About Roller Chain and Sprockets

More

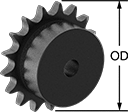

Sprockets for Metric Roller Chain

Designed to meet ISO 606 and DIN 8187 international dimensional standards, these sprockets are for use with compatible ISO and DIN roller chain. They come machined to the shaft diameter size listed and are machinable up to the maximum shaft diameter size.

For technical drawings and 3-D models, click on a part number.

| Number of Teeth | For Shaft Dia., mm | For Max. Shaft Dia., mm | OD, mm | Overall Wd., mm | Hub Dia., mm | Material | Specifications Met | Each | |

For ISO 05B Roller Chain (8 mm Pitch) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 8 | 6 | 8 | 24 | 12 | 13 | Steel | DIN 8187, ISO 606 | 0000000 | 000000 |

| 9 | 6 | 8 | 26.6 | 12 | 15 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

| 10 | 8 | 11 | 29.2 | 12 | 17 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

| 11 | 8 | 11 | 31.7 | 13 | 18 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

| 12 | 8 | 12 | 33.5 | 13 | 20 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

| 13 | 8 | 20 | 36.7 | 13 | 23 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

| 14 | 8 | 15 | 39.9 | 13 | 25 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

| 15 | 8 | 18 | 42 | 13 | 28 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

| 16 | 8 | 19 | 45 | 14 | 30 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

| 17 | 8 | 20 | 47.6 | 14 | 30 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

| 18 | 8 | 22 | 50 | 14 | 30 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

| 19 | 8 | 24 | 52.5 | 14 | 30 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

| 20 | 8 | 25 | 55 | 14 | 30 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

| 21 | 8 | 25 | 57.5 | 14 | 35 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

| 22 | 8 | 25 | 60 | 14 | 35 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

| 23 | 8 | 17 | 62 | 14 | 35 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

| 24 | 8 | 17 | 64.6 | 14 | 35 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

| 25 | 8 | 25 | 67.5 | 14 | 35 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

| 26 | 10 | 22 | 69.5 | 16 | 40 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

| 28 | 10 | 22 | 74.8 | 16 | 40 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

| 30 | 10 | 30 | 80.5 | 16 | 40 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

Idler Sprockets for Metric Roller Chain

Keep constant tension on your drive with these sprockets that press against your metric ISO roller chain to take up slack and reduce wear and vibration. They rotate freely on built-in ball bearings, which are double sealed to keep dirt out, and are for use with roller chain tensioners. All come with a finished bore that fits directly onto your shaft—no need for machining. These sprockets meet ISO 606, which is an international standard for dimensions and materials.

For technical drawings and 3-D models, click on a part number.

Bearing | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Number of Teeth | For Shaft Dia., mm | OD, mm | Overall Wd., mm | Hub Dia., mm | Material | Type | Material | Specifications Met | Each | |

For ISO 05B Roller Chain (8 mm Pitch) | ||||||||||

| 23 | 16 | 62 | 18 | 40 | Steel | Ball | Steel | ISO 606 | 0000000 | 000000 |

Timing Belt Idler Pulleys

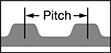

Add these free-spinning pulleys to your timing belt setup to minimize vibration and keep belts from wearing out. The needle bearing at the center of these pulleys is lined with small, cylindrical rollers that reduce friction as they rotate. This bearing allows both the pulley and the shaft it’s mounted on to spin independently. Made from iron or steel, these pulleys are strong and wear-resistant. The black oxide coating protects the pulleys from corrosion in dry environments.

Curved teeth have more surface contact with belts than traditional trapezoidal teeth, which allows you to apply more torque without damaging belts. These teeth fit together seamlessly to prevent backlash, or unwanted movement of the belt on the pulley, for a smooth, quiet cycle. They are also known as curvilinear belt pulleys.

For technical drawings and 3-D models, click on a part number.

| For Max. Belt Wd., mm | OD, mm | Number of Teeth | Teeth Shape | Pitch, mm | For Shaft Dia., mm | Dia., mm | Bore Type | Inside Wd., mm | Outside Wd., mm | Overall Wd., mm | Pitch Dia., mm | Number of Flanges | Fabrication | Material | Bearing Type | Hub Dia., mm | Each | |

For GT Belt Trade Size | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 90 | 32 | Curved | 8 | 20 | 80.12 | Plain | 20 | 31.5 | 46.23 | 81.48 | 2 | Machined | Black-Oxide Iron | Needle Roller | 69.85 | 0000000 | 0000000 |

| 30 | 100 | 36 | Curved | 8 | 30 | 90.3 | Plain | 30 | 48 | 48 | 91.67 | 2 | Machined | Black-Oxide Iron | Needle Roller | __ | 0000000 | 000000 |

For GT2 Belt Trade Size | ||||||||||||||||||

| 21 | 90 | 32 | Curved | 8 | 20 | 79.88 | Plain | 21 | 31.5 | 45.97 | 81.48 | 2 | Machined | Black-Oxide Iron | Needle Roller | 69.85 | 0000000 | 000000 |

| 62 | 100 | 36 | Curved | 8 | 30 | 90.07 | Plain | 62 | 73.91 | 91.19 | 91.67 | 2 | Machined | Black-Oxide Iron | Needle Roller | 79.5 | 0000000 | 000000 |

High-Strength Corrosion-Resistant HTD Timing Belt Pulleys

Move belts forward and backward or stop and start them in precise positions, especially in areas where rust is a concern. The curved teeth on these high-torque drive (HTD) pulleys have more surface contact with belts than traditional trapezoidal teeth, which allows you to apply more torque without damaging belts. These teeth fit together seamlessly to prevent backlash, or unwanted movement of the belt on the pulley, for a smooth, quiet cycle. These pulleys are often used in 3D printing, machine tool drives, robotics, and other applications where precision is essential. They are also known as curvilinear belt pulleys.

Pair pulleys with an HTD timing belt that has the same pitch. The width of your belt should not be larger than the maximum belt width listed.

Stainless steel pulleys can be wetted repeatedly without rusting or staining.

Bushing-mount pulleys grip the shaft more securely than press-fit pulleys, but require a quick-disconnect (QD) bushing or a split-tapered bushing (not included).

For technical drawings and 3-D models, click on a part number.

| OD, mm | Number of Teeth | Pitch, mm | For Shaft Dia. | Bore Type | Inside Wd., mm | Outside Wd., mm | Overall Wd., mm | Pitch Dia., mm | Number of Flanges | Fabrication | Hub Dia., mm | Each | |

For 20 mm Max. Belt Wd. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 65.08 | 22 | 8 | 1/2" | Plain | 22.35 | 28.58 | 44.45 | 54.66 | 2 | Machined | 41.28 | 0000000 | 0000000 |

For 30 mm Max. Belt Wd. | |||||||||||||

| 65.08 | 22 | 8 | 1/2" | Plain | 31.75 | 38.1 | 53.98 | 54.66 | 2 | Machined | 41.28 | 0000000 | 000000 |

| 69.85 | 24 | 8 | 1/2" | Plain | 31.75 | 38.1 | 53.98 | 59.74 | 2 | Machined | 46.04 | 0000000 | 000000 |

| 74.6 | 26 | 8 | 1/2" | Plain | 31.75 | 38.1 | 57.15 | 64.846 | 2 | Machined | 50.8 | 0000000 | 000000 |

| OD, mm | Number of Teeth | Pitch, mm | ID | Bore Type | For Bushing Style | Inside Wd., mm | Outside Wd., mm | Overall Wd., mm | Pitch Dia., mm | Number of Flanges | Fabrication | Each | |

For 20 mm Max. Belt Wd. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 70 | 26 | 8 | 1.374" | Finished | Quick Disconnect Style JA | 22.35 | 28.58 | 28.58 | 62.22 | 2 | Machined | 0000000 | 0000000 |

| 80.17 | 28 | 8 | 1.625" | Finished | Split Tapered Style H | 22.35 | 28.58 | 28.58 | 71.3 | 2 | Machined | 0000000 | 000000 |

| 84.94 | 30 | 8 | 1.625" | Finished | Split Tapered Style H | 22.35 | 28.58 | 28.58 | 76.4 | 2 | Machined | 0000000 | 000000 |

| 95.25 | 34 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 22.35 | 28.58 | 28.58 | 86.59 | 2 | Machined | 0000000 | 000000 |

| 110.34 | 40 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 22.35 | 28.58 | 28.58 | 101.854 | 2 | Machined | 000000 | 000000 |

| 120.65 | 44 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 22.35 | 28.58 | 28.58 | 112.04 | 2 | Machined | 0000000 | 000000 |

| 130.99 | 48 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 22.35 | 28.58 | 28.58 | 122.22 | 2 | Machined | 0000000 | 000000 |

| 150.8 | 56 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 22.35 | 28.58 | 28.58 | 141.224 | 2 | Machined | 0000000 | 000000 |

For 30 mm Max. Belt Wd. | |||||||||||||

| 78.49 | 28 | 8 | 1.625" | Finished | Split Tapered Style H | 33.32 | 38.1 | 38.1 | 71.3 | 2 | Machined | 0000000 | 000000 |

| 84.94 | 30 | 8 | 1.625" | Finished | Split Tapered Style H | 31.75 | 38.1 | 38.1 | 76.4 | 2 | Machined | 0000000 | 000000 |

| 90.48 | 32 | 8 | 1.625" | Finished | Split Tapered Style H | 31.75 | 38.1 | 38.1 | 81.48 | 2 | Machined | 0000000 | 000000 |

| 95.25 | 34 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 31.75 | 38.1 | 38.1 | 86.59 | 2 | Machined | 000000 | 000000 |

| 110.34 | 40 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 31.75 | 38.1 | 38.1 | 101.854 | 2 | Machined | 0000000 | 000000 |

| 120.65 | 44 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 31.75 | 38.1 | 38.1 | 112.04 | 2 | Machined | 0000000 | 000000 |

| 130.99 | 48 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 31.75 | 38.1 | 38.1 | 122.22 | 2 | Machined | 0000000 | 000000 |

| 150.8 | 56 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 31.75 | 38.1 | 38.1 | 142.6 | 2 | Machined | 0000000 | 000000 |

For 50 mm Max. Belt Wd. | |||||||||||||

| 95.25 | 34 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 53.98 | 60.33 | 60.33 | 86.59 | 2 | Machined | 0000000 | 000000 |

| 100 | 36 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 53.98 | 60.33 | 60.33 | 91.67 | 2 | Machined | 0000000 | 000000 |

| 110.34 | 40 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 53.98 | 60.33 | 60.33 | 101.854 | 2 | Machined | 0000000 | 000000 |

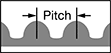

High-Strength HTD Timing Belt Pulleys

These HTD (high torque drive) pulleys have a curved tooth shape that provides higher strength than trapezoidal teeth. Select a pulley with a maximum belt width that’s the same or larger than your timing belt width.

Press-fit mount pulleys come machined to the for shaft diameter size and are machinable up to the for maximum shaft diameter size.

Bushing-mount pulleys grip the shaft more securely than pulleys that press fit. Quick-disconnect (QD) bushings and split-tapered bushings sold separately.

For technical drawings and 3-D models, click on a part number.

| For Belt Trade Size | OD, mm | Number of Teeth | Pitch, mm | For Shaft Dia. | For Max. Shaft Dia. | Bore Type | Inside Wd., mm | Outside Wd., mm | Overall Wd., mm | Pitch Dia., mm | Number of Flanges | Fabrication | Material | Hub Dia., mm | Each | |

For 20 mm Max. Belt Wd. | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H8M | 65.03 | 22 | 8 | 1/2" | 1.188" | Plain | 22.23 | 28.58 | 44.45 | 56.032 | 2 | Machined | Black-Oxide Iron | 41.28 | 00000000 | 000000 |

For 30 mm Max. Belt Wd. | ||||||||||||||||

| H8M | 65.03 | 22 | 8 | 1/2" | 1.188" | Plain | 31.75 | 38.1 | 53.98 | 56.032 | 2 | Machined | Black-Oxide Iron | 41.28 | 00000000 | 00000 |

| H8M | 70.11 | 24 | 8 | 1/2" | 1 1/4" | Plain | 31.75 | 38.1 | 53.98 | 61.112 | 2 | Machined | Black-Oxide Iron | 46.02 | 00000000 | 00000 |

| H8M | 74.93 | 26 | 8 | 1/2" | 1 1/4" | Plain | 31.75 | 38.1 | 57.15 | 66.217 | 2 | Machined | Black-Oxide Iron | 50.8 | 00000000 | 00000 |

| For Belt Trade Size | OD, mm | Number of Teeth | Pitch, mm | ID | Bore Type | For Bushing Style | Inside Wd., mm | Outside Wd., mm | Overall Wd., mm | Pitch Dia., mm | Number of Flanges | Fabrication | Material | Each | |

For 12 mm Max. Belt Wd. | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R8M | 74.6 | 26 | 8 | 1.346" | Finished | Quick Disconnect Style JA | 14.66 | 21.01 | 33.71 | 66.218 | 2 | Machined | Black-Oxide Steel | 00000000 | 0000000 |

| R8M | 80.16 | 28 | 8 | 1.574" | Finished | Split Tapered Style H | 14.66 | 21.01 | 30.54 | 71.298 | 2 | Machined | Black-Oxide Steel | 00000000 | 000000 |

| R8M | 84.94 | 30 | 8 | 1.574" | Finished | Split Tapered Style H | 14.66 | 21.01 | 30.54 | 76.403 | 2 | Machined | Black-Oxide Steel | 00000000 | 000000 |

| R8M | 90.48 | 32 | 8 | 1.574" | Finished | Split Tapered Style H | 14.66 | 21.01 | 30.54 | 81.483 | 2 | Machined | Black-Oxide Steel | 00000000 | 000000 |

For 20 mm Max. Belt Wd. | |||||||||||||||

| H8M | 74.93 | 26 | 8 | 1.375" | Finished | Quick Disconnect Style JA | 22.23 | 28.58 | 28.58 | 66.217 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 80.01 | 28 | 8 | 1.625" | Finished | Split Tapered Style H | 22.23 | 28.58 | 28.58 | 71.297 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 85.09 | 30 | 8 | 1.625" | Finished | Split Tapered Style H | 22.23 | 28.58 | 28.58 | 76.403 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 97.03 | 34 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 22.35 | 28.7 | 28.7 | 86.588 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 109.99 | 40 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 22.35 | 28.7 | 28.7 | 101.854 | 2 | Machined | Black-Oxide Iron | 0000000 | 00000 |

| H8M | 120.91 | 44 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 22.35 | 28.7 | 28.7 | 112.039 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 131.07 | 48 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 22.35 | 28.7 | 28.7 | 122.224 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 151.13 | 56 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 22.35 | 28.7 | 28.7 | 142.595 | 2 | Machined | Black-Oxide Iron | 00000000 | 000000 |

For 22 mm Max. Belt Wd. | |||||||||||||||

| R8M | 74.6 | 26 | 8 | 1.346" | Finished | Quick Disconnect Style JA | 24.64 | 30.99 | 43.69 | 66.218 | 2 | Machined | Black-Oxide Steel | 00000000 | 000000 |

| R8M | 80.16 | 28 | 8 | 1.574" | Finished | Split Tapered Style H | 24.64 | 30.99 | 40.52 | 71.298 | 2 | Machined | Black-Oxide Steel | 00000000 | 000000 |

| R8M | 84.94 | 30 | 8 | 1.574" | Finished | Split Tapered Style H | 24.64 | 30.99 | 40.52 | 76.403 | 2 | Machined | Black-Oxide Steel | 00000000 | 000000 |

| R8M | 90.48 | 32 | 8 | 1.574" | Finished | Split Tapered Style H | 24.64 | 30.99 | 30.99 | 81.483 | 2 | Machined | Black-Oxide Steel | 00000000 | 000000 |

For 30 mm Max. Belt Wd. | |||||||||||||||

| H8M | 80.01 | 28 | 8 | 1.625" | Finished | Split Tapered Style H | 31.75 | 38.1 | 38.1 | 71.297 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 85.09 | 30 | 8 | 1.625" | Finished | Split Tapered Style H | 31.75 | 38.1 | 38.1 | 76.403 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 89.92 | 32 | 8 | 1.625" | Finished | Split Tapered Style H | 31.88 | 38.23 | 38.23 | 81.483 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 97.03 | 34 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 31.88 | 38.23 | 38.23 | 86.588 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 109.99 | 40 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 31.88 | 38.23 | 38.23 | 101.854 | 2 | Machined | Black-Oxide Iron | 0000000 | 00000 |

| H8M | 120.91 | 44 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 31.88 | 38.23 | 38.23 | 112.039 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 131.07 | 48 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 31.88 | 38.23 | 38.23 | 122.224 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 151.13 | 56 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 31.88 | 38.23 | 38.23 | 142.595 | 2 | Machined | Black-Oxide Iron | 00000000 | 000000 |

For 50 mm Max. Belt Wd. | |||||||||||||||

| H8M | 97.03 | 34 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 54.1 | 60.45 | 60.45 | 86.588 | 2 | Machined | Black-Oxide Iron | 0000000 | 000000 |

| H8M | 100.08 | 36 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 54.1 | 60.45 | 60.45 | 91.668 | 2 | Machined | Black-Oxide Iron | 0000000 | 000000 |

| H8M | 109.99 | 40 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 54.1 | 60.45 | 60.45 | 101.854 | 2 | Machined | Black-Oxide Iron | 0000000 | 000000 |

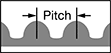

High-Strength Ultra-Quiet Timing Belt Pulleys

Teeth are curved and set in an offset pattern for high strength with 25% less operating noise than pulleys and belts with trapezoidal teeth. Select a pulley with a maximum belt width that’s the same or larger than your timing belt width.

Press-fit mount pulleys come machined to the for shaft diameter size and are machinable up to the for maximum shaft diameter size.

Bushing-mount pulleys grip the shaft more securely than pulleys that press fit. Quick-disconnect (QD) bushings and split-tapered bushings sold separately.

For technical drawings and 3-D models, click on a part number.

| OD, mm | Number of Teeth | Pitch, mm | For Shaft Dia. | For Max. Shaft Dia. | Bore Type | Outside Wd., mm | Overall Wd., mm | Pitch Dia., mm | Fabrication | Material | Hub Dia., mm | Each | |

For 16 mm Max. Belt Wd. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 44.45 | 18 | 8 | 1/2" | 7/8" | Plain | 17 | 29 | 46 | Cast | Magnesium-Phosphate-Coated Iron | 38.7 | 0000000 | 0000000 |

For 32 mm Max. Belt Wd. | |||||||||||||

| 62.23 | 25 | 8 | 1/2" | 1 3/8" | Plain | 33 | 49 | 64 | Cast | Magnesium-Phosphate-Coated Iron | 53.5 | 0000000 | 000000 |

| OD, mm | Number of Teeth | Pitch, mm | ID | Bore Type | For Bushing Style | Outside Wd., mm | Overall Wd., mm | Pitch Dia., mm | Fabrication | Material | Each | |

For 16 mm Max. Belt Wd. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 69.85 | 28 | 8 | 1.625" | Finished | Split Tapered Style H | 17 | 17 | 71 | Cast | Magnesium-Phosphate-Coated Iron | 0000000 | 0000000 |

| 90.43 | 36 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 17 | 17 | 92 | Cast | Magnesium-Phosphate-Coated Iron | 0000000 | 000000 |

For 32 mm Max. Belt Wd. | ||||||||||||

| 100.59 | 40 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 33 | 33 | 102 | Cast | Magnesium-Phosphate-Coated Iron | 0000000 | 000000 |

| 120.91 | 48 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 33 | 33 | 122 | Cast | Magnesium-Phosphate-Coated Iron | 0000000 | 000000 |

Ultra-High-Strength Poly Chain Timing Belt Pulleys

Curved teeth with a high pitch provide superior load distribution and reduce wear. They mount with a bushing for a more secure grip on the shaft than set screws. Bushing is not included. Select a pulley with a maximum belt width that’s the same or larger than your timing belt width.

For technical drawings and 3-D models, click on a part number.

| OD, mm | Number of Teeth | Pitch, mm | ID | Bore Type | For Bushing Style | Inside Wd., mm | Outside Wd., mm | Overall Wd., mm | Pitch Dia., mm | Number of Flanges | Fabrication | Material | Each | |

For 12 mm Max. Belt Wd. | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 66.04 | 22 | 8 | 1.386" | Finished | Taper-Lock Style 1008 | 15.24 | 22.35 | 22.35 | 56 | 2 | Machined | Black-Oxide Steel | 0000000 | 0000000 |

| 101.6 | 36 | 8 | 2.25" | Finished | Taper-Lock Style 1610 | 18.29 | 25.4 | 25.4 | 92 | 2 | Machined | Black-Oxide Steel | 0000000 | 000000 |

| 124.46 | 45 | 8 | 2.75" | Finished | Taper-Lock Style 2012 | 14.48 | 21.59 | 31.75 | 115 | 2 | Machined | Black-Oxide Steel | 0000000 | 000000 |

For 21 mm Max. Belt Wd. | ||||||||||||||

| 66.04 | 22 | 8 | 1.386" | Finished | Taper-Lock Style 1008 | 23.37 | 30.48 | 30.48 | 56 | 2 | Machined | Black-Oxide Steel | 0000000 | 000000 |

| 101.6 | 36 | 8 | 2.25" | Finished | Taper-Lock Style 1610 | 23.37 | 30.48 | 30.48 | 92 | 2 | Machined | Black-Oxide Steel | 0000000 | 000000 |

| 124.46 | 45 | 8 | 2.75" | Finished | Taper-Lock Style 2012 | 24.64 | 31.75 | 31.75 | 115 | 2 | Machined | Black-Oxide Steel | 0000000 | 000000 |

For 36 mm Max. Belt Wd. | ||||||||||||||

| 89.99 | 32 | 8 | 1.875" | Finished | Taper-Lock Style 1210 | 40.89 | 42.24 | 47.2 | 81.48 | 2 | Cast | Black-Oxide Iron | 00000000 | 000000 |

| 100.03 | 36 | 8 | 2.25" | Finished | Taper-Lock Style 1610 | 40.89 | 42.24 | 47.2 | 91.67 | 2 | Cast | Black-Oxide Iron | 00000000 | 000000 |

| 127.13 | 45 | 8 | 2.75" | Finished | Taper-Lock Style 2012 | 40.89 | 42.24 | 47.2 | 114.58 | 2 | Cast | Black-Oxide Iron | 00000000 | 000000 |