Small Spot Rockwell Hardness Testers

A microscope measures the indentation made by a small diameter ball penetrator to provide a hardness reading.

Ball Indenter | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Rockwell Hardness Scale | Hardness Measuring Range | Accuracy | Ht. | Dia. | Material | Dia. | Batteries Included | Includes | Each | |

For Use On Alloy Steel | ||||||||||

| C | 20-65 | ±1.5 | 7 1/2" | 7/8" | Carbide | 1/16" | Yes | 60X Illuminated Microscope with Calibrated Scale | 0000000 | 000000000 |

Benchtop Rockwell Hardness Testers

Bring material right to your bench to measure its hardness. These testers use a carbide indenter to take accurate Rockwell hardness readings every time. They come with a calibration certificate traceable to NIST that states they’ve passed a test for accuracy. With a durable metal body, these testers stand up to many environments, from heat treat facilities to workshops to inspection labs. They show readings on a dial—no need to hook them up to a power source.

These testers come with indenters for different scales, three anvils, four test blocks, and a case to store accessories. Use the included cover to shield them from dust when they’re not in use.

Throat | Ball Indenter | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rockwell Hardness Scale | Hardness Measuring Range | Measuring Increments | Accuracy | Ht. | Wd. | Dp. | Ht. | Dp. | Dial Dia. | Material | Dia. | Includes | Specifications Met | Each | |

For Use On Aluminum, Brass, Bronze, Copper, Iron, Alloy Steel, Low-Carbon Steel, Steel, Titanium | |||||||||||||||

| A, B, C, D, F, G | 20-100 | 1 | ±1 | 30" | 8 1/2" | 20" | 6 5/8" | 6 1/2" | 4" | Carbide | 1/16" | C-Scale Diamond Indenter, Ball Indenter, Three Anvils (Two Flat, One V), Four Test Blocks, Storage Case | ASTM E18 | 0000000 | 000000000 |

Portable Rockwell Hardness Testers

Test hardness right on your production floor. Unlike benchtop testers, these portable ones don’t require you to move large or hard-to-access parts. They use an indenter to measure the hardness of aluminum, brass, and steel. These testers can be used at any angle without affecting accuracy.

For heat-treated material harder than Rockwell C20, use the optional C-scale diamond indenter.

Throat | Ball Indenter | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rockwell Hardness Scale | Hardness Measuring Range | Measuring Increments | Accuracy | Ht. | Wd. | Dp. | Ht. | Dp. | Dial Dia. | Material | Dia. | Includes | Specifications Met | Each | |

For Use On Aluminum, Brass, Alloy Steel, Low-Carbon Steel | |||||||||||||||

| A, B, C, D, E, F, G, H, K | 0-100 | 1 | ±1.5 | 11" | 8" | 1 1/2" | 4 1/2" | 2 1/4" | 2 1/4" | Carbide | 1/16" | Three Anvils (Convex, V, Flat) | ASTM E110 | 0000000 | 000000000 |

| Optional C-Scale Diamond Indenter | 0000000 | Each | 0000000 |

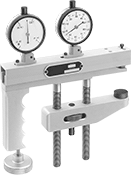

Pressure-Grip Rockwell Hardness Testers

Operate these testers with one hand. Squeeze the handles until the penetrator contacts the test material and a reading appears on the dial indicator.

Throat | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rockwell Hardness Scale | Hardness Measuring Range | Measuring Increments | Accuracy | Lg. | Ht. | Width | Ht. | Dp. | For Max. Material Thick. | Includes | Each | |

For Use On Aluminum, Brass, Low-Carbon Steel | ||||||||||||

| B | 20-100 | 4 | ±1 | 8" | 3" | 1" | 3/8" | 1" | 1/4" | Extra Indenter, Test Strip | 0000000 | 000000000 |

For Use On Aluminum | ||||||||||||

| E | 25-110 | 4.25 | ±1 | 8" | 3" | 1" | 3/8" | 1" | 1/4" | Extra Indenter, Test Strip | 0000000 | 00000000 |

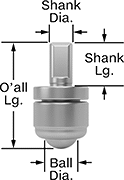

Ball Indenters for Brinell Hardness Tests

A key component of Brinell hardness testers, these ball indenters are hard enough to make impressions on most metal. Made of carbide, they won’t deform as they press into hard material. Shallow indentations mean a material is hard and deep indentations show that it is soft. Use the diameter of the indentations created by these balls as part of the calculation to find your material’s hardness rating. These ball indenters meet ISO 6506 and ASTM E10 standards for Brinell hardness testing. The shank diameter is a standard size for bench-top Brinell hardness testers.

2.5 mm diameter ball indenters are a good choice when testing material with limited space for measuring or material that is thin and may fracture under heavy loads. They make less contact when indenting your material surface than larger diameter indenters.

10 mm diameter ball indenters are the most commonly used and work well for testing soft material that might deform under heavy loads. They have a large contact area when indenting your material surface, so they distribute the applied load over a larger surface area than smaller diameter indenters. This means there is less stress and pressure at the indentation site.

For technical drawings and 3-D models, click on a part number.

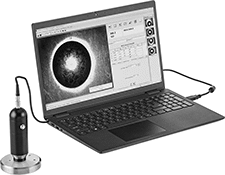

Digital Scopes for Brinell Hardness Testers

Finding your Brinell hardness doesn’t have to be so hard—these scopes scan and measure indents, then calculate the hardness for you. Accurate and efficient, these scopes replace the need for bulky microscopes and manually measuring and calculating hardness. Connect these scopes to your computer and use the included software to see a live image of the indent on your screen. You can zoom in 4X and adjust the focus to capture a wide range of indent diameters. To fine tune the automatic measurement, simply drag your cursor. Use the software to set test parameters, convert the value to other hardness scales, and validate the test results. The software also marks any measurements that fall out of your set specifications. When you’re finished, you can generate a customizable Microsoft Word or Excel report for your records.

| For Ball Indenter Dia., mm | Hardness Measuring Range | Focus Type | Camera Megapixels | Resolution | Number of Lenses | Ht. | Dia. | Housing Material | Computer Compatibility | Includes | Each | |

For Use On Aluminum, Brass, Bronze, Cast Iron, Iron, Alloy Steel, Stainless Steel, Steel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.8-6 | 8-650 | Adjustable | 1.3 | 0.0001 | 2 | 4 3/4" | 1 1/2" | Aluminum | PC | Carrying Case, One Calibrated Test Block, Software, USB Cable | 0000000 | 000000000 |

Portable Digital Hardness Testers

Quickly test large parts or metal bar stock with our most precise hardness testers. These testers are portable and can be brought to facilities and jobsites to test items that are too large to move. While some hardness testers only work on one type of metal, these testers work on most metals. They have a rebound hammer that bounces back after impact—the distance it rebounds indicates the hardness of your surface. To obtain accurate readings, steel and other hard metals must be at least 1” thick and aluminum and other soft metals must be at least 3” thick.

Convert your measurements between Rockwell, Vickers, Brinell, or Shore hardness ratings. Your readings will show on a backlit digital display so you can test even in low light. Store up to 100 measurements with their built-in memory or transfer the data to your PC using the USB port.

Probe | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Hardness Measuring Range (For Scale) | Accuracy | Ht. | Wd. | Dia. | Cable Lg. | Min. Material Thick. | Batteries Included | Includes | Each | |

For Use On Aluminum, Brass, Bronze, Copper, Cast Iron, Iron, Alloy Steel, Stainless Steel, Steel | ||||||||||

| Brinell 93-650 Durometer 0-100 (A, D, OO) Leeb 100-950 (D) Rockwell 20-100 (B, C) Vickers 83-976 | ±0.5% | 1 1/4" | 2 7/8" | 3/32" | 58" | 1" | Yes | Carrying Case, Cleaning Brush, Test Block | 0000000 | 000000000 |