Eyebolts—For Lifting

Zinc-plated steel eyebolts offer good corrosion resistance.

Galvanized steel eyebolts have a hot-dipped finish for more corrosion resistance than zinc-plated steel.

Note: Capacities listed are for vertical lifting only. Eyebolts with shoulder can be used for angular lifting up to 45°, but the capacities will be significantly reduced. For angular lifting, we recommend Hoist Rings.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Thread | With Shoulder | ||||||||

|---|---|---|---|---|---|---|---|---|---|

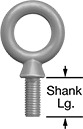

| Size | Pitch, mm | Lg., mm | Shank Lg., mm | Overall Lg., mm | Eye Dia., mm | Vertical Capacity, lbs. | Specifications Met | Each | |

Steel | |||||||||

| M6 | 1 | 12 | 12 | 46 | 19 | 450 | __ | 0000000 | 00000 |

| M7 | 1 | 14 | 14 | 56 | 22 | 800 | __ | 0000000 | 0000 |

| M8 | 1.25 | 16 | 16 | 64 | 25 | 1,100 | __ | 0000000 | 0000 |

| M8 | 1.25 | 76 | 76 | 129 | 25 | 975 | __ | 0000000 | 00000 |

| M10 | 1.5 | 20 | 20 | 75 | 27 | 1,600 | __ | 0000000 | 0000 |

| M12 | 1.75 | 24 | 24 | 86 | 30 | 2,250 | __ | 0000000 | 0000 |

| M12 | 1.75 | 76 | 76 | 138 | 30 | 2,250 | __ | 0000000 | 00000 |

| M14 | 2 | 28 | 28 | 104 | 33 | 3,500 | __ | 0000000 | 00000 |

| M16 | 2 | 32 | 32 | 108 | 35 | 3,500 | __ | 0000000 | 00000 |

| M16 | 2 | 76 | 76 | 151 | 35 | 3,500 | __ | 0000000 | 00000 |

| M18 | 2.5 | 36 | 36 | 118 | 38 | 4,700 | __ | 0000000 | 00000 |

| M18 | 2.5 | 76 | 76 | 158 | 38 | 4,700 | __ | 0000000 | 00000 |

| M20 | 2.5 | 40 | 40 | 135 | 41 | 6,275 | __ | 0000000 | 00000 |

| M24 | 3 | 48 | 48 | 152 | 46 | 8,450 | __ | 0000000 | 00000 |

| M27 | 3 | 48 | 48 | 169 | 51 | 11,425 | __ | 0000000 | 00000 |

| M30 | 3.5 | 60 | 60 | 192 | 55 | 14,075 | __ | 0000000 | 00000 |

| M36 | 4 | 72 | 72 | 223 | 63 | 19,725 | __ | 0000000 | 00000 |

| M42 | 4.5 | 84 | 84 | 263 | 73 | 26,300 | __ | 0000000 | 000000 |

| M48 | 5 | 96 | 96 | 296 | 82 | 36,075 | __ | 0000000 | 000000 |

Zinc-Plated Steel | |||||||||

| M6 | 1 | 13 | 13 | 49 | 19 | 150 | DIN 580 | 0000000 | 0000 |

| M8 | 1.25 | 13 | 13 | 49 | 20 | 300 | DIN 580 | 0000000 | 0000 |

| M10 | 1.5 | 17 | 17 | 62 | 25 | 500 | DIN 580 | 0000000 | 0000 |

| M12 | 1.75 | 21 | 21 | 73 | 30 | 725 | DIN 580 | 0000000 | 0000 |

| M16 | 2 | 27 | 27 | 89 | 35 | 1,525 | DIN 580 | 0000000 | 00000 |

| M20 | 2.5 | 30 | 30 | 101 | 40 | 2,625 | DIN 580 | 0000000 | 00000 |

| M24 | 3 | 36 | 36 | 126 | 50 | 3,950 | DIN 580 | 0000000 | 00000 |

| M30 | 3.5 | 45 | 45 | 154 | 60 | 7,050 | DIN 580 | 0000000 | 00000 |

| M36 | 4 | 54 | 54 | 182 | 70 | 10,125 | DIN 580 | 0000000 | 00000 |

| M42 | 4.5 | 63 | 63 | 210 | 80 | 13,875 | DIN 580 | 0000000 | 000000 |

| M48 | 5 | 68 | 68 | 236 | 90 | 18,950 | DIN 580 | 0000000 | 000000 |

Galvanized Steel | |||||||||

| M6 | 1 | 26 | 26 | 60 | 19 | 450 | __ | 0000000 | 0000 |

| M7 | 1 | 29 | 29 | 70 | 22 | 800 | __ | 0000000 | 0000 |

| M8 | 1.25 | 32 | 32 | 83 | 25 | 975 | __ | 0000000 | 0000 |

| M10 | 1.5 | 35 | 35 | 92 | 28 | 1,625 | __ | 0000000 | 0000 |

| M12 | 1.75 | 38 | 38 | 102 | 30 | 2,250 | __ | 0000000 | 0000 |

| M14 | 2 | 45 | 45 | 121 | 35 | 3,500 | __ | 0000000 | 00000 |

| M16 | 2 | 45 | 45 | 121 | 35 | 3,500 | __ | 0000000 | 00000 |

| M18 | 2.5 | 51 | 51 | 133 | 38 | 4,700 | __ | 0000000 | 00000 |

| M20 | 2.5 | 57 | 57 | 152 | 43 | 6,275 | __ | 0000000 | 00000 |

| M24 | 3 | 64 | 64 | 170 | 46 | 8,450 | __ | 0000000 | 00000 |

| M27 | 3 | 70 | 70 | 191 | 51 | 11,425 | __ | 0000000 | 00000 |

| M30 | 3.5 | 76 | 76 | 210 | 55 | 14,075 | __ | 0000000 | 00000 |

| M36 | 4 | 89 | 89 | 241 | 63 | 19,725 | __ | 0000000 | 00000 |

Rotating Eyebolts—For Lifting

Unlike conventional eyebolts, you can rotate the eye 360° to match the angle of your load.

Powder-coated steel eyebolts are impact resistant, but less corrosion resistant than stainless steel eyebolts. They include a removable key for tightening the bolt.

Stainless steel eyebolts are more corrosion resistant than powder-coated steel eyebolts.

Note: Capacities listed are for vertical lifting only. Eyebolts with shoulder can be used for angular lifting up to 45°, but the capacities will be significantly reduced. For angular lifting, we recommend Hoist Rings.

Warning: Never use to lift people or items over people.

Thread | With Shoulder | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Lg., mm | Shank Lg., mm | Overall Lg., mm | Eye Dia., mm | Vertical Capacity, lbs. | Color | Each | |

Powder-Coated Steel | |||||||||

| M6 | 1 | 9 | 9 | 46 | 20 | 200 | Pink | 00000000 | 000000 |

| M8 | 1.25 | 12 | 12 | 58 | 25 | 650 | Pink | 00000000 | 00000 |

| M10 | 1.5 | 15 | 15 | 61 | 25 | 850 | Pink | 00000000 | 00000 |

| M12 | 1.75 | 18 | 18 | 73 | 30 | 1,650 | Pink | 0000000 | 00000 |

| M14 | 2 | 18 | 18 | 73 | 30 | 1,650 | Pink | 00000000 | 000000 |

| M16 | 2 | 24 | 24 | 88 | 35 | 3,300 | Pink | 0000000 | 000000 |

| M18 | 2.5 | 24 | 24 | 88 | 35 | 3,300 | Pink | 00000000 | 000000 |

| M20 | 2.5 | 30 | 30 | 104 | 40 | 5,050 | Pink | 0000000 | 000000 |

| M24 | 3 | 36 | 36 | 127 | 48 | 7,050 | Pink | 0000000 | 000000 |

| M27 | 3 | 36 | 36 | 126 | 49 | 7,050 | Pink | 00000000 | 000000 |

| M30 | 3.5 | 45 | 45 | 158 | 60 | 9,900 | Pink | 00000000 | 000000 |

| M36 | 4 | 54 | 54 | 190 | 73 | 15,400 | Pink | 00000000 | 000000 |

| M48 | 5 | 72 | 72 | 252 | 96 | 26,450 | Pink | 00000000 | 000000 |

Stainless Steel | |||||||||

| M12 | 1.75 | 18 | 18 | 75 | 30 | 1,100 | Gray | 00000000 | 000000 |

| M16 | 2 | 9 | 24 | 90 | 35 | 2,200 | Gray | 00000000 | 000000 |

Nylon-Coated Eyebolts—For Lifting

Route wire and cable through the smooth eye without snagging.

Note: Capacities listed are for vertical lifting only. Eyebolts with shoulder can be used for angular lifting up to 45°, but the capacities will be significantly reduced. For angular lifting, we recommend Hoist Rings.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Thread | With Shoulder | |||||||

|---|---|---|---|---|---|---|---|---|

| Size | Lg. | Shank Lg. | Eye Dia. | Vertical Capacity, lbs. | Temperature Range, °F | Overall Lg. | Each | |

Nylon-Coated Steel | ||||||||

| 7/16"-14 | 1 3/8" | 1 3/8" | 1 1/16" | 2,000 | 30° to 275° | 3 5/8" | 0000000 | 000000 |

| 9/16"-12 | 1 5/8" | 1 5/8" | 1 1/4" | 3,200 | 30° to 275° | 4 1/2" | 0000000 | 00000 |

| 7/8"-9 | 2 1/4" | 2 1/4" | 1 11/16" | 7,000 | 30° to 275° | 6" | 0000000 | 00000 |

| 1"-8 | 2 1/2" | 2 1/2" | 1 13/16" | 9,000 | 30° to 275° | 7" | 0000000 | 00000 |

Thread | With Shoulder | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Lg., mm | Shank Lg., mm | Eye Dia., mm | Vertical Capacity, lbs. | Temperature Range, °F | Overall Lg., mm | Each | |

Nylon-Coated Steel | |||||||||

| M6 | 1 | 12 | 12 | 19 | 450 | 30° to 275° | 47 | 0000000 | 000000 |

| M8 | 1.25 | 12 | 12 | 25 | 450 | 30° to 275° | 61 | 0000000 | 00000 |

| M10 | 1.5 | 20 | 20 | 28 | 1,625 | 30° to 275° | 75 | 0000000 | 00000 |

| M12 | 1.75 | 24 | 24 | 30 | 2,250 | 30° to 275° | 85 | 0000000 | 00000 |

| M12 | 1.75 | 76 | 76 | 30 | 2,250 | 30° to 275° | 137 | 0000000 | 00000 |

| M14 | 2 | 28 | 28 | 35 | 3,500 | 30° to 275° | 103 | 0000000 | 00000 |

| M16 | 2 | 32 | 32 | 35 | 3,500 | 30° to 275° | 106 | 0000000 | 00000 |

| M18 | 2.5 | 36 | 36 | 38 | 4,700 | 30° to 275° | 117 | 0000000 | 00000 |

| M20 | 2.5 | 40 | 40 | 43 | 6,275 | 30° to 275° | 135 | 0000000 | 00000 |

| M24 | 3 | 48 | 48 | 46 | 8,450 | 30° to 275° | 153 | 0000000 | 00000 |

| M30 | 3.5 | 60 | 60 | 55 | 14,075 | 30° to 275° | 194 | 0000000 | 00000 |

Eye Nuts—For Lifting

Create your own lifting eye by adding an eye nut to a stud or bolt.

Zinc-plated steel eye nuts offer good corrosion resistance.

Galvanized steel eye nuts have a hot-dipped finish for more corrosion resistance than zinc-plated steel.

Note: Capacity applies to the eye nut only. The stud or bolt you use will affect the overall capacity. Eye nuts are for vertical lifting only.

Warning: Never use to lift people or items over people.

Thread | ||||||||

|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Overall Lg., mm | Eye Dia., mm | Vertical Capacity, lbs. | Specifications Met | Each | ||

Steel | ||||||||

| B | M8 | 1.25 | 57 | 22 | 1,100 | __ | 0000000 | 000000 |

| B | M12 | 1.75 | 76 | 28 | 2,300 | __ | 0000000 | 00000 |

| B | M16 | 2 | 95 | 35 | 3,700 | __ | 0000000 | 00000 |

| B | M18 | 2.5 | 98 | 38 | 6,000 | __ | 0000000 | 00000 |

| B | M20 | 2.5 | 100 | 41 | 7,600 | __ | 0000000 | 00000 |

| B | M24 | 3 | 120 | 44 | 11,000 | __ | 0000000 | 00000 |

| B | M30 | 3.5 | 139 | 50 | 14,000 | __ | 0000000 | 000000 |

| B | M36 | 4 | 165 | 63 | 19,000 | __ | 0000000 | 000000 |

Zinc-Plated Steel | ||||||||

| A | M6 | 1 | 36 | 20 | 150 | DIN 582 | 0000000 | 0000 |

| A | M8 | 1.25 | 36 | 20 | 300 | DIN 582 | 0000000 | 0000 |

| A | M10 | 1.5 | 45 | 25 | 500 | DIN 582 | 0000000 | 0000 |

| A | M12 | 1.75 | 53 | 30 | 725 | DIN 582 | 0000000 | 00000 |

| A | M16 | 2 | 62 | 35 | 1,525 | DIN 582 | 0000000 | 00000 |

| A | M20 | 2.5 | 71 | 40 | 2,625 | DIN 582 | 0000000 | 00000 |

| A | M24 | 3 | 90 | 50 | 3,950 | DIN 582 | 0000000 | 00000 |

| A | M30 | 3.5 | 109 | 60 | 7,050 | DIN 582 | 0000000 | 00000 |

Galvanized Steel | ||||||||

| C | M6 | 1 | 43 | 19 | 350 | __ | 0000000 | 00000 |

| C | M8 | 1.25 | 52 | 25 | 650 | __ | 0000000 | 00000 |

| C | M10 | 1.5 | 64 | 31 | 800 | __ | 0000000 | 00000 |

| C | M12 | 1.75 | 64 | 31 | 1,700 | __ | 0000000 | 00000 |

| C | M16 | 2 | 81 | 38 | 2,500 | __ | 0000000 | 00000 |

| C | M20 | 2.5 | 110 | 50 | 3,500 | __ | 0000000 | 00000 |

| C | M24 | 3 | 110 | 50 | 5,000 | __ | 0000000 | 00000 |