Filter by

For Use With

Tube Material

Material

Cooling Capacity

Heat Sink Material

Overall Width

Power

U.S.–Mexico–Canada Agreement (USMCA) Qualifying

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Width

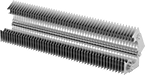

Clamp-On Heat Sinks for Pipe and Tube

Overall | 12" Overall Length | 24" Overall Length | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

For Copper Tube Size | For OD | Ht. | Wd. | Heat Sink Material | Cooling Cap., BTU/hr | Each | Cooling Cap., BTU/hr | Each | |||

| 1/2 | 5/8" | 2 1/8" | 2 1/8" | Aluminum | 430 | 0000000 | 000000 | 860 | 0000000 | 000000 | |

| 3/4 | 7/8" | 2 1/8" | 2 1/8" | Aluminum | 590 | 0000000 | 00000 | 1,100 | 0000000 | 00000 | |

| 1 | 1 1/8" | 2 1/8" | 2 1/8" | Aluminum | 1,600 | 0000000 | 00000 | 3,300 | 0000000 | 000000 | |

| 1 1/4 | 1 3/8" | 2 1/8" | 2 1/8" | Aluminum | 1,500 | 0000000 | 00000 | 3,000 | 0000000 | 000000 | |

Heat Pipes

Round

Pipes | Pipe Benders | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg., mm | Cooling Capacity (Installed Length) | Temp. Range, ° F | Material | Working Fluid | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Grooved Wick Heat Pipe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 200 | 100 BTU/hr (125 mm), 130 BTU/hr (100 mm), 90 BTU/hr (150 mm) | 90 to 245 | Copper | Water | 0000000 | 000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300 | 60 BTU/hr (200 mm), 90 BTU/hr (150 mm), 50 BTU/hr (250 mm) | 90 to 245 | Copper | Water | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 200 | 170 BTU/hr (125 mm), 210 BTU/hr (100 mm), 140 BTU/hr (150 mm) | 90 to 245 | Copper | Water | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300 | 130 BTU/hr (200 mm), 180 BTU/hr (150 mm), 100 BTU/hr (250 mm) | 90 to 245 | Copper | Water | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sintered Wick Heat Pipe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 210 BTU/hr (40 mm), 170 BTU/hr (50 mm), 140 BTU/hr (60 mm) | 90 to 245 | Copper | Water | 0000000 | 0000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 150 | 140 BTU/hr (60 mm), 110 BTU/hr (75 mm), 90 BTU/hr (90 mm) | 90 to 245 | Copper | Water | 0000000 | 0000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 200 | 100 BTU/hr (80 mm), 80 BTU/hr (100 mm), 70 BTU/hr (120 mm) | 90 to 245 | Copper | Water | 0000000 | 0000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 250 | 80 BTU/hr (100 mm), 60 BTU/hr (125 mm), 50 BTU/hr (150 mm) | 90 to 245 | Copper | Water | 0000000 | 0000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70 | 650 BTU/hr (28 mm), 520 BTU/hr (35 mm), 430 BTU/hr (42 mm) | 90 to 245 | Copper | Water | 0000000 | 0000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 450 BTU/hr (40 mm), 360 BTU/hr (50 mm), 300 BTU/hr (60 mm) | 90 to 245 | Copper | Water | 0000000 | 0000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 150 | 300 BTU/hr (60 mm), 240 BTU/hr (75 mm), 200 BTU/hr (90 mm) | 90 to 245 | Copper | Water | 0000000 | 0000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 250 | 180 BTU/hr (100 mm), 140 BTU/hr (125 mm), 120 BTU/hr (150 mm) | 90 to 245 | Copper | Water | 0000000 | 0000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 350 | 120 BTU/hr (140 mm), 100 BTU/hr (175 mm), 80 BTU/hr (210 mm) | 90 to 245 | Copper | Water | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70 | 940 BTU/hr (28 mm), 760 BTU/hr (35 mm), 630 BTU/hr (42 mm) | 90 to 245 | Copper | Water | 0000000 | 0000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 660 BTU/hr (40 mm), 530 BTU/hr (50 mm), 440 BTU/hr (60 mm) | 90 to 245 | Copper | Water | 0000000 | 0000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 150 | 440 BTU/hr (60 mm), 350 BTU/hr (75 mm), 290 BTU/hr (90 mm) | 90 to 245 | Copper | Water | 0000000 | 0000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 200 | 330 BTU/hr (80 mm), 260 BTU/hr (100 mm), 220 BTU/hr (120 mm) | 90 to 245 | Copper | Water | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 350 | 190 BTU/hr (140 mm), 150 BTU/hr (175 mm), 120 BTU/hr (210 mm) | 90 to 245 | Copper | Water | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

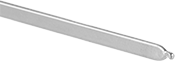

Flat

Lg., mm | Thk., mm | Cooling Capacity (Installed Length) | Temp. Range, ° F | Material | Working Fluid | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Sintered Wick Heat Pipe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5.1 mm Wide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70 | 2.5 | 160 BTU/hr (42 mm), 130 BTU/hr (53 mm), 110 BTU/hr (63 mm) | 90 to 245 | Copper | Water | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 2.5 | 110 BTU/hr (60 mm), 90 BTU/hr (75 mm), 70 BTU/hr (90 mm) | 90 to 245 | Copper | Water | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 150 | 2.5 | 70 BTU/hr (90 mm), 60 BTU/hr (113 mm), 50 BTU/hr (135 mm) | 90 to 245 | Copper | Water | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 200 | 2.5 | 50 BTU/hr (120 mm), 40 BTU/hr (150 mm), 30 BTU/hr (180 mm) | 90 to 245 | Copper | Water | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6.44 mm Wide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70 | 3 | 220 BTU/hr (42 mm), 170 BTU/hr (53 mm), 150 BTU/hr (63 mm) | 90 to 245 | Copper | Water | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 3 | 150 BTU/hr (60 mm), 120 BTU/hr (75 mm), 100 BTU/hr (90 mm) | 90 to 245 | Copper | Water | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 150 | 3 | 100 BTU/hr (90 mm), 80 BTU/hr (113 mm), 60 BTU/hr (135 mm) | 90 to 245 | Copper | Water | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 200 | 3 | 70 BTU/hr (120 mm), 60 BTU/hr (150 mm), 50 BTU/hr (180 mm) | 90 to 245 | Copper | Water | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

9.45 mm Wide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 75 | 5 | 380 BTU/hr (45 mm), 310 BTU/hr (56 mm), 250 BTU/hr (68 mm) | 90 to 245 | Copper | Water | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 150 | 5 | 190 BTU/hr (90 mm), 150 BTU/hr (113 mm), 120 BTU/hr (135 mm) | 90 to 245 | Copper | Water | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 200 | 5 | 140 BTU/hr (120 mm), 110 BTU/hr (150 mm), 90 BTU/hr (180 mm) | 90 to 245 | Copper | Water | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 350 | 5 | 80 BTU/hr (210 mm), 60 BTU/hr (263 mm), 50 BTU/hr (315 mm) | 90 to 245 | Copper | Water | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

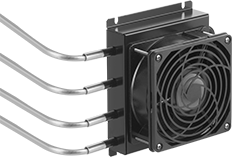

Heat Sinks for Water

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cooling Cap., BTU/hr | Gender | Ht. | Wd. | Dp. | Heat Sink Material | No. of Fans | Max. Pressure, psi | Max. Flow Rate, gpm | Max. Temp., ° F | Voltage (Electrical Phase) | Current, amp | Cord Lg., ft. | Mounting Slot Wd. | Tube OD | Choose a Fitting Connection | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Copper Tube—For Water | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,300 | Male | 6 9/16" | 6 3/4" | 2 13/16" | Copper | 1 | 150 | 2 | 400 | 120V AC (Single) | 0.16 | 2 | 3/16" | 3/8" | 37° Flared , Tube Stem | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,500 | Male | 5 3/4" | 6 1/2" | 3 5/8" | Copper | 1 | 150 | 2 | 400 | 120V AC (Single) | 0.16 | 2 | 7/32" | 3/8" | 37° Flared , Tube Stem | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2,200 | Male | 5 3/4" | 11 3/8" | 3 5/16" | Copper | 2 | 150 | 2 | 400 | 120V AC (Single) | 0.16 | 2 | 7/32" | 3/8" | 37° Flared , Tube Stem | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4,200 | Male | 9" | 9 11/16" | 4 1/2" | Copper | 1 | 150 | 2 | 400 | 120V AC (Single) | 0.25 | 2 | 7/32" | 3/8" | 37° Flared , Tube Stem | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4,400 | Male | 12" | 11 11/16" | 6 1/16" | Copper | 1 | 150 | 4 | 400 | 120V AC (Single) | 0.29 | 2 | 7/32" | 1/2" | 37° Flared , Tube Stem | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7,100 | Male | 9" | 17 11/16" | 4 1/2" | Copper | 2 | 150 | 2 | 400 | 120V AC (Single) | 0.25 | 2 | 7/32" | 3/8" | 37° Flared , Tube Stem | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8,800 | Male | 12" | 21 15/16" | 5 5/8" | Copper | 2 | 150 | 4 | 400 | 120V AC (Single) | 0.29 | 2 | 7/32" | 1/2" | 37° Flared , Tube Stem | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Tube—For Corrosive Liquids and Deionized Water | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,300 | Male | 6 9/16" | 7" | 2 13/16" | Stainless Steel | 1 | 150 | 2 | 400 | 120V AC (Single) | 0.16 | 2 | 3/16" | 3/8" | 37° Flared , Tube Stem | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,500 | Male | 5 13/16" | 6 1/8" | 3 11/16" | Stainless Steel | 1 | 150 | 2 | 400 | 120V AC (Single) | 0.16 | 2 | 3/16" | 3/8" | 37° Flared , Tube Stem | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2,200 | Male | 5 13/16" | 10 7/8" | 3 11/16" | Stainless Steel | 2 | 150 | 2 | 400 | 120V AC (Single) | 0.16 | 2 | 3/16" | 3/8" | Tube Stem | 000000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4,200 | Male | 9" | 9 3/16" | 4 13/16" | Stainless Steel | 1 | 150 | 2 | 400 | 120V AC (Single) | 0.25 | 2 | 3/16" | 3/8" | 37° Flared , Tube Stem | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4,400 | Male | 12" | 11 3/16" | 6 1/16" | Stainless Steel | 1 | 150 | 4 | 400 | 120V AC (Single) | 0.29 | 2 | 3/16" | 1/2" | Tube Stem | 000000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7,100 | Male | 9" | 17 3/16" | 4 1/2" | Stainless Steel | 2 | 150 | 2 | 400 | 120V AC (Single) | 0.25 | 2 | 3/16" | 3/8" | Tube Stem | 000000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8,800 | Male | 12" | 21 3/16" | 6 1/16" | Stainless Steel | 2 | 150 | 4 | 400 | 120V AC (Single) | 0.29 | 2 | 3/16" | 1/2" | Tube Stem | 000000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||