Remote-Reading Tension Force Gauges

Safely view your tension force measurements on a handheld receiver up to 450 ft. away when moving bulk material with cranes and hoists. These gauges are also called dynamometers and crane scales. Made of steel, they’re durable enough to briefly hold heavy loads up to 500% of their capacity. But, they will no longer take measurements if the load exceeds 200%. Warning lights will flash first when your load exceeds capacity, then again when it reaches 133% capacity. To prevent overloads, the peak-hold setting displays the highest measurement. The tare function lets you reset the gauge to zero after attaching a container to weigh only the material inside. These gauges include a calibration certificate traceable to NIST that states they’ve passed a test for accuracy. They also meet IEC and ASME safety and fatigue standards.

Because their indicators and load cells are IP rated, these gauges stand up to washdowns and brief submersion common to food and chemical plants. They’re also safe to use outdoors since they’re NEMA rated to seal out weather.

These gauges come with two shackles that work with other lifting fittings, such as clevis hooks. The included batteries power their load cells for up to 2,000 hours.

Capacity | Accuracy | Measuring Increments | Shackle | Temp. Range, °F | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| English | Metric | Newtons | English | Metric | Newtons | English | Metric | Newtons | Ht. | Wd. | Dp. | Opening Ht. | Opening Wd. | Load Point | Remote Receiver | Each | |

Gauges | |||||||||||||||||

| 2,000 lbs. | 900 kg | 8,800 N | ±2 lbs. | ±1 kg | ±9 N | 1 lbs. | 0.5 kg | 5 N | 4 7/8" | 4" | 3 1/4" | 1 3/8" | 1" | -15° to 175° | 0° to 155° | 0000000 | 000000000 |

| 4,000 lbs. | 1,800 kg | 17,700 N | ±4 lbs. | ±2 kg | ±18 N | 2 lbs. | 1 kg | 9 N | 4 7/8" | 4" | 3 1/4" | 1 3/8" | 1" | -15° to 175° | 0° to 155° | 0000000 | 00000000 |

| 10,000 lbs. | 4,500 kg | 44,400 N | ±10 lbs. | ±5 kg | ±45 N | 5 lbs. | 2 kg | 23 N | 5 3/8" | 4" | 3 1/4" | 2 3/8" | 1 3/4" | -15° to 175° | 0° to 155° | 0000000 | 00000000 |

| 20,000 lbs. | 9,000 kg | 88,900 N | ±20 lbs. | ±9 kg | ±89 N | 10 lbs. | 5 kg | 45 N | 7 3/4" | 4" | 4 5/8" | 3 3/4" | 2 5/8" | -15° to 175° | 0° to 155° | 0000000 | 00000000 |

| 50,000 lbs. | 22,600 kg | 222,400 N | ±50 lbs. | ±23 kg | ±222 N | 10 lbs. | 5 kg | 50 N | 9 3/8" | 4" | 4 5/8" | 5 3/4" | 3 55/64" | -15° to 175° | 0° to 155° | 0000000 | 00000000 |

Wire Crimp Pull Testers

Stress test an electrical connection to make sure it won't come apart. Often used to check the quality of electrical connections during manufacturing, these pull testers measure the force needed to pull terminals and other connectors off of wires and tubes. They work with many different wire diameters, including most insulation types—turn the wire end fixture until you find a slot that fits your wire. To help you automate tests, you can set these testers to automatically store or output data, and to zero out when a test sample breaks. For pass/fail testing, you can set high and low points—an alarm will sound if the sample falls out of the set range. A backlit LCD makes it easy to read measurements, even in low lighting.

These testers include software that lets you gather continuous data or focus in on a single data point. Export your measurements to Excel using the included USB cable. You can also send data to your computer or PLC via RS-232, Digimatic code, or analog outputs. These testers come with a calibration certificate traceable to NIST that states they've passed a test for accuracy.

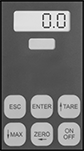

Manual testers have a large, easy-to-grab lever. Press it toward the wire end holder to apply force and pull it away to release the wire. A loading bar on the screen shows you how much force you’ve applied, so you know when the sample is close to breaking. Arrows indicate whether the force is high, low, or in your set range.

Automatic testers begin pulling as soon as a sample is loaded and reset once the test is complete. Red and green indicators next to the screen light up to show whether your sample is high, low, or in your set range.

Ring terminal fixtures have pins instead of grooves to hold your wire end. Fit a ring terminal onto a pin with a matching diameter to test it.

For Wire | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | Accuracy | Measuring Increments | Ht. | Wd. | Dp. | Dia. | Gauge | Data Connection Type | Batteries Included | Battery Type | Min. Sample Lg. | Includes | Each | |

Aluminum Housing | ||||||||||||||

| 200 lbs. (English) 100 kg (Metric) 1000 N (Newtons) | ±2% | 0.1 lbs. (English) 0.05 kg (Metric) 0.5 N (Newtons) | 4 1/2" | 14 3/4" | 6 1/4" | 0.01" to 0.25" | 30-3 | Micro USB-B, HD15 | Yes | Rechargeable | 6 1/2" | AC Adapter, Windows-Compatible Software, 6 ft. Long USB Cable | 0000000 | 000000000 |

For Wire | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | Accuracy | Measuring Increments | Ht. | Wd. | Dp. | Dia. | Gauge | Data Connection Type | Electrical Connection Type | Cord Lg., ft. | Min. Sample Lg. | Includes | Each | |

Aluminum Housing | ||||||||||||||

| 200 lbs. (English) 100 kg (Metric) 1000 N (Newtons) | ±2% | 0.1 lbs. (English) 0.05 kg (Metric) 0.5 N (Newtons) | 5 5/16" | 14 3/4" | 6 1/4" | 0.01" to 0.25" | 30-3 | Micro USB-B, HD15 | Plug | 6 | 6 1/2" | Windows-Compatible Software, 6 ft. Long USB Cable | 0000000 | 000000000 |

| Pin Dia. | Each | |

| 1/8" to 3/8" | 0000000 | 0000000 |