Battery Cable Connector Lockouts

Padlock these lockouts over the ends of battery cables to keep forklifts, pallet jacks, and other machinery powered off during maintenance. They signal that equipment is being serviced, preventing accidental startups. These lockouts have space for two padlocks, so teams can safely perform two maintenance tasks at once.

Made from nonconductive plastic, they insulate battery terminals and protect workers from accidental shocks, helping you comply with OSHA 29 CFR 1910.147 requirements for the control of electricity. These lockouts are also rated UL 94 HB, which means they have been tested in a horizontal position for flame resistance; the slow-burning plastic keeps flames from spreading.

Hinged lockouts fully enclose battery cable ends and inline connections. Fit battery connectors, such as lugs and terminal clamps, over the internal post to hold cables in place.

Slide-on lockouts are best for large battery connectors.

For Max. Connector | Cable Opening | Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Wd. | Ht. | For No. of Battery Cables | Wd. | Ht. | Post Dia. | Lg. | Wd. | Ht. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Temp. Range, °F | Color | Specifications Met | Each | |

Hinged | ||||||||||||||||

Plastic | ||||||||||||||||

| 2 5/8" | 1 1/2" | 1 1/4" | 1 | 1" | 1" | 1/4" | 3 3/4" | 2 7/8" | 1 3/8" | 2 | 5/16" | -40° to 212° | Red | OSHA Compliant 29 CFR 1910.147, UL 94 HB | 0000000 | 000000 |

| 2 5/8" | 2 3/4" | 1 5/8" | 2 | 2" | 1 3/8" | 1/4" | 5 3/4" | 4 1/8" | 1 3/4" | 2 | 5/16" | -40° to 212° | Red | OSHA Compliant 29 CFR 1910.147, UL 94 HB | 0000000 | 00000 |

Slide On | ||||||||||||||||

Plastic | ||||||||||||||||

| 4 1/2" | 2 7/8" | 1 3/8" | __ | __ | __ | __ | 5 1/4" | 3 1/8" | 2 1/2" | 2 | 5/16" | -40° to 212° | Red | OSHA Compliant 29 CFR 1910.147, UL 94 HB | 0000000 | 00000 |

Electrical Plug Lockouts

Lock out a plug that powers machinery so no one starts it up during maintenance. Place a plug into the cylinder of these lockouts and secure with a padlock. All can fit a standard electrical plug that has a single cord. Made of plastic, they resist corrosion and are nonconductive for use with electronics. These lockouts help you comply with OSHA 29 CFR 1910.147, which requires electrical circuits to be locked out to prevent injury.

Lockouts for 2 or more padlocks let multiple people add their own padlock. This keeps everyone safe until all of the maintenance work is done and all padlocks are removed.

Lockouts with 2 holes for electrical plugs let you insert a cord from either end. That means you can lock out two devices at once, or lock out both the plug and socket of the same cord.

Lockouts with 5 holes for electrical plugs have a variety of hole sizes to handle different cord diameters. They’ll fit dual-cord battery plugs for forklifts, as well as standard single-cord plugs. Use them with gas-powered equipment, too—the largest hole on these lockouts fits a gas cylinder valve.

Lockouts with adjustable-fit closure let you secure any cord diameter up to 1 1/4”. Slide the two top lids against each other to change the hole size.

Lockouts with a message alert passersby that a plug has been locked out for safety.

Lockouts that meet UL 2809-2 are made of 100% recycled materials and are sustainably sourced to meet ongoing purchasing requirements for LEED-certified facilities.

For Plug | Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | For Max. Cord Dia. | No. of Holes for Electrical Plugs | Max. Lg. | Wd. | Lg. | Wd. | Ht. | Dia. | Temp. Range, ° F | Message | Features | Specifications Met | Each | |

Yellow Plastic | |||||||||||||||

| 1 | 5/16" | 1 1/4" | 1 | 5 1/2" | 1 1/2"-3" | 6 1/4" | __ | __ | 3 1/2" | 32° to 275° | __ | Adjustable-Fit Closure | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 |

| 4 | 3/8" | 1 1/8" | 2 | 4 3/4" | 1 1/2"-2 3/4" | 7 1/4" | __ | __ | 4 1/4" | -20° to 140° | __ | __ | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

| 4 | 3/8" | 1 7/16" | 2 | 10 1/4" | 1/2"-4 1/2" | 12 1/2" | __ | __ | 5" | 0° to 175° | __ | __ | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 |

Yellow Plastic (English/Spanish Message) | |||||||||||||||

| 3 | 9/16" | 1 1/4" | 1 | 5 1/2" | 1 1/2"-3" | 7" | __ | __ | 3 3/4" | -25° to 200° | Danger—Do Not Plug In/No Conectar | Adjustable-Fit Closure | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 000000000 | 00000 |

Red Plastic (English Message) | |||||||||||||||

| 2 | 11/32" | 1/2" | 2 | 3 1/8" | 1/2"-1 5/8" | 3 1/2" | 3 1/8" | 2" | __ | 0° to 175° | Danger—Locked Out—Do Not Remove | __ | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 |

| 3 | 9/16" | 1/2" | 2 | 3" | 3/4"-2" | 3 1/2" | __ | __ | 2 1/2" | -25° to 200° | Danger—Do Not Operate—Equipment Locked Out | __ | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 000000000 | 00000 |

| 6 | 9/32" | 1 1/8", 1", 1" | 5 | 6 3/4" | 1/2"-2 1/2" | 7 1/4" | 4 1/4" | 3" | __ | -40° to 300° | Danger—Do Not Operate—Equipment Locked Out | __ | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 00000 |

Air Hose Lockouts

Block air hoses from connecting to compressed air. These lockouts secure with a padlock and lockout tag so your equipment doesn't start up during repairs. They also help you comply with OSHA 29 CFR 1910.147 requirements for locking out controls to prevent injuries.

Style D can lock out an air hose and electrical plug at the same time. Stash them in your tool bag so you don’t have to carry two separate types of lockouts when completing maintenance work.

Lockouts for more than one padlock let multiple people add their own padlock as they start a job. Until the last padlock is removed, these lockouts won’t open.

For Plug | Overall | Temp. Range, °F | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | For Coupling Size | For Hose Connection Type | For Quick Disconnect Component | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | For Max. Cord Dia. | Max. Lg. | Wd. | Lg. | Wd. | Ht. | Min. | Max. | Color | Label Included | Message | Each | |

Cover | ||||||||||||||||||

Plastic | ||||||||||||||||||

| D | 1/8 | Quick Disconnect | Plug | 4 | 1/4" | 1/4" | 5" | 2"-3 1/2" | 6 1/4" | 4 1/2" | 3 3/4" | 0° | 175° | Red | Yes | Lockout Device—Do Not Plug In | 0000000 | 000000 |

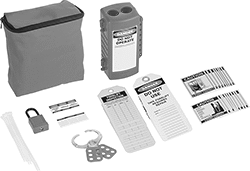

Forklift Lockout Sets with Padlock

Prevent injuries while servicing a forklift—these kits come with everything you need to perform lockout tagout procedures. They include a lockout device that fully covers a gas cylinder and connectors, preventing accidental startup. An eye-catching red padlock, hasp, lockout, and carrying bag alert others to the maintenance and signal they should proceed with caution. These kits help you comply with OSHA 29 CFR 1910.147, which requires the battery or gas cylinder to be locked out during maintenance.

| For Use With | Includes | Specifications Met | Each | |

| Battery Cable Connectors, Electrical Plugs, Gas Cylinders | 1 Each: 1/4" Shackle Diameter Keyed Differently Padlock with Label 1 Each: Lockout Hasp 1 Each: Plug Lockout 10 Each: Forklift Inspection Tags 10 Each: Lockout Tags 20 Each: Safety Labels 10 Each: Cable Ties Carrying Case | OSHA Compliant 29 CFR 1910.147 | 0000000 | 0000000 |