UN-Compliant Tanks

Also known as an intermediate bulk container (IBC), these tanks are designed to safely ship liquids. They're tested to comply with United Nations regulations for packaging and shipping hazardous material over land, sea, or air. These regulations aim to prevent hazardous spills caused by accidents or rough package handling. Unlike round drums, these tanks can be tightly packed side-by-side to maximize your floor space. They’re protected by a rigid tubular steel cage. They can be stacked two high when tank is full and four high when empty.

Note: It is the responsibility of the shipper to follow regulatory guidelines for properly packaging and labeling all hazardous materials and ensure the appropriate method for shipping.

For technical drawings and 3-D models, click on a part number.

Max. Fork | Drain | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Wd. | Dp. | Ht. | Thick. | Fill Opening Dia. | Graduation Marks | No. of Entry Points for Forklifts | Wd. | Ht. | Pipe Size | Gender | Max. Temp., °F | Shipping Standard | Features | Each | |

White HDPE Plastic with Galvanized Steel Pallet | ||||||||||||||||

| 150 | 40" | 48" | 30" | 1/16" | 6 5/8" | 25 gal. | 4 | 14" | 3" | 2 NPS | Male | 160° | UN31HA1/Y | Butterfly Valve, Cage | 00000000 | 0000000 |

| 275 | 40" | 48" | 46" | 1/16" | 6" | 25 gal., 100 L | 4 | 9" | 2 1/2" | 2 NPS | Male | 160° | UN31HA1/Y | Butterfly Valve, Cage, Threaded 2 NPS Fill Cap Plug | 0000000 | 000000 |

| Red Replacement Fill Cap with TPE Rubber Seal | 0000000 | Each | 000000 |

Max. Fork | Drain | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Wd. | Dp. | Ht. | Thick. | Fill Opening Dia. | Graduation Marks | No. of Entry Points for Forklifts | Wd. | Ht. | Coupling Size | Gender | Max. Temp., °F | Shipping Standard | Features | Each | |

White HDPE Plastic with Galvanized Steel Pallet | ||||||||||||||||

| 135 | 40" | 48" | 27" | 1/16" | 6" | __ | 4 | 14 1/2" | 3 1/2" | __ | Male | 140° | UN31HA1/Y1.9/100 | Cage, Threaded 2 NPT Fill Cap Plug | 00000000 | 0000000 |

| 330 | 40" | 48" | 53" | 1/16" | 6" | 25 gal., 100 L | 4 | 12" | 3 1/2" | 2 | Male | 160° | UN31HA1/Y | Ball Valve, Cage, Threaded 2 NPS Fill Cap Plug | 0000000 | 000000 |

| Red Replacement Fill Cap with TPE Rubber Seal | 0000000 | Each | 000000 |

UV-Resistant UN-Compliant Tanks

Protect shipments of hazardous material during transit. A UV-resistant coating shields these tanks from sun damage, preventing leaks through weakened walls. They’re also protected by a rigid steel cage. These tanks comply with United Nations regulations for packaging and shipping hazardous material over land, sea, or air.

These tanks are also known as intermediate bulk containers (IBCs). They store five times as much material as a 55 gal. drum. Unlike round drums, these tanks can be tightly packed side-by-side to maximize your floor space. For added capacity, stack them two high when full or four high when empty.

Note: It is the responsibility of the shipper to follow regulatory guidelines for properly packaging and labeling all hazardous materials and ensure the appropriate method for shipping.

For technical drawings and 3-D models, click on a part number.

Max. Fork | Drain | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Wd. | Dp. | Ht. | Thick. | Fill Opening Dia. | Graduation Marks | No. of Entry Points for Forklifts | Wd. | Ht. | Pipe Size | Gender | Max. Temp., °F | Shipping Standard | Features | Each | |

White HDPE Plastic with Galvanized Steel Pallet | ||||||||||||||||

| 275 | 40" | 48" | 46" | 1/16" | 6" | 25 gal., 100 L | 4 | 9" | 2 1/2" | 2 NPS | Male | 160° | UN31HA1/Y | Butterfly Valve, Cage, Threaded 2 NPS Fill Cap Plug | 0000000 | 0000000 |

| For Fill Opening Dia. | Material | Color | Seal Material | Features | Each | |

| 6" | Polyethylene Plastic | Red | TPE Rubber | Threaded 2 NPS Fill Cap Plug | 0000000 | 000000 |

Sanitary Easy-Drain Tanks

Store and transport liquids in bulk in sanitary environments such as food and pharmaceutical plants. These tanks have a one-piece sloped bottom for easy and complete drainage, a highly polished surface, and continuously welded seams. By leaving no room for liquid to hang around after use, their design prevents bacterial growth. Made of stainless steel, they resist frequent washdowns with harsh sanitizers. They connect with quick-clamp fittings—also known as tri-clamp fittings—so they’re easily disassembled for regular cleaning. Also known as intermediate bulk containers (IBCs), these tanks take up less floor space than drums. They can also be stacked up to three high to save additional space, even when full. All meet National Fire Protection Agency Code 30 for use with flammable and combustible liquids.

For technical drawings and 3-D models, click on a part number.

Drain | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Width | Depth | Height | Gauge | Weight, lbs. | Fill Opening Diameter | Tube OD | Fitting Flange OD | Leg Height | Space Saving Features | Specifications Met | Each | |

304 Stainless Steel | |||||||||||||

| 180 | 42" | 48" | 29" | 10 | 332 | 22 1/2" | 2" | 2.516" | 9" | Stackable | NFPA 30 | 0000000 | 000000000 |

| 250 | 42" | 48" | 35" | 10 | 375 | 22 1/2" | 2" | 2.516" | 9" | Stackable | NFPA 30 | 0000000 | 00000000 |

| 300 | 42" | 48" | 41" | 10 | 432 | 22 1/2" | 2" | 2.516" | 9" | Stackable | NFPA 30 | 0000000 | 00000000 |

| 350 | 42" | 48" | 47" | 10 | 465 | 22 1/2" | 2" | 2.516" | 9" | Stackable | NFPA 30 | 0000000 | 00000000 |

| 450 | 42" | 48" | 59" | 10 | 530 | 22 1/2" | 2" | 2.516" | 9" | Stackable | NFPA 30 | 0000000 | 00000000 |

| 550 | 42" | 48" | 71" | 10 | 645 | 22 1/2" | 2" | 2.516" | 9" | Stackable | NFPA 30 | 0000000 | 00000000 |

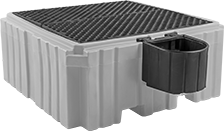

Plastic Spill-Control Pallets for UN-Compliant Tanks

The 52" × 52" grating is sized to hold an IBC tank. The grating is removable for easy cleaning.

Add a bucket (sold separately) to catch spills and drips when dispensing from the tank. Bucket has a spill capacity of 3 gallons; spills larger than 3 gallons are channeled into the well in the bottom of the pallet.

Usable | Max. Fork | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Weight Capacity, lbs. | Lg. | Wd. | Ht. | Lg. | Wd. | Grating Material | Color | Grating Color | No. of Entry Points for Forklifts | Wd. | Ht. | Space Saving Features | Each | |

Polyethylene Plastic—Meets EPA 40 CFR 264.175 | |||||||||||||||

| 350 | 8,500 | 62" | 62" | 28" | 52" | 52" | Polyethylene Plastic | Yellow | Black | 2 | 7 1/4" | 4" | Stackable | 00000000 | 000000000 |

| Black Polyethylene Plastic Bucket, 19 1/2" Lg. × 16" Wd. × 14 1/2" Ht. | 00000000 | Each | 0000000 |

Water Heaters

An adjustable thermostat automatically turns the heater on when the temperature drops below your set temperature and off when it rises above your set temperature. Adjust the set temperature with the dial. These heaters cannot be sold to the regions listed due to local energy efficiency requirements.

Estimated yearly energy cost is based on electricity cost of $0.12 per kWh. For more information, visit www.ftc.gov/energy.

First hour rating is the maximum amount of hot water that a unit can supply in one hour, starting with a full tank of hot water.

| Tank Cap., gal. | Wattage, W | Current, A | Estimated Yearly Energy Cost | First Hour Rating | Temp. Control Range, °F | Pipe Size | Thread Type | Gender | Connection Location | Electrical Connection Type | Ht. | Dia. | Cannot Be Sold To | Each | |

120V AC, Single Phase | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2.5 | 1,440 | 12 | Not Rated | Not Rated | 90° to 150° | 3/4 | NPT | Male | Top | Plug | 14 1/2" | __ | Canada | 0000000 | 0000000 |

| 6 | 1,650 | 13.8 | Not Rated | Not Rated | 90° to 150° | 3/4 | NPT | Male | Side | Hardwire | 15 1/4" | 14 1/4" | Canada | 0000000 | 000000 |

| 10 | 1,650 | 13.8 | Not Rated | Not Rated | 90° to 150° | 3/4 | NPT | Male | Side | Hardwire | 18 1/4" | 16" | Canada | 0000000 | 000000 |

| 19 | 1,650 | 13.8 | Not Rated | Not Rated | 90° to 150° | 3/4 | NPT | Male | Side | Hardwire | 24 3/4" | 18" | Canada | 0000000 | 000000 |

240V AC, Single Phase | |||||||||||||||

| 6 | 1,500 | 6.3 | Not Rated | Not Rated | 90° to 150° | 3/4 | NPT | Male | Side | Hardwire | 15 1/4" | 14 1/4" | Canada | 0000000 | 000000 |

| 10 | 1,500 | 6.3 | Not Rated | Not Rated | 90° to 150° | 3/4 | NPT | Male | Side | Hardwire | 18 1/4" | 18 1/4" | Canada | 0000000 | 000000 |

| 19 | 1,500 | 10.5 | Not Rated | Not Rated | 90° to 150° | 3/4 | NPT | Male | Side | Hardwire | 24 3/4" | 18" | Canada | 0000000 | 000000 |

| 30 | 4,500 | 18.8 | $555 | 47 gal. | 120° to 150° | 3/4 | NPT | Male | Top | Hardwire | 46 1/2" | 19" | Canada | 0000000 | 000000 |

| 50 | 4,500 | 18.8 | $555 | 62 gal. | 120° to 150° | 3/4 | NPT | Male | Top | Hardwire | 49 3/4" | 24" | Canada | 0000000 | 000000 |

Insulating Wrap-Around Heaters for Pails, Drums, and Totes

Also known as heat blankets, these heaters completely surround containers for fast heating and increased heat retention in unheated and drafty areas. Do not use in hazardous areas.

Heaters with an adjustable thermostat automatically turn on when the temperature drops below your set temperature and off when it rises above your set temperature. Adjust the set temperature with the keypad.

Heaters with a nonadjustable thermostat output a consistent heat and turn on and off intermittently to maintain that temperature. Since you can’t change their heat output, there’s no need to monitor them and no risk of tampering, which could damage containers and their contents.

Add insulated top covers to reduce heat loss and speed up heating. Covers with a through-port access flap give you easy access and further minimize heat loss.

For Container | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | Dp. | Ht. | Wattage, W | Watt Density, W/sq. in. | Voltage | Electrical Phase | Current, A | Max. Heat Output, °F | NEMA Style | For Surface Material | Material | Features | Each | |

For 55- Gallon Containers | |||||||||||||||

Adjustable Thermostat—50° to 160° F Temp. Control Range | |||||||||||||||

| 22 5/16" | __ | __ | 34" | 770 | 1 | 120V AC | Single | 6.4 | 160° | 5-15 | Plastic | Silicone/Fiberglass Blend Fabric | __ | 0000000 | 0000000 |

Adjustable Thermostat—50° to 450° F Temp. Control Range | |||||||||||||||

| 22 5/16" | __ | __ | 34" | 1,600 | 2 | 120V AC | Single | 13.3 | 450° | 5-15 | Metal | Silicone/Fiberglass Blend Fabric | __ | 0000000 | 000000 |

| 22 5/16" | __ | __ | 34" | 1,600 | 2 | 240V AC | Single | 6.7 | 450° | 6-15 | Metal | Silicone/Fiberglass Blend Fabric | __ | 0000000 | 000000 |

For 275- Gallon Containers | |||||||||||||||

Nonadjustable Thermostat | |||||||||||||||

| __ | 40" | 48" | 46" | 1,440 | 0.25 | 120V AC | Single | 12 | 135° | 5-15 | Fiberglass, Metal, Plastic | Vinyl Plastic | Overheat Protection, Resettable Fuse | 000000 | 00000000 |

For 330- Gallon Containers | |||||||||||||||

Nonadjustable Thermostat | |||||||||||||||

| __ | 48" | 40" | 56" | 1,440 | 0.25 | 120V AC | Single | 12 | 135° | 5-15 | Fiberglass, Metal, Plastic | Vinyl Plastic | Overheat Protection | 000000 | 00000000 |

For 355- Gallon Containers | |||||||||||||||

Time-Frequency Controller | |||||||||||||||

| __ | 40"-48" | 40"-48" | 36" | 1,440 | __ | 120V AC | Single | 12 | 160° | 5-15 | Metal, Plastic | Silicone/Fiberglass Blend Fabric | Overheat Protection | 0000000 | 00000000 |

| __ | 40"-48" | 40"-48" | 36" | 2,880 | __ | 240V AC | Single | 12 | 160° | 6-15 | Metal, Plastic | Silicone/Fiberglass Blend Fabric | Overheat Protection | 0000000 | 00000000 |

For 415- Gallon Containers | |||||||||||||||

Time-Frequency Controller | |||||||||||||||

| __ | 40"-48" | 40"-48" | 42" | 1,440 | __ | 120V AC | Single | 12 | 160° | 5-15 | Metal, Plastic | Silicone/Fiberglass Blend Fabric | Overheat Protection | 0000000 | 00000000 |

| __ | 40"-48" | 40"-48" | 42" | 2,880 | __ | 240V AC | Single | 12 | 160° | 6-15 | Metal, Plastic | Silicone/Fiberglass Blend Fabric | Overheat Protection | 0000000 | 00000000 |

For 475- Gallon Containers | |||||||||||||||

Time-Frequency Controller | |||||||||||||||

| __ | 40"-48" | 40"-48" | 48" | 1,440 | __ | 120V AC | Single | 12 | 160° | 5-15 | Metal, Plastic | Silicone/Fiberglass Blend Fabric | Overheat Protection | 0000000 | 00000000 |

| Thick. | Dia. | Lg. | Wd. | Material | Insulation Material | Features | Each | |

For Heaters for 55-Gallon Containers | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1.2" | 22 5/16" | __ | __ | Silicone/Fiberglass Blend Fabric | Fiberglass | __ | 0000000 | 0000000 |

For Heaters for 355-, 415-, and 475-Gallon Containers | ||||||||

| 0.4" | __ | 56" | 48" | Silicone/Fiberglass Blend Fabric | Fiberglass | Through-Port Access Flap | 0000000 | 000000 |

Insulating Wrap-Around Heaters for Diesel Exhaust Fluid (DEF) Totes

Extend the shelf life of your diesel exhaust fluid (DEF) while storing it in cold places. Also called heat blankets, these heaters wrap around 330 gal. DEF totes to evenly warm the fluid inside. They’re insulated with foam, so they retain heat even in chilly environments. Designed for DEF totes with a built-in pump, these heaters have an extended frame to fit the pump housing and an opening for the pump equipment. Manually set the temperature with the digital keypad. A thermostat automatically turns these heaters on and off to maintain the set temperature. To prevent overheating, a resettable fuse opens if the temperature rises above the maximum heat output.

Secure these heaters with the included buckles and straps—no need for adhesive. They’re quick to unbuckle and remove once your tote is empty. Made of heavy duty vinyl, these heaters stand up to scuffs, water, and UV rays, so they last even outdoors. The vinyl is NFPA rated for flame retardance; however, you shouldn’t use these heaters near combustible gases or dust. A ground fault circuit interrupter (GFCI) is built in to their power cord to prevent electrical shocks.

Add an insulated top cover to stop heat from escaping through the top of your tote. The cover has a flap that folds down to insulate the opening for pump equipment.

Heaters | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Container | Insulated Top Covers | |||||||||||||||

| Wd. | Dp. | Ht. | Wattage, W | Watt Density, W/sq. in. | Voltage | Electrical Phase | Current, A | Max. Heat Output, °F | NEMA Style | For Surface Material | Material | Features | Each | Each | ||

For 330- Gallon Containers | ||||||||||||||||

-30° to 135° F Temp. Control Range | ||||||||||||||||

| 48" | 40" | 56" | 1,440 | 0.25 | 120V AC | Single | 12 | 135° | 5-15 | Metal, Plastic | Vinyl Plastic | Overheat Protection, Resettable Fuse | 0000000 | 000000000 | 0000000 | 0000000 |

Heated Storage Enclosures

Temporarily store and warm items—these enclosures heat the space inside them. They’re often used to keep drums and palletized items from freezing at chilly jobsites and to maintain the viscosity of materials such as resins. A thermostat automatically turns the heater on and off, so they won’t drop below or rise above the set temperature. These enclosures have a vinyl cover that insulates to help keep the space warm. When closed, the cover shields your items from dirt, rain, and snow. Open the cover on either side to access your items. These enclosures collapse for easy storage.

Enclosures with a nonadjustable thermostat keep the temperature between 90° and 110° F.

Enclosures with an adjustable thermostat have a keypad to change your set temperature.

Interior | Overall | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Wattage, W | Voltage | Electrical Phase | Current, A | Max. Heat Output, °F | Electrical Connection Type | NEMA Style | For Use Outdoors | Frame Material | Material | Each | |

Nonadjustable Thermostat | |||||||||||||||||

| 32" | 44" | 46" | 36" | 48" | 48" | 800 | 120V AC | Single | 6.67 | 100° | Plug | 5-15 | Yes | Plastic | Vinyl | 0000000 | 000000000 |

| 36" | 44" | 46" | 40" | 48" | 48" | 800 | 120V AC | Single | 6.67 | 100° | Plug | 5-15 | Yes | Plastic | Vinyl | 0000000 | 00000000 |

Adjustable Thermostat—72° to 120° F Temp. Control Range | |||||||||||||||||

| 44" | 44" | 46" | 48" | 48" | 48" | 1,440 | 120V AC | Single | 12 | 120° | Plug | 5-15 | Yes | Steel | Vinyl | 0000000 | 00000000 |

Expansion Tanks for Drinking Water

--254778721a21610474326-p9@halfx_637460495290491699.png?ver=imagenotfound)

These tanks meet NSF/ANSI Standard 61 for use with drinking (potable) water. Use them to accommodate the expansion of heated water and provide a cushion of compressed air in closed water-heating systems. All of these tanks have a diaphragm, which completely separates air and water. They prevent water loss by eliminating the need to expel hot water from systems during each heating cycle.

For technical drawings and 3-D models, click on a part number.

Tank End (E1) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Dia. | Overall Lg. | Connection Pipe Size | Pipe Connection Thread Type | Pipe Connection Gender | Wall Gauge, ga. | Max. Temp., °F | Max. Pressure, psi | Diaphragm Material | Specifications Met | Each | |

Beige-Painted Steel | ||||||||||||

| 2.1 | 8" | 11" | 3/4 | NPT | Male | 16 | 200° | 150 | Butyl Rubber | NSF/ANSI 61 | 000000 | 000000 |

| 4.5 | 10 1/2" | 13 1/2" | 3/4 | NPT | Male | 16 | 200° | 150 | Butyl Rubber | NSF/ANSI 61 | 000000 | 000000 |

| 8.5 | 12 1/2" | 19 3/16" | 3/4 | NPT | Male | 16 | 200° | 150 | Butyl Rubber | NSF/ANSI 61 | 000000 | 000000 |

ASME-Code Expansion Tanks for Water

--7cc059f10c41610560320-p9@halfx_637461359604633535.png?ver=imagenotfound)

Manufactured in accordance with ASME BPVC.VIII.1, these tanks accommodate the expansion of heated water and provide a cushion of compressed air in closed water-heating systems. They prevent water loss by eliminating the need to expel hot water from systems during each heating cycle.

For technical drawings and 3-D models, click on a part number.

Tank End Connection Pipe Size | Tank Side Connection Pipe Size | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Dia. | Overall Lg. | Lg. (A) | Lg. (B) | Lg. (C) | (E1) | (E2) | (S1) | (S2) | Pipe Connection Thread Type | Pipe Connection Gender | Wall Gauge, ga. | Max. Temp., °F | Max. Pressure, psi | Expansion Tank Type | Each | |

Gray-Painted Steel | |||||||||||||||||

| 15 | 12" | 34 1/4" | 7" | 19" | 8" | 1/2 | 1/2 | 1 | 1 | NPT | Female | 13 | 450° | 150 | Bladderless | 00000000 | 0000000 |

| 30 | 14" | 49 9/16" | 8 3/8" | 31 1/4" | 10" | 1/2 | 1/2 | 1 1/2 | 1 1/2 | NPT | Female | 12 | 450° | 150 | Bladderless | 00000000 | 000000 |

| 40 | 14" | 64 5/8" | 8 3/8" | 46 1/4" | 10" | 1/2 | 1/2 | 1 1/2 | 1 1/2 | NPT | Female | 12 | 450° | 150 | Bladderless | 00000000 | 000000 |

| 80 | 20" | 66 1/8" | 10 3/4" | 42" | 16" | 1/2 | 1/2 | 2 | 2 | NPT | Female | 11 | 450° | 150 | Bladderless | 00000000 | 000000 |

Expansion Tanks for Water

Use these tanks to accommodate the expansion of heated water and provide a cushion of compressed air in closed water-heating systems. They prevent water loss by eliminating the need to expel hot water from systems during each heating cycle.

Galvanized steel tanks are hot-dipped for maximum corrosion resistance.

For technical drawings and 3-D models, click on a part number.

--7c3c6a02a0d1610558279-p9@halfx_637461339024669794.png?ver=imagenotfound)

Tank Side Connection Pipe Size | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Dia. | Overall Lg. | Lg. (A) | Lg. (B) | Tank End Connection Pipe Size (E1) | (S1) | (S2) | Pipe Connection Thread Type | Pipe Connection Gender | Wall Gauge, ga. | Max. Temp., °F | Max. Pressure, psi | Expansion Tank Type | Each | |

| 8 | 9" | 32" | 5" | 11" | 3/4 | 1/2 | 1/2 | NPT | Female | 14 | 450° | 75 | Bladderless | 000000 | 0000000 |

| 15 | 12" | 30" | 4" | 11" | __ | 1/2 | 1/2 | NPT | Female | 14 | 450° | 75 | Bladderless | 000000 | 000000 |

| 18 | 12" | 36" | 4" | 14" | __ | 1/2 | 1/2 | NPT | Female | 14 | 450° | 75 | Bladderless | 000000 | 000000 |

--2f436187df31610558284-p9@halfx_637461338101519682.png?ver=imagenotfound)

-1610456742-p9@halfx_637460319512142470.png?ver=imagenotfound)

Tank End Connection Pipe Size | Tank Side Connection Pipe Size | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Dia. | Overall Lg. | Lg. (A) | Lg. (B) | Lg. (C) | (E1) | (E2) | (E3) | (S1) | (S2) | (S3) | Pipe Connection Thread Type | Pipe Connection Gender | Wall Gauge, ga. | Max. Temp., °F | Max. Pressure, psi | Expansion Tank Type | Each | |

| 8 | 12" | 19" | 4" | 4" | 8 13/16" | 1/2 | 1/2 | 2 | 1 1/4 | 1/2 | 1/2 | NPT | Female | 14 | 450° | 75 | Bladderless | 0000000 | 0000000 |

| 15 | 12" | 33" | 4" | 11" | 8 13/16" | 1/2 | 1/2 | 2 | 1 1/4 | 1/2 | 1/2 | NPT | Female | 14 | 450° | 75 | Bladderless | 0000000 | 000000 |

| 40 | 14" | 63" | 4" | 26" | 8 13/16" | 1/2 | 1/2 | 2 | 1 1/4 | 1/2 | 1/2 | NPT | Female | 14 | 450° | 75 | Bladderless | 0000000 | 000000 |

Tank Funnels

Pour liquids into tanks with a wide opening. A tab holds the funnel securely against tank openings, eliminating the need to hold the funnel while pouring. To easily transfer large quantities, these funnels have an extra-wide mouth. Ridges inside the funnel allow liquids to drain quickly and reduce splashing during pouring.

Optional lids keep out dust and other contaminants and help contain tank odors.

For technical drawings and 3-D models, click on a part number.

Water Baths

Heat samples in containers to a precise and uniform temperature. Unlike hot plates and burners, these water baths use indirect heat, so they’re a good option for warming chemicals and other substances that could ignite or burn.

Adjust the temperature in 0.1° increments on the digital display, which shows both the actual water temperature and the set temperature in either Fahrenheit or Celsius. An alarm signals when the temperature fluctuates above or below your set range.

Optional sloped lids give you extra vertical space to heat tall containers. They also divert condensation down the sides of the bath to prevent sample contamination.

Inside | Overall | Temp. Setting Range | Temp. Accuracy | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Ht. | Wd. | Dp. | Ht. | Wd. | Dp. | °F | °C | °F | °C | Wattage | Voltage | Tank Material | Housing Material | Plug Type | Cord Lg., ft. | Each | |

| 2.6 | 5 7/8" | 9 1/2" | 11 3/4" | 9 1/2" | 11 1/2" | 15 1/2" | 75° to 210° | 25° to 100° | ±0.4° | ±0.2° | 650 W | 120V AC | Stainless Steel | Powder-Coated Steel | Three Prong | 5 1/2 | 0000000 | 0000000 |

Overall | ||||||

|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Material | Features | Each | |

| 5 1/2" | 10 1/2" | 13" | Stainless Steel | Thermometer Hole | 0000000 | 0000000 |