Rockwell Hardness Testing File Sets

Set includes six files and a chart to convert to Vickers scale. It is an economical way to determine the hardness of steel on the Rockwell C-scale. Handles are marked with Rockwell hardness values. If a file can scratch your material, then your material is softer than the file. If a file cannot scratch your material, then your material is harder than the file.

| Includes | Material | Tip Shape | Each | |

For Use On Steel | ||||

|---|---|---|---|---|

| Rockwell C40 File, Rockwell C45 File, Rockwell C50 File, Rockwell C55 File, Rockwell C60 File, Rockwell C65 File, Vickers Scale Conversion Chart | Steel | Curved | 00000000 | 0000000 |

Rockwell Hardness Testing Files

An economical way to determine the hardness of steel on the Rockwell C-scale. Handles are marked with Rockwell hardness values. If a file can scratch your material, then your material is softer than the file. If a file cannot scratch your material, then your material is harder than the file.

| For Rockwell Hardness Scale | Material | Tip Shape | Choose a Hardness | Each | |

For Use On Steel | |||||

|---|---|---|---|---|---|

| C | Steel | Curved | 00000000 | 000000 | |

Small Spot Rockwell Hardness Testers

A microscope measures the indentation made by a small diameter ball penetrator to provide a hardness reading.

Ball Indenter | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Rockwell Hardness Scale | Hardness Measuring Range | Accuracy | Ht. | Dia. | Material | Dia. | Batteries Included | Includes | Each | |

For Use On Alloy Steel | ||||||||||

| C | 20-65 | ±1.5 | 7 1/2" | 7/8" | Carbide | 1/16" | Yes | 60X Illuminated Microscope with Calibrated Scale | 0000000 | 000000000 |

Rockwell Hardness Calibration Test Blocks

Make sure your hardness testers are accurately calibrated. Blocks are marked with their corresponding Rockwell hardness and a serial number.

All blocks come with a calibration certificate traceable to NIST that states they've passed a test for accuracy.

| Hardness Scale | Accuracy | Ht. | Wd. | Dp. | Specifications Met | Choose a Hardness | Each | |

| C | ±5 | 1 1/2" | 2 1/2" | 1/4" | ASTM E18 | 00000000 | 0000000 |

Benchtop Rockwell Hardness Testers

Bring material right to your bench to measure its hardness. These testers use a carbide indenter to take accurate Rockwell hardness readings every time. They come with a calibration certificate traceable to NIST that states they’ve passed a test for accuracy. With a durable metal body, these testers stand up to many environments, from heat treat facilities to workshops to inspection labs. They show readings on a dial—no need to hook them up to a power source.

These testers come with indenters for different scales, three anvils, four test blocks, and a case to store accessories. Use the included cover to shield them from dust when they’re not in use.

Throat | Ball Indenter | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rockwell Hardness Scale | Hardness Measuring Range | Measuring Increments | Accuracy | Ht. | Wd. | Dp. | Ht. | Dp. | Dial Dia. | Material | Dia. | Includes | Specifications Met | Each | |

For Use On Aluminum, Brass, Bronze, Copper, Iron, Alloy Steel, Low-Carbon Steel, Steel, Titanium | |||||||||||||||

| A, B, C, D, F, G | 20-100 | 1 | ±1 | 30" | 8 1/2" | 20" | 6 5/8" | 6 1/2" | 4" | Carbide | 1/16" | C-Scale Diamond Indenter, Ball Indenter, Three Anvils (Two Flat, One V), Four Test Blocks, Storage Case | ASTM E18 | 0000000 | 000000000 |

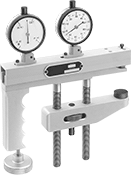

Portable Rockwell Hardness Testers

Test hardness right on your production floor. Unlike benchtop testers, these portable ones don’t require you to move large or hard-to-access parts. They use an indenter to measure the hardness of aluminum, brass, and steel. These testers can be used at any angle without affecting accuracy.

For heat-treated material harder than Rockwell C20, use the optional C-scale diamond indenter.

Throat | Ball Indenter | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rockwell Hardness Scale | Hardness Measuring Range | Measuring Increments | Accuracy | Ht. | Wd. | Dp. | Ht. | Dp. | Dial Dia. | Material | Dia. | Includes | Specifications Met | Each | |

For Use On Aluminum, Brass, Alloy Steel, Low-Carbon Steel | |||||||||||||||

| A, B, C, D, E, F, G, H, K | 0-100 | 1 | ±1.5 | 11" | 8" | 1 1/2" | 4 1/2" | 2 1/4" | 2 1/4" | Carbide | 1/16" | Three Anvils (Convex, V, Flat) | ASTM E110 | 0000000 | 000000000 |

| Optional C-Scale Diamond Indenter | 0000000 | Each | 0000000 |

Portable Digital Hardness Testers

Quickly test large parts or metal bar stock with our most precise hardness testers. These testers are portable and can be brought to facilities and jobsites to test items that are too large to move. While some hardness testers only work on one type of metal, these testers work on most metals. They have a rebound hammer that bounces back after impact—the distance it rebounds indicates the hardness of your surface. To obtain accurate readings, steel and other hard metals must be at least 1” thick and aluminum and other soft metals must be at least 3” thick.

Convert your measurements between Rockwell, Vickers, Brinell, or Shore hardness ratings. Your readings will show on a backlit digital display so you can test even in low light. Store up to 100 measurements with their built-in memory or transfer the data to your PC using the USB port.

Probe | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Hardness Measuring Range (For Scale) | Accuracy | Ht. | Wd. | Dia. | Cable Lg. | Min. Material Thick. | Batteries Included | Includes | Each | |

For Use On Aluminum, Brass, Bronze, Copper, Cast Iron, Iron, Alloy Steel, Stainless Steel, Steel | ||||||||||

| Brinell 93-650 Durometer 0-100 (A, D, OO) Leeb 100-950 (D) Rockwell 20-100 (B, C) Vickers 83-976 | ±0.5% | 1 1/4" | 2 7/8" | 3/32" | 58" | 1" | Yes | Carrying Case, Cleaning Brush, Test Block | 0000000 | 000000000 |

Ultrasonic Portable Hardness Testers

Using ultrasonic vibrations, these testers determine hardness without leaving an indent on hardened materials. They only leave minimal damage on softer metal and work on metal as thin as 0.08”. Use the included test block to determine the right amount of force to apply to your probe. To perform a test, press the diamond tip probe into your material and apply consistent pressure for reliable results. These testers are highly precise and convert measurements between Rockwell, Vickers, and Brinell ratings. Measurements are shown on a backlit digital display, so you can read them even in dark or dimly lit areas. Store up to 2,000 readings with their built-in memory or transfer the data to your PC using the USB port. Small enough to carry, take these testers to your material. Their lithium ion (Li-Ion) battery keeps them running for up to six hours before recharging is required. Energy efficiency requirements restrict sales to the listed areas.

NIST calibrated test blocks are included to help you understand how to properly press the probe to your material for an accurate result. The test blocks can also be used to recalibrate the device. These testers must be calibrated to the specific hardness scale and material being tested. They come pre-calibrated with five combinations: aluminum on the Rockwell B scale, brass on the Rockwell B scale, steel on the Rockwell C and B scales, and steel on the Brinell scale.

Probe | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hardness Measuring Range (For Scale) | Accuracy | Ht. | Wd. | Dia. | Cable Lg. | Min. Material Thick. | For Max. Surface Finish, microinch | Batteries Included | Battery Type | Includes | Cannot Be Sold To | Each | |

For Use On Aluminum, Brass, Bronze, Copper, Alloy Steel, Stainless Steel, Steel | |||||||||||||

| Brinell 75-650 Durometer 26-99 (OO) Leeb 170-960 (D) Rockwell 20-100 (A, B, C) Vickers 80-999 | ±3% | 7" | 3 1/8" | 7/8" | 58" | 0.08" | 400 | Yes | Rechargeable | 5 kgf Probe, Carrying Case, Test Block | CA, OR | 0000000 | 000000000 |