Filter by

Flow Measurement Unit

Maximum Flow

For Use With

Measurement Unit

Measures

Flow Measurement Type

Calibrated With

Wetted Parts Material

Body Material

REACH

Mounting Location

Maximum Pressure @ Temperature

Fitting Material

Connects To

Circuit Protection

Export Control Classification Number (ECCN)

RoHS

DFARS Specialty Metals

Communication Protocol

Performance

Noncontact Flow Transmitters

|

Using ultrasonic waves, these transmitters measure the flow rate of your liquid from outside your pipe. They're a good choice for applications where you need to retrofit your system or avoid liquid coming into contact with the transmitter. Also known as transducers, these transmitters convert measurements to an electrical pulse that can be interpreted by receiving devices, such as remote displays and programmable logic controllers (PLCs). The pulse outputs match the input voltage of the transmitter. The higher the flow, the more pulses they send. For your receiving device to interpret the signal, you will need to calibrate it for the measurement range and output signal of the transmitter. They only give accurate readings within the rated measurement range. Configure them for either a 4-20mA or digital pulse output when installing.

A digital display makes it easy to check flow rate and configure settings. Clamp these transmitters onto your pipe with the included mounting hardware and gel pads. They measure flow no matter the mounting orientation.

These transmitters are calibrated with water but can be used with other liquids and will generally measure accurately, even if they differ in viscosity and density. You can recalibrate them in the field for accurate readings on pipe and operating conditions.

Flow Range for Pipe Size, gpm | Input Voltage | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Measurement Type | For Pipe Size | 3/4 | 2 | 4 | End-to-End Lg. | Accuracy | Temp. Range, ° F | Min., V DC | Max. | Mounting Position | Field Recalibratable | Enclosure Rating | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

One Digital Pulse Output and One 4-20 mA Analog Transmitter Output—Wire Lead Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polycarbonate Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ultrasonic | 3/4 to 4 | 0 to 45 | 0 to 320 | 0 to 1,285 | 9 3/4" | -3% to 3% | 32 to 185 | 12 | 24V AC/24V DC | Any Angle | Yes | IP54 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Accuracy Flow and Temperature Transmitters

|

Also known as magmeters, these transmitters use a magnetic field to measure flow rate and temperature with high accuracy. Because they use a magnetic field, they only work with conductive liquids, such as water. These transmitters, also known as transducers, convert measurements to an electrical signal that can be interpreted by receiving devices, such as remote displays and programmable logic controllers (PLCs) to monitor flow or control equipment. For your receiving device to interpret the signal, you will need to calibrate it for the measurement range and output signal of the transmitter. As flow or temperature increases, the output signal increases. These transmitters have one analog output for flow and another for temperature. They only give accurate readings within the rated measurement range. A digital display makes it easy to view readings and adjust settings at the source. Mount these transmitters inline with your pipe system. They measure flow correctly in any mounting orientation.

These transmitters are calibrated with water. They can only be used with liquids with a conductivity of at least 20 µS/cm.

Flow Range | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Measurement Type | Pipe Connections | Gallons per Minute, gpm | Liters per Minute, L/min | End-to-End Lg. | Accuracy | Max. Pressure @ Temp. | Temp. Range, ° F | Input Voltage Range, V DC | Mounting Position | Field Recalibratable | Enclosure Rating | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Two 4-20 mA Analog Transmitter Outputs—4-Pole Micro M12 Connection Plugs | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel/Plastic/Polybutylene Body with 316 Stainless Steel Fitting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Magnetic Induction | 2 NPT Female | 1.3 to 158.5 | 5 to 600 | 7 1/16" | -0.8% to 0.8% | 225 psi @ 70° F | 0 to 175 | 20 to 30 | Any Angle | No | IP65, IP67 | 00000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

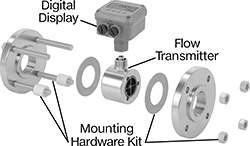

Build-Your-Own Flanged Pipe Flow Transmitters

|

Components Sold Separately (Pipe Flanges Not Included) |

Install these transmitters between two flanges in a flanged pipe system to measure flow rate and send the data to a remote display or programmable logic controller (PLC). For easy cleaning and maintenance, you can slide the transmitter out from between the flanges. A complete transmitter consists of a flow transmitter, display, and mounting hardware kit (all components sold separately). Flowing liquid turns the turbine in the transmitter, while the easy-to-read display counts the number of turns to measure and transmit the flow. The display also shows total and batch flow volumes. Use these transmitters with clean, low-viscosity liquids to avoid clogging or other damage to the internal parts. Mount them inline with your pipe system. They’re accurate in any mounting orientation.

Also known as transducers, these transmitters help you monitor status or control equipment by converting measurements to a digital pulse that can be interpreted by receiving devices. Each pulse is a spike of voltage. The higher the flow, the more pulses they send. For your receiving device to interpret the signal from the transmitter, you will need to calibrate it for the measurement range and output signal of the transmitter. Transmitters will only provide accurate readings within the rated measurement range.

The transmitters are calibrated with water but can be used with other liquids.

Flow Transmitters

|

Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Measurement Type | Pipe Size | Flow Range, gpm | Bore Size | OD | Type | For Flange ANSI Class | End-to-End Lg. | Accuracy | Max. Pressure @ Temp. | Temp. Range, ° F | Mounting Position | Field Recalibratable | Pulse Frequency per Volume, pulse per gal. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

One Digital Pulse Output—2-Pin BNC Connection Plug | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316/316L Stainless Steel Body with 316/316L Stainless Steel Fitting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Turbine | 2 | 5 to 50 | 1" | 3 5/8" | Round | 150 | 2 1/2" | -1.0% to 1.0% | 285 psi @ 70° F | -150 to 350 | Any Angle | No | 850 | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Turbine | 2 | 15 to 180 | 1 1/2" | 3 5/8" | Round | 150 | 2 1/2" | -1.0% to 1.0% | 285 psi @ 70° F | -150 to 350 | Any Angle | No | 325 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

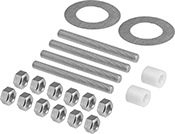

Mounting Hardware Kits

|

For Pipe Size | For Flange ANSI Class | Includes | Each | |||

|---|---|---|---|---|---|---|

| 2 | 150 | 4 Studs, 12 Nuts, 2 Gaskets, 2 Centering Rings | 0000000 | 0000000 | ||