About Carbon Steel, Alloy Steel, Spring Steel, and Cast Iron

More

About Shafts

More

Easy-to-Machine 1215 Carbon Steel Rods

- Yield Strength: 60,000 psi

- Hardness: Rockwell B85 (Medium)

- Heat Treatable: Yes

- Max. Hardness After Heat Treatment: Not Rated

- Fabrication: Cold Worked

- Specifications Met: ASTM A108

A lead-free alternative to 12L14, 1215 carbon steel contains the same amount of sulfur and phosphorus for excellent machinability. It’s often used for shaft couplings, studs, and pins. For added wear resistance, you can harden its surface with heat treating. These rods meet ASTM A108 standards for manufacturing processes and performance.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| Dia. | Dia. Tolerance | 1/2 ft. Lg. | 1 ft. Lg. | 2 ft. Lg. | 3 ft. Lg. | 4 ft. Lg. | 6 ft. Lg. | 8 ft. Lg. | 12 ft. Lg. | |

| 3/16" | -0.002" to 0" | 0000000 | ||||||||

| 1/4" | -0.002" to 0" | 0000000 | ||||||||

| 5/16" | -0.002" to 0" | 0000000 | ||||||||

| 3/8" | -0.002" to 0" | 0000000 | ||||||||

| 7/16" | -0.002" to 0" | 0000000 | ||||||||

| 1/2" | -0.002" to 0" | 0000000 | ||||||||

| 5/8" | -0.002" to 0" | 0000000 | ||||||||

| 3/4" | -0.002" to 0" | 0000000 | ||||||||

| 7/8" | -0.002" to 0" | 0000000 | ||||||||

| 1" | -0.002" to 0" | 0000000 | ||||||||

| 1 1/8" | -0.002" to 0" | 0000000 | ||||||||

| 1 1/4" | -0.002" to 0" | 0000000 | ||||||||

| 1 3/8" | -0.002" to 0" | 0000000 | ||||||||

| 1 1/2" | -0.002" to 0" | 0000000 | ||||||||

| 1 3/4" | -0.003" to 0" | 0000000 | ||||||||

| 2" | -0.003" to 0" | 0000000 | ||||||||

| 2 1/2" | -0.003" to 0" | 0000000 | ||||||||

| 3" | -0.004" to 0" | 0000000 | ||||||||

| 3 1/2" | -0.004" to 0" | 0000000 | ||||||||

| 4" | -0.004" to 0" | 0000000 | ||||||||

| 6mm | -0.013mm to 0mm | 0000000 | ||||||||

| 8mm | -0.013mm to 0mm | 0000000 | ||||||||

| 10mm | -0.013mm to 0mm | 0000000 | ||||||||

| 12mm | -0.013mm to 0mm | 0000000 | ||||||||

| 15mm | -0.013mm to 0mm | 0000000 | ||||||||

| 20mm | -0.013mm to 0mm | 0000000 | ||||||||

| 25mm | -0.013mm to 0mm | 0000000 | ||||||||

| 30mm | -0.013mm to 0mm | 0000000 |

Tight-Tolerance Easy-to-Machine 1215 Carbon Steel Rods

- Yield Strength: Not Rated

- Hardness: Not Rated

- Heat Treatable: Yes

- Max. Hardness After Heat Treatment: Not Rated

- Specifications Met: ASTM A108

Precision ground and held to a strict tightness tolerance, these rods are ready for turning in a lathe. A lead-free alternative to 12L14, 1215 carbon steel contains the same amount of sulfur and phosphorus for excellent machinability. It is often used for shaft couplings, studs, and pins.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Easy-to-Machine 1215 Carbon Steel Bars

- Yield Strength: 60,000 psi

- Hardness: Rockwell B85 (Medium)

- Heat Treatable: Yes

- Max. Hardness After Heat Treatment: Not Rated

- Fabrication: Cold Worked

- Specifications Met: ASTM A108

A lead-free alternative to 12L14, 1215 carbon steel contains the same amount of sulfur and phosphorus for excellent machinability. It’s often used for jigs and fixtures. For added wear resistance, it can be surface hardened with heat treating. These bars have been manufactured to meet ASTM A108 standards for quality and performance.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| Thick. | Thick. Tolerance | Wd. | 1/2 ft. Lg. | 1 ft. Lg. | 2 ft. Lg. | 3 ft. Lg. | 4 ft. Lg. | 6 ft. Lg. | 8 ft. Lg. | |

| 1/2" | -0.002" to 0" | 1/2" | 0000000 | |||||||

| 5/8" | -0.002" to 0" | 5/8" | 0000000 | |||||||

| 3/4" | -0.002" to 0" | 3/4" | 0000000 | |||||||

| 1" | -0.003" to 0" | 1" | 0000000 | |||||||

| 1 1/4" | -0.003" to 0" | 1 1/4" | 0000000 | |||||||

| 1 1/2" | -0.003" to 0" | 1 1/2" | 0000000 | |||||||

| 1 3/4" | -0.004" to 0" | 1 3/4" | 0000000 | |||||||

| 2" | -0.004" to 0" | 2" | 0000000 | |||||||

| 2 1/2" | -0.004" to 0" | 2 1/2" | 0000000 |

Easy-to-Machine 1215 Carbon Steel Hex Bars

- Yield Strength: 60,000 psi

- Hardness: Rockwell B85 (Medium)

- Heat Treatable: Yes

- Max. Hardness After Heat Treatment: Not Rated

- Specifications Met: ASTM A108

A lead-free alternative to 12L14, 1215 carbon steel contains the same amount of sulfur and phosphorus for excellent machinability. It is often used for shaft couplings, studs, and pins.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| Wd. | Wd. Tolerance | 1 ft. Lg. | 3 ft. Lg. | 6 ft. Lg. | |

| 1/4" | -0.002" to 0" | 0000000 | |||

| 3/8" | -0.002" to 0" | 0000000 | |||

| 1/2" | -0.002" to 0" | 0000000 | |||

| 5/8" | -0.002" to 0" | 0000000 | |||

| 11/16" | -0.002" to 0" | 0000000 | |||

| 3/4" | -0.002" to 0" | 0000000 | |||

| 13/16" | -0.003" to 0" | 0000000 | |||

| 7/8" | -0.003" to 0" | 0000000 | |||

| 15/16" | -0.003" to 0" | 0000000 | |||

| 1" | -0.003" to 0" | 0000000 | |||

| 1 1/2" | -0.003" to 0" | 0000000 | |||

| 2" | -0.004" to 0" | 0000000 | |||

| 2 1/2" | -0.004" to 0" | 0000000 | |||

| 3" | -0.005" to 0" | 0000000 |

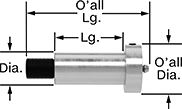

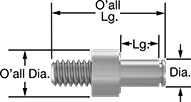

Thread-Mount Idler Rotary Shafts

Thread these shafts into a tapped hole to support idler sprockets and pulleys in tensioning applications.

Shafts with a shaft collar come with a grease fitting for easy lubrication of your pulleys and sprockets. Adjust the collar to the width of your component.

Shafts with retaining ring grooves come with a retaining ring and spacers to position your component and hold it in place.

For technical drawings and 3-D models, click on a part number.

Overall | Thread | Groove | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Lg. | Lg. | Dia. | Size | Pitch | Lg. | Wd. | Dia. | End-to-Groove Lg. | Edge Type | Fabrication | Hardness Rating | Hardness | Each | |

Inch with Shaft Collar—1215 Carbon Steel | |||||||||||||||

| 1/2" | 1 1/16" | 2 9/32" | 1" | 3/8"-16 | __ | 7/16" | __ | __ | __ | Chamfered | Hardened | Very Hard | Rockwell C58 | 00000000 | 000000 |

| 5/8" | 1 1/4" | 3 3/8" | 1 1/8" | 1/2"-20 | __ | 7/8" | __ | __ | __ | Chamfered | Hardened | Very Hard | Rockwell C58 | 00000000 | 00000 |

| 3/4" | 2 7/16" | 4 3/8" | 1 1/4" | 1/2"-20 | __ | 7/8" | __ | __ | __ | Chamfered | Hardened | Very Hard | Rockwell C58 | 00000000 | 00000 |

| 1" | 1 1/2" | 3 3/8" | 1 1/2" | 3/4"-16 | __ | 7/8" | __ | __ | __ | Chamfered | Hardened | Very Hard | Rockwell C58 | 000000 | 00000 |

| 1" | 2 1/2" | 4 3/8" | 1 1/2" | 3/4"-16 | __ | 7/8" | __ | __ | __ | Chamfered | Hardened | Very Hard | Rockwell C58 | 000000 | 00000 |

| 1" | 3 1/2" | 5 3/8" | 1 1/2" | 3/4"-16 | __ | 7/8" | __ | __ | __ | Chamfered | Hardened | Very Hard | Rockwell C58 | 000000 | 00000 |

| 1 1/2" | 3 1/4" | 5 11/16" | 2 1/4" | 1"-14 | __ | 1 5/16" | __ | __ | __ | Chamfered | Hardened | Very Hard | Rockwell C58 | 00000000 | 00000 |

| 1 1/2" | 5 1/4" | 7 11/16" | 2 1/4" | 1"-14 | __ | 1 5/16" | __ | __ | __ | Chamfered | Hardened | Very Hard | Rockwell C58 | 00000000 | 00000 |

Inch with Retaining Ring Grooves—Zinc-Plated 1215 Carbon Steel | |||||||||||||||

| 1/4" | 3/8" | 1 1/16" | 1/2" | 1/4"-20 | __ | 21/64" | 0.029" | 0.21" | 0.063" | Chamfered | __ | Not Rated | Not Rated | 000000 | 0000 |

| 3/8" | 7/16" | 1 7/32" | 3/4" | 1/4"-20 | __ | 11/32" | 0.039" | 0.303" | 0.125" | Chamfered | __ | Not Rated | Not Rated | 000000 | 00000 |

| 1/2" | 5/8" | 1 9/16" | 1" | 5/16"-18 | __ | 1/2" | 0.046" | 0.396" | 0.125" | Chamfered | __ | Not Rated | Not Rated | 000000 | 00000 |

| 5/8" | 5/8" | 1 19/32" | 1 1/8" | 5/16"-18 | __ | 17/32" | 0.046" | 0.485" | 0.125" | Chamfered | __ | Not Rated | Not Rated | 000000 | 00000 |

| 3/4" | 5/8" | 1 25/32" | 1 1/4" | 3/8"-16 | __ | 45/64" | 0.056" | 0.58" | 0.125" | Chamfered | __ | Not Rated | Not Rated | 000000 | 00000 |

| 1" | 5/8" | 2" | 1 1/2" | 1/2"-13 | __ | 15/16" | 0.056" | 0.835" | 0.125" | Chamfered | __ | Not Rated | Not Rated | 000000 | 00000 |

Metric with Retaining Ring Grooves—Zinc-Plated 1215 Carbon Steel | |||||||||||||||

| 8mm | 9mm | 28mm | 15mm | M6 | 1 mm | 8mm | 0.733mm | 6.35mm | 2.56mm | Chamfered | __ | Medium | Rockwell B84 | 0000000 | 0000 |

| 10mm | 11mm | 34mm | 19mm | M8 | 1.25 mm | 10.66mm | 0.99mm | 7.69mm | 3.12mm | Chamfered | __ | Medium | Rockwell B84 | 0000000 | 00000 |

| 12mm | 12mm | 35mm | 22mm | M8 | 1.25 mm | 10.66mm | 0.99mm | 8.71mm | 3.12mm | Chamfered | __ | Medium | Rockwell B84 | 0000000 | 00000 |

| 20mm | 15mm | 45mm | 31mm | M12 | 1.75 mm | 16mm | 1.422mm | 14.73mm | 4.06mm | Chamfered | __ | Medium | Rockwell B84 | 0000000 | 00000 |

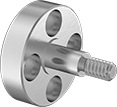

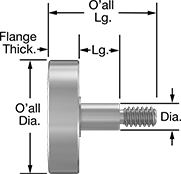

Flange-Mount Idler Rotary Shafts

Mount the flange to a machine or wall to support idler sprockets and pulleys in tensioning applications. They include washers and a nut to position your component and hold it in place.

For technical drawings and 3-D models, click on a part number.

Overall | Thread | Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Lg. | Lg. | Dia. | Size | Pitch | Lg. | Flange Thick. | Bolt Circle Dia. | No. of | Dia. | Edge Type | Hardness Rating | Hardness | Each | |

Inch—Zinc-Plated 1215 Carbon Steel | |||||||||||||||

| 1/4" | 3/8" | 1" | 1 1/16" | 10-24 | __ | 11/32" | 9/32" | 23/32" | 4 | 5/32" | Straight | Not Rated | Not Rated | 0000000 | 000000 |

| 3/8" | 7/16" | 1 3/16" | 1 1/4" | 5/16"-18 | __ | 15/32" | 9/32" | 29/32" | 4 | 5/32" | Straight | Not Rated | Not Rated | 0000000 | 00000 |

| 1/2" | 5/8" | 1 1/2" | 1 7/16" | 7/16"-14 | __ | 19/32" | 9/32" | 1 3/32" | 4 | 5/32" | Straight | Not Rated | Not Rated | 0000000 | 00000 |

| 5/8" | 5/8" | 1 21/32" | 1 5/8" | 1/2"-13 | __ | 23/32" | 5/16" | 1 1/4" | 4 | 5/32" | Straight | Not Rated | Not Rated | 0000000 | 00000 |

| 3/4" | 5/8" | 1 27/32" | 1 7/8" | 5/8"-11 | __ | 7/8" | 11/32" | 1 7/16" | 4 | 3/16" | Straight | Not Rated | Not Rated | 0000000 | 00000 |

| 1" | 5/8" | 2 1/8" | 2 1/4" | 7/8"-9 | __ | 1 3/32" | 13/32" | 1 3/4" | 4 | 1/4" | Straight | Not Rated | Not Rated | 0000000 | 00000 |

Metric—Zinc-Plated 1215 Carbon Steel | |||||||||||||||

| 8mm | 9mm | 24mm | 28mm | M6 | 1 mm | 6.6mm | 7mm | 20mm | 4 | 3mm | Straight | Medium | Rockwell B84 | 0000000 | 00000 |

| 10mm | 11mm | 28mm | 30mm | M8 | 1.25 mm | 8.26mm | 7mm | 22mm | 4 | 3mm | Straight | Medium | Rockwell B84 | 0000000 | 00000 |

| 12mm | 12mm | 33mm | 36mm | M10 | 1.5 mm | 9.9mm | 9mm | 26mm | 4 | 4mm | Straight | Medium | Rockwell B84 | 0000000 | 00000 |

| 20mm | 15mm | 46mm | 50mm | M18 | 2.5 mm | 16.56mm | 11mm | 36mm | 4 | 6mm | Straight | Medium | Rockwell B84 | 0000000 | 00000 |

Splined Rotary Shafts

Good for hydraulic systems, machine tools, and other high-torque applications, these shafts have teeth that transmit high rotational loads. Compared to keyed shafts, they last longer and handle higher torque. They’re also better than keyed shafts for applications requiring frequent disassembly or adjustments because you can move bushings along their splines.

Parallel splines have large, straight-sided teeth that resemble machine keys and transmit more torque than involute spline teeth. These splines are known as straight splines.

Involute splines have curved teeth, similar to the teeth on a gear. These teeth make more contact with a bushing than the teeth on parallel splines, so these splines are less prone to wear. They handle misalignment and reduce vibration.

Bushings act as a surface to transmit rotary motion or to position a load along the length of the shaft. If welded into place, these bushings can act as a coupler, connecting two splined shafts.

For technical drawings and 3-D models, click on a part number.

Shafts | Sleeve Bushings | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Spline Lg. | No. of Splines | Lg. | Edge Type | Hardness Rating | Hardness | Each | Each | ||

Inch—1215 Carbon Steel | ||||||||||

| 1" | 10" | 6 | 10" | Chamfered | Not Rated | Not Rated | 0000000 | 0000000 | 0000000 | 000000 |

| 1 1/8" | 10" | 6 | 10" | Chamfered | Not Rated | Not Rated | 0000000 | 000000 | 0000000 | 00000 |

| 1 1/4" | 10" | 6 | 10" | Chamfered | Not Rated | Not Rated | 0000000 | 000000 | 0000000 | 000000 |

| 1 1/4" | 10" | 10 | 10" | Chamfered | Not Rated | Not Rated | 0000000 | 000000 | 0000000 | 000000 |

| 1 3/8" | 10" | 6 | 10" | Chamfered | Not Rated | Not Rated | 0000000 | 000000 | 0000000 | 00000 |

| 1 1/2" | 10" | 6 | 10" | Chamfered | Not Rated | Not Rated | 0000000 | 000000 | 0000000 | 000000 |

| 1 5/8" | 10" | 6 | 10" | Chamfered | Not Rated | Not Rated | 0000000 | 000000 | 0000000 | 000000 |

| 1 3/4" | 10" | 6 | 10" | Chamfered | Not Rated | Not Rated | 0000000 | 000000 | 0000000 | 000000 |

Shafts | Sleeve Bushings | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Spline Lg. | No. of Splines | Lg. | Pitch | Pressure Angle | Edge Type | Hardness Rating | Hardness | Each | Each | ||

Inch—1215 Carbon Steel | ||||||||||||

| 5/8" | 6" | 9 | 6" | 0.563" | 30° | Chamfered | Not Rated | Not Rated | 0000000 | 0000000 | 0000000 | 000000 |

| 7/8" | 6" | 13 | 6" | 0.813" | 30° | Chamfered | Not Rated | Not Rated | 0000000 | 000000 | 0000000 | 000000 |

| 1" | 8" | 15 | 8" | 0.938" | 30° | Chamfered | Not Rated | Not Rated | 0000000 | 000000 | 0000000 | 000000 |

| 1 1/4" | 10" | 14 | 10" | 1.167" | 30° | Chamfered | Not Rated | Not Rated | 0000000 | 000000 | 0000000 | 000000 |

| 1 3/8" | 10" | 21 | 10" | 1.313" | 30° | Chamfered | Not Rated | Not Rated | 0000000 | 000000 | 0000000 | 000000 |

| 1 3/4" | 10" | 13 | 10" | 1.625" | 30° | Chamfered | Not Rated | Not Rated | 0000000 | 000000 | 0000000 | 000000 |

| 1 3/4" | 10" | 27 | 10" | 1.688" | 30° | Chamfered | Not Rated | Not Rated | 0000000 | 000000 | 0000000 | 000000 |