Gauge Marking Labels

Identify acceptable or critical temperatures or pressures at a glance. More convenient than cutting circles out of square sheet labels, these come in a variety of diameters to fit standard gauge dials. Trim different color wedges and stick them to your dial to define specific ranges. Often found in visual workplace and lean manufacturing initiatives, such as 5S and Total Productive Maintenance (TPM).

| Dia. | Mount Type | Material | Temp. Range, ° F | Pkg. Qty. | Pkg. | |

Green | ||||||

|---|---|---|---|---|---|---|

| 1" | Adhesive Back | Polyester Plastic | -40° to 300° | 54 | 00000000 | 000000 |

| 1 1/2" | Adhesive Back | Polyester Plastic | -40° to 300° | 24 | 0000000 | 00000 |

| 2" | Adhesive Back | Polyester Plastic | -40° to 300° | 15 | 0000000 | 00000 |

| 2 1/2" | Adhesive Back | Polyester Plastic | -40° to 300° | 12 | 0000000 | 00000 |

| 3" | Adhesive Back | Polyester Plastic | -40° to 300° | 6 | 0000000 | 00000 |

| 3 1/2" | Adhesive Back | Polyester Plastic | -40° to 300° | 6 | 0000000 | 00000 |

| 4" | Adhesive Back | Polyester Plastic | -40° to 300° | 4 | 000000 | 00000 |

| 4 1/2" | Adhesive Back | Polyester Plastic | -40° to 300° | 3 | 0000000 | 00000 |

| 5" | Adhesive Back | Polyester Plastic | -40° to 300° | 2 | 00000000 | 00000 |

| 6" | Adhesive Back | Polyester Plastic | -40° to 300° | 2 | 00000000 | 00000 |

Yellow | ||||||

| 1" | Adhesive Back | Polyester Plastic | -40° to 300° | 54 | 00000000 | 00000 |

| 1 1/2" | Adhesive Back | Polyester Plastic | -40° to 300° | 24 | 0000000 | 00000 |

| 2" | Adhesive Back | Polyester Plastic | -40° to 300° | 15 | 0000000 | 00000 |

| 2 1/2" | Adhesive Back | Polyester Plastic | -40° to 300° | 12 | 000000 | 00000 |

| 3" | Adhesive Back | Polyester Plastic | -40° to 300° | 6 | 0000000 | 00000 |

| 3 1/2" | Adhesive Back | Polyester Plastic | -40° to 300° | 6 | 0000000 | 00000 |

| 4" | Adhesive Back | Polyester Plastic | -40° to 300° | 4 | 0000000 | 00000 |

| 4 1/2" | Adhesive Back | Polyester Plastic | -40° to 300° | 3 | 0000000 | 00000 |

| 5" | Adhesive Back | Polyester Plastic | -40° to 300° | 2 | 00000000 | 00000 |

| 6" | Adhesive Back | Polyester Plastic | -40° to 300° | 2 | 00000000 | 00000 |

Red | ||||||

| 1" | Adhesive Back | Polyester Plastic | -40° to 300° | 54 | 00000000 | 00000 |

| 1 1/2" | Adhesive Back | Polyester Plastic | -40° to 300° | 24 | 0000000 | 00000 |

| 2" | Adhesive Back | Polyester Plastic | -40° to 300° | 15 | 0000000 | 00000 |

| 2 1/2" | Adhesive Back | Polyester Plastic | -40° to 300° | 12 | 0000000 | 00000 |

| 3" | Adhesive Back | Polyester Plastic | -40° to 300° | 6 | 0000000 | 00000 |

| 3 1/2" | Adhesive Back | Polyester Plastic | -40° to 300° | 6 | 0000000 | 00000 |

| 4" | Adhesive Back | Polyester Plastic | -40° to 300° | 4 | 0000000 | 00000 |

| 4 1/2" | Adhesive Back | Polyester Plastic | -40° to 300° | 3 | 0000000 | 00000 |

| 5" | Adhesive Back | Polyester Plastic | -40° to 300° | 2 | 00000000 | 00000 |

| 6" | Adhesive Back | Polyester Plastic | -40° to 300° | 2 | 00000000 | 00000 |

| No. of Pieces | Includes | Mount Type | Material | Temp. Range, ° F | Pkg. Qty. | Pkg. | |

Green | |||||||

|---|---|---|---|---|---|---|---|

| 15 | Five each of 1 1/2" Dia. Four each of 2" Dia. Three each of 2 1/2" Dia. Two each of 3" Dia. One each of 4" Dia. | Adhesive Back | Polyester Plastic | -40° to 300° | 15 | 00000000 | 000000 |

Yellow | |||||||

| 15 | Five each of 1 1/2" Dia. Four each of 2" Dia. Three each of 2 1/2" Dia. Two each of 3" Dia. One each of 4" Dia. | Adhesive Back | Polyester Plastic | -40° to 300° | 15 | 00000000 | 00000 |

Red | |||||||

| 15 | Five each of 1 1/2" Dia. Four each of 2" Dia. Three each of 2 1/2" Dia. Two each of 3" Dia. One each of 4" Dia. | Adhesive Back | Polyester Plastic | -40° to 300° | 15 | 00000000 | 00000 |

Pocket Electronic Thickness Gauges

Small enough to fit between your thumb and index finger, use this gauge for quick thickness checks on paper, film, and other flat stock. It has zero-position memory, also known as absolute (ABS) positioning, which retains the measuring position when the gauge is turned off. A zero-set button allows you to start measuring at any point.

Pocket Electronic Thickness Gauges with Calibration Certificate

This gauge comes with a calibration certificate traceable to NIST that states it has passed a test for accuracy. Small enough to fit between your thumb and index finger, use it for quick thickness checks on paper, film, and other flat stock. It has zero-position memory, also known as absolute (ABS) positioning, which retains the measuring position when the gauge is turned off. A zero-set button allows you to start measuring at any point.

Starrett Pocket Dial Thickness Gauges with Calibration Certificate

These gauges come with a calibration certificate traceable to NIST that states they've passed a test for accuracy. They fit between your thumb and index finger for quick thickness checks on paper, film, and other flat stock. Operate by pulling the serrated finger slide to raise the spindle.

Economy Pocket Dial Thickness Gauges

Small enough to fit between your thumb and index finger, use these gauges for quick thickness checks on paper, film, and other flat stock. Operate by pulling the serrated finger slide to raise the spindle.

Anvil | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Measuring Range | Accuracy | Measuring Increments | Measurement per Dial Revolution | Throat Dp. | Face Dia. | Face Material | Dial Face Color | Each | |

| 0"-0.5" | ±0.001" | 0.001" | 0.1" | 1/2" | 0.23" | Steel | White | 00000000 | 000000 |

Wet-Coating-Thickness Gauges

Measure the thickness of wet coatings such as paint. These gauges display readings in mils on one side and microns on the other side. For readings in mils, one mil equals 0.001".

For Coating Thick. | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Coating Type | Mil | Microns | Wd. | Lg. | Material | Specifications Met | Each | |

For Use On Aluminum, Copper, Plastic, Stainless Steel, Steel | ||||||||

| Nonconductive, Nonmagnetic | 1-118 | 25-3,000 | 2 5/8" | 3" | Aluminum | ASTM D4414, ISO 2808 | 000000 | 000000 |

Adhesive-Back Temperature-Indicating Sheets

Liquid crystals on these sheets change color as surface temperature increases. The crystals change from black to red, red to green, and green to blue as the temperature rises to the temperature points. When the surface cools, the sheets return to black.

6" × 6" | 12" × 12" | |||||

|---|---|---|---|---|---|---|

| Temperature Points, ° F | Accuracy, ° F | Indicator Use | Each | Each | ||

3 Points | ||||||

| 77°, 79°, 86° | ±2° | Continuous | 0000000 | 000000 | 0000000 | 000000 |

| 86°, 88°, 95° | ±2° | Continuous | 0000000 | 00000 | 000000 | 00 |

| 95°, 97°, 104° | ±2° | Continuous | 0000000 | 00000 | 0000000 | 00000 |

| 104°, 106°, 113° | ±2° | Continuous | 0000000 | 00000 | 000000 | 00 |

| 113°, 115°, 122° | ±2° | Continuous | 0000000 | 00000 | 0000000 | 00000 |

Pressure Recording Film

Create an instant, permanent image of pressure distribution and magnitude. These sheets of film help you identify uneven pressure that can lead to leaks and stress fractures. Use them between any two surfaces that touch each other, such as bolted joints, welding fixtures, and jigs. Tiny capsules within the film burst at specific pressure levels, causing the film to change color. This produces an instant map of pressure variation, similar to a heat map. For a custom size, cut the film with scissors.

0.008" thick film includes two 0.004" thick sheets that must be used together.

Pressure variance analysis kits include a sheet of pressure film and instructions on how to send your film to the manufacturer for analysis. The manufacturer runs the analysis through specialized software. This software gives you more accurate results than the color correlation manual. Within a few days of sending your sample in, you’ll receive an email with a full report on the force distribution and magnitude.

Use a color correlation manual (sold separately) with pressure film to determine the magnitude of the pressure measurements. The manual includes best practices and color correlation charts to help you match the colors on your film readout to the correct values.

A color sample pack includes a color correlation manual and one 3" × 4" piece of film in each of these pressure ranges: 28-85, 70-350, 350-1,400, 1,400-7,100, and 7,100-18,500 psi.

Film | Color Correlation Manual | Color Sample Pack | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pressure Range, psi | Image Produced | Resolution | Temp. Range, °F | Accuracy | Each | Each | Pkg. | |||

Pressure Film | ||||||||||

10 5/8" × 12" | ||||||||||

0.004" Thick. | ||||||||||

| 1,400-7,100 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 000000 | 00000000 | 000000 |

| 7,100-18,500 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 00000 | 000000000 | 00000 | 00000000 | 00000 |

0.008" Thick. | ||||||||||

| 28-85 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 00000 | 000000000 | 00000 | 00000000 | 00000 |

| 70-350 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 00000 | 000000000 | 00000 | 00000000 | 00000 |

| 350-1,400 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 00000 | 000000000 | 00000 | 00000000 | 00000 |

0.02" Thick. | ||||||||||

| 18,500-43,200 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 00000 | 000000000 | 00000 | 00000000 | 00000 |

10 5/8" × 24" | ||||||||||

0.004" Thick. | ||||||||||

| 1,400-7,100 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 00000 | 000000000 | 00000 | 00000000 | 00000 |

| 7,100-18,500 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 00000 | 000000000 | 00000 | 00000000 | 00000 |

0.008" Thick. | ||||||||||

| 28-85 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 70-350 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 350-1,400 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 00000 | 000000000 | 00000 | 00000000 | 00000 |

0.02" Thick. | ||||||||||

| 18,500-43,200 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 00000 | 000000000 | 00000 | 00000000 | 00000 |

10 5/8" × 36" | ||||||||||

0.004" Thick. | ||||||||||

| 1,400-7,100 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 7,100-18,500 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

0.008" Thick. | ||||||||||

| 28-85 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 70-350 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 350-1,400 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

0.02" Thick. | ||||||||||

| 18,500-43,200 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

10 5/8" × 48" | ||||||||||

0.004" Thick. | ||||||||||

| 1,400-7,100 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

0.008" Thick. | ||||||||||

| 28-85 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 70-350 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 350-1,400 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

11" × 17" | ||||||||||

0.02" Thick. | ||||||||||

| 2-20 | Grayscale | __ | 0° to 150° | Not Rated | 0000000 | 00000 | 000000 | 00 | 000000 | 00 |

12" × 21 1/4" | ||||||||||

0.315" Thick. | ||||||||||

| 28-85 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 70-350 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 350-1,400 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 00000 | 000000000 | 00000 | 00000000 | 00000 |

12 5/8" × 12" | ||||||||||

0.004" Thick. | ||||||||||

| 8-28 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 000000 | 00 |

0.008" Thick. | ||||||||||

| 0.9-7.2 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 000000 | 00 |

12 5/8" × 24" | ||||||||||

0.004" Thick. | ||||||||||

| 8-28 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 000000 | 00 |

12 5/8" × 36" | ||||||||||

0.004" Thick. | ||||||||||

| 8-28 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 000000 | 00 |

12 5/8" × 48" | ||||||||||

0.004" Thick. | ||||||||||

| 8-28 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 000000 | 00 |

Pressure Variance Analysis Kit | ||||||||||

10 5/8" × 12" | ||||||||||

0.004" Thick. | ||||||||||

| 1,400-7,100 | Color | 5-15 μ | 70° to 95° | ±4% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 7,100-18,500 | Color | 5-15 μ | 70° to 95° | ±4% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

0.008" Thick. | ||||||||||

| 28-85 | Color | 5-15 μ | 70° to 95° | ±4% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 70-350 | Color | 5-15 μ | 70° to 95° | ±4% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 350-1,400 | Color | 5-15 μ | 70° to 95° | ±4% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

0.02" Thick. | ||||||||||

| 18,500-43,200 | Color | 5-15 μ | 70° to 95° | ±4% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

12" × 21 1/4" | ||||||||||

0.315" Thick. | ||||||||||

| 28-85 | Color | 5-15 μ | 70° to 95° | ±4% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 70-350 | Color | 5-15 μ | 70° to 95° | ±4% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 350-1,400 | Color | 5-15 μ | 70° to 95° | ±4% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

12 5/8" × 12" | ||||||||||

0.008" Thick. | ||||||||||

| 0.9-7.2 | Color | 5-15 μ | 70° to 95° | ±4% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

Roller impression analysis kits are also known as NIP impression kits. They include three sheets of film, a color correlation manual specific to roller systems, and a shipping envelope to send your film in for analysis. The manufacturer runs the analysis through specialized software. This software gives you more accurate results than the color correlation manual. Within a few days of sending your sample in, you’ll receive an email with a full report on the force distribution and magnitude.

| Pressure Range, psi | Image Produced | Resolution | Temp. Range, °F | Accuracy | Includes | Each | |

12" × 10" | |||||||

|---|---|---|---|---|---|---|---|

0.004" Thick. | |||||||

| 70-7,100 | Color | 5-15 μ | 70° to 95° | ±4% | Color Correlation Manual, Shipping Envelope, Three Sheets | 000000000 | 0000000 |

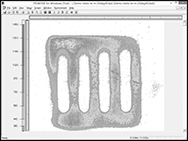

Pressure Testing Analysis Systems

Take lab-quality scans of pressure recording film for frequent onsite measurements. These systems detect color changes in the film to spot issues that can cause leaks and stress fractures. They’re often used with bolted joints, metal stamping, and nip rollers to measure and adjust for uneven pressure when setting up a new job. They’re also known as TOPAQ analysis systems. The scanner comes calibrated for reading pressure recording film.

The included software renders color pressure images in detail for more accurate results than visual inspection with a color correlation manual. You can create 3D images, grids, and graphs. Zoom in for a closer look at the pressure distribution throughout your system.

This is not a finite element analysis (FEA) tool. While an FEA tool uses models to predict stress and potential failures, these evaluate pressure based on your actual system. This means you’re more likely to catch issues caused by material imperfections, environmental conditions, and other real-world factors.

For Sheet | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Scanner Resolution | Lg. | Wd. | Paper Size | Scan Speed | Accuracy | Lg. | Wd. | Ht. | Data Connection Type | Wattage | Voltage | Cord Lg., ft. | Plug Type | Includes | Each | |

| 200 dpi | 8 1/2" | 11" | Letter | 40 Seconds | ±4% | 11 1/2" | 17" | 2" | USB-A | 20W | 120V AC | 10 | Two Prong | 6 ft. Long USB Cord, Scanner, Windows Compatible Software | 0000000 | 000000000 |