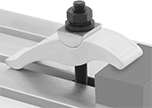

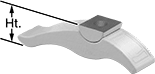

Self-Supporting Setup Clamps

Eliminating the need for step blocks or other rear support, the pivoting rocker clamps workpieces of various thicknesses. Use these clamps with T-slot nuts or bolts to secure a workpiece, vise, or fixture to a machine table.

For technical drawings and 3-D models, click on a part number.

| For Max. Workpiece Thick. | For Stud Dia. | Lg. | Wd. | Ht. | Material | Each | |

| 1" | 3/8" | 3" | 1 1/8" | 1 1/4" | Iron | 00000000 | 000000 |

| 1 1/4" | 3/8" | 3 3/4" | 1 1/8" | 1 1/4" | Iron | 00000000 | 00000 |

| 1 3/4" | 1/2" | 4 1/4" | 1 1/2" | 1 1/2" | Iron | 00000000 | 00000 |

| 2 1/2" | 1/2" | 5 3/4" | 1 1/2" | 1 1/2" | Iron | 00000000 | 00000 |

| 2 3/4" | 5/8" | 5 1/2" | 1 3/4" | 1 5/8" | Iron | 00000000 | 00000 |

| 3" | 1" | 9" | 2 7/8" | 3 3/8" | Iron | 00000000 | 000000 |

| 3 1/2" | 5/8" | 6 3/4" | 1 3/4" | 1 5/8" | Iron | 00000000 | 00000 |

| 3 1/2" | 3/4" | 7" | 2 1/8" | 2 1/4" | Iron | 00000000 | 00000 |

| 5" | 3/4" | 9" | 2 1/8" | 2 1/4" | Iron | 00000000 | 00000 |

| 5" | 1" | 11 1/8" | 2 7/8" | 3 3/8" | Iron | 00000000 | 000000 |

Heavy Duty Bar Clamps

Hold up to five times the capacity of standard bar clamps. Pull the lever to slide the clamping arm along the bar; release to lock in place. Use the handle for final tightening. These are also known as I-beam clamps.

For technical drawings and 3-D models, click on a part number.

Opening | ||||||

|---|---|---|---|---|---|---|

| Max. | Min. | Reach | Holding Capacity, lbs. | Body Material | Each | |

| 24" | 0" | 1 13/16" | 6,000 | Steel | 000000 | 000000 |

| 30" | 0" | 2" | 5,100 | Steel | 000000 | 00000 |

| 36" | 0" | 1 13/16" | 6,000 | Steel | 000000 | 00000 |

| 48" | 0" | 1 13/16" | 6,000 | Steel | 000000 | 00000 |

| 60" | 0" | 1 13/16" | 6,000 | Steel | 000000 | 00000 |

| 72" | 0" | 1 13/16" | 6,000 | Steel | 000000 | 000000 |

| 84" | 0" | 2" | 5,100 | Steel | 000000 | 00000 |

| 96" | 0" | 2" | 5,100 | Steel | 000000 | 00000 |

Tight-Clearance Any-Length Bar Clamps

All adjustments can be made from one end, allowing clamping in tight spaces. Place the arms on a pipe that is threaded at one end and at least 12" long to create your own bar clamp. The clamping surfaces have removable plastic pads that prevent damage to material. These are also known as pipe clamps.

For technical drawings and 3-D models, click on a part number.

Any-Length Bar Clamps

Place the arms on a pipe that is threaded at one end and at least 12" long to create your own bar clamp. Turn the handle to tighten. The clamping surfaces have removable plastic pads that prevent damage to material. These are also known as pipe clamps.

For technical drawings and 3-D models, click on a part number.

Parallel-Jaw Bar Clamps/Spreaders

The large, flat jaws remain parallel when clamping to apply even pressure without denting or marring the workpiece. Reverse the arms to use these clamps as spreaders. Pull the handle to lock or release the clamping arm.

For technical drawings and 3-D models, click on a part number.

Opening | Spreader Opening | |||||||

|---|---|---|---|---|---|---|---|---|

| Max. | Min. | Max. | Min. | Reach | Holding Capacity, lbs. | Body Material | Each | |

| 12" | 0" | 15 5/16" | 10 1/2" | 3 3/4" | 1,000 | Steel | 0000000 | 000000 |

| 18" | 0" | 21 1/2" | 10 1/2" | 3 3/4" | 1,000 | Steel | 0000000 | 00000 |

| 24" | 0" | 28 3/4" | 10 1/2" | 3 3/4" | 1,000 | Steel | 0000000 | 00000 |

| 40" | 0" | 44 1/2" | 10 1/2" | 3 3/4" | 1,000 | Steel | 0000000 | 00000 |

| 50" | 0" | 52 1/2" | 10 1/2" | 3 3/4" | 1,000 | Steel | 0000000 | 00000 |

Bench-Mount Bar-Style Hold-Down Clamps

Permanently mount the base to the work surface and easily move the clamp on and off the surface. The clamping arm slides freely along the bar for quick positioning. Use the handle for final tightening.

Copper-plated clamp components resist weld spatter.

For technical drawings and 3-D models, click on a part number.