Filter by

Color

Height

Safety Barrier Component

Mounting Position

Fitting Connection

Closure Method

Width

Slide Material

Specifications Met

DFARS Specialty Metals

Length

Most Likely Products

All Results

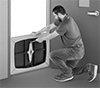

Safety Equipment

Heating, Ventilation, and Air Conditioning

Fluid Handling

Building and Machinery Hardware

Facility and Grounds Maintenance

Material Handling

Communication