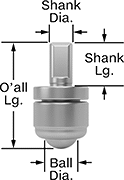

Ball Indenters for Brinell Hardness Tests

A key component of Brinell hardness testers, these ball indenters are hard enough to make impressions on most metal. Made of carbide, they won’t deform as they press into hard material. Shallow indentations mean a material is hard and deep indentations show that it is soft. Use the diameter of the indentations created by these balls as part of the calculation to find your material’s hardness rating. These ball indenters meet ISO 6506 and ASTM E10 standards for Brinell hardness testing. The shank diameter is a standard size for bench-top Brinell hardness testers.

2.5 mm diameter ball indenters are a good choice when testing material with limited space for measuring or material that is thin and may fracture under heavy loads. They make less contact when indenting your material surface than larger diameter indenters.

10 mm diameter ball indenters are the most commonly used and work well for testing soft material that might deform under heavy loads. They have a large contact area when indenting your material surface, so they distribute the applied load over a larger surface area than smaller diameter indenters. This means there is less stress and pressure at the indentation site.

For technical drawings and 3-D models, click on a part number.