 | |

LCN 4011 | ||||||||||||

| 24"-54" | 24"-42" | Left | Free Moving | __ | Opens In | __ | 140° | Yes | ANSI A156.4 Grade 1 UL 10C UL Listed | 0000000 | 000000 | |

| 24"-54" | 24"-42" | Left | Hold Open | __ | Opens In | __ | 140° | Yes | ANSI A156.4 Grade 1 | 0000000 | 000000 | |

| 24"-54" | 24"-42" | Left | Hold Open Delayed Close | 5 to 60 | Opens In | __ | 140° | Yes | ANSI A156.4 Grade 1 | 0000000 | 000000 | |

| 24"-54" | 24"-42" | Left | Delayed Close | 5 to 60 | Opens In | __ | 140° | Yes | ANSI A156.4 Grade 1 UL 10C UL Listed | 0000000 | 000000 | |

| 24"-54" | 24"-42" | Right | Free Moving | __ | Opens In | __ | 140° | Yes | ANSI A156.4 Grade 1 UL 10C UL Listed | 0000000 | 000000 | |

| 24"-54" | 24"-42" | Right | Hold Open | __ | Opens In | __ | 140° | Yes | ANSI A156.4 Grade 1 | 0000000 | 000000 | |

| 24"-54" | 24"-42" | Right | Hold Open Delayed Close | 5 to 60 | Opens In | __ | 140° | Yes | ANSI A156.4 Grade 1 | 0000000 | 000000 | |

| 24"-54" | 24"-42" | Right | Delayed Close | 5 to 60 | Opens In | __ | 140° | Yes | ANSI A156.4 Grade 1 UL 10C UL Listed | 0000000 | 000000 | |

LCN 4021 | ||||||||||||

| 24"-54" | 24"-42" | Left | Free Moving | __ | __ | Opens Out | 180° | Yes | ANSI A156.4 Grade 1 UL 10C UL Listed | 0000000 | 000000 | |

| 24"-54" | 24"-42" | Left | Hold Open | __ | __ | Opens Out | 140° | Yes | ANSI A156.4 Grade 1 | 0000000 | 000000 | |

| 24"-54" | 24"-42" | Right | Free Moving | __ | __ | Opens Out | 180° | Yes | ANSI A156.4 Grade 1 UL 10C UL Listed | 0000000 | 000000 | |

| 24"-54" | 24"-42" | Right | Hold Open | __ | __ | Opens Out | 140° | Yes | ANSI A156.4 Grade 1 | 0000000 | 000000 | |

LCN 4040XP | ||||||||||||

| 24"-60" | 24"-48" | Reversible | Free Moving | __ | Opens In, Opens Out | Opens Out | 120° | Yes | ANSI A156.4 Grade 1 UL 10C UL Listed | 0000000 | 000000 | |

| 24"-60" | 24"-48" | Reversible | Hold Open | __ | Opens In, Opens Out | Opens Out | 120° | Yes | ANSI A156.4 Grade 1 | 0000000 | 000000 | |

LCN 4111 | ||||||||||||

| 28"-54" | 28"-42" | Left | Free Moving | __ | Opens Out | __ | 180° | Yes | ANSI A156.4 Grade 1 UL 10C UL Listed | 0000000 | 000000 | |

| 28"-54" | 28"-42" | Left | Hold Open | __ | Opens Out | __ | 180° | Yes | ANSI A156.4 Grade 1 | 0000000 | 000000 | |

| 28"-54" | 28"-42" | Right | Free Moving | __ | Opens Out | __ | 180° | Yes | ANSI A156.4 Grade 1 UL 10C UL Listed | 0000000 | 000000 | |

| 28"-54" | 28"-42" | Right | Hold Open | __ | Opens Out | __ | 180° | Yes | ANSI A156.4 Grade 1 | 0000000 | 000000 | |

Corbin Russwin DC3000 | ||||||||||||

| 28"-54" | 30"-48" | Reversible | Free Moving | __ | Opens In, Opens Out | Opens Out | 180° | Yes | ANSI A156.4 Grade 1 UL 10C UL Listed | 0000000 | 000000 | |

| 28"-54" | 30"-48" | Reversible | Hold Open | __ | Opens In, Opens Out | Opens Out | 180° | Yes | ANSI A156.4 Grade 1 | 0000000 | 000000 | |

Corbin Russwin DC6200 | ||||||||||||

| 28"-54" | 30"-48" | Reversible | Free Moving | __ | Opens Out | __ | 180° | Yes | ANSI A156.4 Grade 1 UL 10C UL Listed | Gray | 0000000 | 000000 |

| 28"-54" | 30"-48" | Reversible | Hold Open | __ | Opens Out | __ | 180° | Yes | ANSI A156.4 Grade 1 UL 10C UL Listed | Gray | 0000000 | 000000 |

Corbin Russwin DC8200 | ||||||||||||

| 28"-54" | 30"-48" | Reversible | Free Moving | __ | Opens Out | __ | 180° | Yes | ANSI A156.4 Grade 1 UL 10C UL Listed | Gray | 0000000 | 000000 |

| 28"-54" | 30"-48" | Reversible | Hold Open | __ | Opens Out | __ | 180° | Yes | ANSI A156.4 Grade 1 UL 10C UL Listed | Gray | 0000000 | 000000 |

Sargent 281 | ||||||||||||

| 32"-48" | 32"-36" | Reversible | Free Moving | __ | Opens In, Opens Out | Opens Out | 180° | Yes | ANSI A156.4 Grade 1 UL 10C UL Listed | Gray | 0000000 | 000000 |

| 32"-48" | 32"-36" | Reversible | Hold Open | __ | Opens In, Opens Out | Opens Out | 180° | Yes | ANSI A156.4 Grade 1 UL 10C UL Listed | Gray | 0000000 | 000000 |

High-Traffic Door Closers with Built-In Stop

A built-in stop prevents doors from opening too far—good when wall- or floor-stops can’t be used. Designed for frequently used doors, these closers last twice as long as standard door closers. They can replace Yale, Dorma, Falcon, Stanley, Parker, and Cal-Royal models with the same mounting hole pattern. These closers are reversible for right or left door-swing directions. All meet ANSI A156.4 Grade 1 durability, strength, and performance standards for door controls. Closers that meet UL 10C for fire-rated doors meet positive pressure fire test standards.

Free-moving closers pull doors shut after you've opened them.

Hold-open closers hold doors open until you close them with a slight push or pull on the door.

For Door Wd. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Interior | Exterior | For Door Swing Direction | Opening/Closing Action | Door Mount Opening Direction | Range of Motion | Mounting Hardware Included | Specifications Met | Choose a Finish | Each | |

LCN 1460/1461 | ||||||||||

| 24"-60" | 24"-48" | Reversible | Free Moving | Opens Out | 100° | Yes | ANSI A156.4 Grade 1 UL 10C UL Listed | 0000000 | 0000000 | |

| 24"-60" | 24"-48" | Reversible | Hold Open | Opens Out | 100° | Yes | ANSI A156.4 Grade 1 | 0000000 | 000000 | |

LCN 4040XP | ||||||||||

| 24"-60" | 24"-48" | Reversible | Free Moving | Opens Out | 110° | Yes | ANSI A156.4 Grade 1 UL 10C UL Listed | 0000000 | 000000 | |

| 24"-60" | 24"-48" | Reversible | Hold Open | Opens Out | 110° | Yes | ANSI A156.4 Grade 1 | 0000000 | 000000 | |

Freezer Door Closers

Often used on large freezer and cold-storage doors, these closers are designed for doors that weigh 200 lbs. or more. Mount them to the face of your door and frame just above the door's lowest hinge. These free-moving closers pull doors shut after you've opened them. They are reversible for right or left door-swing directions. Offset is the space between the door face and the frame when the door is closed.

| For Door Swing Direction | For Max. Door Offset | Projection | Opening/Closing Action | Mounting Location | Range of Motion | Mounting Hardware Included | Material | Finish | Each | |

| Reversible | 7/8" | 2 7/16" | Free Moving | Door, Frame | 175° | Yes | Iron | Zinc Plated | 0000000 | 0000000 |

High-Torque Single U-Joints

With a maximum torque of at least 11,600 in.-lbs., these U-joints handle more torque than any other U-joint in our offering. They’re single U-joints, meaning they connect and transfer torque between shafts that are misaligned at an angle. Often found in continuously running applications, they operate at higher speeds and last longer than other types of joints, thanks to their needle bearings.

Connect these U-joints to shafts using the included set screws. Unlike U-joints that use spring pins, there’s no drilling required. All have a grease fitting, so you can use a grease gun to lubricate all of the bearings at once.

Your shafts’ misalignment will affect the speed and torque the U-joint will be able to transmit. The more the shafts are misaligned, the less speed and torque the U-joint will be able to transmit.

For technical drawings and 3-D models, click on a part number.

For Shaft | O'all | Keyway | Torque | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Dp. | Joint Dia. | Ht. | Lg. | Wd. | Dp. | Max. Operating Angle | Max. Speed, rpm | Max. Torque, in.-lbs. | 3° Operating Angle | 10° Operating Angle | Includes | Each | |

Iron with Steel Bearings | ||||||||||||||

| 3/4" | 1 13/64" | 1 5/8" | 2 3/8" | 5" | 3/16" | 3/32" | 45° | 1,000 | 11,600 | 1,260 in.-lbs. @ 1,000 rpm | 720 in.-lbs. @ 1,000 rpm | Grease Fitting | 000000 | 0000000 |

| 7/8" | 1 13/64" | 1 5/8" | 2 3/8" | 5" | 3/16" 1/4" | 3/32" 1/8" | 45° | 1,000 | 11,600 | 1,260 in.-lbs. @ 1,000 rpm | 720 in.-lbs. @ 1,000 rpm | Grease Fitting | 000000 | 000000 |

| 1" | 1 13/64" | 1 5/8" | 2 3/8" | 5" | 3/16" 1/4" | 3/32" 1/8" | 45° | 1,000 | 11,600 | 1,260 in.-lbs. @ 1,000 rpm | 720 in.-lbs. @ 1,000 rpm | Grease Fitting | 000000 | 000000 |

| 1 1/8" | 1 5/32" | 2 1/4" | 2 5/16" | 5" | 1/4" 5/16" | 1/8" 5/32" | 45° | 1,000 | 11,600 | 1,260 in.-lbs. @ 1,000 rpm | 720 in.-lbs. @ 1,000 rpm | Grease Fitting | 000000 | 000000 |

| 1 1/4" | 1 5/32" | 2 1/4" | 2 5/16" | 5" | 1/4" 5/16" | 1/8" 5/32" | 45° | 1,000 | 11,600 | 1,260 in.-lbs. @ 1,000 rpm | 720 in.-lbs. @ 1,000 rpm | Grease Fitting | 000000 | 000000 |

| Replacement Bearing Assembly for Iron U-Joints | 00000000 | Each | 000000 |